SHORTCUT - Engineering News-Record - McGraw Hill Construction

SHORTCUT - Engineering News-Record - McGraw Hill Construction

SHORTCUT - Engineering News-Record - McGraw Hill Construction

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

THE CONSTRUCTION WEEKLY<br />

<strong>Engineering</strong> <strong>News</strong>-<strong>Record</strong><br />

April 27, 2009 enr.com<br />

MUMBAI<br />

<strong>SHORTCUT</strong><br />

After years of delay,<br />

4.7 km viaduct will ease<br />

chronic congestion

Introducing<br />

TM<br />

New!<br />

Exclusively at www.thebluebook.com<br />

Want to work smarter when it comes<br />

to managing your contacts<br />

Booths<br />

S11745 & N2653<br />

Login!

Now there’s a customized way to select, sort, view<br />

and save your contact information...<br />

Your way. Online.<br />

Quickly upload and manage your contacts<br />

Set your display to view the fields that are most<br />

important to you (i.e.: Labor Affiliation, License, Rank,<br />

Project Type, Areas Serviced, Trade Associations, etc.)<br />

Quickly find qualified vendors for<br />

your current or future projects<br />

Track ITBs and RFQs sent and received<br />

Easily view and access your recent search results<br />

View your recently added contacts<br />

Sort and find information quickly by:<br />

company name, city, state, zip, phone, contact, etc.<br />

View a company’s Ad, Profile or link directly to<br />

their Website to find the information you need<br />

Easily add and delete companies to/from your<br />

private list and let The Blue Book keep<br />

your contact information up-to-date<br />

Your contacts will be highlighted when you<br />

search The Blue Book for additional vendors<br />

Send ITBs and RFQs to your contacts<br />

www.thebluebook.com<br />

888-303-2243

April 27, 2009 Contents<br />

<br />

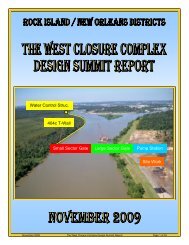

COVER STORY<br />

Mumbai Miracle<br />

18 After years of delays, the new<br />

Bandra-Worli Sea Link will cut a trip<br />

across Mahim Bay in Mumbai, India,<br />

from about 40 minutues to six. The<br />

4.7-km viaduct with two cable-stayed<br />

spans is slated to open to traffi c in<br />

mid-May.<br />

Cover photo courtesy of Swaminathan/Wikipedia;<br />

photo right by Janice L. Tuchman for ENR<br />

14 Military <strong>Construction</strong>: Guam needs<br />

more U.S. funds to redeploy military, says<br />

GAO<br />

Buildings<br />

14 Claims: Thornton-Tomasetti is cleared in<br />

Indiana library defect suit<br />

15 Materials: Problems continue to grow<br />

with drywall made in China<br />

DEPARTMENTS<br />

5 Videos<br />

6 <strong>Construction</strong> Week<br />

9 Washington Observer<br />

16 <strong>Construction</strong> Economics<br />

24 Products<br />

26 Pulse<br />

28 Viewpoint<br />

New emphasis on high-speed rail. Page 10.<br />

PHOTO LEFT COURTESY OF THE CALIFORNIA HIGH SPEED RAIL; RIGHT COURTESY OF THE FLORIDA DEPT. OF HEALTH<br />

NEWS<br />

Transportation<br />

10 High-Speed Rail: DOT sketches out<br />

high-speed-rail plan<br />

Business & Economics<br />

12 Economic Stimulus: BuRec, EPA map<br />

out $1.6 billion of new funding<br />

13 Corruption: Illinois boosts project funding<br />

but not without major reform<br />

<strong>Engineering</strong> <strong>News</strong>-<strong>Record</strong><br />

SERVING THE INDUSTRY SINCE 1874<br />

Drywall woes. Page 15<br />

ENR (<strong>Engineering</strong> <strong>News</strong>-<strong>Record</strong>), (ISSN 0891-9526).<br />

Published weekly except for one week in January, March,<br />

April, May, July, August, September, October, November and<br />

December; 42 weeks a year by The <strong>McGraw</strong>-<strong>Hill</strong> Companies,<br />

1221 Ave. of the Americas, New York, N.Y. 10020. Founder:<br />

James H. <strong>McGraw</strong> (1860-1948). Executive, editorial, circulation, advertising offices: Two Penn Plaza, New York, N.Y. 10121-<br />

2298. Phone (212) 512-2000. Postmaster: Please send address changes to ENR/<strong>Engineering</strong> <strong>News</strong>-<strong>Record</strong>, Attention: Fulfi llment<br />

Manager, P.O. Box 5730, Harlan, IA 51593. Periodicals postage paid at New York, N.Y., and at additional mailing offi ces. Canada<br />

Post Publication Mail Agreement No.40012501. Registered for GST as The <strong>McGraw</strong>-<strong>Hill</strong> Companies. GST #R123075673. RETURN<br />

UNDELIVERABLE CANADIAN ADDRESSES TO: DPGM Ltd., 2-7496 Bath Road, Mississauga, ON L4T 1L2. Email: enrcustserv@<br />

cdsfullfi llment.com. Copyright, printing and reprinting: Titles <strong>Engineering</strong> <strong>News</strong>-<strong>Record</strong> (ENR) and CONSTRUCTION WEEK<br />

reg. ® in U.S. Patent Offi ce. Copyright © 2009 by The <strong>McGraw</strong>-<strong>Hill</strong> Companies. All rights reserved. Officers of The <strong>McGraw</strong>-<br />

<strong>Hill</strong> Companies, Inc.: Harold W. <strong>McGraw</strong> III, Chairman, President, and Chief Executive Offi cer; Robert J. Bahash, Executive Vice<br />

President and Chief Financial Offi cer; Kenneth M. Vittor, Executive Vice President and General Counsel. <strong>McGraw</strong>-<strong>Hill</strong> <strong>Construction</strong>:<br />

For subscriber services call:<br />

(877) 876-8208 or (515) 237-3681<br />

GO TO MY.ENR.COM FOR PASSWORD-<br />

PROTECTED ONLINE ACCESS.<br />

Not getting ENR Insider and <strong>News</strong><br />

Alerts Please call (877) 876-8208<br />

additional content online<br />

enrcom<br />

Norbert W. Young, Jr., FAIA, President; John Murphy, Director, Finance. Where necessary, permission is granted by copyright owner<br />

for those registered with Copyright Clearance Center (CCC), 222 Rosewood Drive, Danvers, Mass. 01923, www.copyright.com,<br />

to photocopy any article herein for personal or internal reference use only for the fl at fee of $1.20 per copy for each article. ENR<br />

<strong>Construction</strong> Economics, Top Rankings and Sourcebooks available for a fee in downloadable PDF format at www.ENR.com. Send<br />

payment to CCC. ISSN 0891-9526/92. Copying for other than personal or internal reference use without express permission of The<br />

<strong>McGraw</strong>-<strong>Hill</strong> Companies is prohibited. Write the editor to request such permission. Printed in the USA. Subscription rates<br />

for individuals in the field of the publication: U.S. and possessions, $82 per year (single copies $9.95 in U.S.); Canada and<br />

Mexico, $89 per year; outside North America, $195 per year. Please allow four to six weeks for shipment. Subscriber service<br />

and single copies: (877) 876-8208 or (515) 237-3681. Send all correspondence, notices and subscription orders to Fulfi llment<br />

Manager, ENR, P.O. Box 5730, Harlan, IA 51593. If possible, attach address label from a recent issue. Please contact customer<br />

service to change your name or address. If the postal authorities alert us that your magazine is undeliverable, we have no<br />

further obligation unless we receive a corrected address within two years. Please allow a month for change of address to take<br />

effect. Classifi ed advertising: Send ads to ENR, Classifi ed Advertising, Two Penn Plaza, 9th Floor, New York, NY 10121. Phone (212)<br />

904-2815.<br />

enr.com April 27, 2009 ENR 3

y<br />

Signature valid<br />

aturd<br />

a Gru<br />

Build on formwork expertise<br />

03/2008 us<br />

Frami<br />

The powerful lightweight<br />

clamp system in feet and inches<br />

Safe.<br />

Fast.<br />

Efficient.<br />

• Slashes handset labor costs<br />

• Uses only 3 clamps<br />

per 9‘ panel<br />

• Can be ganged with<br />

no additional hardware<br />

Corporate Headquarters<br />

Doka USA, Ltd.<br />

214 Gates Road<br />

Little Ferry, NJ 07643<br />

Tel: (201) 329-7839<br />

Tel: (877) DOKA-USA<br />

Fax: (201) 641-6254<br />

E-Mail: usa@doka.com<br />

www.dokausa.com<br />

Regional Contacts<br />

Little Ferry, NJ (201) 641-6500<br />

Baltimore, MD (410) 368-8390<br />

Channahon, IL (815) 521-3700<br />

Lawrenceville, GA (770) 962-7914<br />

Tomball, TX (281) 516 2211<br />

Riverside, CA (951) 509-0023<br />

Fort Pierce, FL (888) 460-3652<br />

Doka Canada Ltd.<br />

5404 – 36th Street S.E.<br />

Calgary AB T2C 1P1<br />

Canada<br />

Tel: (403) 243 66 29<br />

Fax (403) 243 67 87<br />

E-Mail: Canada@doka.com

Videos<br />

View From Technology’s Frontier<br />

Golden-i, a verbally controlled Bluetooth computer interface, wowed the crowd at the FIATECH<br />

meeting. See how the device works on ENR.com this week.<br />

How does FIATECH pursue its mission to find technology solutions to problems in construction<br />

Find out by listening in as ENR Senior Editor Tom Sawyer interviews FIATECH Director Ric Jackson.<br />

When ENR's Technology Senior<br />

Editor Tom Sawyer picks up<br />

his video camera, something<br />

interesting is bound to happen. Browsers<br />

on ENR.com will not be disappointed by<br />

what he captured at the recent conference<br />

in Las Vegas of FIATECH, a group that<br />

concentrates on technology solutions<br />

to construction problems, including<br />

interoperability. Sawyer wondered if<br />

technology would take a lower profile in<br />

the middle of a recession. That is not the<br />

case, from what we see here.<br />

In one video, viewers can see the debut<br />

of the Golden-i headset, a jobsite communications<br />

device. “We’ve been coining the<br />

phrase ‘information snacking,’ because this<br />

is what Golden-i is about,” says Chris Parkinson,<br />

Golden-i software consultant to<br />

Kopin Corp., who demonstrated the device<br />

to Sawyer. “It’s about getting the information<br />

you need and getting back to your<br />

work. You’re not meant to sit here and<br />

watch videos for five hours at a go.”<br />

FIATECH also showcased some of the<br />

most important efforts aimed at industry<br />

interoperability. Sawyer interviews Ric<br />

Jackson, FIATECH founding director, who<br />

described one advance. “What we’ve produced<br />

is a mechanism to tie software together<br />

and companies together, but we can<br />

also tie standards together,” says Jackson.<br />

We hope watching these reports will help<br />

you tie your world together. Enjoy. <br />

enrcom<br />

TO READ MORE BLOGS OR RESPOND TO THIS<br />

AND OTHERS, VISIT OUR WEBSITE, ENR.COM<br />

enr.com<br />

<strong>Engineering</strong><br />

<strong>News</strong>-<strong>Record</strong><br />

PRESIDENT, MCGRAW-HILL CONSTRUCTION<br />

Norbert W. Young, Jr, norbert_young@mcgraw-hill.com<br />

VICE PRESIDENT, GROUP PUBLISHER<br />

James H. <strong>McGraw</strong> IV, jay_mcgraw@mcgraw-hill.com<br />

VICE PRESIDENT, INDUSTRY ANALYTICS, ALLIANCES &<br />

STRATEGIC INITIATIVES<br />

Harvey M. Bernstein, harvey_bernstein@mcgraw-hill.com<br />

VICE PRESIDENT, MARKETING & PRODUCT DEVELOPMENT<br />

Potoula Chresomales, potoula_chresomales@mcgraw-hill.com<br />

SENIOR DIRECTOR, MARKETING COMMUNICATIONS<br />

Katherine Malangone, kathy_malangone@mcgraw-hill.com<br />

MANAGER, MARKETING COMMUNICATIONS<br />

Erica Mileo, erica_mileo@mcgraw-hill.com<br />

VICE PRESIDENT, BUSINESS SERVICES<br />

Maurice Persiani, maurice_persiani@mcgraw-hill.com<br />

GROUP CIRCULATION MANAGER<br />

Joanne Rue-Policare, joanne_rue@mcgraw-hill.com<br />

VICE PRESIDENT, BUSINESS OPERATIONS<br />

Timothy J. Ryan, tim_ryan@mcgraw-hill.com<br />

PRODUCTION MANAGER<br />

Gary Graizzaro, gary_graizzaro@mcgraw-hill.com<br />

SENIOR DIRECTOR, FINANCE:<br />

John Murphy, john_murphy@mcgraw-hill.com<br />

FINANCE DIRECTOR:<br />

Ike B. Chong, ike_chong@mcgraw-hill.com<br />

VICE PRESIDENT, MEDIA SALES<br />

Paul L. Bonington, paul_bonington@mcgraw-hill.com<br />

ADVERTISING SALES<br />

Northeast: Matt McLiverty, matt_mcliverty@mcgraw-hill.com<br />

MidAtlantic: Charles Fagan, charles_fagan@mcgraw-hill.com<br />

Southeast: Gary Merrill, gary_merrill@mcgraw-hill.com<br />

Southwest/Central: Joel Gregg, joel_gregg@mcgraw-hill.com<br />

Midwest: (<strong>Construction</strong> Equipment)<br />

Steve Werschulz, steve_wershculz@mcgraw-hill.<br />

Pacific: (Technology)<br />

Roy J. Kops, roy_kops@mcgraw-hill.com<br />

WORKFORCE/RECRUITMENT<br />

Brian Monteleone brian_monteleone@mcgraw-hill.com<br />

Diane Soister, Diane_Soister@mcgraw-hill.com<br />

SPECIAL SECTIONS<br />

Al D’Alessandro, al_dalessandro@mcgraw-hill.com<br />

enr.com April 27, 2009 ENR 5

<strong>Construction</strong> Week<br />

Environmental<br />

Six States in Oil-and-Gas Zones<br />

Get $500 Million for Coast Fixes<br />

Six coastal states will receive nearly $500<br />

million from the U.S. Interior Dept. to<br />

help them alleviate environmental impacts<br />

of oil-and-gas development, the agency<br />

said on April 20. Louisiana tops the list<br />

with $121 million, followed by Alaska at<br />

$37.5 million, Texas at $35.6 million, Mississippi<br />

at $23.8 million, Alabama at $19.7<br />

million and California at $5 million. The<br />

agency will distribute the funds in fiscal<br />

2009 and 2010, the final two years of the<br />

Coastal Impact Assistance Program,<br />

which Congress created in 2005 for states<br />

adjacent to oil-and-gas production on the<br />

Outer Continental Shelf. Lawmakers authorized<br />

the agency to distribute $250<br />

million annually from fiscal 2007 through<br />

fiscal 2010, using production proceeds.<br />

“The funding we provide through this<br />

program goes a long way to restore portions<br />

of our coastline, and I look forward<br />

to working with each of the states on their<br />

upcoming projects,” said Interior Secretary<br />

Ken Salazar. <br />

Corruption<br />

Probe of New York Utility Yields<br />

Two More <strong>Construction</strong> Arrests<br />

The U.S. Attorney in Brooklyn, N.Y., announced<br />

two new arrests related to an<br />

ongoing probe of corruption on construction<br />

projects of giant New York utility<br />

Consolidated Edison. The sting had led<br />

to charges filed in January against 10 cur-<br />

rent and former Con Ed construction officials<br />

for receiving $1 million in kickbacks<br />

from contractors. Benton J. Campbell<br />

said Russell Ball, CEO of Roadway <strong>Construction</strong><br />

Inc., Brooklyn, was charged on<br />

April 16 with paying “tens of thousands<br />

of dollars in bribes” to Con Ed officials on<br />

water-main and utility-line construction<br />

projects between 2002 and 2004. He made<br />

the payments in exchange for the cooperation<br />

of an unnamed Con Ed supervisor<br />

in approving inflated invoices. The supervisor<br />

also shared proceeds with other utility<br />

managers. Charged on April 15 was<br />

Joseph Lioi, a retired chief construction<br />

inspector for Con Ed. Authorities allege<br />

he solicited and accepted $24,000 in kickbacks<br />

from an unnamed contractor on<br />

utility projects in 2007. The defendants<br />

could not be reached. <br />

Lawsuits<br />

Partial Settlement Announced<br />

For 2006 Fatal Crane Collapse<br />

General contractor Lease Crutcher Lewis<br />

and structural engineer Magnusson Klemencic<br />

Associates have settled a lawsuit<br />

with the family of the man who died in his<br />

apartment when the boom of a 210-ft<br />

tower crane toppled while working on<br />

Tower 333 in Bellevue, Wash. Details of<br />

the settlement were not disclosed. An<br />

LCL action against MKA, part of the suit,<br />

remains unresolved. According to MKA<br />

Chairman and CEO Jon D. Magnusson,<br />

MKA designed the crane base assuming a<br />

tie-in to the building frame in the initial<br />

configuration, but the crane was erected<br />

without a tie-in. The reason for this is the<br />

subject of the dispute, he says. A citation<br />

following the 2006 crane collapse issued<br />

against MKA by the state Dept. of Labor<br />

and Industries recently was vacated by the<br />

state Board of Industrial Insurance Appeals.<br />

The state labor agency also cited<br />

LCL and fined it $5,600, for “failure to<br />

obtain measurements to ensure cranebase<br />

deflection limits were not exceeded,”<br />

says Bill Lewis, LCL chairman. <br />

Parks<br />

Landscape Architects Seek<br />

‘Makeover’ of National Mall<br />

Calling the state of the National Mall in<br />

Washington, D.C., an “international embarrassment,”<br />

a panel of leading design<br />

experts has recommended that the National<br />

Park Service amend an improvement<br />

plan unveiled earlier this year to<br />

make it broader and more environmentally<br />

sustainable. The plan calls for a ban<br />

on new monuments and statues and a redesign<br />

of the Union Square/Capitol Reflecting<br />

Pool area. Angela Dye, president<br />

of the American Society of Landscape<br />

Architects, who facilitated the panel, says<br />

the Park Service’s current plan would improve<br />

the mall but does not go far enough.<br />

The panel recommends the Park Service<br />

hold a design competition and work with<br />

the National Capital Planning Commission<br />

and the Architect of the Capitol to<br />

develop a more integrated, expansive and<br />

sustainable plan. <br />

enr.com<br />

<strong>Engineering</strong><br />

<strong>News</strong>-<strong>Record</strong><br />

PRESIDENT, MCGRAW-HILL CONSTRUCTION<br />

Norbert W. Young, Jr, norbert_young@mcgraw-hill.com<br />

VICE PRESIDENT, GROUP PUBLISHER<br />

James H. <strong>McGraw</strong> IV, jay_mcgraw@mcgraw-hill.com<br />

VICE PRESIDENT, INDUSTRY ANALYTICS, ALLIANCES &<br />

STRATEGIC INITIATIVES<br />

Harvey M. Bernstein, harvey_bernstein@mcgraw-hill.com<br />

VICE PRESIDENT, MARKETING & PRODUCT DEVELOPMENT<br />

Potoula Chresomales, potoula_chresomales@mcgraw-hill.com<br />

SENIOR DIRECTOR, MARKETING COMMUNICATIONS<br />

Katherine Malangone, kathy_malangone@mcgraw-hill.com<br />

MANAGER, MARKETING COMMUNICATIONS<br />

Erica Mileo, erica_mileo@mcgraw-hill.com<br />

VICE PRESIDENT, BUSINESS SERVICES<br />

Maurice Persiani, maurice_persiani@mcgraw-hill.com<br />

GROUP CIRCULATION MANAGER<br />

Joanne Rue-Policare, joanne_rue@mcgraw-hill.com<br />

VICE PRESIDENT, BUSINESS OPERATIONS<br />

Timothy J. Ryan, tim_ryan@mcgraw-hill.com<br />

PRODUCTION MANAGER<br />

Gary Graizzaro, gary_graizzaro@mcgraw-hill.com<br />

SENIOR DIRECTOR, FINANCE:<br />

John Murphy, john_murphy@mcgraw-hill.com<br />

FINANCE DIRECTOR:<br />

Ike B. Chong, ike_chong@mcgraw-hill.com<br />

VICE PRESIDENT, MEDIA SALES<br />

Paul L. Bonington, paul_bonington@mcgraw-hill.com<br />

ADVERTISING SALES<br />

Northeast: Matt McLiverty, matt_mcliverty@mcgraw-hill.com<br />

MidAtlantic: Charles Fagan, charles_fagan@mcgraw-hill.com<br />

Southeast: Gary Merrill, gary_merrill@mcgraw-hill.com<br />

Southwest/Central: Joel Gregg, joel_gregg@mcgraw-hill.com<br />

Midwest: (<strong>Construction</strong> Equipment)<br />

Steve Werschulz, steve_wershculz@mcgraw-hill.<br />

Pacific: (Technology)<br />

Roy J. Kops, roy_kops@mcgraw-hill.com<br />

WORKFORCE/RECRUITMENT<br />

Brian_monteleone@mcgraw-hill.com<br />

Diane Soister, Diane_Soister@mcgraw-hill.com<br />

SPECIAL SECTIONS<br />

Al D’Alessandro, al_dalessandro@mcgraw-hill.com<br />

6 ENR April 27, 2009 enr.com

Time To Get Cracking Call Brandenburg.<br />

Brandenburg ®<br />

Industrial Service Company<br />

Toll free 800.932.2869 | email@brandenburg.com | www.brandenburg.com

Congratulations<br />

ENR would like to congratulate the 2008 Top 25 <strong>News</strong>makers and The Award of Excellence<br />

Winner, Bernard Amadei - Founder, Engineers Without Borders-USA. All winners were announced<br />

at ENR’s 44th Annual Award of Excellence event on March 26, 2009, in New York City.<br />

FOR A COMPLETE LISTING OF WINNERS GO TO:<br />

http://enr.construction.com/people/awards/2009/0107.asp<br />

Sponsored By:<br />

www.enr.com

EPA Takes Step Toward Regulating Carbon<br />

While environmental groups<br />

are cheering the Environmental<br />

Protection Agency’s<br />

April 17 announcement<br />

that it has determined that<br />

greenhouse gases could pose<br />

a threat to public health and<br />

welfare, critics charge that using<br />

the Clean Air Act to regulate<br />

greenhouse-gas emissions could<br />

prove costly.<br />

“Trying to regulate [greenhouse emissions]<br />

under the Clean Air Act is going to<br />

add costs and delays to transportation<br />

projects,” says Nick Goldstein, American<br />

Road and Transportation Builders Association<br />

assistant general counsel and director<br />

of regulatory affairs.<br />

EPA’s “endangerment” finding, which<br />

is subject to a 60-day comment period<br />

before it becomes final, is not a formal<br />

rule. But it could trigger regulation of<br />

greenhouse gases for the first time under<br />

the Clean Air Act if Congress does not<br />

pass legislation to address global warming.<br />

EPA’s endangerment finding, a reversal<br />

of Bush administration policy, came in<br />

response to the 2007 Supreme Court rul-<br />

WAXMAN<br />

ing in Massachusetts v. EPA. The court<br />

concluded that carbon could be considered<br />

a “pollutant” under the Clean Air<br />

Act and ordered EPA to determine<br />

whether carbon emissions<br />

constitute an “endangerment” to<br />

public health. Former EPA Administrator<br />

Stephen Johnson said<br />

during the final weeks of the<br />

Bush term that using the act to<br />

regulate greenhouse gases could<br />

have a chilling effect on the economy but<br />

left the determination of whether greenhouse<br />

gases pose a potential health threat<br />

to the next administration.<br />

Environmental groups say the EPA<br />

announcement lays the groundwork for<br />

addressing the effects of climate change,<br />

through the regulatory or legislative process.<br />

Joe Mendelson, National Wildlife<br />

Federation global-warming policy director,<br />

calls EPA’s finding “a game-changer<br />

for climate policy that has repercussions<br />

domestically and abroad.”<br />

Washington Observer<br />

“ One way or another, powerplants are going<br />

to be regulated.”<br />

— DAN REIDINGER, EDISON ELECTRIC INSTITUTE<br />

The Obama administration repeatedly<br />

has said it would prefer that Congress<br />

take action rather than have its agencies<br />

issue regulations. In the House, Energy<br />

and Commerce Committee Chairman<br />

Henry Waxman (D-Calif.) and Rep. Ed<br />

Markey (D-Mass.) have released a draft<br />

bill. They hope the committee will vote<br />

on it by the Memorial Day recess.<br />

Industry groups say they also prefer<br />

legislation. “That is our strong preference,”<br />

says Dan Riedinger, spokesman for<br />

the Edison Electric Institute. But the genie<br />

is out of the bottle. “One way or another,<br />

powerplants are going to be regulated,<br />

whether by agency or<br />

Congress,” he says.<br />

ARTBA’s Goldstein says<br />

using the Clean Air Act to<br />

regulate greenhouse gases<br />

could push more counties out of attainment,<br />

which could stall funds for transportation<br />

projects. But David Doniger,<br />

climate center policy director for the<br />

Natural Resources Defense Council,<br />

notes, “The Clean Air Act is intended to<br />

adapt to new pollution problems as they<br />

are discovered and recognized.” <br />

By Pam Hunter<br />

<br />

Stimulus: More<br />

Than $3.3 Billion<br />

for Smart Grid<br />

Administration offi cials on April 16<br />

outlined plans to distribute more<br />

than $3.3 billion in smart-grid- technology<br />

development grants and an<br />

additional $615 million for smartgrid<br />

storage through the American<br />

Recovery and Reinvestment<br />

Act. The grants will range from<br />

$500,000 to $20 million for smartgrid<br />

applications and $100,000<br />

to $5 million for grid monitoring<br />

devices.<br />

“We need an upgraded electrical<br />

grid to take full advantage of<br />

the vast renewable resources in<br />

this country,” said Vice President<br />

Joe Biden. Commerce Secretary<br />

Gary Locke said administration offi<br />

cials will hold a meeting in Washington,<br />

D.C., in May to discuss<br />

the development of industrywide<br />

standards to help make the smart<br />

grid a reality.<br />

NERC: Transmission<br />

Grid Must be<br />

Updated<br />

A new study from the North American<br />

Electric Reliability Corp., the<br />

U.S. electric-utility watchdog<br />

group, finds that the nation’s increasing<br />

reliance on renewableenergy<br />

power sources will require<br />

policymakers to clear the way for<br />

updating the nation’s transmissions<br />

system. NERC says adding<br />

high levels of wind, solar and<br />

ocean energy, deemed “variable<br />

generation” for their intermittent<br />

characteristics, will require “signifi<br />

cant transmission additions and<br />

reinforcements” to ensure grid reliability.<br />

NERC projects that more<br />

than 145,000 MW of new variable<br />

resources will be added to the<br />

country’s bulk power system within<br />

10 years. Denise Bode, CEO of<br />

American Wind Energy Association<br />

,praises NERC’s report, saying,<br />

“These reforms are needed to<br />

maintain system reliability.”<br />

E-Verify: Deadline<br />

Pushed Back<br />

A Third Time<br />

The Obama administration has extended<br />

the deadline until June 30<br />

for implementation of mandatory<br />

E-Verify use by federal contractors<br />

to determine employment eligibility<br />

of their new hires. The policy<br />

was set to go into effect on Jan. 15.<br />

“The extension provides the administration<br />

an adequate opportunity<br />

to review the entire rule prior<br />

to its applicability to federal contractors<br />

and subcontractors,” says<br />

the Dept. of Homeland Security. <br />

—Compiled by Pam Hunter and<br />

Cathy Cash<br />

enr.com April 27, 2009 ENR 9

For $8 billion of Sti<br />

<br />

<strong>News</strong> April 27, 2009<br />

HIGH-SPEED RAIL<br />

DOT Sketches Plan<br />

For High-Speed Rail<br />

First round of grant awards for ready-to-go projects is expected to be made by late summer<br />

Drawing on $8 billion from the federal economic<br />

stimulus, the Obama administration has laid out a<br />

blueprint for developing high-speed rail in 100- to<br />

600-mile-long corridors around the country. The<br />

plan, which the U.S. Dept. of Transportation unveiled<br />

April 16, does not say which projects will be<br />

funded. DOT will start awarding the first<br />

round of grants for ready-to-go upgrades<br />

to existing routes by late summer. A second<br />

phase would have a longer-range<br />

focus. However, carrying out the plan’s<br />

lofty aims will require much more than $8<br />

billion. It is uncertain where that new<br />

money will come from.<br />

Still, it is clear is high-speed rail has<br />

barreled to a top place on the federal<br />

transportation priority list. Underlining<br />

the plan’s importance, President Barack<br />

Obama appeared at DOT headquarters<br />

to endorse a program “to transform travel<br />

in America with an historic investment in<br />

high-speed rail.”<br />

The plan encompasses new service at<br />

speeds exceeding 150 miles per hour,<br />

“emerging and regional” service between<br />

90 mph and 150 mph on dedicated or<br />

shared track and upgrades to existing service<br />

running from 79 mph to 90 mph.<br />

The 27-page DOT plan will be followed<br />

by detailed program guidance, due<br />

by June 17, and then by a National Rail<br />

Plan mandated by a separate passengerrail<br />

measure enacted last year.<br />

10 ENR April 27, 2009 enr.com<br />

Obama said an initial round of grants<br />

“will focus on projects that can create jobs<br />

and benefits in the near-term.” He added,<br />

“We are talking about using existing infrastructure<br />

to increase speeds on some<br />

routes from 70 mph to over 100 mph [by]<br />

improving tracks, crossings, signal systems.”<br />

For now, DOT is not saying how<br />

much of the $8 billion will be awarded in<br />

The administration’s plan “is to transform<br />

travel in America with an historic<br />

investment in high-speed rail.”<br />

— PRESIDENT BARACK OBAMA<br />

grants for those shorter-term shovelready<br />

rail-upgrade projects.<br />

Shrinking Distances<br />

According to the President, the next phase<br />

will focus on “shrinking distances within<br />

our regions.” He said there are “at least<br />

10 major corridors...of 100 to 600 miles<br />

in length with the potential for successful<br />

high-speed rail systems.”<br />

Jeff Morales, senior vice president with<br />

Parsons Brinckerhoff in Sacramento, Calif.,<br />

says the DOT plan indicates “they<br />

really are looking at this not just as a onetime<br />

shot of the $8 billion [for] economic<br />

recovery but as a sustained program. To<br />

me, that is something pretty significant<br />

that states and local governments should<br />

certainly take note of.”<br />

The $8 billion, which is only available<br />

through Sept. 30, 2012, under the American<br />

Recovery and Reinvestment Act,<br />

does not require a state to put up matching<br />

money. That is a great attraction.<br />

Much of the competition for highspeed-rail<br />

dollars will center on 11 corridors<br />

that U.S. DOT secretaries have<br />

designated since 1991 (see map). Officials<br />

from states along those corridors<br />

already are making a pitch<br />

to be selected. California,<br />

which envisions an 800-mile,<br />

$46-billion set of lines, hopes<br />

to win 40% to 50% of the $8<br />

billion. In the near-term, the<br />

state’s High Speed Rail Authority has<br />

identified $3.6 billion of grade separations<br />

and support infrastructure that already are<br />

designed and ready to start construction<br />

by March 2010, says Executive Director<br />

Mehdi Morshed.<br />

With a $9.95-billion high-speed-rail<br />

bond issue that voters approved last November,<br />

“We have already awarded millions<br />

of dollars in contracts and will continue<br />

with or without federal funds,”

mulus Money<br />

High-Speed-Rail Corridors Competing<br />

For $8 Billion of Federal Stimulus Money<br />

KEY<br />

MAP COURTESY OF U.S. DEPT. OF TRANSPORTATION<br />

Pacific Northwest<br />

California<br />

Designated High-speed Rail Corridor<br />

Northeast Corridor (NEC)<br />

Other Passenger Rail Routes<br />

South Central<br />

Morshed says. But he also notes the federal<br />

stimulus funds would accelerate the<br />

awarding of the first big rail-construction<br />

contracts, including those for two bridge<br />

projects, between San Francisco and San<br />

Jose and between Los Angeles and Anaheim.<br />

Those awards could come as early<br />

as the end of the summer.<br />

In Contention<br />

Midwest officials also are in the game.<br />

Governors of five states in the region<br />

wrote to DOT Secretary Ray LaHood on<br />

April 10 to promote three corridors: Chicago-Milwaukee-Madison-Minneapolis/<br />

St.Paul-Chicago-St. Louis; Chicago-St.<br />

Louis; and Chicago-Detroit-Pontiac.<br />

States such as Illinois, Wisconsin and<br />

Michigan have ready-to-go projects that<br />

could qualify for the first round of rail<br />

stimulus grants, says Rick Harnish, executive<br />

director of the Midwest High<br />

Speed Rail Association, Chicago. That<br />

near-term work could include upgrading<br />

existing track, adding passing sidings and<br />

new signal systems, he says.<br />

Chicago Hub<br />

Network<br />

Gulf Coast<br />

Northern New England<br />

Empire<br />

Florida<br />

Keystone<br />

The Midwest also is in the running for<br />

the longer-range corridor-funding round,<br />

Harnish says. One possible candidate<br />

route is Chicago to St. Louis, with a goal<br />

of a trip of three and a half to four hours.<br />

He says of current train service, “If it’s on<br />

time, it’s five and a half.”<br />

In Florida, voters sank high-speed-rail<br />

plans in 2004, but advocates hope to revive<br />

the idea and tap stimulus money. In<br />

an April 1 letter to Florida High Speed<br />

Rail Authority Chairman Lee Chira, state<br />

DOT Secretary Stephanie C. Kopelousos<br />

proposed updating rail environmental<br />

documents and pursuing a federal record<br />

of decision. But she also noted $9 billion<br />

of transportation projects were deferred<br />

over two years and said it is “unlikely that<br />

new projects can be prioritized and [state]<br />

funds committed to this effort.”<br />

Amtrak also could be in the mix. “We<br />

anticipate that states and Amtrak, either<br />

in combination or separately, will be able<br />

to apply for these funds,” says Amtrak<br />

spokesman Cliff Black. The stimulus gives<br />

Amtrak $1.3 billion for capital improvements,<br />

and those funds are<br />

committed to specific projects<br />

(ENR 3/23, p.19).<br />

Black adds, “We do have<br />

other projects” that could<br />

be eligible for some of the<br />

$8 billion.<br />

Fredric Berger, chairman<br />

of The Louis Berger<br />

Group Inc. in Washington,<br />

D.C., was disappointed that<br />

DOT’s plan did not actively<br />

NEC embrace magnetic-levitation<br />

technology, although it<br />

does not exclude mag-lev<br />

from funding. Berger says<br />

Southeast mag-lev has energy-efficiency<br />

and other advantages<br />

over traditional rail. “It is<br />

21st-century, and why<br />

shouldn’t we be doing that”<br />

he asks. But Berger says<br />

DOT’s program will lead to<br />

substantial design, regulatory<br />

and other work.<br />

The prospect of new<br />

funds has charged up rail<br />

planners from coast to coast, but the funds<br />

will only take the plans part of the way.<br />

“The intent of the $8 billion was never<br />

that it would be the end-all and be-all for<br />

the development of high-speed rail,” says<br />

Peter Gertler, vice president and highspeed-rail<br />

practice chairman for design<br />

firm HNTB in Oakland, Calif. “More<br />

monies down the road will be required for<br />

the ultimate implementation,” he adds.<br />

To keep the stimulus momentum going,<br />

Obama has proposed an additional $1<br />

billion a year for five years for high-speed<br />

rail, starting in fiscal 2010. Even if Congress<br />

approves that request, billions more<br />

still would be needed to bring all the rail<br />

plans to completion.<br />

Peter Ruane, CEO of the American<br />

Road & Transportation Builders Association,<br />

has called for a new user fee dedicated<br />

to high-speed rail. HNTB’s Gertler<br />

says there is the potential that the next<br />

multiyear surface-transportation bill will<br />

include “a significant source for more substantive<br />

funding” for high-speed rail. <br />

By Tom Ichniowski and J.T. Long<br />

enr.com April 27, 2009 ENR 11

<strong>News</strong><br />

ECONOMIC STIMULUS<br />

BuRec and EPA Map Out<br />

$1.6 Billion of New Funding<br />

The amount of federal economicstimulus<br />

work continues to grow,<br />

with the April 15 announcements<br />

that the Interior Dept.’s Bureau of Reclamation<br />

has committed $1 billion to projects<br />

throughout the West and that the<br />

Environmental Protection Agency is dividing<br />

$600 million among Superfund<br />

projects at 50 sites.<br />

BuRec included about 30 large<br />

projects and an unspecified number<br />

of smaller ones that it plans to<br />

finance through the stimulus, the<br />

title of which is the American Recovery<br />

and Reinvestment Act<br />

(ARRA). California will receive<br />

the largest share at $260 million.<br />

Interior Secretary Ken Salazar<br />

says California’s projects will expand<br />

water supplies, repair aging<br />

infrastructure and attempt to<br />

mitigate drought effects. Salazar<br />

says an additional $135 million is<br />

available for water reuse and recycling<br />

projects in the state.<br />

California also has BuRec’s<br />

largest single stimulus project, a<br />

$109.8-million screened pumping<br />

plant at the Red Bluff Diversion<br />

Dam on the Sacramento River.<br />

The new plant would give endangered<br />

salmon and green sturgeon<br />

species unrestricted passage upstream<br />

and downstream.<br />

BuRec’s Great Plains Region<br />

will get $234.5 million, including<br />

$59 million for water treatment<br />

plants, an intake structure and<br />

storage facilities at the Garrison<br />

Diversion Unit in North Dakota,<br />

as well as $56.5 million to accelerate<br />

construction of a water-treatment<br />

plant near Vermillion, S.D.<br />

The Pacific Northwest Region<br />

will receive $125.2 million, including<br />

$50 million to build a siphon<br />

complex near Moses Lake, Wash. The allocation<br />

for the Lower Colorado Region<br />

is $107.9 million, Upper Colorado Region<br />

$28.3 million and the Central Utah<br />

Project $50 million.<br />

The bureau does not have a timetable<br />

yet for getting the stimulus projects under<br />

contract, says spokesman Kip White. He<br />

Bureau of Reclamation Stimulus Projects<br />

MID-PACIFIC REGION 260.0<br />

Red Bluff Diversion Dam, Calif. (screened pumping plant) 109.8<br />

Battle Creek, Calif. (salmon/steelhead restoration plan) 26.0<br />

GREAT PLAINS REGION 234.5<br />

Garrison Diversion Unit, N.D. (water-treatment plants,<br />

intake structure, storage facilities)<br />

Lewis and Clark rural water system, S.D., Minn., Iowa<br />

(accelerate water-treatment-plant construction)<br />

Fort Peck/Dry Prairie project, Mont. (finish water-treatment<br />

plant, water-supply lines<br />

LOWER COLORADO REGION 107.9<br />

Pima-Maricopa irrigation project, Ariz. (canal mileage<br />

and check structures)<br />

Yuma area, Ariz. (repair, replace water-management and<br />

-delivery facilities)<br />

PACIFIC NORTHWEST REGION 125.2<br />

Weber siphon complex, Wash. 50.0<br />

CENTRAL UTAH PROJECT 50.0<br />

Utah lake-system pipelines 41.0<br />

UPPER COLORADO REGION 28.3<br />

Animas-La Plata, Colo., N.M. (Navajo Nation pipeline,<br />

other projects)<br />

SOURCES: BUREAU OF RECLAMATION<br />

Largest. Red Bluff Diversion Dam to get pumping plant.<br />

says BuRec will measure projects against<br />

several criteria, including how shovelready<br />

they are as the agency moves into<br />

the contracting stage. White says the<br />

stimulus contracts will be managed by<br />

BuRec’s five regions and the Central Utah<br />

Project office. “That is the way all of our<br />

contracting is done,” he adds.<br />

EPA says its Superfund stimulus funds<br />

will speed hazardous-waste cleanup already<br />

under way and fund new projects.<br />

It plans to use the aid on National Priorities<br />

List sites, primarily on existing<br />

contracts. New Jersey has eight sites on<br />

the stimulus list, the most of any state.<br />

More than $25 million per location<br />

will go to sites in New Bedford<br />

Harbor, Mass.; Camden/<br />

Gloucester, N.J.; Florence Township,<br />

N.J.; South Plainfield, N.J.;<br />

Ottawa County, Okla.; Omaha,<br />

Neb.; and Eureka, Utah.<br />

59.0 One of the first beneficiaries<br />

will be the Iron Mountain Mine<br />

56.5 site near Redding, Calif., set to<br />

receive $10 million to $25 million.<br />

The money is expected to<br />

40.0<br />

cut the time needed to dredge,<br />

treat and dispose of sediment in<br />

the Keswick Reservoir’s Spring<br />

36.8<br />

Creek Arm from three years to 18<br />

months. The stimulus also will<br />

36.25<br />

help finance pipelines and pump<br />

stations to move contaminated<br />

sediment from the Spring Creek<br />

Arm to a disposal cell, construction<br />

of which will begin in May.<br />

The project has been divided<br />

into four packages. Three covering<br />

the pumping station, pipeline<br />

12.1 and treatment plant already have<br />

been put out for bid. Within the<br />

next two months, EPA expects to<br />

bid the final package, for dredging,<br />

says Rick Sugarek, EPA’s project<br />

manager.<br />

Factors EPA considered in selecting<br />

the ARRA-funded sites<br />

include readiness, human and ecological<br />

risk and opportunities to<br />

trim costs and schedules. <br />

By Pam Hunter<br />

and Tom Ichniowski<br />

BUREAU OF RECLAMATION<br />

12 ENR April 27, 2009 enr.com

PHOTO BY AP/WIDEWORLD<br />

CORRUPTION<br />

Illinois Boosts Project Funding<br />

But Not Without Major Reform<br />

Scrutiny. Ousted Gov. Rod Blagojevich (D) has pleaded not guilty to federal corruption charges.<br />

With one former governor in federal<br />

prison and another possibly<br />

on his way, prosecutors have argued<br />

that Illinois is perhaps the most corrupt<br />

state in the nation. Fed up with the<br />

scandals, lawmakers are promising<br />

changes in the way contractors do business<br />

with the Land of Lincoln.<br />

In the wake of scandal and the economic<br />

stimulus act, proposals for reform<br />

measures are flowing through both chambers<br />

of the statehouse in Springfield, Ill.<br />

“We haven’t seen the final package yet,<br />

but indications are they are comprehensive<br />

and far-reaching,” says Rep. Kathleen<br />

Ryg (D), who is sponsoring a bill to prioritize<br />

transportation projects. Issues under<br />

discussion include greater accountability<br />

in the bid process, transparency of<br />

contracts, public access to information,<br />

inclusion and documentation of minority<br />

and women-owned enterprises and tighter<br />

restrictions on campaign contributions.<br />

Industry supporters say they are encouraged<br />

by the buzz. “We’ve struggled<br />

too long under this cloud,” says Mike<br />

Sturino, president of the Itasca, Ill.-based<br />

Illinois Road and Transportation Builders<br />

Association. “It has made the state less<br />

competitive because businesses are hesitant<br />

to relocate here, and the public is less<br />

willing to support programs because of<br />

suspicion of the government.”<br />

Meanwhile, the state is ramping up for<br />

increased infrastructure spending. If recently<br />

appointed Gov. Patrick Quinn (D)<br />

gets his way, the state will see its first<br />

capital bill in 10 years. Called Illinois Jobs<br />

Now, the $26-billion budget includes $14<br />

billion for roads and bridges and $5 billion<br />

for public transit. It will be funded<br />

through a combination of state, federal<br />

and local funds and fees. Authorization<br />

for the first $3 billion came on April 3,<br />

when Gov. Quinn signed into law HB-<br />

289, also called the “Jump Start Capital<br />

Plan” or the “mini-capital bill,” for critical<br />

infrastructure improvements.<br />

Illinois also has received $1.6 billion in<br />

federal stimulus funds for infrastructure<br />

enhancements and repair to existing<br />

roads. The contracts were let for so-called<br />

shovel-ready projects.<br />

April 3 was the same day ousted Gov.<br />

Rod Blagojevich, his brother Robert and<br />

four others were indicted on federal corruption<br />

charges for their fund-raising<br />

activities (ENR 4/13 p. 9). Among them<br />

are two construction executives: roofing<br />

contractor Christopher Kelly and William<br />

Cellini, head of the Illinois Asphalt<br />

Pavement Association. All deny the<br />

charges.<br />

As for reforms, two panels are working<br />

on recommendations. The Illinois Reform<br />

Commission was assembled by Gov.<br />

Quinn, and the Joint Commission on<br />

Government Reform is made up of state<br />

lawmakers. The governor’s office also<br />

launched a new Website where people can<br />

report wrongdoing, fraud and waste at all<br />

levels of state and municipal government<br />

(www.whistleblower.illinois.gov).<br />

One legislative proposal gaining bipartisan<br />

traction is Ryg’s HB-2359, the<br />

Transportation Investment and Accountability<br />

Act. The bill advocates forming a<br />

new Illinois Transportation Policy Committee<br />

that would prioritize capital projects<br />

for the Illinois Dept. of Transportation,<br />

provide greater transparency for<br />

contracts and level opportunities for contractors<br />

in different locations.<br />

Not all cleanup efforts are legislated.<br />

IDOT is conducting two assessments on<br />

its own to develop a risk-management<br />

plan. One specifically is aimed at stimulus<br />

projects for financing, staffing and contracting<br />

public works. Some high-risk<br />

areas, such as subrecipient monitoring,<br />

already have been identified and a mitigation<br />

plan put in place, says Paris Ervin,<br />

IDOT communication manager. In addition,<br />

Illinois is one of 16 states whose<br />

stimulus spending will be audited by the<br />

federal government.<br />

“Everyone is keeping a close eye on<br />

how money is spent, and that’s the way it<br />

should be,” says Daniel Gallagher, president<br />

of Thornton, Ill.-based Gallagher<br />

Asphalt Corp. and a board member for<br />

the National Asphalt Pavement Association.<br />

“We don’t want another Bridge to<br />

Nowhere kind of thing.” <br />

By Pamela Dittmer McKuen<br />

enr.com April 27, 2009 ENR 13

<strong>News</strong><br />

CLAIMS<br />

Thornton-Tomasetti Is Cleared<br />

In Indiana Library Defect Suit<br />

In the latest twist in a long controversy,<br />

an Indiana circuit court<br />

jury on April 15 cleared structural<br />

engineer Thornton-Tomasetti<br />

Inc., New York City, of fraud<br />

charges brought by the Indianapolis-Marion<br />

County Public Library,<br />

related to the troubled renovation<br />

and expansion of the city’s<br />

central library.<br />

The library project originally<br />

was budgeted at $103 million but<br />

was completed two years late, in<br />

December 2007, and as much as<br />

$50 million over budget. Other<br />

project contractors previously settled with<br />

the library for a total of $21.5 million,<br />

including its construction manager, a joint<br />

venture of Turner <strong>Construction</strong> Co.,<br />

Trotter <strong>Construction</strong> Co. Inc. and Shiel<br />

Sexton Co. Inc. But the jury declined to<br />

award the library $24.5 million from<br />

Thornton-Tomasetti after a five-week<br />

trial. It also awarded the firm $712,000<br />

Done. Library’s structural engineer was sued by project owner.<br />

sought in a countersuit. “In 30 years of<br />

practicing engineering, including forensic<br />

engineering, I’ve never heard a case like<br />

that,” says firm CEO Daniel Cuoco.<br />

The library says it “continued to seek<br />

legal redress because we believed in the<br />

validity of our claim that there were issues<br />

with Thornton-Tomasetti’s work.” In<br />

2003, cracks were observed in columns<br />

and beams supporting a new two-story<br />

underground garage, which also served as<br />

a foundation for the six-story expansion.<br />

Library officials claimed that Thornton-<br />

Tomasetti contributed to the problem by<br />

adding rebar to the gararge and misrepresented<br />

its rationale for the change.<br />

Cuoco contends that honeycombing<br />

had formed—possibly<br />

due in part to a lack of vibration<br />

of concrete—after forms were<br />

stripped in the post-tensioned garage.<br />

He says the firm recommended<br />

adding rebar to correct the<br />

problem. “I wouldn’t say it was a<br />

unique situation for a concrete<br />

project,” Cuoco says. The project<br />

was halted in March 2004 but eventually<br />

was completed by Smoot<br />

<strong>Construction</strong> Co., Columbus,<br />

Ohio.<br />

Mike Coghlan, capital projects<br />

manager for the library, would not speculate<br />

on why the other contractors agreed<br />

to settle, and executives of those firms<br />

could not be reached. Coghlan says the<br />

library’s board of directors met in executive<br />

committee on April 16 to discuss<br />

whether to pursue further legal remedies<br />

but did not announce any future step. <br />

By Craig Barner<br />

MILITARY CONSTRUCTION<br />

Guam Needs More U.S. Funds To Redeploy Military, Says GAO<br />

Even with billions committed<br />

by the U.S. military to Guam<br />

infrastructure upgrades to<br />

support proposed troop redeployment<br />

there, the U.S. Government<br />

Accountability Offi ce says the tiny<br />

island needs more U.S. government<br />

help to cover its required share of<br />

costs to expand ports and roads,<br />

the power grid and water-wastewater<br />

facilities needed to accommodate<br />

a projected 15% population<br />

increase.<br />

GAO says that the U.S. Defense<br />

Dept. is funding infrastructure<br />

costs on Guam “directly related” to<br />

the movement of 17,000 U.S. Marines<br />

and dependents from the island<br />

of Okinawa and from other<br />

locations, as well as providing<br />

“some funds toward civilian infrastructure.”<br />

But the Guam government must<br />

fund “civilian requirements related<br />

to the buildup,” GAO says. Island<br />

offi cials already have told the Senate<br />

Energy and Natural Resources<br />

Committee that they would request<br />

at least $6.1 billion for fi scal 2010<br />

to fund infrastructure work. According<br />

to GAO, Guam’s wastewater<br />

treatment plants are operating<br />

at near capacity and face a 25%<br />

demand increase, while its electric<br />

grid is “inadequate.”<br />

GAO contends that while a federal<br />

governmentwide working<br />

group coordinates Guam funding<br />

needs, it does not have authority to<br />

direct agency budget allocations.<br />

GAO says only pressure from top<br />

DOD offi cials “can marshal the resources<br />

from member agencies”<br />

needed to meet Guam’s infrastructure<br />

needs.<br />

GAO says construction on Guam<br />

could start in fi scal 2010 to meet<br />

the projected 2014 deadline for<br />

troop movements, but military and<br />

industry sources speculate that<br />

overall funding issues in the U.S.<br />

and in Japan, which is also set to<br />

fund redeployment, could push<br />

that date back. There also are delays<br />

in completing required environmental<br />

reviews.<br />

DOD Deputy Undersecretary<br />

Wayne Army concurs with the report<br />

but says the time allowed for<br />

its review was “compressed.” According<br />

to Guam Congresswoman<br />

Madeline Bordallo, DOD’s concurrence<br />

with the GAO report’s conclusion<br />

is “signifi cant.” <br />

PHOTO COURTESY OF INDIANAPOLIS-MARION COUNTY PUBLIC LIBRARY<br />

14 ENR April 27, 2009 enr.com

PICTURES COURTESY OF THE FLORIDA DEPT. OF HEALTH<br />

MATERIALS<br />

Problems Continue To Grow<br />

With Drywall Made in China<br />

Amid a growing chorus of complaints,<br />

two U.S. Senators have<br />

introduced legislation to recall<br />

Chinese-made drywall and to ban further<br />

imports until federal safety standards are<br />

developed. Meanwhile, Florida’s governor<br />

has asked the U.S. Environmental Protection<br />

Agency to help the state develop and<br />

implement chemical-testing strategies.<br />

Senators Bill Nelson (D-Fla.) and<br />

Mary L. Landrieu (D-La.) introduced<br />

legislation on Mar 30 pressing the Consumer<br />

Product Safety Commission to<br />

recall Chinese-made drywall and work<br />

with federal testing labs to determine the<br />

exact level of hazard posed by off-gassing<br />

from the drywall. The bill also calls for an<br />

interim ban on imports. “This defective<br />

Normal<br />

Chinese drywall represents an attack on<br />

our homeowners, a defrauding of our<br />

homebuilders and another obstacle on our<br />

road to recovery,” says Landrieu. “The<br />

federal government now has a responsibility<br />

to assess the full scope of the problem<br />

and immediately prohibit further<br />

importation.”<br />

Since 2006 over 550 million lb of drywall<br />

has been imported to the U.S., with<br />

60% going to Florida, say the senators.<br />

Nelson says about 60 million lb arrived in<br />

Louisiana and 27 million lb in Mississippi<br />

during that same period. Landrieu and<br />

Nelson estimate between 60,000 and<br />

100,000 homes may contain “potentially<br />

defective drywall.” Other states affected<br />

by the imported material include Virginia,<br />

Abnormal<br />

Puzzle. Chinese-made drywall could be the cause of household corrosion and sulfur smells.<br />

Alabama and California.<br />

Earlier this year, several lawsuits were<br />

filed in Florida alleging products from<br />

Knauf Gips KG, Knauf Plasterboard<br />

Tianjin Co. Ltd. (KPT) and Taishan Gypsum<br />

Co. Ltd. produced sulfur-smelling<br />

gasses and corrosion of copper wiring and<br />

piping (ENR 2/9 p. 15). KPT says its<br />

half-inch drywall was imported between<br />

January and October 2006 and represents<br />

less than 20% of the Chinese plasterboard<br />

imported between 2005 and 2007.<br />

At least 289 complaints have been recorded<br />

by the Florida Dept. of Health<br />

(FDOH). On April 3, Florida Gov. Charlie<br />

Crist (R) wrote the Environmental<br />

Protection Agency and Centers for Disease<br />

Control and Prevention requesting<br />

assistance with chemical testing. He noted<br />

that preliminary FDOH tests confirmed<br />

“the presence of strontium sulfide and<br />

elemental sulfur in drywall from China.”<br />

Further, the testing confirmed that the<br />

drywall generated hydrogen sulfide, carbonyl<br />

sulfide and carbon disulfide when<br />

exposed to high humidity or heat. “All of<br />

these compounds are capable of causing<br />

the type of corrosion identified in the<br />

complaint homes and at sufficient concentrations<br />

could pose a health hazard,” says<br />

Crist. He wants a testing program to see<br />

if a health advisory is warranted.<br />

In late January, FDOH commissioned<br />

an analysis of four drywall samples: one<br />

American-made, one unmarked, one<br />

marked Knauf and one marked Made in<br />

China. The report from Unified <strong>Engineering</strong><br />

Inc., Aurora, Ill., noted there is a<br />

distinct difference in drywall manufactured<br />

in the U.S. and China. “The Chinese<br />

samples contained traces of strontium<br />

sulfide inclusions and more organic<br />

material than the [U.S.] sample,” it said.<br />

“However, it is not yet known if either<br />

contributed to the odor. The Chinese<br />

samples gave off a sulfur odor when exposed<br />

to extreme heat and moisture.”<br />

Different types of drywall may have<br />

been used in the same house. “We are in<br />

the process of identifying a lab for further<br />

testing of indoor-air samples,” says Susan<br />

S. Smith, FDOH press secretary. <br />

By William J. Angelo, with Steven Setzer<br />

enr.com April 27, 2009 ENR 15

<strong>Construction</strong> Economics<br />

Cost Indexes<br />

<strong>Construction</strong> Cost Index<br />

This month’s 0.1% decline in the CCI<br />

also pulled down the index’s annual<br />

infl ation rate by 0.1%.<br />

APRIL 2009 % CHG. % CHG.<br />

20-CITY: 1913=100 INDEX VALUE MONTH YEAR<br />

CONSTRUCTION COST 8528.39 –0.1 +5.1<br />

COMMON LABOR 18015.79 0.0 +5.4<br />

WAGE $/HR. 34.23 0.0 +5.4<br />

Building Cost Index<br />

A 0.3% dip in materials costs cut the<br />

BCI’s annual escalation rate from 4.3%<br />

last month to 4.1%.<br />

APRIL 2009 % CHG. % CHG.<br />

20-CITY: 1913=100 INDEX VALUE MONTH YEAR<br />

BUILDING COST 4761.05 –0.1 +4.1<br />

SKILLED LABOR 8112.22 0.0 +4.1<br />

WAGE $/HR. 45.02 0.0 +4.1<br />

Materials Cost Index<br />

Cement, steel and lumber prices all<br />

fell, dragging year-to-year materials<br />

escalation down to 4.1%.<br />

APRIL 2009 % CHG. % CHG.<br />

20-CITY: 1913=100 INDEX VALUE MONTH YEAR<br />

MATERIALS 2713.54 –0.3 +4.1<br />

CEMENT $/TON 100.91 –0.8 –0.4<br />

STEEL $/CWT 44.83 –0.2 +8.4<br />

LUMBER $/MBF 411.60 –0.7 –4.2<br />

Public Works Keeps Head Above Water<br />

While public sector growth has<br />

slowed in recent months (see<br />

chart), public construction this<br />

February remained slightly ahead of<br />

February 2008’s pace. On a<br />

seasonally adjusted basis, total public<br />

construction in February was running<br />

at an annual rate of $301 billion,<br />

which was up 0.8% from January and<br />

3.4% from February 2008’s pace,<br />

according to the U.S. Dept. of<br />

Commerce. On a year-to-date basis,<br />

total public construction through the<br />

fi rst two months of the year totaled<br />

$38.8 billion, or 0.9% above the same<br />

period a year ago. This was better<br />

than the 15% year-to-year decline<br />

recorded for the private sector during<br />

the same period.<br />

The institutional offi ce building<br />

market is off to a strong start, with<br />

$2.37 billion in new construction<br />

put-in-place through February. That<br />

was 20.9% above 2008’s total. Public<br />

school work accounted for $11.7<br />

billion of all public works during the<br />

fi rst two months of the year. That<br />

market was up 5.2% above 2008’s<br />

level. Highway construction appears<br />

to be waiting for its stimulus push.<br />

Through February, highway work was<br />

running 2% below a year ago.<br />

Sewerage work was down 3.4%.<br />

$ BIL.<br />

317<br />

311<br />

305<br />

299<br />

Total Public <strong>Construction</strong><br />

OCT. NOV. DEC. JAN. FEB.<br />

2008–2009<br />

SOURCE: U.S. DEPT OF COMMERCE. CONSTRUCTION PUT-IN-PLACE,<br />

SEASONALLY ADJUSTED RATE IN CURRENT DOLLARS.<br />

Public <strong>Construction</strong><br />

MARKET: YEAR-TO-DATE 2009 2008 % CHG. % CHG.<br />

$ BIL. FEB. FEB. MONTH YEAR<br />

TOTAL PUBLIC CONSTRUCTION 38.83 38.48 +0.6 +0.9<br />

Residential 1.06 1.04 +4.2 +1.9<br />

Office 2.37 1.96 –2.5 +20.9<br />

Commercial 0.48 0.50 –8.4 –4.0<br />

Health care 1.40 1.37 +3.1 +2.2<br />

Educational 11.73 11.16 –0.5 +5.1<br />

Public safety 1.92 1.62 –6.0 +18.5<br />

Amusement and recreation 1.52 1.59 +4.7 –4.4<br />

Transportation 3.24 3.31 +3.8 –2.1<br />

Power 1.20 1.66 +10.0 –27.7<br />

Highway and street 7.54 7.70 +2.1 –2.1<br />

Sewage and waste disposal 3.35 3.47 –0.6 –3.5<br />

Water supply 2.16 2.04 –0.9 +5.9<br />

Conservation and development 0.74 0.81 0.0 –8.6<br />

SOURCE: DEPT. OF COMMERCE, CONSTRUCTION PUT-IN-PLACE.<br />

Structural Steel, Rebar, Building Sheet, Piling<br />

ITEM UNIT ATLANTA BALTIMORE BIRMINGHAM BOSTON CHICAGO CINCINNATI CLEVELAND DALLAS DENVER DETROIT KANSAS CITY<br />

STANDARD STRUCTURAL SHAPES: AVERAGE cwt 42.12 –45.00 56.17 43.56 +37.85 –45.00 48.50 41.35 39.97 38.92 65.48<br />

Channel beams, 6” DEEP, 8.2 LB/LF cwt 43.44 –44.00 55.10 41.22 +37.00 45.00 50.83 41.00 37.42 42.97 62.65<br />

I-beams, 6” DEEP, 12.5 lb/lf cwt 45.88 –48.00 61.45 44.60 +36.75 –45.00 46.23 38.92 42.10 37.65 68.65<br />

Wide-flange, 8” DEEP, 31 LB/LF cwt 37.04 –43.00 51.95 44.85 +39.80 –45.00 48.44 44.12 40.38 36.14 65.15<br />

REINFORCING BARS:<br />

Grade 60, #4 cwt 41.70 –35.00 44.50 39.30 +38.52 28.00 40.00 38.35 40.55 39.00 62.00<br />

Epoxy-coated cwt — — — 56.17 57.25 — 63.00 — 46.98 53.00 —<br />

HOT-ROLLED CARBON STEEL PLATE:<br />

12 gauge, 48” x 10’ cwt 39.00 –40.00 50.65 35.78 38.39 –35.00 74.80 42.15 40.37 68.12 49.00<br />

EXPANDED METAL LATH:<br />

Std diamond mesh, 3.4 LB/SY, GALVANIZED cwt 194.00 230.00 150.00 178.40 191.78 243.00 — 195.40 197.08 — —<br />

Flat-ribbed, 3.4 lb/sy cwt 217.00 — 193.00 207.27 217.25 — — 223.25 201.12 — —<br />

BUILDING SHEET & PLATE:<br />

Aluminum sheet, 3003H14, 36” x 96” cwt 191.00 178.50 193.00 187.00 180.60 –180.00 220.90 193.90 197.00 220.00 —<br />

STAINLESS STEEL SHEET:<br />

14 gauge cwt 171.90 –110.00 197.00 134.00 137.37 –120.50 190.90 142.20 159.00 242.00 135.00<br />

16 gauge cwt 167.31 –111.00 212.00 136.80 138.50 –122.50 230.30 146.00 165.00 240.00 136.00<br />

20 gauge cwt 172.32 –119.00 246.00 142.46 145.65 –124.50 228.23 148.00 172.50 240.00 141.00<br />

STAINLESS STEEL PLATE:<br />

304, 1/4”, 72” x 240” cwt 175.80 –134.00 275.00 144.45 188.00 –198.00 152.50 176.15 185.00 250.00 184.00<br />

316, 1/4”, 96” x 140” cwt 243.60 +275.00 — 277.29 206.95 –401.00 290.00 202.34 231.00 285.00 156.00<br />

STEEL PILING: H-PILE<br />

HP10 x 42 cwt 27.75 –55 69.20 25.88 25.34 58.00 24.75 25.53 28.10 25.20 —<br />

+ or – denotes price has risen or fallen since previous report. Monthly market quotations by ENR fi eld reporters as of April 17, 2009. All prices are spot prices quoted from a single source. All prices<br />

are FOB warehouse except metal lath, which is FOB city. Stainless steel sheet prices are for type 304, 2B fi nish, 48 x 120-in. Steel piles are high-strength A572. Some prices may include taxes or<br />

discounts for prompt payment, etc. Product specifi cations may vary depending on what is most commonly used or most accessible in a city. All quantities are truckloads unless noted. Quotes for<br />

16 ENR April 27, 2009 enr.com

Recession Cuts Into Rebar Prices<br />

Growing weakness in the nonresidential<br />

building market is cutting into prices for<br />

concrete reinforcing bar. In April, ENR’s 20-city<br />

average price for rebar fell 3.4%. The most<br />

recent decline pushed rebar prices 10.1%<br />

below last summer’s peak. However, the<br />

market is still feeling the impact of a record<br />

ENR’s Materials Price Indexes<br />

1992=100<br />

215<br />

210<br />

205<br />

200<br />

195<br />

190<br />

1992=100<br />

157<br />

156<br />

155<br />

154<br />

153<br />

Structural Steel, Rebar, Building Sheet, Piling<br />

ITEM<br />

WIDE-FLANGE<br />

J A S O N D J F M A<br />

2008-2009<br />

During the last eight months<br />

prices have declined 10.1%.<br />

ALUMINUM SHEET<br />

152<br />

J A S O N D J F M A<br />

2008-2009<br />

Recent declines have pushed prices<br />

0.9% below a year ago.<br />

1992=100<br />

215<br />

210<br />

205<br />

200<br />

195<br />

SOURCE: MCGRAW-HILL CONSTRUCTION RESEARCH & ANALYTICS/ENR.<br />

surge in prices during the fi rst half of last year<br />

and ENR’s average rebar price is still 4.2%<br />

above a year ago. That year-to-year escalation<br />

rate should start to fall off in coming months as<br />

prices continue to weaken and the market<br />

moves “out of range” of the steep price hikes<br />

posted in May and June of last year.<br />

REINFORCING BAR<br />

190<br />

J A S O N D J F M A<br />

2008-2009<br />

Prices have fallen 10.4%<br />

since last August.<br />

1992=100<br />

135 170<br />

132 166<br />

129 162<br />

126 164<br />

123 154<br />

120 150<br />

STAINLESS STEEL SHEET<br />

J A S O N D J F M A<br />

2008-2009<br />

Prices held steady<br />

after falling 10% below last year’s level.<br />

20-City Average<br />

enr.com<br />

FOR A COMPLETE HISTORY OF COST<br />

INDEXES, VISIT OUR WEBSITE, ENR.COM.<br />

% CHG. % CHG.<br />

ITEM UNIT PRICE MO. YEAR<br />

STANDARD STRUCTURAL SHAPES: AVERAGE cwt 44.53 –0.7 +5.7<br />

Channel beams, 6” DEEP, 8.2 LB/LF cwt 44.71 –0.4 +7.8<br />

I-beams, 6” DEEP, 12.5 LB/LF cwt 45.05 –0.8 +4.5<br />

Wide-flange, 8” DEEP, 31 LB/LF cwt 43.84 –0.8 +4.9<br />

REINFORCING BARS:<br />

Grade 60, #4 cwt 39.51 –3.4 +4.2<br />

Epoxy-coated cwt 57.87 0.0 +6.1<br />

HOT-ROLLED CARBON STEEL PLATE:<br />

12 gauge, 48” x 10’ cwt 48.60 –1.5 +8.7<br />

EXPANDED METAL LATH:<br />

Std diamond mesh, 3.4 LB/SY, GALVANIZED cwt 201.43 0.0 –1.3<br />

Flat-ribbed, 3.4 LB/SY cwt 217.82 0.0 +0.4<br />

BUILDING SHEET & PLATE:<br />

Aluminum sheet, 3003H14, 36” x 96” cwt 190.98 0.0 –0.9<br />

STAINLESS STEEL SHEET:<br />

14 gauge cwt 165.84 –0.3 –11.4<br />

16 gauge cwt 174.56 –0.3 –9.5<br />

20 gauge cwt 175.41 –0.2 –8.2<br />

STAINLESS STEEL PLATE:<br />

304, 1/4”, 72” x 240” cwt 183.97 –0.2 –4.5<br />

316, 1/4”, 96” x 140” cwt 232.85 –0.3 +0.2<br />

STEEL PILING: H-PILE<br />

HP10 x 42 cwt 32.06 –1.5 +0.7<br />

Canada<br />

UNIT LOS ANGELES MINNEAPOLIS NEW ORLEANS NEW YORK PHILADELPHIA PITTSBURGH ST. LOUIS SAN FRANCISCO SEATTLE MONTREAL TORONTO<br />

STANDARD STRUCTURAL SHAPES: AVERAGE cwt 45.49 34.06 40.04 51.60 46.13 44.80 +43.60 44.15 +36.90 +63.33 69.33<br />

Channel beams, 6” DEEP, 8.2 LB/LF cwt 44.70 42.13 38.07 51.60 45.85 40.80 55.02 43.26 32.19 –50.00 70.00<br />

I-beams, 6” DEEP, 12.5 lb/lf cwt 46.71 30.05 39.30 52.80 46.95 48.00 38.79 45.30 37.93 +85.00 73.00<br />

Wide-flange, 8” DEEP, 31 LB/LF cwt 45.07 29.99 42.75 50.40 45.60 45.60 36.98 43.88 40.57 55.00 65.00<br />

REINFORCING BARS:<br />

Grade 60, #4 cwt 41.41 37.00 39.30 54.00 37.15 44.85 34.00 40.46 38.53 49.00 —<br />

Epoxy-coated cwt 59.52 57.00 — — 51.48 57.50 70.00 57.74 — 82.00 —<br />

HOT-ROLLED CARBON STEEL PLATE:<br />

12 gauge, 48” x 10’ cwt 47.05 80.00 38.08 — 39.77 42.00 90.50 44.02 31.70 48.00 75.00<br />

EXPANDED METAL LATH:<br />

Std diamond mesh, 3.4 LB/SY, GALVANIZED cwt 198.10 112.50 194.41 — 268.15 — — 198.90 175.50 — —<br />

Flat-ribbed, 3.4 lb/sy cwt 215.30 156.25 225.18 — 278.00 — — 216.01 187.75 — —<br />

BUILDING SHEET & PLATE:<br />

Aluminum sheet, 3003H14, 36” x 96” cwt 187.48 208.00 184.43 — 170.65 171.00 220.90 188.36 190.84 180.00 275.00<br />

STAINLESS STEEL SHEET:<br />

14 gauge cwt 175.99 238.00 162.55 — 137.85 154.00 238.00 182.81 155.80 93.00 274.00<br />

16 gauge cwt 185.76 292.00 168.48 — 139.35 156.00 255.00 184.39 170.05 95.00 274.00<br />

20 gauge cwt 180.94 251.92 171.55 — 142.00 164.00 239.00 182.11 159.55 97.00 274.00<br />

STAINLESS STEEL PLATE:<br />

304, 1/4”, 72” x 240” cwt 184.29 261.41 162.42 — 132.90 164.00 195.50 184.99 209.00 107.00 290.00<br />

316, 1/4”, 96” x 140” cwt 230.78 270.00 192.15 — 143.70 200.00 262.00 231.81 193.60 104.00 330.59<br />

STEEL PILING: H-PILE<br />

HP10 x 42 cwt 28.99 25.20 27.40 — 25.15 — 23.80 29.36 26.31 +80.00 63.00<br />

Montreal and Toronto are in Canadian dollars and a mix of metric and American units. The above prices are not intended to represent the prevailing or average price in a city but are designed to track<br />

price movement from a single source for a given quantity and specifi cation over time.<br />

enr.com April 27, 2009 ENR 17

Cover Story Bridges<br />

By Janice L. Tuchman in Mumbai with Neelam Mathews<br />

LONG ROAD TO

Reality<br />

Long-awaited link across<br />

the bay will ease traffic and<br />

create a signature gateway<br />

to Mumbai<br />

After years of legal delays, monsoons, heavy lifting<br />

and a lot of fancy formwork, the Bandra-Worli Sea Link, a 4.7-<br />

kilometer viaduct with two cable-stayed spans, made its final connection<br />

on April 20 and is slated to open to traffic in mid-May. When<br />

it does, the bypass over the sea will cut the time of a trip across<br />

Mahim Bay in Mumbai, India, from about 40 minutes to just six.<br />

Drivers who had to suffer through 23 traffic lights to make the<br />

trip from Bandra in north Mumbai to Worli in the southern part<br />

of the city will face only four on the new route, planned by the<br />

Maharashtra State Road Development Corp.<br />

Hindustan <strong>Construction</strong> Co. (HCC)<br />

started work on the project in 2000. It<br />

faced a one-year delay because the developer<br />

could not gain access to the site. An<br />

original 1998 design by Jacobs Sverdrup<br />

called for the original cable-stayed span’s<br />

twin decks to share pylons. This design<br />

was modified in 2003 by Dar al-Handasah<br />

Shair and Partners, London. MSRDC<br />

had decided to build one of the twin decks<br />

ahead of the other, hoping for an earlier<br />

start for toll revenue, so Dar al-Handasah<br />

revised the structure so that each deck was<br />

independently supported by its own pylon.<br />

But more delay was ahead. The Bandra<br />

cable-stayed section was planned so that<br />

fishing boats from the Mahim fishing village<br />

could pass below the bridge without<br />

getting shattered by monsoon waves. The<br />

original design had only one 500-meterlong<br />

cable-stayed section, with 50-m transition<br />

spans on both sides. Then, after the<br />

contract was awarded to HCC, the Worli<br />

fishing village at the other end protested.<br />

Villagers went to court claiming they<br />

should not be forced to go all the way to<br />

Bandra to pass through the channel. The<br />

courts agreed, and the design was sig-<br />

Inclined. Two four-legged pylons lean<br />

together, creating a formwork challenge.<br />

nificantly altered by adding the second<br />

cable-stayed bridge, which is 350 m long,<br />

including transition spans. Environmental<br />

objections to the project also went all the<br />

way to India’s Supreme Court, resulting<br />

in moving the alignment 200 m farther<br />

away from shore.<br />

Through all this, HCC stuck with the<br />

job, its leaders say, not just because they<br />

had invested so much in specialized equipment.<br />

“Apart from investing our money,<br />

we had invested our heart and soul. We<br />

are confident we will be long remembered<br />

for having brought ease to Mumbai’s commuters,”<br />

said Jimmy Mogal, HCC’s vice<br />

president of corporate communications.<br />

Rough Seas<br />

The work then faced its natural challenge:<br />

the tides and storms of India’s west coast<br />

on the Arabian Sea. Santosh Rai, HCC<br />

planning manager, says the contractor had<br />

to plan the job around monsoons, where<br />

winds range from 70 or 80 kilometers per<br />

hour up to 120 kmph. The bridge is designed<br />

to withstand 264 kmph winds at<br />