June 2009 - Alabama State Port Authority

June 2009 - Alabama State Port Authority

June 2009 - Alabama State Port Authority

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Aker Solutions<br />

Named <strong>2009</strong> <strong>Alabama</strong> Medium Manufacturer of the Year<br />

Terry Gilbreath will be responsible for keeping operations smooth throughout the <strong>Port</strong> of Mobile.<br />

Security in both the <strong>Port</strong> of Mobile’s private and public terminals<br />

is stronger now, he said, due to the industry’s implementation<br />

of the Maritime Transportation Safety Act. The <strong>Port</strong> <strong>Authority</strong><br />

has installed security cameras, fencing, beefed up its<br />

<strong>Port</strong> Police force and implemented other security measures<br />

as part of its facility security plan. Another security change<br />

was the application of TWIC, or Transportation Worker Identification<br />

Credential, which was required for unescorted access<br />

to port facilities starting in December 2008.<br />

“There have been very evident changes in port security, but<br />

there’s also been very obvious growth since 2002,” Gilbreath<br />

said. When he was last in Mobile, construction on the new<br />

Mobile Container Terminal had not even started, McDuffie<br />

was handling about half the coal volumes than it handles today,<br />

and Austal was not building Littoral Combat Ships. “The<br />

<strong>Authority</strong> has seen new facilities, industries and services roll<br />

into <strong>Port</strong> City,” he said.<br />

Gilbreath explained. “Mobile still has areas to develop. And it will<br />

continue to grow. It’s one of the reasons I’m happy to be here.”<br />

One of the defining characteristics of Mobile is its location on<br />

the central Gulf Coast and, by extension, the effect of hurricanes<br />

on the shipping industry, oil transportation and offshore<br />

oil facilities.<br />

“Many industry watchers track how well we respond and get<br />

ships moving again, whether it’s oil shipments for our area<br />

gasoline refineries, coal shipments for our utilities or just other<br />

deep-draft vessels moving into the harbor that carry vital goods for<br />

area and regional manufacturers and retailers,” said Gilbreath.<br />

“Getting the port up and running and restoring channel use<br />

for ships is critical after storm events. Many consumers in our<br />

market rely on these shipments to support the basic necessities<br />

of life” he said.<br />

Gilbreath was in New Orleans with the Coast Guard for Hurricanes<br />

Katrina and Rita in 2005, making him aware of how<br />

the Coast Guard responds to hurricanes and what to expect<br />

as the port readies for storms. He was already on staff with<br />

the <strong>Alabama</strong> <strong>State</strong> <strong>Port</strong> <strong>Authority</strong> for the 2008 hurricane season,<br />

which included impacts from storms Gustav and Ike. Gilbreath<br />

noted the port still had to fully prepare as if Mobile was<br />

in the direct path of the storms. The storm season preparation<br />

and operations plan, which are continuously updated by<br />

<strong>Port</strong> <strong>Authority</strong> management, provide the framework for storm<br />

preparation and post-storm recovery efforts. While the 2008<br />

storms inflicted minimal damage, both storms delivered high<br />

tide, an increased number of oil field supply vessels seeking<br />

refuge on Mobile River, and resulted in channel restrictions<br />

while missing aids to navigation were restored. “Storm season<br />

requires a high level of planning, communications and<br />

coordination amongst many players,” said Gilbreath. The harbor<br />

master, along with <strong>Port</strong> <strong>Authority</strong> management, interface<br />

daily with the Coast Guard, the Army Corps of Engineers and<br />

NOAA, as well as industry groups through phone calls and<br />

e-communications. “From what I see, the level of communications<br />

and coordination throughout the port results is our ability<br />

to quickly return to operations,” he said.<br />

Gilbreath is a graduate of the U.S. Coast Guard Academy<br />

with a bachelor’s degree in chemistry. He also holds a master’s<br />

degree in physics from University of Connecticut.<br />

“My family and I really love the area and have always considered<br />

it home,” Gilbreath said. “I’m honored to have been<br />

selected for this position.”<br />

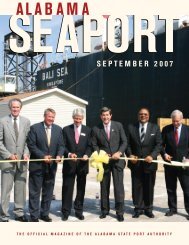

From left, Business Council of <strong>Alabama</strong> President and CEO William Canary;<br />

Gov. Bob Riley; Aker Vice President Marc Quenneville; and Mike Bailey,<br />

president, <strong>Alabama</strong> Technology Network.<br />

Aker Solutions of Mobile was honored by the Business Council<br />

of <strong>Alabama</strong> and the <strong>Alabama</strong> Technology Network, in partnership<br />

with the Chamber of Commerce Association of <strong>Alabama</strong><br />

and the National Association of Manufacturers, with the<br />

<strong>2009</strong> <strong>Alabama</strong> Medium Manufacturer of the Year Award. The<br />

award goes to a manufacturing company that employs 100 to<br />

399 people and has demonstrated superior performance in<br />

the areas of customer focus, employee commitment, operational<br />

excellence, continuous improvement, profitable growth<br />

and investment in training and retraining.<br />

Aker Solutions is a leading global provider of engineering<br />

and construction services, and manufacturer of technological<br />

products and integrated solutions. It produces subsea steel<br />

tube umbilicals and steel tube flying leads for the offshore oil<br />

and gas industry. Despite highly competitive market conditions,<br />

Aker increased the profitability of its Mobile operation<br />

and has experienced more than 50 percent return on its investment.<br />

Aker made a $10.7 million investment in capital in<br />

the past three years and plans for another $2 million investment<br />

in the next year.<br />

The <strong>Alabama</strong> Manufacturer of the Year Awards program is<br />

an annual recognition of <strong>Alabama</strong> manufacturing enterprises<br />

that exhibit excellence in leadership, performance, profitability<br />

and work force relations. The awards are presented in three<br />

size categories to ensure fair recognition of all applicants<br />

regardless of the size of their work force. The fourth award<br />

From left (in front) Johnny Patterson; Dan Appleton; Marc Quenneville,<br />

holding the award; Jim Altieri; Angel Persson; and Belinda Thomason.<br />

and category presented is the “Emerging Manufacturer” that<br />

recognizes superior performance among manufacturers that<br />

have been in operation for five or fewer years. Winning manufacturers<br />

are selected by an independent panel of judges<br />

who look for demonstrations of superior performance in the<br />

areas of customer focus, employee commitment, operational<br />

excellence, continuous improvement, profitable growth and<br />

investment in training and retraining.<br />

Other winners were:<br />

Emerging Manufacturer of the Year<br />

(in operation for five or fewer years):<br />

– Hyundai Motor Manufacturing <strong>Alabama</strong>, LLC, Montgomery<br />

Large Manufacturer of the Year<br />

(400 or more employees)<br />

– Teledyne Brown Engineering, Huntsville<br />

Small Manufacturer of the Year<br />

(1-99 employees)<br />

Vulcan Materials Company, Fort Payne<br />

8 <strong>Alabama</strong> Seaport • june <strong>2009</strong> <strong>Alabama</strong> Seaport • june <strong>2009</strong> 9