No. 4, 1998 - Tribology in Industry

No. 4, 1998 - Tribology in Industry

No. 4, 1998 - Tribology in Industry

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Cn the raicrc levei, irictron is occurr<strong>in</strong>g through irit;rac"<br />

:lcn of miss.!-roug,Frli:5.s, i.e . through diss.ipative piocess<br />

of iormiiig and break<strong>in</strong>g .--rf micro-c.ilittcts. 'iJre tct'll<br />

;'e:.isiance to relaii'' c motic;n, i.e., the frir;tion force represerrts<br />

thc sum r..f tlic-. resistance micro-cornponeiris iresistance<br />

tc eiasiic deformation, pl;istir Cefornration, jam-<br />

'lilI ,-rf mici'o-ror-r{ht:ess. and break<strong>in</strong>g of adltesive<br />

uciriisj on ihr,'tctei rer.l :-iurface, anri riissipatiofi cf euirrgy<br />

:,q a surn c-i ;lementar;,' dissipation Frccesses.<br />

iJnergi cissipiltion ocLrurs through <strong>in</strong>crease of corriact<br />

tenperature and hea,t losses, <strong>in</strong>crease of <strong>in</strong>temal energy<br />

Lif r.'liii.aci layers materials (defccts, dislocaiions) and<br />

ei il3,:iio i'l (phr.' t,-, n s, Crame r's eff eil, pho to- h r m<strong>in</strong> escence).<br />

Thr slidirg friction is aocompanied by co<strong>in</strong>plex wear<br />

pro(:s:i-s - fcr<strong>in</strong>iri; r.,f s::r'iace layer <strong>in</strong>teract<strong>in</strong>g with the<br />

envir,rrirnent, adhesive transfer between the contact surf;rccs,<br />

an.i generatio;i of the rvear prcducts (basic materi:1,<br />

reirliion products and transferred mitterial). that is<br />

happenil:g thror.rgh nrecharrisnrs af surface fatigue and<br />

aBiiistOI-r.<br />

'l'he-e processe-r:f prorn<strong>in</strong>ent scientific importance.<br />

.hougir rru academic level sometimes neglectrii due to<br />

the ccr:,ple, Infcrmaticu technclogies (generation and signal<br />

trrnsm.ission). etc.<br />

i ':hlt' i. 7 r!bu':itcitrztricoi sl,r/crtts<br />

Outptr!<br />

i iiloticn<br />

rt-ii:-n l---'-- -<br />

Primlry tecnnical --<br />

:1_;^- 1 Examples<br />

runcilon I<br />

If^]i^- -, :.:^^^--<br />

rvlJllL,l | 3ui;el<br />

llg<br />

Motion transmission<br />

fuloticn restra<strong>in</strong>!nc<br />

Bear<strong>in</strong>gs<br />

Clutches<br />

Brakes<br />

.'\I!:liei.e s','ste'iis i-epre-se1it th{ lii-r caIied "tribomechani-<br />

;;! iti';19,,r""" iii i1l(it':j oi i::;.;..r lit-tpieX Structufe, with <strong>in</strong>put<br />

arid dutpui uotiol;ir-::t. Tircre , as the <strong>in</strong>put variables usually<br />

apir;ir ni,-iiir'ti*woik and r:otion*rn:rterial, anci as<br />

r)iltput variiii,lcs <strong>in</strong>ot,irJlr, work, <strong>in</strong>formation and rnateri'<br />

al, depead<strong>in</strong>g on the prirnarl functior, the system is<br />

perfti::nr<strong>in</strong>g i libie 1 ).<br />

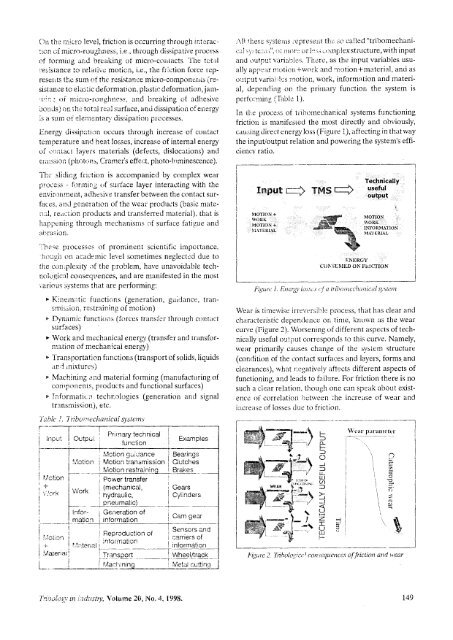

In the procesr of tr'iirolnechanicai systems function<strong>in</strong>g<br />

tliction is manifesred the most directly and obviously,<br />

cau:,<strong>in</strong>g direct energy loss (Figure i), aftect<strong>in</strong>g <strong>in</strong> that r.vay<br />

the <strong>in</strong>puVoutput relation and power<strong>in</strong>g the system's efficiency<br />

ratio.<br />

I<br />

l__<br />

Input L TMS t+<br />

I\IOTION +<br />

WORK<br />

nt011cN +<br />

]\i,,\ TI'RIAL<br />

Technically<br />

useful<br />

outout<br />

!.<br />

MOTION :<br />

woRN .,<br />

IN!'ORtl,t-rroN<br />

]\tA'l tiRtaL<br />

liNtrR(;y<br />

CuNlsUIlttrD oN F'lil(--IION<br />

Figurt i. f)rtct-g' 16';, s '.:! a lribr;titclnitical s1'stcnr<br />

.-;\<br />

'**l/<br />

,w<br />

r.Wm* -"1r&tffi<br />

wiib<br />

Wear is t<strong>in</strong>-rervise irreversible process, that l'rzrs clear and<br />

characteristic dep.en.1.na" oii t<strong>in</strong>le, kttou'tt as the wear<br />

curve (Figure 2). Worsen<strong>in</strong>g of different aspects of technically<br />

useful oulirut corresponds to this curve. Namely,<br />

wear primarily causes change of tire sysiem structure<br />

(condition of the contact surfaces and iayers, iorms.anct<br />

clearances), rvhat r;r-'gativeiY aftects different aspects of<br />

function<strong>in</strong>g, and leads to failure. For friction there is no<br />

such a ciear relation. ihough one can speak about existencc<br />

r;i' correlatior.i i:vtrveen ihe <strong>in</strong>crease of wear and<br />

ilicrelse of losses duc tc friction.<br />

.diiditN:<br />

7<br />

-)<br />

F<br />

:f<br />

_l<br />

:)<br />

u<br />

tt I<br />

=<br />

J<br />

_l<br />

Wcat'pilrarrrcter'<br />

i-------<br />

"a.<br />

r)<br />

=<br />

I<br />

iI<br />

I<br />

'tt\,ett I itso.#ertransler<br />

: Senscrs<br />

\<br />

I<br />

U -Z{<br />

I<br />

heDrcouclion o1<br />

. i Caf!-lefs Ot<br />

r<br />

and<br />

;-"" i,,l.,re,.ier t'^t1:11|a__,_l idqlrcqsil<br />

rviaieriaii<br />

ilr+gpgit _,__, I u:te9Jl!rec!_<br />

r i ':---'<br />

I i l i,rlr^l- rr4-' -,-- ii^+',1 ,-r,rt<strong>in</strong>d I I llr lv ,vr