Extrusion Introduction An extruder is a common machine in industry ...

Extrusion Introduction An extruder is a common machine in industry ...

Extrusion Introduction An extruder is a common machine in industry ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Extrusion</strong><br />

<strong>Introduction</strong><br />

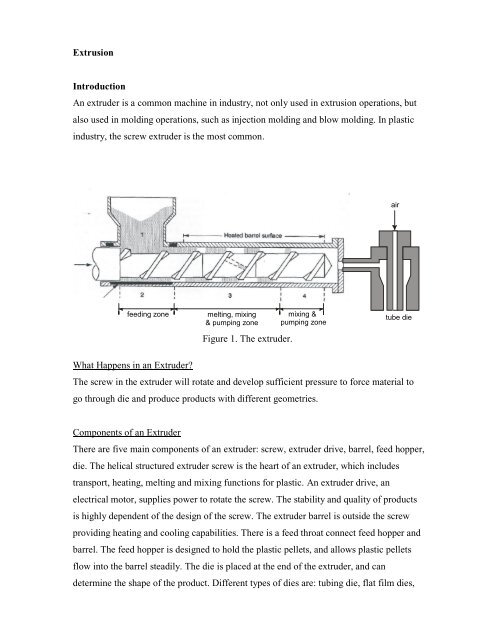

<strong>An</strong> <strong>extruder</strong> <strong>is</strong> a <strong>common</strong> <strong>mach<strong>in</strong>e</strong> <strong>in</strong> <strong>in</strong>dustry, not only used <strong>in</strong> extrusion operations, but<br />

also used <strong>in</strong> mold<strong>in</strong>g operations, such as <strong>in</strong>jection mold<strong>in</strong>g and blow mold<strong>in</strong>g. In plastic<br />

<strong>in</strong>dustry, the screw <strong>extruder</strong> <strong>is</strong> the most <strong>common</strong>.<br />

air<br />

feed<strong>in</strong>g zone<br />

melt<strong>in</strong>g, mix<strong>in</strong>g<br />

& pump<strong>in</strong>g zone<br />

Figure 1. The <strong>extruder</strong>.<br />

mix<strong>in</strong>g &<br />

pump<strong>in</strong>g zone<br />

tube die<br />

What Happens <strong>in</strong> an Extruder<br />

The screw <strong>in</strong> the <strong>extruder</strong> will rotate and develop sufficient pressure to force material to<br />

go through die and produce products with different geometries.<br />

Components of an Extruder<br />

There are five ma<strong>in</strong> components of an <strong>extruder</strong>: screw, <strong>extruder</strong> drive, barrel, feed hopper,<br />

die. The helical structured <strong>extruder</strong> screw <strong>is</strong> the heart of an <strong>extruder</strong>, which <strong>in</strong>cludes<br />

transport, heat<strong>in</strong>g, melt<strong>in</strong>g and mix<strong>in</strong>g functions for plastic. <strong>An</strong> <strong>extruder</strong> drive, an<br />

electrical motor, supplies power to rotate the screw. The stability and quality of products<br />

<strong>is</strong> highly dependent of the design of the screw. The <strong>extruder</strong> barrel <strong>is</strong> outside the screw<br />

provid<strong>in</strong>g heat<strong>in</strong>g and cool<strong>in</strong>g capabilities. There <strong>is</strong> a feed throat connect feed hopper and<br />

barrel. The feed hopper <strong>is</strong> designed to hold the plastic pellets, and allows plastic pellets<br />

flow <strong>in</strong>to the barrel steadily. The die <strong>is</strong> placed at the end of the <strong>extruder</strong>, and can<br />

determ<strong>in</strong>e the shape of the product. Different types of dies are: tub<strong>in</strong>g die, flat film dies,

lown film dies, etc. In th<strong>is</strong> lab, we are us<strong>in</strong>g an annular structured tub<strong>in</strong>g die. Note that<br />

the size and shape of the extruded products will not be exactly the same as the size and<br />

shape of the die, because of several reasons: draw down, cool<strong>in</strong>g, swell<strong>in</strong>g and relaxation.<br />

Figure 2. The cross section of the die for tubes.<br />

<strong>Extrusion</strong> L<strong>in</strong>es<br />

For a complete extrusion process, <strong>in</strong> addition to <strong>extruder</strong>, upstream and downstream<br />

equipment <strong>is</strong> needed to produce useful products. The ma<strong>in</strong> equipment of an extrusion l<strong>in</strong>e<br />

<strong>is</strong> res<strong>in</strong> handl<strong>in</strong>g, dry<strong>in</strong>g system, <strong>extruder</strong>, post-shap<strong>in</strong>g or calibrat<strong>in</strong>g device, cool<strong>in</strong>g<br />

device, take-up device, and cutter or saw. The extrusion l<strong>in</strong>e <strong>in</strong> th<strong>is</strong> lab <strong>in</strong>cludes <strong>extruder</strong>,<br />

take-off roller and cool<strong>in</strong>g water trough, which are shown <strong>in</strong> Figure 3.<br />

Air<br />

Take-off roller<br />

Extruder<br />

Cool<strong>in</strong>g water trough<br />

Figure 3. The extrusion l<strong>in</strong>e <strong>in</strong> th<strong>is</strong> lab, <strong>in</strong>clud<strong>in</strong>g <strong>extruder</strong>, take-off roller and cool<strong>in</strong>g<br />

water trough.

Objectives for <strong>Extrusion</strong><br />

1. Determ<strong>in</strong>e the material volumetric feed<strong>in</strong>g rates based on different screw rotat<strong>in</strong>g<br />

speed (ω).<br />

2. F<strong>in</strong>d the tube dimensions based on different screw rotat<strong>in</strong>g speeds (ω), different takeoff<br />

speeds (v t ) and different pressure differences (p i ).<br />

3. Compare the experiment data with theoretical prediction.<br />

Proposed Goals<br />

1. Run the equipment and determ<strong>in</strong>e the volumetric feed<strong>in</strong>g rates based on different<br />

screw rotat<strong>in</strong>g speeds. Plot the volumetric feed<strong>in</strong>g rate versus screw rotat<strong>in</strong>g speed.<br />

Refer “Investigation of the Thickness (θ) of Tube with Different Screw Rotat<strong>in</strong>g<br />

Speeds (ω)” <strong>in</strong> Experimental Procedures.<br />

2. Plot the tube thickness versus screw rotat<strong>in</strong>g speed (ω), take-off speed (v t ) and<br />

pressure difference (p i ).<br />

Refer “Investigation of the Thickness (θ) of Tube with Different Screw Rotat<strong>in</strong>g<br />

Speeds (ω)”, “Investigation of the Thickness (θ) of Tube with Different Take-Off<br />

Speeds (v t )” and “Investigation of the Thickness (θ) of Tube with Different Pressure<br />

Differences (p i )” <strong>in</strong> Experimental Procedures, respectively.<br />

Internal air pressure<br />

(p i ) Hopper<br />

Die<br />

Screw<br />

Screw rotat<strong>in</strong>g speed<br />

(ω)<br />

Motor<br />

Motor<br />

Take-off speed<br />

(v t )<br />

Output material<br />

Figure 4. Scheme of control variables <strong>in</strong> th<strong>is</strong> experiment, where ω <strong>is</strong> the screw rotat<strong>in</strong>g<br />

speed, v t <strong>is</strong> the take-off speed of the roller and p i <strong>is</strong> the <strong>in</strong>ternal air pressure.

Theory<br />

Theoretical Background<br />

In th<strong>is</strong> lab, we are go<strong>in</strong>g to use an annular structured tub<strong>in</strong>g die to produce tubes <strong>in</strong><br />

different dimensions. When a polymer melt <strong>is</strong> extruded through an annular die and<br />

stretched under tension to a desired diameter, a hollow tube can be made. Although the<br />

overall process that <strong>in</strong>volves die swell followed by draw down (or stretch<strong>in</strong>g) <strong>is</strong> rather<br />

complicated as <strong>in</strong>dicated <strong>in</strong> Figure 5, analytic understand<strong>in</strong>g of the process can be made<br />

under some simplify<strong>in</strong>g assumptions.<br />

die exit<br />

die swell zone<br />

r<br />

z=0<br />

z<br />

r = R o (z)<br />

r = R i (z)<br />

u = (u, w)<br />

draw down region<br />

z=L<br />

F, w L<br />

Figure 5. The diagram for analyz<strong>in</strong>g polymer flow through the die.

In Figure 5., r and z are the radial and axial direction, respectively. R o (z) and R i (z) are the<br />

outer and <strong>in</strong>ner radius at different z position, respectively. The polymer flow<strong>in</strong>g velocity<br />

<strong>is</strong> def<strong>in</strong>ed as u, which <strong>in</strong>clud<strong>in</strong>g r-direction velocity u and z-direction velocity w.<br />

When a polymer melt flows out of the die exit, “die swell” occurs <strong>in</strong> that the polymer<br />

melt expands <strong>in</strong> the radial direction (i.e., swells) due to residual stress <strong>in</strong> the melt. Die<br />

swell <strong>is</strong> a very complicated phenomenon because it depends on the stra<strong>in</strong> h<strong>is</strong>tory (i.e.,<br />

memory effect) <strong>in</strong> the die as well as the rheological properties (both v<strong>is</strong>cous and<br />

v<strong>is</strong>coelastic) of the melt. Thus, prediction of it <strong>is</strong> very difficult. The die swell, however, <strong>is</strong><br />

restricted to a very short region near the die exit and an analytic progress can be made by<br />

simply neglect<strong>in</strong>g the die swell region and focus<strong>in</strong>g on the draw-down region.<br />

The simplify<strong>in</strong>g assumptions for the current analys<strong>is</strong> are<br />

a) Isothermal and ax<strong>is</strong>ymmetric flow<br />

b) Length of the draw-down region (L) <strong>is</strong> much longer than the radius of the exit hole of<br />

the die<br />

c) V<strong>is</strong>cous force <strong>is</strong> dom<strong>in</strong>ant and the v<strong>is</strong>coelastic force, <strong>in</strong>ertia, gravity and surface<br />

tension are negligible.<br />

d) Newtonian fluid<br />

Although polymer melts are non-Newtonian and the v<strong>is</strong>coelasticity effects are often<br />

important, the current flow of <strong>in</strong>terest <strong>is</strong> weakly extensional and slow. Furthermore, the<br />

shear stra<strong>in</strong> <strong>is</strong> also very weak throughout the entire draw-down region for th<strong>is</strong> free<br />

surface problem. Thus, the Newtonian assumption <strong>is</strong> not too restrictive. Consider<strong>in</strong>g that<br />

the v<strong>is</strong>cosity of polymer melts are quite high, assumption (c) <strong>is</strong> also not very restrictive.<br />

As the draw-down region <strong>is</strong> typically exposed to the air, the temperature may decrease as<br />

it flows down due to the cool<strong>in</strong>g by air. However, the temperature variation may not be<br />

very large unless air <strong>is</strong> blown aga<strong>in</strong>st the polymer melt for forced convective cool<strong>in</strong>g.<br />

We consider the cyl<strong>in</strong>drical coord<strong>in</strong>ates while determ<strong>in</strong><strong>in</strong>g the variables <strong>in</strong> the <strong>extruder</strong><br />

process. Figure 6. <strong>is</strong> the figure of a standard cyl<strong>in</strong>drical system.

Figure 6. Standard cyl<strong>in</strong>drical coord<strong>in</strong>ate<br />

Govern<strong>in</strong>g Equations<br />

Under the assumptions ((a)~(d)), the govern<strong>in</strong>g equations, cont<strong>in</strong>uity equation and the r-<br />

and z-directional momentum equation, for the flow <strong>in</strong> the draw-down region are as<br />

follows:<br />

1 <br />

r r ru<br />

p<br />

r<br />

p<br />

z<br />

<br />

<br />

( ) + w<br />

<br />

z = 0 (1)<br />

1<br />

<br />

<br />

2<br />

u <br />

ru<br />

<br />

<br />

(2)<br />

r<br />

<br />

r r<br />

1<br />

<br />

r<br />

<br />

<br />

2<br />

z <br />

2<br />

w w <br />

r <br />

r r 2<br />

z <br />

(3)<br />

As <strong>in</strong>dicated <strong>in</strong> Figure 5, u and w are the r- and z-directional component of the velocity<br />

vector u. R o (z) and R i (z) are the position of the outer and the <strong>in</strong>ner surface of the tube<br />

that should be also determ<strong>in</strong>ed as the solution along with u, w and p for th<strong>is</strong> free surface<br />

problem.<br />

The boundary conditions at the two free surfaces are follows,<br />

At r = R o (z),<br />

u<br />

<br />

<br />

<br />

<br />

R o<br />

z<br />

<br />

<br />

<br />

w<br />

<br />

0<br />

(4)

R o<br />

2 <br />

z<br />

p<br />

<br />

1 <br />

<br />

u<br />

<br />

<br />

<br />

r<br />

<br />

<br />

<br />

2<br />

R o<br />

z<br />

w<br />

z<br />

<br />

<br />

<br />

<br />

<br />

<br />

1 <br />

<br />

<br />

<br />

u<br />

<br />

2<br />

r<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

2<br />

R<br />

<br />

o <br />

u<br />

<br />

z <br />

<br />

z<br />

<br />

R o <br />

u<br />

<br />

<br />

z <br />

z<br />

w<br />

r<br />

<br />

<br />

<br />

w<br />

<br />

r<br />

<br />

<br />

<br />

<br />

<br />

<br />

R o<br />

z<br />

0<br />

2<br />

<br />

<br />

<br />

<br />

w <br />

<br />

z <br />

<br />

(5)<br />

(6)<br />

At r = R i (z),<br />

u <br />

<br />

<br />

<br />

R i<br />

2 <br />

z<br />

p p i<br />

R i<br />

z<br />

<br />

<br />

<br />

w<br />

<br />

<br />

u<br />

<br />

<br />

<br />

r<br />

<br />

1 <br />

<br />

<br />

<br />

0<br />

w<br />

z<br />

2<br />

R i<br />

z<br />

<br />

<br />

<br />

<br />

<br />

<br />

1 <br />

<br />

<br />

<br />

<br />

<br />

<br />

u<br />

<br />

2<br />

r<br />

<br />

<br />

<br />

2<br />

R<br />

<br />

i <br />

u<br />

<br />

z <br />

<br />

z<br />

<br />

<br />

<br />

<br />

R i <br />

u<br />

<br />

<br />

z <br />

z<br />

w<br />

r<br />

w<br />

r<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

0<br />

R i<br />

z<br />

2<br />

<br />

<br />

<br />

<br />

w <br />

<br />

z <br />

<br />

(7)<br />

(8)<br />

(9)<br />

Here (4) and (7) are the k<strong>in</strong>ematic conditions, (5) and (8) the tangential stress balances,<br />

and (6) and (9) are the normal stress balances at the outer and the <strong>in</strong>ner surfaces of the<br />

tube. In (9), p i <strong>is</strong> the pressure <strong>in</strong>side the tube (i.e., <strong>in</strong>ternal pressure) that can be<br />

controlled. That <strong>is</strong>, the <strong>in</strong>ner (hence the outer) radius can be controlled by vary<strong>in</strong>g the<br />

<strong>in</strong>ternal pressure when other conditions are fixed.<br />

At z = 0,<br />

R i<br />

ri<br />

, R o ro<br />

, w w o<br />

(10)<br />

At z = L,<br />

w w L<br />

(11)<br />

Here w o <strong>is</strong> the average velocity <strong>in</strong> the axial direction that <strong>is</strong> determ<strong>in</strong>ed once the output<br />

flow rate and the die geometry (i.e., r i and r o ) are specified. the axial velocity at z = L<br />

(i.e., position the fiber <strong>is</strong> quenched or solidified <strong>in</strong>stantaneously). w L <strong>is</strong> also known as the<br />

take-up velocity (v t ) that <strong>is</strong> controlled by the take-up device.

With boundary conditions occur at r = R o (z), r = R i (z), z = 0 and z = L, the <strong>in</strong>ner and<br />

outer surface profile can be determ<strong>in</strong>ed as follows.<br />

R ( z )<br />

i<br />

<br />

<br />

<br />

<br />

exp<br />

<br />

2<br />

i<br />

r<br />

<br />

<br />

<br />

(1 r<br />

2<br />

i<br />

) / w ( z )<br />

p<br />

i<br />

(1 w ( z )) <br />

<br />

<br />

w ( z ) <br />

2<br />

i<br />

r<br />

<br />

<br />

<br />

<br />

<br />

<br />

1 / 2<br />

(12)<br />

R<br />

o<br />

( z )<br />

<br />

<br />

R<br />

<br />

2<br />

i<br />

( z ) <br />

(1 r<br />

2<br />

i<br />

w ( z )<br />

) <br />

<br />

<br />

1 / 2<br />

(13)<br />

w<br />

( z ) exp <br />

z <br />

(14)<br />

<br />

w L<br />

ln <br />

w o<br />

<br />

<br />

<br />

(15)<br />

where r i and r o are known as the die geometry factors (i.e., <strong>in</strong>ner and outer diameters of<br />

exit of the die), w o <strong>is</strong> output rate at die exit and w L <strong>is</strong> the take-off velocity.<br />

Sample Calculations<br />

Figure 7 through 9 provide the theoretical predictions given by the equations (12) through<br />

(15) for the follow<strong>in</strong>g conditions:<br />

the outer radius of the die, r o : 2.788 mm (7/32” diameter)<br />

the <strong>in</strong>ner radius of the die, r i : 1.588 mm (1/8” diameter)<br />

draw span, L :<br />

v<strong>is</strong>cosity, :<br />

50 cm<br />

1000 Pa-s<br />

density, : 0.92 g/cm 3<br />

mass flow rate, m :<br />

take-up speed, w(L) :<br />

<strong>in</strong>ternal pressure, p i :<br />

50 g/m<strong>in</strong><br />

40 cm/s<br />

0 ~60 Pa

8.0<br />

7.0<br />

6.0<br />

5.0<br />

4.0<br />

3.0<br />

2.0<br />

1.0<br />

0.0<br />

W(z)<br />

0.0 0.2 0.4 0.6 0.8 1.0<br />

Figure 7. Dimensionless axial velocity<br />

1.0<br />

pi = 0 Pa<br />

1.0<br />

pi = 20 Pa<br />

0.8<br />

0.8<br />

0.6<br />

0.6<br />

0.4<br />

0.4<br />

0.2<br />

0.0<br />

Ro(z)<br />

Ri(z)<br />

0.0 0.2 0.4 0.6 0.8 1.0<br />

z<br />

(a)<br />

0.2<br />

0.0<br />

Ro(z)<br />

Ri(z)<br />

0.0 0.2 0.4 0.6 0.8 1.0<br />

z<br />

(b)<br />

1.0<br />

pi = 40 Pa<br />

1.0<br />

pi = 60 Pa<br />

0.8<br />

0.8<br />

0.6<br />

0.6<br />

0.4<br />

0.4<br />

0.2<br />

0.0<br />

Ro(z)<br />

Ri(z)<br />

0.0 0.2 0.4 0.6 0.8 1.0<br />

z<br />

(c)<br />

0.2<br />

0.0<br />

Ro(z)<br />

Ri(z)<br />

0.0 0.2 0.4 0.6 0.8 1.0<br />

z<br />

(d)<br />

Figure 8. Variation of <strong>in</strong>ner and outer radius of the tube at various <strong>in</strong>ternal pressure

0.7<br />

Ri(z)/Ro(z)<br />

(<strong>in</strong>creas<strong>in</strong>g pi)<br />

pi = 60 Pa<br />

0.6<br />

pi = 0 Pa<br />

0.5<br />

0.0 0.2 0.4 0.6 0.8 1.0<br />

Figure 9. Variation of <strong>in</strong>ner to outer radius ratio for various <strong>in</strong>ternal pressure<br />

Operat<strong>in</strong>g Procedures<br />

General Operations<br />

Start Up<br />

Die<br />

Off On<br />

Zone 3 Zone 2 Zone 1<br />

On Off Auto<br />

On Off Auto<br />

On Off Auto<br />

S D S 3 S 2 S 1<br />

Thermal meter<br />

for each zone<br />

T D T 3 T 2 T 1<br />

Ammeter for<br />

each zone<br />

Screw rotat<strong>in</strong>g speed<br />

15 rpm<br />

Stop<br />

Start<br />

Present temp. of die<br />

325 ℉<br />

Motor<br />

Motor speed<br />

controller<br />

Figure 10. The control panel of the extrusion system.

1. Switch the ma<strong>in</strong> power from “OFF” to “ON”.<br />

2. Turn the heat<strong>in</strong>g switches of Zone 1 (S 1 ), Zone 2 (S 2 ) and Zone 3 (S 3 ) to “Auto.” Turn<br />

the heat<strong>in</strong>g switch of Die (S D ) to “On.”<br />

3. Adjust the temperature of each zone to the desired temperature. (Goal temperature<br />

depends on the material we are us<strong>in</strong>g. For DYNH-1, the goal temperature T 1 =250°F<br />

T 2 =280°F, T 3 =280°F and T D =280°F)<br />

WARNING: EVERY PART OF THE EQUIPMENT IS EXTREMLY HOT. DON’T<br />

TOUCH IT.<br />

4. Wait until green light <strong>is</strong> d<strong>is</strong>played on every thermal meter, and check that the “present<br />

temperature of die” <strong>is</strong> the same as the goal temperature.<br />

5. Wait for another 15 m<strong>in</strong>utes to make sure the temperature of die <strong>in</strong>deed reaches the<br />

goal temperature.<br />

WARNING: EXTREMELY HOT POLYMER MAY SHOOT OUT AND<br />

SERIOUSLY HURT PEOPLE IF YOU FORGET TO WAIT ANOTHER 15<br />

MINUTES BEFORE STARTING.<br />

6. The equipment <strong>is</strong> ready to start.<br />

7. Place a water bath under die to cool down the output material.<br />

8. Make sure there are enough DYNH-1 beads <strong>in</strong> hopper.<br />

9. Press green “Start” button on the control panel.<br />

WARNING: NEVER STAND IN FRONT OF DIE SECTION AFTER START.<br />

10. Slowly adjust the motor speed to make the screw rotate at a certa<strong>in</strong> speed. (Stand<br />

beh<strong>in</strong>d the motor, you can see the screw rotation direction <strong>is</strong> counter-clockw<strong>is</strong>e.)<br />

11. Open the air valve.<br />

12. Introduce air <strong>in</strong>to the die to provide a certa<strong>in</strong> <strong>in</strong>ternal pressure (p i ).<br />

13. Open the feed gate of hopper to <strong>in</strong>troduce DYNH-1 beads <strong>in</strong>to barrel.<br />

Shut Down<br />

1. Close the feed gate of hopper.<br />

2. Let the screw run until barrel <strong>is</strong> empty, which means there <strong>is</strong> no more material go<strong>in</strong>g<br />

out.

3. Slowly adjust the motor speed to zero.<br />

4. Press red “Stop” button on the control panel.<br />

5. Turn off the switches of Zone 1 (S 1 ), Zone 2 (S 2 ) and Zone 3 (S 3 ) and Die (S D ) to<br />

“Off.”<br />

6. Switch the ma<strong>in</strong> power to “OFF.”<br />

7. Place the warn<strong>in</strong>g board near die section.<br />

WARNING: EVERY PART OF THE EQUIPMENT IS STILL EXTREMLY HOT.<br />

DON’T TOUCH IT.<br />

Experimental Procedures<br />

In th<strong>is</strong> experiment, different dimensions of tube will be obta<strong>in</strong>ed by chang<strong>in</strong>g three<br />

variables: screw rotation speed (ω), take-off speed (v t ) and <strong>in</strong>ternal pressure (p i ).<br />

D o (R o ) and m can be measured. Based on the conservation of mass shown as follows, D i<br />

(R i ) can be calculated.<br />

2<br />

D<br />

D v m<br />

2<br />

4<br />

o<br />

i<br />

t<br />

(16)<br />

where D o <strong>is</strong> the outer diameter of tube, which can be measured; ρ <strong>is</strong> the density of the<br />

material used <strong>in</strong> th<strong>is</strong> experiment, which <strong>is</strong> DYNH-1, and m <strong>is</strong> the mass feed<strong>in</strong>g rate,<br />

which <strong>is</strong> related to the screw rotation speed.<br />

NOTE: You can time and collect tube. Then, Weigh the rod and get the mass feed<strong>in</strong>g<br />

rate. Furthermore, divide the mass feed<strong>in</strong>g rate by density of DYNH-1, and volumetric<br />

feed<strong>in</strong>g rate can be obta<strong>in</strong>ed.<br />

Then, the thickness of the tube can be easily obta<strong>in</strong>ed.<br />

θ = R o − R i (17)

These are the experimental dimensions of tube. By compar<strong>in</strong>g experimental data with<br />

theoretical prediction, you can f<strong>in</strong>d out how the model works.<br />

Investigation of the Thickness of Tube with Different Screw Rotat<strong>in</strong>g Speeds<br />

1. Develop a table as follows:<br />

Table 1. Table for the dimensions of the tube with different screw rotat<strong>in</strong>g speeds,<br />

different take-off speeds and different pressure differences.<br />

ω<br />

(rpm)<br />

v t<br />

(m/s)<br />

p i<br />

(psi)<br />

Run 1 ω ○1 v t ○1 p i ○1<br />

Run 2 ω ○2 v t ○1 p i ○1<br />

Run 3 ω ○3 v t ○1 p i ○1<br />

Run 4 ω ○4 v t ○1 p i ○1<br />

Run 5 ω ○5 v t ○1 p i ○1<br />

Run 1 ω ○3 v t ○1 p i ○1<br />

Run 2 ω ○3 v t ○2 p i ○1<br />

Run 3 ω ○3 v t ○3 p i ○1<br />

Run 4 ω ○3 v t ○4 p i ○1<br />

Run 5 ω ○3 v t ○5 p i ○1<br />

Run 1 ω ○3 v t ○3 p i ○1<br />

Run 2 ω ○3 v t ○3 p i ○2<br />

Run 3 ω ○3 v t ○3 p i ○3<br />

Run 4 ω ○3 v t ○3 p i ○4<br />

Run 5 ω ○3 v t ○3 p i ○5<br />

m V<br />

(kg/m<strong>in</strong>) (m 3 /m<strong>in</strong>)<br />

SECTION 1<br />

SECTION 2<br />

SECTION 3<br />

w o<br />

(m/s)<br />

R o<br />

(mm)<br />

R i<br />

(mm)<br />

2. Fix the take-off speed, and slowly adjust motor speed to make the screw rotate at a<br />

certa<strong>in</strong> speed (rpm).<br />

3. Record the pressure gauge of the die section.<br />

4. Start to time and collect the tube.<br />

5. Weigh the tube and get the mass feed<strong>in</strong>g rate. Then, divide the mass feed<strong>in</strong>g rate by<br />

density of DYNH-1, and volumetric feed<strong>in</strong>g rate can be obta<strong>in</strong>ed.<br />

6. Calculate the output speed by divid<strong>in</strong>g the volumetric feed<strong>in</strong>g rate with cross area at<br />

the exit of die.<br />

θ<br />

(mm)

7. Measure the outer diameter (D o ) of the obta<strong>in</strong>ed tube to obta<strong>in</strong> outer radius (R o ).<br />

8. Calculate the <strong>in</strong>ner diameter (Di) from Eq. (16) to obta<strong>in</strong> <strong>in</strong>ner radius (R i ).<br />

9. Calculate the thickness (θ) from Eq. (17)<br />

10. Repeat several different screw rotat<strong>in</strong>g speeds to f<strong>in</strong><strong>is</strong>h section 1 <strong>in</strong> Table 1. (Choose<br />

at least 5 different screw rotat<strong>in</strong>g speeds.)<br />

11. Plot tube outer and <strong>in</strong>ner radius versus screw rotat<strong>in</strong>g speed and versus theoretical<br />

prediction.<br />

(Note: the diagrams may or may not be l<strong>in</strong>ear.)<br />

Investigation of the Thickness of Tube with Different Take-Off Speeds<br />

1. Fix the screw rotat<strong>in</strong>g speed and <strong>in</strong>ternal pressure (p i ), and adjust the take-off speed<br />

(v t ) to a certa<strong>in</strong> value.<br />

2. Record the pressure gauge of the die section.<br />

3. Refer to the previous section to get the volumetric feed<strong>in</strong>g rate at a specific screw<br />

rotat<strong>in</strong>g speed (rpm).<br />

4. Measure the outer diameter (D o ) of the obta<strong>in</strong>ed tube to obta<strong>in</strong> outer radius (R o ).<br />

5. Calculate the <strong>in</strong>ner diameter (Di) to obta<strong>in</strong> <strong>in</strong>ner radius (R i ) and thickness (θ) from<br />

Eq. (16) and Eq. (17), respectively.<br />

6. Repeat with several different take-off speeds to f<strong>in</strong><strong>is</strong>h section 2 <strong>in</strong> Table 1. (Choose at<br />

least 5 different take-off speeds.)<br />

7. Plot tube outer and <strong>in</strong>ner radius versus take-off speed and versus theoretical<br />

prediction.<br />

(Note: the diagrams may or may not be l<strong>in</strong>ear.)<br />

Investigation of the Thickness of Tube with Different Pressure Differences<br />

1. Fix the screw rotat<strong>in</strong>g speed and take-off speed, and adjust the <strong>in</strong>ternal pressure (p i ) to<br />

a certa<strong>in</strong> value.<br />

2. Record the pressure gauge of the die section.<br />

3. Refer to the previous section to get the volumetric feed<strong>in</strong>g rate at a specific screw<br />

rotat<strong>in</strong>g speed (rpm).<br />

4. Measure the outer diameter (D o ) of the obta<strong>in</strong>ed tube to obta<strong>in</strong> outer radius (R o ).

5. Calculate the <strong>in</strong>ner diameter (Di) to obta<strong>in</strong> <strong>in</strong>ner radius (R i ) and thickness (θ) from<br />

Eq. (16) and Eq. (17), respectively.<br />

6. Repeat with several different <strong>in</strong>ternal pressures to f<strong>in</strong><strong>is</strong>h section 3 <strong>in</strong> Table 1. (Choose<br />

at least 5 different <strong>in</strong>ternal pressures.)<br />

7. Plot tube outer and <strong>in</strong>ner radius versus <strong>in</strong>ternal pressure and versus theoretical<br />

prediction.<br />

(Note: the diagrams may or may not be l<strong>in</strong>ear.)<br />

Notations<br />

u Velocity factor (m/s)<br />

u r-directional component of the velocity vector u (m/s)<br />

w z-directional component of the velocity vector u (m/s)<br />

μ V<strong>is</strong>cosity of fluid (Pas)<br />

w o Output speed at die exit (m/s)<br />

w L Take-off speed (m/s)<br />

r o Outer radius at die exit (mm)<br />

r i Inner radius at die exit (mm)<br />

R o Outer radius of tube (mm)<br />

R i Inner radius of tube (mm)<br />

p i Internal pressure (pa)<br />

ω Screw rotat<strong>in</strong>g speed (rpm)<br />

v t Take-off speed (m/s)<br />

m Mass feed<strong>in</strong>g rate of DYNH-1 (kg/m<strong>in</strong>)<br />

V Volumetric feed<strong>in</strong>g rate of DYNH-1 (m 3 /m<strong>in</strong>)<br />

ρ Density of DYNH-1 (kg/m 3 )<br />

D o Outer diameter of tube (mm)<br />

D i Inner diameter of tube (mm)<br />

θ Thickness of tube (mm)<br />

Reference<br />

Dr. Chang-Won Park, <strong>Extrusion</strong> of Hollow Tubes<br />

Mark, H. F. (ed.), Encyclopedia of Polymer Science and Technology, Edition 3 rd ., John<br />

Wiley & Sons (2004) (Vol. 2)<br />

Stanley Middleman, Fundamentals of Polymer Process<strong>in</strong>g, McGraw Hill (1977)