MadISon GaS & ElEctrIc - Stuart B. Millner & Associates

MadISon GaS & ElEctrIc - Stuart B. Millner & Associates MadISon GaS & ElEctrIc - Stuart B. Millner & Associates

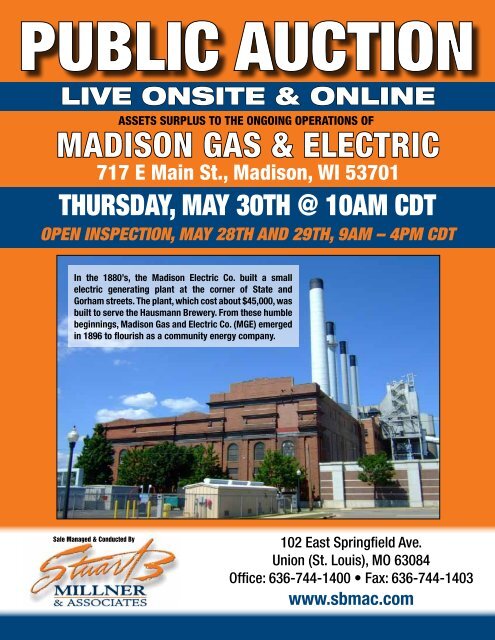

LIVE ONSITE & ONLINE assets surplus to the ongoing operations of Madison Gas & Electric 717 E Main St., Madison, WI 53701 Thursday, May 30th @ 10AM CDT OPEN INSPECTION, May 28th and 29th, 9AM – 4PM CDT In the 1880’s, the Madison Electric Co. built a small electric generating plant at the corner of State and Gorham streets. The plant, which cost about $45,000, was built to serve the Hausmann Brewery. From these humble beginnings, Madison Gas and Electric Co. (MGE) emerged in 1896 to flourish as a community energy company. Sale Managed & Conducted By

- Page 2 and 3: Steam Turbines and Generators: Alli

- Page 4 and 5: Condensers Condenser, Turbine: surf

- Page 6 and 7: Coal Handling Equipment Pennsylvani

- Page 8 and 9: Pumps & Motors NEW NEW NEW NEW-Alle

- Page 10 and 11: Heat Exchangers, Feedwater Heaters

- Page 12: Stuart B. Millner & Associates (SBM

LIVE ONSITE & ONLINE<br />

assets surplus to the ongoing operations of<br />

Madison Gas & Electric<br />

717 E Main St., Madison, WI 53701<br />

Thursday, May 30th @ 10AM CDT<br />

OPEN INSPECTION, May 28th and 29th, 9AM – 4PM CDT<br />

In the 1880’s, the Madison Electric Co. built a small<br />

electric generating plant at the corner of State and<br />

Gorham streets. The plant, which cost about $45,000, was<br />

built to serve the Hausmann Brewery. From these humble<br />

beginnings, Madison Gas and Electric Co. (MGE) emerged<br />

in 1896 to flourish as a community energy company.<br />

Sale Managed & Conducted By

Steam Turbines and Generators: Allis Chalmers & Westinghouse<br />

Steam Turbine Generator: Allis Chalmers: AIEE-ASME Preferred Standard Steam Turbine; AC Generator, 3 Turbine, 30000 KW, 13800 Volts, 85% PF, 3<br />

phase, 60 cycle, 3600 R.P.M., Hydrogen Cooled, Pressure 0.5-15, KVA 35294-40588, Stator Amp’s 1477-1699, Excitation Amp’s 350-385, Excitation<br />

Volts 250-250, Serial # 154640; Approx. total weight of both turbine and generator has a unit is about 532,000#, Generator Stator is about 155,000#,<br />

Generator Rotor is about 36,000#, Turbine Spindle is about 30,000#, Turbine Upper Half of Cylinder & Exhaust End about 60,000#; Gear Reducer,<br />

Turning Gear, 3 Turbine: Spiral Bevel-Herringbone Gear reducer, Size 9VRA, Ratio, 17.83:1, HP 20, R.P.M. 85.7, Turbine 16.9 R.P.M.; Turbine, Steam, 3<br />

Generator, Rated KW 30000, Capability KW 33000, Speed R.P.M. 3600, Initial Pressure 850 PSIG, Initial Temp<br />

Steam Turbine Generator: Allis-Chalmers, Turbine, Steam, 4 Generator, (Straight Reaction double Flow tandem Compound type Turbine-Connected<br />

to a two pole, sixty cycle three phase generator, with a gear driven combined main & pilot exciter) w/Generator, Air Cooled, KVA 25000, 80 % PF, KW<br />

20,000, Volts 13600, Amp’s 1063 MAX, 3 PH, 60 cycles, Temp Rise-Stator 60 C, Rotor 85 C, Excitation 250 volts, Amp’s, 306, R.P.M. 3600, Serial #<br />

132230; Gear Reducer, Turning Gear, sets on top of a No.4 and No5. bearing case cover, with lower 7 upper turning gear case, drive motor & sheave<br />

guard; Motor, Turning Gear, Type ARH, Frame 326, HP 20, 3 PH, R.P.M. 1530, Volts 220, Amp’s 53; Exciter,4 Generator Allis Chalmers, Pilot Exciter Serial<br />

#132582, Volts NO Load 125, Volts Full Load 125, Amp’s 28, R.P.M. 1500; Main Exciter serial # 132581, Volts Full Load 250, Amp’s 400, R.P.M. 1500<br />

2<br />

Visit www.sbmac.com for additional photos and upcoming events

Steam Turbines and Generators: Allis Chalmers & Westinghouse<br />

Steam Turbine Generator: Westinghouse-Turbine, Steam, 5 Generator, Serial # 5-A4421-1, Rated KW 20,000, MAX KW 25000, R.P.M. 3600, Initial<br />

Pressure 825 PSIG, Initial Temp. 825 C, EXH Pressure 20” VAC; Westinghouse-Hydrogen cooled, Generator-KW 20000-23000, KVA 25000-28750,<br />

Amp’s 1048-1205, %PF 80-80, Volts 13800, PH 3, cycle 60, R.P.M. 3600, Serial # 1531P875; Motor, Turning Gear; Exciter<br />

Steam Turbine - Non-Condensing Turbine Generator Unit, over all dimensions- length 37’6”, width 12’ height 8’ - total weight 100 tons<br />

SBMA OFFERS COMPLETE “TURNKEY” SOLUTIONS<br />

3

Condensers<br />

Condenser, Turbine: surface condenser-single-pass-divided water box,<br />

overall length-26’6”, active tube length-10’0 1/2” - C/Ito top condensate<br />

well-8’8”, diameter of shell-9’11” - operating weight in tons-74, part 3<br />

for tubes-3,600pcs@10’0 1/2”, F00875003501103 .875x.035 01, spec<br />

11, Spec ASME SA24995 ED, full finish, annealand nickle<br />

Condenser, Turbine: contains 5100 inhibited admiralty, no. 18 B.W.G.,<br />

3/4”outside diameter, with 20ft. 0in. Effective length to give 20,000<br />

square ft. of cooling surface.<br />

Condenser Turbine, Contains 2680 Arsenical Copper tubes 3/4” diameter<br />

and 24ft. Effective cooling surface of 12,600 sq. ft.<br />

Condenser Turbine, Contains 12,500 Sq. ft. of effective condensing<br />

surface made up of 2658-3/4” O.D. #18 BWG Phosphorized admiralty<br />

tubes, 24’-0” Long<br />

4 CAN’T ATTEND THIS SALE BID ONLINE AT BIDSPOTTER.COM

Boilers<br />

Boiler bent tube type Containing 3,650 Sq. ft. of heating surface. Class<br />

three drum, the drum shells and heads are of open hearth steel, 70,000<br />

pounds per Sq. in. tensile strength, bottom drum, dia. 42”, Shell length<br />

13’-10, tube plates 2”, shell plates 2’ Upper front drum dia. 60”, Shell<br />

length 16”-6”, tube plates 3’, Shell plates 3”. Boiler tubes hot drawn<br />

seamless steel, first banks no. 54 Size 3-1/4”<br />

Boiler, Drums & Drum Heads are constructed of 70,000 pounds per<br />

square inch tensile plate by fusion welded process, the drum heads<br />

of the drums are dished type each with a 16 inch round manhole. All<br />

connecting tubes are expanded into grooved tube holes in the drums.<br />

Number of drums per boiler are three, Diameter of drum at 54”, the<br />

thickness of shell is 2-3/4”, thickness of heads is 2-25/32”, length<br />

overall is 19’-0; diameter of drum at 36”, Thickness of shell is 2-7/9”,<br />

Thickness of heads is 2-17/32”, length overall is 18’3”<br />

Boiler Approximate water holding capacity in pounds per unit is 39,000<br />

normal water lever, hydrostatic: 59,500 Capacity Lb. HR.-20,000, Design<br />

Press PSI 950 Steam Temp. - 880 F, Boiler H.S. Sq. Ft.-8511, Built in 1968<br />

Boiler Capacity-80,000 Design Press. OSI-300, Steam Temp. 525 F<br />

Boiler H.S. Sq. Ft.-5022 Built in 1967<br />

Boiler: Application-Gas Flow, Type-CC1352A, Model-A Serial #131041,<br />

Max. Capacity 400,000 CFH, (ORIFICE: Concentric, Material-304 Stainless<br />

steel, thickness 1/8”, Outside diameter - 11”, hole diameter-5.510” Ratio<br />

hole top pipe I.D.-.6904), (Flow Meter: Serial #410514, Type CE3531,<br />

Model E101F, Class 1PA<br />

SBMA – SELL. BUY. MANAGE. APPRAISE. CONDUCTING INDUSTRIAL AUCTIONS SINCE 1981.<br />

5

Coal Handling Equipment<br />

Pennsylvania Model TKKB 26X40<br />

Frozen Coal Granulator, Ser #6582<br />

Albert Products Inc. CARHOE 2<br />

railcar unloading system. New in<br />

2001.<br />

Car Shaker Unit<br />

Eriez Suspended Electromagnet<br />

Separator Model SC-1 SE7515, Style<br />

9920702, Serial Number 120014, 115 volts,<br />

Hertz DC, 68.4 Amps, with Control Model<br />

Number N12-10K41, 480 volts, 120 DC out,<br />

Style 9920703, Serial Number 120014<br />

Enclosed Belt Conveyor 30” x 58’ 10 5/8”. Bayshore Telescoping<br />

Chute with Controls. Enclosed Belt Conveyor 30” x 312’ 4 1/2”<br />

Enclosed Belt Conveyor 30” x 216’ 5 1/4”<br />

Buhler Drag Chain Conveyor 25” x 57’, 20HP<br />

Pennsylvania Posimetric coal feeder/scale, type<br />

& size 1032x1, S/N 6391, w/control cabinet & coal<br />

shoot approx. 24”x24”x117”<br />

Control Unit, Coal Feeder, Boiler: Type # 1032X2<br />

Pennsylvania<br />

Ash Crusher, Bottom Ash Unloader, (motor;<br />

Cat.#E190, model #E190, frame 8145T, Type<br />

UTP, ENCL-TE, class F, 3 PH, HP 2, R.P.M. 1725<br />

design C, code L, volts 208-230/460, amp’s<br />

6.50-6.20/3.10) - (gear box; series 2000, ratio,<br />

78.1 input 1745 rpm, output torque 5202 lbs.),<br />

crusher; ser #20303<br />

6<br />

A MULTI MILLION DOLLAR OFFERING OF WORLD CLASS EQUIPMENT!

Coal Handling Equipment<br />

SEVERAL<br />

AVAILABLE<br />

MULTIPLE<br />

AVAILABLE<br />

Raymond Bowl mill No. 533 coal<br />

pulverizer s/n 40044 , w/primary air<br />

fan , both driven by General Electric<br />

motor type KG 200 hp, 1175 rpm,<br />

63355 frame, 4000 volt, 3 phase, 60<br />

cycles, m/n 5KG6335AR1, s/n 5633488<br />

Babcock & Wilcox coal pulverizer<br />

type E ,size 56 class 111BA s/n 4323<br />

w/Westinghouse type CS motor, s/n<br />

2S4N8795, style 4-N-8795, frame<br />

876-C, 100 hp, 585 rpm, 4160 volt, 3<br />

phase, 60 cycles<br />

Mac model M dust collection bag<br />

house approx. 10’x23’,w/Mac rotary air<br />

lock & 9”screw conveyer approx. 19’<br />

Stock Equipment Co. Coal inlet<br />

slide gate , type 24-SR-VB-SP-<br />

S-E, approx. 24”x24”<br />

Pulverizer Type D Pulverizer,<br />

Series 100, Size 144, Type #22113<br />

Serial 3162<br />

CHOOSE FROM<br />

SEVERAL<br />

Buffalo Grate air fan type R, size<br />

60-5, shop order # 78L-6765 w/<br />

Westinghouse 60 hp motor, 1775<br />

rpm, 364TZ frame, 460 volt, 73 amp, 3<br />

phase, 60Hz, m/n TBFC, s/n 7901<br />

15+ AVAILABLE<br />

Diamond power specialty Co. Soot<br />

blower model IR-A38-C, w/motor<br />

m/n 38894-1A, 1200 rpm, frame 56-<br />

30001E, 220/440 volt, 1.2/1.6 amp, 3<br />

phase, 60 cycles (IR5)<br />

8D belt conveyer horizontal section<br />

approx. 29’, incline section approx.<br />

33’, 18” belt width<br />

Storage/feeder bunker approx. 14’x20’, w/2 tandem automatic traversing open<br />

screw auger conveyer system, w/2 motors type TR, 20 hp, 1750/2300 rpm, frame<br />

B2810ATZ, 500 volt, 33.6 amp, Identification # 1KA678993-XD, w/2 gear reducers<br />

Falk m/n 202-80FZB3B, w/upper walking/service platform between both Bunkers. Raymond Cole feeder s/n 40045<br />

TAKE YOUR<br />

PICK<br />

Mac Equipment Rotory Air Lock/<br />

feeder m/n 30X30 s/n 1407-78<br />

SBMA OFFERS COMPLETE “TURNKEY” SOLUTIONS<br />

7

Pumps & Motors<br />

NEW<br />

NEW<br />

NEW<br />

NEW-Allen Bradley 40 hp inverter duty<br />

motor, 1775 rpm, frame 324T, 230/460 volt,<br />

95.4/47.7 amp, 3 phase, 60 Hz, Cat# 1329RC-<br />

HA25H18XGH-382, s/n 6270861<br />

NEW-Allen Bradley 60 hp inverter duty<br />

motor, 1780 rpm, frame X364T, 230/460 volt,<br />

136/68 amp, 3 phase, 60 Hz, Cat# 1329RC-<br />

HA40H18XGH-1935, s/n 6530556<br />

NEW-Allen Bradley 75 hp inverter duty<br />

motor, 1780 rpm, frame X365T, 230/460 volt,<br />

174/87 amp, 3 phase, 60 Hz, Cat# 1329RC-<br />

HA50H18XGH-1378, Id # 6530557<br />

Motor ID Fan HP 500, 3 PH Frame 6809S, Type-<br />

HS, Volts 4160, Amp’s 64, R.P.M. 710, Design - B<br />

Cide F, SF 1.15, INSL Class-B, oil Capacity 4qts<br />

(1) General Electric-Motor, 4 FWP: Frame 6339Y, Type K,<br />

Volts 4000, Amp’s 77, 3PH, R.P.M. 3550, HP 600, (#4): Serial<br />

# 269778130010M70, Type COGX, Frame 589SV, HP 700,<br />

R.P.M. 3680, Volts 4160, PH 3, Amp’s 87; (1) Ingersoll Rand-<br />

PUMP,6 STAGE FEEDWATER PUMP 825 No. 2: Size 3HMTA-9,<br />

GPM 420, R.P.M. 3560, Serial # 09513160, Heat Ft. 3375<br />

Motor, FD Fan HP 300 PH 3, Frame 1589, Type<br />

H, Design B, Code F, Volts 4160, Amp’s 32.4<br />

R.P.M. 1200 Serial #1351281<br />

General Electric-induction motor, HP-600,<br />

RPM’s-3580, Volts-4000, Amp’s-77, Type-K,<br />

Frame-6339Y<br />

(1) General Electric-Motor, 3 FWP: Frame 6339Y, Type K,<br />

Volts 4000, Amp’s 77, 3PH, R.P.M. 3550, HP 600, (#4): Serial<br />

# 269778130010M70, Type COGX, Frame 589SV, HP 700,<br />

R.P.M. 3680, Volts 4160, PH 3, Amp’s 87; (1) Ingersoll Rand-<br />

PUMP,6 STAGE FEEDWATER PUMP 825 No. 2: Size 3HMTA-9,<br />

GPM 420, R.P.M. 3560, Serial # 09513160, Heat Ft. 3375<br />

Pump, ID Fan Hyd Cplng Oil Pump, Boiler: Figure<br />

#1F35, Type 27, SPWC #5, Serial #412511<br />

Motor condensate pump: Cat # Mo4004TE,<br />

Frame 324T, Code G, 3 Ph, R.P.M. 1770 HP 40-<br />

4P, Volts 230/460 Amp’s 93.6/46.8, Serial @<br />

FD7350212000<br />

Westinghouse-Motor, Gland Steam Vacuum<br />

Pump, 5 Turbine: Frame 213, Cycle 55, Type<br />

ABFC, 3 PH, R.P.M. 1730, Volts 220/440, Amp’s<br />

8.2/4.1, Serila # 1778230, Series # 5508<br />

(2) General Electric-Pump, 4A & 4B Cooling<br />

Water, 4 Turbine: induction, Model 5K1-324-A2,<br />

Frame 324, Type KF, Volts 220/440, 3 PH, Amp’s<br />

21.1/10.6, HP 7 1/2, R.P.M. 7760<br />

8<br />

CAN’T ATTEND THIS SALE BID ONLINE AT BIDSPOTTER.COM

Motor Controls & Various Electrical<br />

Square D Motor control center, approx.<br />

40”x92”, 2 section, 9 buckets<br />

Square D Motor control center, double side,<br />

approx. 60”x92”, 3 section,14 & 17 buckets<br />

Square D Motor control center, approx.<br />

60”x92”, 3 section, 9 buckets<br />

(4) General Electric QHT transformer dry type QL indoor/type QL-WP Weatherproof with WP kit, 3 phase, 60 Hz, class AA, KVA 27, HV 460, approx.<br />

weight 305 Lbs. m/n 9T23B4002 G22<br />

Magnetics Industrial Control Div.- PRECIPITATOR<br />

TRANSFORMER STEP LOW: Dry Type, KVA-150, PH 2-3,<br />

(Primary Volts 480-30-3W, Amp’s 180)( Secondary Volts<br />

480-20-4W, Amp’s 156) type PCB, Class AA, Weight 1500<br />

Lbs., Spec.# 1-11056, Serial # 9023<br />

MULTIPLE BANKS<br />

AVAILABLE<br />

Sta Rite Tansformer - 7 OUT PRECIPITATOR<br />

TRANSFORMER STEP LOW: 3 PH, KVA 224, Type<br />

DCP, Rise 150 C, Approx. WT. LBS.-1675, Serial<br />

# 226611F75, H.V.-4160, I.V.-480 Switchgear Panel, Electric Fuse-Auxiliary<br />

Allen-Bradly-Tack hopper feeder frequency<br />

drive, 1336 Plus, vector, 480 volts, 3 PH<br />

Babbit LS 7000 level switch w/cabinet & electronics, Delavan<br />

microwave 320 position & level control detection system, microwave<br />

320 circuit card s/n T13702 for void detection,3- Modicon PLCs 2/1 ports<br />

m/n PC-E984-265, Allen Bradley current monitor Cat# 809S-E2D60,<br />

NCC 6 position timer control board # 0044 DNC-T2006-A10, FACTS 4<br />

channel analog module m/n F4-04AD, 2- AC TECH speed adjustable<br />

ac motor controllers m/n M1410C input voltage 400/480 3 phase 1<br />

HP 2.8/2.4 amp, 8- Allen Bradley limit switches m/n Bulletin 801-NX7,<br />

Babbit level switch LS7000, 2- Telatemp flame scanner lDD-llU m/n<br />

110-12-17, 24 volt power supply, UV-eye flame detector/scanner type<br />

45UV5 mod.# 1000, Maxfire 30 tip assembly 70 Deg. angle]<br />

LOADS<br />

OF<br />

WIRE<br />

Reel of wire<br />

Visit sbmac.com for a calendar of upcoming auctions<br />

9

Heat Exchangers, Feedwater Heaters & Super Heaters<br />

(2) Superchanger heat<br />

exchangers m/n UX-216-HP-82<br />

s/n P-34206-H, max psi 100, max<br />

temp 225F, surface area 322.9 sq.<br />

ft., year 1985<br />

Griscom Russell Co.; Feedwater<br />

Heater, No 1 (3A) No.2 (3B): Type<br />

GSU, Size 23-6-179, serial #<br />

52909A, Shell 30” to 25, VAC tubes<br />

75, HSB-WP-Tubes 75 lbs<br />

Miscellaneous Equipment<br />

Westinghouse-Motor Drive, Air Heater, 7 Boiler: Type CSP, Frame 264,<br />

Class 1, Style 4N4393, 3 PH, HP 5, volts 220/440, Amp’s 15.2/17.6,<br />

R.P.M. 1160; Falk-Gear Reducer, Motor Drive, Air Heater, 7 Boiler: Model<br />

# 5561RZ, R.P.M. 6.1, Ratio 196<br />

SEVERAL<br />

AVAILABLE<br />

Foxboro model E44BP electronic<br />

transmitter, range 0-15 psi, calib.<br />

4-20 MA, element- spiral, m/n<br />

E44BP-FFNI, ref./n 3938093.<br />

ASSORTED BEARINGS- 4-7/16” Sleeve<br />

bearing housing for Westinghouse,<br />

4 - 4-7/16” Sleeve bearing liner<br />

assembly,2- pillow block bearing<br />

liners, GURNEY/MRC: 417R,2- 417<br />

radial,CJB: 417,N.D.: 30321,AMERICAN<br />

ROLLER BEARING:2- AD5236SM,<br />

AD5236,AD5222SM,AD5224SM ,AD5<br />

226SM,AD5230SM,TP144W99,TP138<br />

W99,SKF: 9- RLS8-2RS1, 5309, 6309<br />

Micro Motion flow sensor m/n<br />

DS100S129SU, s/n 176054, assorted<br />

brass safety valves: Kunkle 2 x<br />

2” m/n 6010JHEO1-AM, 1-1/2”<br />

m/n 6010HGEO1-AM, 3/4” m/n<br />

6010EDEO1-LM, 1/2” m/n 20-C01,<br />

Watts 1” m/n M, Spence 1” fig. #<br />

041AFEA, 2x 1-1/2” fig. # 820NHGA-A,<br />

Consolidated 1” type 1543F, 2” type<br />

1543J-LP<br />

SEVERAL<br />

AVAILABLE<br />

Fisher valve type 667, size, 45, s/n<br />

10325570, body FF, size 4<br />

Rexnord gear reducer, type<br />

SKZH75C28A-R-T-324T, # T05-<br />

67726-01A, Mtg. position L1,<br />

T2(lbf.in) 70800, n2(rpm) 63<br />

Rexnord gear reducer, type<br />

SFN45B, Mtg position B3, T2(lbf.<br />

In) 9900,# 43377-01A, Falk gear<br />

reducer m/n 4107J14, ratio: 14.43,<br />

Diamond Power 1/6 hp motor,<br />

1725 rpm, frame 56CZ, 230/460<br />

volt, .8/.4 amp, 3 phase, 60 Hz<br />

Painted stainless steal heat<br />

shields for rail car thaw building<br />

heater<br />

Exciter Main Generator Field 3<br />

Generator Serial #156238, K.W.<br />

100, R.P.M. 3600, Field Amp’s 400,<br />

Colts full load 25<br />

10 Visit www.sbmac.com for additional photos and upcoming events

Vehicle Tire Wash Facility<br />

Wheel Wash LTD Vehicle Tire Wash Facility:(w/(1) main pump panel motor controller, motor-US Electricla-model #8091A, Design B, frame 256JM,<br />

Type UT4, ENCL-TE, SF-1.21, code G,Class F, 3PH, HP 20, volts208-230/460, amps 57.4-49.8/24.9) & (1) truck washer station PLC enclosure subpanel<br />

W/controls; vehicle sensor, entry door outer photo-eye, entry door open limit switch, entry door closed limit switch, entry door inner photo-eye, drip<br />

time photo-eye, exit door open & closed limit switches.<br />

Bag House<br />

30 Ton Bridge Crane<br />

Bridgecrane, Toledo 30 ton capacity, s/n 01037<br />

5 1/2 Ton Hoist<br />

Baghouse, PDF System (Outside):mode # BP169-12-W, Installed<br />

Weight-17,185 LBS., Opertaing weight-hopper 1/3 full=19,703 LBAS.,<br />

plenum-12 GA. Mild stl Hopper-12 GA. Mild Stl., Tube sheet-3/16” THK.<br />

Mild Stl., Stiffeners-VERT. 3’X3’X1/4” ANG. Mild Stl., Venturis carbon<br />

steel Accum. 5”X5” Mild Steel Pulse Valves= QTY. & size-13 @1 1/2”,<br />

Enclosure Solenoid-GOYEN, Pre. Gauge Differential- Photohelic-0/10”<br />

W.G., Enclosure timer- NEMA 4 dust tight w/photohelic & transmitter,<br />

equipment: 1/4” thick carbon<br />

5 1/2 Ton Shaw Box Car Shaker Hoist<br />

A MULTI MILLION DOLLAR OFFERING OF WORLD CLASS EQUIPMENT!<br />

11

<strong>Stuart</strong> B. <strong>Millner</strong> & <strong>Associates</strong> (SBMA) are<br />

quickly emerging as the industry leader<br />

with the implementation of its POWER<br />

PLANT DECOMMISSIONING (PPD) division.<br />

Since 1981, SBMA has completed over<br />

1500 industrial plant closures with<br />

its TOTAL PLANT DEACTIVATION (TPD)<br />

division. A refinement modeled after<br />

this program, the decommissioning of<br />

power plant requires an additional set of<br />

specialized protocols in order to achieve<br />

maximum return for both owners and<br />

shareholders. SBMA’s POWER PLANT<br />

DECOMMISSIONING (PPD) division<br />

has completed, or is the process of<br />

completing 21 projects nationwide.<br />

102 East Springfield Ave.<br />

Union (St. Louis), MO 63084<br />

www.sbmac.com<br />

WI Auctioneer 1079-052<br />

AUCTION TERMS AND CONDITIONS:<br />

1. PAYMENT TERMS:<br />

a. Balance of Bidder’s invoice may be paid by cash, cashier’s<br />

check, wire transfer, or company check. All checks must be<br />

accompanied by a letter from the payer’s bank guaranteeing<br />

unqualified payment to STUART B. MILLNER & ASSOCIATES<br />

(hereinafter “SBMA”). (A $25.00 fee shall be assessed to<br />

Buyer for all returned checks).<br />

b. Payment is due in full upon receipt of invoice. If payment is<br />

not received within 24 hours of the conclusion of the auction,<br />

Buyer’s invoice will be voided, and all items will be forfeited<br />

with NO REFUND of deposit or payment. All legal fees, collection<br />

fees and any other charges arising from nonpayment will<br />

be paid by the Buyer.<br />

c. All methods of payment shall be made payable to STUART B.<br />

MILLNER & ASSOCIATES.<br />

d. Wire-transfer instructions are available at the registration<br />

desk or by calling the SBMA office at 636-744-1400.<br />

e. No purchases may be removed until complete settlement is<br />

made with cleared funds. Buyer is responsible for the complete<br />

removal of Buyer’s purchase(s).<br />

f. Each buyer shall be responsible for payment of any city, county<br />

and/or state sales tax that may apply.<br />

g. Buyer is entirely responsible for any customs or duty issues<br />

and/or payments<br />

h. A 15% Buyer Premium applies to all sales. An 18% Buyers<br />

Premium applies to all online sales.<br />

2. CONDITIONS OF SALE:<br />

a. All items up for auction will be sold to the highest bidder in<br />

accordance with the Auctioneer’s Customary Terms of Sale.<br />

b. If an item shall become non-deliverable for any reason, SBMA<br />

shall not, in any event, be liable for non-delivery, or for any<br />

other matter or thing, to any Buyer of any lot, other than for<br />

the return to the Buyer of monies actually paid to SBMA for<br />

said lot, should the Buyer be entitled thereto.<br />

c. SBMA expressly reserves the right to determine the manner<br />

of conducting the auction and to sell items by individual or<br />

group lots, as it may deem appropriate.<br />

d. The Auctioneer and Seller disclaim all warranties, expressed<br />

or implied, about the merchantability of the items and their<br />

fitness for a particular purpose.<br />

e. SBMA assumes no liability for error, omissions, accurate<br />

weights or measures, additions and/or deletions in this<br />

brochure or auction/lot book and all assets are Sold “As Is,<br />

Where Is.” Items offered may or may not be sold as described<br />

and/or photographed in this brochure.<br />

f. Buyer/rigger is responsible for all waste/oil/substance in the<br />

removal of assets, along with all spills that may occur during<br />

the removal process.<br />

g. All sales are made “As Is, Where Is” and Buyer acknowledges<br />

having inspected the property and to be satisfied with same<br />

prior to bidding.<br />

h. All sales are FINAL.<br />

i. The Certificate of Insurance is required to use motorized equipment<br />

or torching equipment on premises for lot removal.<br />

j. Buyer/rigger MUST bring a copy of its liability insurance to the<br />

premises (onsite) and fax a copy to the offices of SBMA. The<br />

insurance certificate must list SBMA and Seller as additional<br />

insureds.<br />

k. All items MUST be paid and picked-up by the last checkout<br />

date or they will be forfeited with no refund of deposit or payment,<br />

unless special arrangements have been made.<br />

l. <strong>Stuart</strong> B. <strong>Millner</strong> & <strong>Associates</strong> shall not be responsible for any<br />

property or bodily damages, howsoever caused, arising from<br />

the pickup or transport of the property, and all risks relating<br />

thereto are fully assumed by Buyer to the complete exoneration<br />

of SBMA. Buyer/rigger waives any and all claim it may<br />

have for any damages, including actual and punitive, whether<br />

caused by negligence, willful misconduct or otherwise,<br />

and assumes all risk related to the removal of its purchases.<br />

m. Buyer will comply with all United States of America Export<br />

Administration Regulations, the Export Administration Act or<br />

any order, license, License Exception, or other authorization<br />

issued there under.<br />

n. For all lots sold as scrap, weight will be estimated until actual<br />

weight is determined during checkout. Once actual weight is<br />

confirmed, Buyer will pay the balance due, if any, or Buyer<br />

will be issued a refund, if due.<br />

o. Buyer must agree to and sign MGE’s safety and environmental<br />

rules prior to any purchasing commitments; online and/<br />

or onsite. These rules can be found at registration, www.<br />

sbmac.com & www.bidspotter.com<br />

DRIVING DIRECTIONS:<br />

Dane County Regional Airport<br />

4000 International Ln, Madison, WI 53704<br />

1) Head north on International LN 2) Turn left onto Packers Ave<br />

3) Slight left to stay on Packers Ave 4) Continue onto Pennsylvania<br />

Ave 5) Turn left onto N 1st St 6) Slight right onto E Washington<br />

Ave 7) Turn left onto S Paterson St 8) Take the 1st right onto E<br />

Main St.<br />

Destination will be on the left<br />

717 E Main St<br />

Madison, WI 53703<br />

acCoMmodations:<br />

Howard Johnson Plaza Hotel<br />

Madison 3841 E Washington Ave, Madison, WI<br />

1.8 mi SE • (608) 244-2481<br />

Baymont Inn And Suites<br />

Madison East 4202 E Towne Blvd, Madison, WI<br />

2.0 mi SE • (608) 241-3861<br />

Best Western East Towne Suites<br />

4801 Annamark Dr, Madison, WI<br />

2.4 mi E • (608) 244-2020<br />

Sale Managed & Conducted By<br />

Bid Online With<br />

World Leader in Live Interactive Auction Broadcasts<br />

12<br />

Visit SBMAC.com for all the details