SUPSALV Skimmer - Supervisor of Salvage and Diving

SUPSALV Skimmer - Supervisor of Salvage and Diving

SUPSALV Skimmer - Supervisor of Salvage and Diving

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SUPSALV</strong> <strong>Skimmer</strong><br />

Spring 1999<br />

Department <strong>of</strong> the Navy<br />

Volume 8, Number 1<br />

From the Captain<br />

Our last issue <strong>of</strong> the<br />

<strong>Skimmer</strong>, dated Summer 1998<br />

(Volume 7, Number 1), introduced a<br />

new format which we plan to continue.<br />

This format consists <strong>of</strong> a feature<br />

article on the cover page, followed<br />

by one or more articles under<br />

the broad topics <strong>of</strong> Readiness<br />

(includes Planning, Training <strong>and</strong><br />

Exercises), Operations, Technology<br />

<strong>and</strong> a Calendar <strong>of</strong> Upcoming Events.<br />

With a fortunate absence <strong>of</strong><br />

large spill events <strong>and</strong> associated<br />

response operations during the previous<br />

six months, this issue is<br />

focused primarily on Readiness <strong>and</strong><br />

Technology. Particularly in the area<br />

<strong>of</strong> contingency planning, technology<br />

is becoming more <strong>and</strong> more important<br />

to a complete readiness posture.<br />

The U.S. Navy is working hard, <strong>and</strong><br />

smartly, on many fronts to leverage<br />

current hardware <strong>and</strong> s<strong>of</strong>tware applications<br />

for environmental protection.<br />

This issue provides an update on<br />

several technology initiatives specific<br />

to Navy oil spill response planning.<br />

Concurrent with our technology<br />

initiatives, we are working<br />

diligently to coordinate our Navy<br />

regional response plan updates with<br />

our other Federal partners, particularly<br />

the U.S. Coast Guard <strong>and</strong><br />

NOAA, <strong>and</strong> with the Area<br />

Committees. Also described in this<br />

issue are the Navy's plans to continue<br />

In This Issue<br />

- From the Captain<br />

- <strong>SUPSALV</strong> Test Water-Cooled Fire-Boom<br />

Blankets<br />

READINESS<br />

Planning<br />

- NOAA Develops All-Risk-All Hazard<br />

ICP Plan<br />

Training<br />

- Response Training for U.S. Marine Corps<br />

Drills&Exercises<br />

- <strong>SUPSALV</strong> Personnel <strong>and</strong> Equipment<br />

Readiness<br />

- Cheatham Annex Equipment Test<br />

- Stockton Equipment Drill <strong>and</strong> Training<br />

Exercise<br />

- Alaska SONS Drill 1998<br />

- <strong>SUPSALV</strong> Assists DESC in OPA 90<br />

Training Compliance<br />

OPERATIONS<br />

- Chinese Vessel Cleaning Operations<br />

TECHNOLOGY<br />

- Fleet Planners Environmental Support<br />

System Development<br />

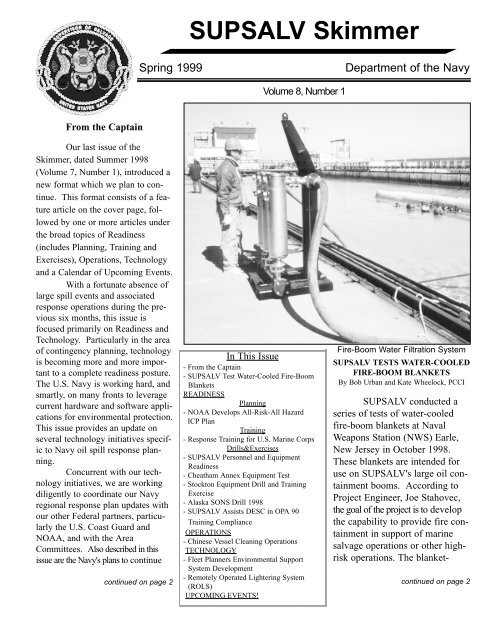

Fire-Boom Water Filtration System<br />

<strong>SUPSALV</strong> TESTS WATER-COOLED<br />

FIRE-BOOM BLANKETS<br />

By Bob Urban <strong>and</strong> Kate Wheelock, PCCI<br />

<strong>SUPSALV</strong> conducted a<br />

series <strong>of</strong> tests <strong>of</strong> water-cooled<br />

fire-boom blankets at Naval<br />

Weapons Station (NWS) Earle,<br />

New Jersey in October 1998.<br />

These blankets are intended for<br />

use on <strong>SUPSALV</strong>'s large oil containment<br />

booms. According to<br />

Project Engineer, Joe Stahovec,<br />

the goal <strong>of</strong> the project is to develop<br />

the capability to provide fire containment<br />

in support <strong>of</strong> marine<br />

salvage operations or other highrisk<br />

operations. The blanketcontinued<br />

on page 2<br />

- Remotely Operated Lightering System<br />

(ROLS)<br />

continued on page 2<br />

UPCOMING EVENTS!

<strong>SUPSALV</strong> <strong>Skimmer</strong><br />

The <strong>Supervisor</strong> <strong>of</strong> <strong>Salvage</strong> <strong>and</strong><br />

<strong>Diving</strong> publishes the <strong>SUPSALV</strong><br />

<strong>Skimmer</strong> to bring you the latest <strong>and</strong><br />

most informative news available on<br />

the Navy Oil Spill program.<br />

Discussion or illustrations <strong>of</strong> commercial<br />

products do not imply<br />

endorsement by the <strong>Supervisor</strong> <strong>of</strong><br />

<strong>Salvage</strong> <strong>and</strong> <strong>Diving</strong> or the U.S.<br />

Navy.<br />

Articles, letters, queries <strong>and</strong> comments<br />

should be directed to the<br />

Comm<strong>and</strong>er, Naval Sea Systems<br />

Comm<strong>and</strong>, NAVSEA 00C, 2531<br />

Jefferson Davis Highway, Arlington,<br />

VA 22242-5160 (Attn: <strong>SUPSALV</strong><br />

<strong>Skimmer</strong>). Visit our web site at<br />

http://www.navsea.navy.mil/sea00c<br />

Captain Bert Marsh, USN<br />

Director <strong>of</strong> Ocean Engineering<br />

<strong>Supervisor</strong> <strong>of</strong> <strong>Salvage</strong> <strong>and</strong> <strong>Diving</strong><br />

NAVSEA 00C<br />

Ninette Sadusky<br />

NOSC Readiness Manager,<br />

00C25A<br />

Managing Editor<br />

Don Graham, PCCI<br />

Production Editor<br />

2<br />

continued from page 1<br />

From the Captain<br />

<strong>and</strong> improve our NOSC Oil <strong>and</strong><br />

Hazardous Substance Spill<br />

Contingency Planning Course<br />

through the addition <strong>of</strong> several new<br />

modules dealing with Risk<br />

Communications <strong>and</strong> Spill<br />

Prevention.<br />

Please pay particular attention<br />

to this issue's Calendar <strong>of</strong><br />

Events. We have attempted to identify<br />

important events for the entire<br />

year in this first issue, <strong>and</strong> we will<br />

update this list with each future<br />

issue.<br />

In addition to summarizing<br />

the feature articles contained in this<br />

issue, I also want to take this opportunity<br />

to inform you that this will be<br />

my last issue <strong>of</strong> the <strong>Skimmer</strong>. I<br />

have enjoyed tremendously the<br />

opportunity to work with each <strong>of</strong><br />

you…sometimes in person, but more<br />

<strong>of</strong>ten through this Newsletter…to<br />

advance the Navy's Oil Spill<br />

Program. Along these lines, I<br />

recently received a comprehensive<br />

briefing from my Pollution<br />

Manager, Will Healy, <strong>and</strong> my<br />

Readiness Coordinator, Ninette<br />

Sadusky, on our Pollution Strategic<br />

Plan <strong>and</strong> where we want to go over<br />

the next three years. I am excited<br />

about the many ideas these individuals<br />

presented <strong>and</strong> secure in the<br />

knowledge that through their<br />

demonstrated dedication <strong>and</strong> hard<br />

work, as well as the tireless effort <strong>of</strong><br />

our dynamic <strong>and</strong> forward-looking<br />

resource sponsor, CNO’s N45, our<br />

pollution program will continue to<br />

advance as a model DOD environmental<br />

program.<br />

The future success <strong>of</strong> our<br />

strategic plan will be communicated<br />

to you by our staff <strong>and</strong> by my successor,<br />

Captain Bert Marsh, who<br />

recently came aboard. The Navy<br />

diving, salvage <strong>and</strong> pollution<br />

response community is truly a small,<br />

close organization, <strong>and</strong> I have had<br />

numerous opportunities to work<br />

with Captain Marsh <strong>and</strong> observe his<br />

skills, knowledge <strong>and</strong> pr<strong>of</strong>essionalism.<br />

I'm leaving you in good h<strong>and</strong>s!<br />

CAPT R. S. McCord<br />

Director <strong>of</strong> Ocean Engineering<br />

<strong>Supervisor</strong> <strong>of</strong> <strong>Salvage</strong> <strong>and</strong> <strong>Diving</strong><br />

continued from page 1<br />

<strong>SUPSALV</strong> Test Water-Cooled<br />

Fire-Boom Blankets<br />

boom system can also support in-situ<br />

burning <strong>of</strong> oil on the sea's surface.<br />

The tests have shown that<br />

water-cooled barriers can withst<strong>and</strong><br />

large oil fires for several<br />

hours with little damage if cooling<br />

water is continuously supplied.<br />

The adaptation <strong>of</strong> this<br />

cooling technique into an effective<br />

blanket cover for the larger<br />

Navy host salvage booms presents<br />

many challenges <strong>and</strong><br />

requires several development<br />

steps in order to build a reliable<br />

full-scale system.<br />

Three types <strong>of</strong> blankets,<br />

each 50 ft. in length, were tested<br />

in the Oil <strong>and</strong> Hazardous<br />

Materials Simulated<br />

Environmental Test Tank (OHM-<br />

SETT) on NWS Earle. The tests<br />

used a unique submerged<br />

Spring 1999

<strong>SUPSALV</strong> <strong>Skimmer</strong><br />

continued from page 2<br />

propane bubbler fire system to<br />

replicate a fully developed<br />

marine oil fire. After several<br />

hours <strong>of</strong> burn testing, the blankets<br />

were inspected for damage,<br />

<strong>and</strong> additional tests were conducted<br />

to determine durability<br />

during h<strong>and</strong>ling, cleaning <strong>and</strong><br />

Spring 1999<br />

<strong>SUPSALV</strong> Test Water-Cooled Fire-Boom Blankets<br />

Blanket Preparation<br />

Fire-Boom Test<br />

maintenance.<br />

The tested prototype blankets<br />

each had different characteristics<br />

which provided insight to<br />

the essential components needed<br />

for a reliable fire-boom blanket<br />

system. Also, performance problems<br />

were identified related to<br />

fitting <strong>of</strong> the blankets onto conventional<br />

host booms. The<br />

results <strong>of</strong> this test program allow<br />

for the development <strong>of</strong> a fullscale<br />

<strong>SUPSALV</strong> fire-boom blanket<br />

system. The next step is to<br />

investigate improvements in<br />

water distribution <strong>and</strong> reliability.<br />

Full-scale system development<br />

<strong>and</strong> evaluation is expected to be<br />

completed next year.<br />

READINESS - PLANNING/TRAINING/<br />

DRILLS&EXERCISE<br />

NOAA DEVELOPS<br />

All-Risk, All-Hazard<br />

ICP PLAN<br />

By Bob Miles, PCCI<br />

With the assistance <strong>of</strong><br />

<strong>SUPSALV</strong>, National Oceanic <strong>and</strong><br />

Atmospheric Administration's<br />

(NOAA) Western Regional<br />

Center (WRC) located in Seattle,<br />

Washington recently developed<br />

an All-Risk, All-Hazard<br />

Response Plan utilizing the<br />

Integrated Contingency Plan<br />

(ICP) format.<br />

Responding to an administrative<br />

order by Washington<br />

state, WRC was charged with<br />

updating its Oil <strong>and</strong> Hazardous<br />

Substance Response Plan. It was<br />

decided to revise the plan in an<br />

ICP format, <strong>and</strong> if possible,<br />

exp<strong>and</strong> the response planning<br />

beyond the usual oil <strong>and</strong> hazardous<br />

substances.<br />

NOAA's WRC campus is<br />

a large federal facility that<br />

employs approximately 1,000<br />

personnel engaged in numerous<br />

research, weather <strong>and</strong> administrative<br />

functions. These personnel<br />

belong to dispirit agencies within<br />

the NOAA organization <strong>and</strong> are<br />

all collocated on the same campus.<br />

Many <strong>of</strong> the research laboratories<br />

contained exotic <strong>and</strong><br />

potentially dangerous chemicals,<br />

albeit in small quantities.<br />

However, WRC did not meet the<br />

thresholds required to fall under<br />

the various federal regulations<br />

that apply to most Navy facilities.<br />

Thus, WRC had a relatively<br />

continued on page 4<br />

3

<strong>SUPSALV</strong> <strong>Skimmer</strong><br />

READINESS - PLANNING/TRAINING/DRILLS&EXERCISE<br />

continued from page 3<br />

NOAA DEVELOPS<br />

All-Risk, All-Hazard<br />

ICP PLAN<br />

free h<strong>and</strong> in formatting its plan<br />

within the ICP guidelines.<br />

Development <strong>of</strong> the plan<br />

did require much coordination<br />

<strong>and</strong> "buy in" meetings among the<br />

many independent organizations<br />

located on the WRC campus.<br />

For response management, the<br />

same response team was utilized<br />

in all responses regardless <strong>of</strong> the<br />

nature <strong>of</strong> the hazard.<br />

The All-Risk, All-Hazard<br />

portion <strong>of</strong> the core plan <strong>of</strong> the<br />

ICP was developed for: oil <strong>and</strong><br />

hazardous substance response;<br />

fire; earthquakes; workplace violence<br />

which included bomb<br />

threats, suspicious packages <strong>and</strong><br />

personnel disturbances; <strong>and</strong><br />

severe weather which included<br />

high winds, floods, heavy snow<br />

<strong>and</strong> power outages.<br />

During November 1998<br />

personnel stationed at Marine<br />

Corps Base Hawaii (MCBH),<br />

located in Kaneohe Bay, HI,<br />

received a tailored spill response<br />

management training course.<br />

MCBH is located in a particularly<br />

environmentally sensitive area on<br />

the windward side <strong>of</strong> Oahu <strong>and</strong><br />

has been proactive in addressing<br />

Response Training for<br />

U.S. Marine Corps<br />

By Bob Miles, PCCI<br />

designed the agenda to address<br />

spill response issues specific to<br />

the Marine Corps operating in<br />

their local Hawaiian environment.<br />

One <strong>of</strong> the more unique<br />

<strong>and</strong> useful presentations was a<br />

roundtable presentation <strong>and</strong> discussion<br />

by the major oil spill<br />

responders located in Hawaii.<br />

Hawaii’s Kaneohe Bay<br />

spill response issues.<br />

The course was patterned<br />

after the Navy On-Scene<br />

Coordinator (NOSC) course<br />

which is presented three times a<br />

year at various locations worldwide.<br />

However, for the MCBH<br />

training, Rocky Owens, MCBH<br />

Environmental Coordinator,<br />

Clean Isl<strong>and</strong>s Council, Marine<br />

Spill Response Corporation-<br />

Hawaii (MSRC), PENCO <strong>and</strong><br />

Tesoro all gave presentations<br />

regarding their capabilities.<br />

After the presentations the representatives<br />

opened the floor for<br />

discussion regarding specific<br />

continued on page 5<br />

4<br />

Spring 1999

<strong>SUPSALV</strong> <strong>Skimmer</strong><br />

READINESS - PLANNING/TRAINING/DRILLS&EXERCISE<br />

continued from page 4<br />

Response Training for<br />

U.S. Marine Corps<br />

issues peculiar to spill response<br />

in Hawaii.<br />

In addition to presentations<br />

by the local responders,<br />

representatives from the National<br />

Oceanic <strong>and</strong> Atmospheric<br />

Administration (NOAA), Hawaii<br />

Department <strong>of</strong> Health <strong>and</strong> the<br />

local Marine Safety Office<br />

(MSO) gave presentations on<br />

Hawaii sensitivities <strong>and</strong> available<br />

resources with which to conduct<br />

an effective response.<br />

While not unique to<br />

Hawaii, the course included two<br />

presentations on public relations.<br />

A similar curriculum has been<br />

added to the NOSC course.<br />

The Federal On-Scene<br />

Coordinator, the State On-Scene<br />

Coordinator <strong>and</strong> the U.S. Marine<br />

Corps (USMC) On-Scene<br />

Coordinator all gave presentations<br />

regarding their roles,<br />

responsibilities <strong>and</strong> response<br />

philosophies <strong>and</strong> priorities.<br />

These presentations were similar<br />

to the NOSC course.<br />

Hawaii State Representative<br />

Briefs USMC<br />

Spring 1999<br />

<strong>SUPSALV</strong> Personnel <strong>and</strong><br />

Equipment Readiness<br />

By Joe Stahovec, <strong>SUPSALV</strong> <strong>and</strong> Ron<br />

Worthington, GPC<br />

Cheatham Annex<br />

Training Exercise<br />

Shore Boom<br />

<strong>SUPSALV</strong>'s oil spill<br />

response capabilities pre-staged<br />

at Cheatham Annex, Virginia,<br />

underwent a deployment training<br />

<strong>and</strong> equipment testing exercise<br />

during the period 31 August<br />

through 4 September 1998. The<br />

major objective <strong>of</strong> the exercise<br />

was to deploy a Class V skimmer<br />

system <strong>and</strong> 1000 feet <strong>of</strong> containment<br />

boom in a timed deployment<br />

drill format. The skimmer<br />

system was deployed within four<br />

hours, <strong>and</strong> the 1000 feet <strong>of</strong><br />

boom was deployed within two<br />

hours. Additional equipment<br />

deployments included the salvage<br />

skim system containing<br />

weir, skim-pak <strong>and</strong> rope mop<br />

skimmers; the <strong>of</strong>fshore fire fighting<br />

system; <strong>and</strong> the supporting<br />

comm<strong>and</strong>, rigging <strong>and</strong> shop vans.<br />

Deployed for the first time was<br />

the USS 42-inch <strong>and</strong> 26-inch<br />

shore boom. This boom with its<br />

bottom two chambers filled with<br />

water is<br />

used to<br />

form a bottom<br />

seal on<br />

the shoreline.<br />

The<br />

outboard<br />

ends <strong>of</strong> the<br />

shore boom<br />

readily connect<br />

to the<br />

USS 42-<br />

inch <strong>and</strong> 26-<br />

inch boom,<br />

forming a<br />

sealed containment<br />

pocket in shoreline interface<br />

operations.<br />

These training exercises<br />

ensure that <strong>SUPSALV</strong> oil spill<br />

recovery equipment <strong>and</strong> personnel<br />

are prepared to support the<br />

Navy's facility <strong>and</strong> fleet operations<br />

worldwide.<br />

Cheatham Annex<br />

Equipment Test<br />

By Joe Stahovec, <strong>SUPSALV</strong> <strong>and</strong> Ron<br />

Worthington, GPC<br />

<strong>SUPSALV</strong> is continually<br />

developing enhanced oil recovery<br />

<strong>and</strong> logistical support systems to<br />

ensure that the Navy is better<br />

prepared to respond to a spill situation.<br />

Developed equipment is<br />

extensively <strong>and</strong> continuously<br />

continued on page 6<br />

5

<strong>SUPSALV</strong> <strong>Skimmer</strong><br />

READINESS - PLANNING/TRAINING/DRILLS&EXERCISE<br />

tested to ensure that both the<br />

equipment <strong>and</strong> the personnel are<br />

efficient <strong>and</strong> effective. During<br />

the period 26 through 30 October<br />

1998, several new systems were<br />

tested in an integrated scenario at<br />

Cheatham Annex. Two new systems,<br />

the oil bladder transfer system<br />

<strong>and</strong> the modular barge system<br />

were integrated with the<br />

floating hose system to transfer<br />

product from<br />

oil storage<br />

bladders<br />

located threequarters<br />

<strong>of</strong> a<br />

mile <strong>of</strong>fshore<br />

to the<br />

Cheatham<br />

Annex Pier.<br />

In this exercise<br />

the modular<br />

barge <strong>and</strong><br />

6<br />

continued from page 5<br />

Cheatham Annex<br />

Equipment Test<br />

Transfer Pump<br />

Transfer System<br />

the oil transfer system <strong>and</strong> the<br />

large oil storage bladder were<br />

anchored <strong>of</strong>f shore. The<br />

smaller oil<br />

recovery<br />

bladders<br />

filled with<br />

water were<br />

towed <strong>and</strong><br />

subsequently<br />

connected to<br />

the transfer<br />

station where<br />

the smaller<br />

bladder contents<br />

were<br />

transferred to<br />

the larger bladder.<br />

Subsequently, the<br />

contents <strong>of</strong> the larger<br />

bladder were<br />

pumped 3,500 feet through the<br />

floating hose system to the pier.<br />

The combination <strong>of</strong> systems<br />

developed <strong>and</strong> tested allows<br />

<strong>SUPSALV</strong> to transfer recovered<br />

product in draft restricted <strong>and</strong><br />

undeveloped terrain operational<br />

scenarios. The many lessons<br />

learned in these testing exercises<br />

will be incorporated into system<br />

configuration<br />

<strong>and</strong> personnel<br />

training<br />

programs<br />

to<br />

further<br />

enhance<br />

capabilities<br />

<strong>and</strong> response<br />

readiness.<br />

Stockton Equipment Drill <strong>and</strong><br />

Training Exercise<br />

By Joe Stahovec, <strong>SUPSALV</strong> <strong>and</strong> Ron<br />

Worthington, GPC<br />

Ropemop Deployment<br />

The <strong>SUPSALV</strong><br />

Emergency Ship <strong>Salvage</strong><br />

Material (ESSM) Base in<br />

Stockton, California conducted a<br />

drill <strong>and</strong> training exercise during<br />

the period 16-20 November<br />

1998. During the drill Stockton<br />

personnel successfully deployed<br />

the Class V skimmer system <strong>and</strong><br />

1000 feet <strong>of</strong> USS 42-inch boom<br />

within the allocated deployment<br />

time frames. Training also<br />

included the deployment <strong>of</strong> the<br />

comm<strong>and</strong>, shop <strong>and</strong> rigging vans.<br />

The hot tap system was deployed<br />

<strong>and</strong> was used to access a ship's<br />

cargo hold by attaching <strong>and</strong><br />

drilling through a ½ inch steel<br />

plate set up to simulate a ship's<br />

hull structure. Additional training<br />

included the deployment <strong>of</strong> the<br />

boom mooring system <strong>and</strong> the<br />

salvage skim system.<br />

The exercise again displayed<br />

the readiness <strong>of</strong> both<br />

equipment <strong>and</strong> personnel located<br />

on the West Coast to support the<br />

Navy, DOD <strong>and</strong> other activities<br />

in the event <strong>of</strong> a significant oil<br />

spill.<br />

Spring 1999

<strong>SUPSALV</strong> <strong>Skimmer</strong><br />

READINESS - PLANNING/TRAINING/DRILLS&EXERCISE<br />

The T/V Northern Dancer<br />

was heading outbound from Port<br />

Valdez laden with 850,000 barrels <strong>of</strong><br />

Alaska North Slope Crude oil when<br />

something went wrong. It ran<br />

aground on Middle Point <strong>of</strong><br />

Montague Isl<strong>and</strong> <strong>and</strong> spilled more<br />

than 307,000 barrels <strong>of</strong> its cargo.<br />

Alyeska immediately responded, but<br />

it was evident by day three that<br />

more resources were needed as the<br />

oil slick proceeded southwest out <strong>of</strong><br />

Prince William Sound threatening<br />

the Gulf <strong>of</strong> Alaska.<br />

This was the scenario<br />

for the Spill <strong>of</strong><br />

National Significance<br />

(SONS) drill held in<br />

Alaska 21-23<br />

September, 1998.<br />

It was the second<br />

such drill in the<br />

United States to test<br />

the capabilities <strong>of</strong><br />

responding to a "rare<br />

catastrophic spill which<br />

greatly exceeds the<br />

response capabilities at the<br />

local or regional level" as<br />

defined in the National Contingency<br />

Plan. The scenario was designed to<br />

test the third day <strong>of</strong> such an event in<br />

which out-<strong>of</strong>-region oil spill<br />

response resources are deployed to<br />

assist.<br />

<strong>SUPSALV</strong> participated in<br />

the equipment deployment portion<br />

<strong>of</strong> the drill. Equipment was mobilized<br />

out <strong>of</strong> Emergency Ship<br />

<strong>Salvage</strong> Material (ESSM) Base<br />

Anchorage to Seward, Alaska.<br />

Equipment mobilized included a<br />

Marco Class V skimming system<br />

with two 24-foot boom h<strong>and</strong>ling<br />

boats, a 18-foot boom tending boat,<br />

a 23-foot inflatable boat, 1,000 feet<br />

Alaska SONS Drill 1998 -- By Lee Majors, GPC<br />

<strong>of</strong> ocean boom, a comm<strong>and</strong> van, a<br />

rigging van <strong>and</strong> a workshop van.<br />

<strong>SUPSALV</strong> was incorporated into<br />

Free Oil Recovery Task Force 7 out<br />

<strong>of</strong> Resurrection Bay to contain <strong>and</strong><br />

recover the oil as it moved southwest<br />

toward Kodiak Isl<strong>and</strong>. The<br />

task force also included a U.S. Coast<br />

Guard (USCG) buoy tender with its<br />

VOSS system, Oil Spill Response<br />

Limited (OSRL) equipment from<br />

Alaska SONS Drill<br />

Southampton, Engl<strong>and</strong>, <strong>and</strong> local<br />

fishing vessels from the Alyeska<br />

Ship Escort Response Vessel System<br />

SERVS response fleet. The fishing<br />

vessels deployed the <strong>SUPSALV</strong><br />

ocean boom in an open apex u-<br />

boom configuration in front <strong>of</strong> the<br />

USCG skimming system. These<br />

vessels also deployed OSRL equipment<br />

in u-boom <strong>and</strong> j-boom recovery<br />

strike teams. Another free oil<br />

recovery task force was mobilized in<br />

the Chenega area <strong>of</strong> Prince William<br />

Sound.<br />

In addition to deploying the<br />

equipment, <strong>SUPSALV</strong> also coordinated<br />

the logistical requirements for<br />

cranes, forklifts <strong>and</strong> similar equipment<br />

for the Seward area. The<br />

Alaska Department <strong>of</strong><br />

Environmental Conservation <strong>and</strong> the<br />

local regional citizens advisory<br />

councils noted that the Marco Class<br />

V skimming system was the first to<br />

be on scene <strong>and</strong> in a skimming formation.<br />

High praise was also given<br />

by the fishing vessels for the durability<br />

<strong>and</strong> ease <strong>of</strong> towing <strong>of</strong><br />

the <strong>SUPSALV</strong> ocean<br />

boom.<br />

The <strong>SUPSALV</strong><br />

Resource Asset<br />

Tracking System<br />

(RATS) was <strong>of</strong> special<br />

interest to all<br />

involved. GPS<br />

transmitters were<br />

deployed on two<br />

fishing vessels, the<br />

USCG buoy tender<br />

<strong>and</strong> a <strong>SUPSALV</strong><br />

boom h<strong>and</strong>ling boat to<br />

assist in tracking the individual<br />

strike teams within the<br />

task force. The display was<br />

maintained in the comm<strong>and</strong> van<br />

<strong>and</strong> was able to track the vessels<br />

during the entire equipment deployment<br />

that extended to the southern<br />

end <strong>of</strong> Resurrection Bay.<br />

The SONS drill again<br />

demonstrated <strong>SUPSALV</strong>'s capability<br />

to respond <strong>and</strong> participate in a unified<br />

response as requested by the<br />

Federal On-Scene Coordinator.<br />

Spring 1999<br />

7

<strong>SUPSALV</strong> <strong>Skimmer</strong><br />

READINESS - PLANNING/TRAINING/DRILLS&EXERCISE<br />

<strong>SUPSALV</strong> Assists DESC in<br />

OPA 90 Training Compliance<br />

By Tom Griggs, PCCI<br />

During 1998 <strong>SUPSALV</strong><br />

provided direct support to the<br />

Defense Energy<br />

Supply<br />

Center<br />

(DESC) in<br />

meeting its<br />

federal training,<br />

drill <strong>and</strong><br />

exercise compliance<br />

requirements<br />

under the Oil<br />

Pollution<br />

Abatement<br />

Act <strong>of</strong> 1990<br />

(OPA 90).<br />

Specifically,<br />

<strong>SUPSALV</strong><br />

provided<br />

training <strong>and</strong><br />

tabletop exercises for Defense<br />

Fuel Supply Points (DFSPs)<br />

Tampa <strong>and</strong> Charleston <strong>and</strong> for<br />

Eielson Air Force Base, where<br />

DESC is responsible for environmental<br />

compliance for the military's<br />

Fairbanks to Eielson<br />

Pipeline.<br />

For each location several<br />

hours <strong>of</strong> "schoolhouse" training<br />

was provided that emphasized the<br />

OPA 90 regulatory requirements<br />

<strong>and</strong> oil spill management using<br />

an incident comm<strong>and</strong> system<br />

(ICS). A thorough review <strong>of</strong> the<br />

facility response plan (FRP) was<br />

also conducted. Following the<br />

half day <strong>of</strong> schoolhouse training,<br />

a half-day tabletop exercise<br />

(TTX) was conducted. In addition<br />

to meeting "core components"<br />

included in the federal<br />

drill <strong>and</strong> exercise program, these<br />

TTXs exercised the ability <strong>of</strong> the<br />

Boom Deployment<br />

activity's spill management team<br />

to: effectively set up an incident<br />

comm<strong>and</strong> system; address difficult<br />

environmental<br />

trade<strong>of</strong>fs;<br />

issue timely<br />

press releases;<br />

<strong>and</strong><br />

evaluate the<br />

facilities'<br />

contracted<br />

response<br />

contractors<br />

or the Oil<br />

Spill Removal<br />

Organizations (OSROs).<br />

DESC has requested<br />

<strong>SUPSALV</strong>'s continued support in<br />

meeting its 1999 <strong>and</strong> 2000 OPA<br />

90 exercise requirements for the<br />

facilities in Tampa, Charleston,<br />

<strong>and</strong> Fairbanks <strong>and</strong> also for DFSP<br />

Verona, New York. <strong>SUPSALV</strong>'s<br />

goal during the<br />

upcoming exercises<br />

is to continue<br />

to refine the<br />

use <strong>of</strong> the ICS,<br />

in a Unified<br />

Comm<strong>and</strong> structure<br />

that includes<br />

the State <strong>and</strong><br />

Federal governments.<br />

SUP-<br />

SALV may be<br />

able to assist<br />

your comm<strong>and</strong><br />

in meeting its<br />

OPA 90 exercise<br />

requirements.<br />

Call Will Healy<br />

at 703-602-8206 ext.<br />

247 to discuss your requirements<br />

in detail.<br />

Boat Returns to Mooring Location<br />

8<br />

Spring 1999

<strong>SUPSALV</strong> <strong>Skimmer</strong><br />

READINESS - OPERATIONS<br />

Chinese Vessel Cleaning<br />

Operations<br />

By Mike Pricola, GPC<br />

One <strong>of</strong> the Two Chinese Vessels<br />

Two Chinese vessels were<br />

seized by U.S. Federal <strong>of</strong>ficials <strong>of</strong>f<br />

the waters <strong>of</strong> Guam U.S.A. The<br />

vessels were reportedly being used<br />

for the smuggling <strong>of</strong> illegal Chinese<br />

immigrants into the United States.<br />

The U.S. Marshals Service tasked<br />

<strong>SUPSALV</strong> with the decontamination<br />

<strong>of</strong> the two vessels to prepare them<br />

for deep ocean disposal.<br />

On September 17, 1998,<br />

<strong>SUPSALV</strong> Emergency Ship <strong>Salvage</strong><br />

Material (ESSM) Base Stockton <strong>and</strong><br />

ESSM Base Hawaii personnel along<br />

with subcontractor personnel began<br />

the decontamination process on the<br />

first vessel. The work was divided<br />

into three major categories: 1) biological<br />

hazard removal, 2) debris<br />

removal <strong>and</strong> 3) petroleum disposal.<br />

On October 6, 1998, the<br />

decontamination process began on<br />

the second vessel. The work on the<br />

second vessel was divided into the<br />

same three major categories as the<br />

first.<br />

The clean-up process <strong>of</strong><br />

both vessels generated a large quantity<br />

<strong>of</strong> waste. Approximately twenty-six<br />

33-gallon bags <strong>of</strong> biological<br />

waste were removed. Additionally,<br />

approximately six yards <strong>of</strong> wet<br />

Spring 1999<br />

garbage, four 30-yard dumpsters <strong>of</strong><br />

general debris, seven 30-yard dumpsters<br />

<strong>of</strong> wood debris <strong>and</strong> approximately<br />

27,000 gallons <strong>of</strong> oily<br />

water/fuel were removed during the<br />

decontamination process. Also three<br />

cubic yards <strong>of</strong> asbestos containing<br />

material were removed.<br />

On October 16, 1998, both<br />

vessels were inspected by the U.S.<br />

Coast Guard Marine Safety Office<br />

on Guam <strong>and</strong> by an inspector from<br />

the Government <strong>of</strong> Guam<br />

Environmental Protection Agency<br />

<strong>and</strong> declared suitable for disposal.<br />

These vessels were turned over to<br />

the Commonwealth <strong>of</strong> the Northern<br />

Marianas Isl<strong>and</strong>s for subsequent<br />

sinking <strong>and</strong> use as recreational dive<br />

sites.<br />

Fleet Planners Environmental<br />

Support System Development<br />

By Fred Touchstone <strong>and</strong> Bill Hanlon, PCCI<br />

<strong>SUPSALV</strong> is taking advantage<br />

<strong>of</strong> new computer tools to assist<br />

fleet planners prepare for operations.<br />

Naval Warfare Publication,<br />

Environmental Protection NWP 4-<br />

11, was recently promulgated in<br />

September 1998. It requires that<br />

Navy <strong>and</strong> Marine Corps comm<strong>and</strong>ers<br />

<strong>and</strong> planners develop an environmental<br />

annex, Annex L, to an<br />

operation order or operation plan.<br />

This requirement ensures that environmental<br />

considerations are factored<br />

into an operation before it<br />

occurs, <strong>and</strong> this proactive assessment<br />

will help the Navy deter<br />

adverse environmental impacts <strong>of</strong><br />

operations.<br />

At the request <strong>of</strong> the Chief<br />

<strong>of</strong> Naval Operations Code N45,<br />

<strong>SUPSALV</strong> is working to incorporate<br />

a prototype Geographic Information<br />

System (GIS) that has been devel-<br />

oped for the Black Sea into an electronic<br />

tool that will help Navy planners<br />

develop an Annex L. The current<br />

Black Sea GIS has all <strong>of</strong> the<br />

information necessary to support an<br />

Annex L creation -- including environmental,<br />

physical, political <strong>and</strong><br />

infrastructure data. Furthermore, the<br />

Black Sea GIS will be <strong>of</strong> significant<br />

value to responders to oil spills <strong>and</strong><br />

will have functionality that can be<br />

<strong>of</strong> use to Navy operational planners.<br />

The Annex L tool will be a<br />

modification <strong>of</strong> this Black Sea GIS.<br />

The planner will only have to "point<br />

<strong>and</strong> click," <strong>and</strong> the program will<br />

instantly print a report <strong>and</strong> describe<br />

all <strong>of</strong> the environmentally sensitive<br />

areas in the region. Planners <strong>and</strong><br />

comm<strong>and</strong>ers will then have the<br />

information to make decisions.<br />

Current development plans<br />

have the system ready for field testing<br />

by June 1999. Watch the SUP-<br />

SALV 00C Website for more information.<br />

Remotely Operated lightering<br />

System (ROLS)<br />

By Eric Glaubitz, <strong>SUPSALV</strong> <strong>and</strong><br />

Tony Kuppersmith, PCCI<br />

Under the auspices <strong>of</strong> the<br />

DOD's Foreign Comparative Testing<br />

(FCT) Program, <strong>SUPSALV</strong> recently<br />

purchased a Remotely Operated<br />

Lightering System (ROLS) from<br />

Frank Mohn A/S (FRAMO) in<br />

Norway. The ROLS functions as a<br />

diver-less hot tap <strong>and</strong> pumping system<br />

to remotely recover petroleum<br />

or other liquid products contained in<br />

the tanks <strong>of</strong> sunken vessels. "Hot<br />

tap" refers to the technique <strong>of</strong><br />

drilling into a tank, pipeline or other<br />

cavity without disturbing or spilling<br />

the contents which are under pres-<br />

continued on page 10<br />

9

<strong>SUPSALV</strong> <strong>Skimmer</strong><br />

continued from page 9<br />

Remotely Operated Lightering System<br />

(ROLS)<br />

sure.<br />

<strong>SUPSALV</strong>'s interest in the<br />

new tool stems from its twenty-year<br />

involvement with diver deployed hot<br />

tap systems. The remotely controlled<br />

ROLS complements an existing<br />

suite <strong>of</strong> diver deployed hot tap<br />

systems prepositioned at Emergency<br />

Ship <strong>Salvage</strong> Material (ESSM) sites.<br />

The new remotely controlled tool<br />

safely extends the depth <strong>and</strong> range<br />

<strong>of</strong> <strong>SUPSALV</strong>'s technical know-how<br />

<strong>and</strong> operational response to salvage<br />

missions.<br />

The ROLS was first utilized<br />

by FRAMO in the spring <strong>of</strong> 1996<br />

under contract to the Finnish<br />

Environment Institute to help recover<br />

the remaining oils from the passenger<br />

ferry M/V Estonia prior to<br />

securing the vessel as a mass grave.<br />

During the summer 1998, SUP-<br />

SALV leased the ROLS to FRAMO<br />

for use in the recovery <strong>of</strong> 500 metric<br />

tons <strong>of</strong> oil from two sunken tank<br />

vessels, the Yuil#1 <strong>and</strong> Osung#3 <strong>of</strong>f<br />

<strong>of</strong> Pusan, Korea. The operation was<br />

included as part <strong>of</strong> the FCT operational<br />

evaluation <strong>of</strong> the ROLS.<br />

<strong>SUPSALV</strong> was permitted wide<br />

access to monitor the oil recovery<br />

operation that was performed by<br />

Smit Tak BV, Rotterdam, the salvage<br />

contractor, <strong>and</strong> FRAMO, the<br />

equipment operator, working under<br />

contract to the Korea Marine<br />

Pollution Response Corp.<br />

(KMPRC).<br />

The unique opportunity to<br />

witness the ROLS performing in a<br />

practical field operation in lieu <strong>of</strong><br />

the earlier scheduled simulation tests<br />

provided <strong>SUPSALV</strong> with evaluation<br />

insights that could not otherwise be<br />

obtained.<br />

“UPCOMING EVENTS”<br />

National Pollution Prevention Roundtable Annual Conference<br />

Washington, DC<br />

6-10 Apr<br />

American Wetl<strong>and</strong>s Conference San Francisco, CA 14-17 Apr<br />

Earth Day<br />

Intl. In-Situ & Bioremediation Symposium<br />

San Diego, CA<br />

17 Apr<br />

19-22 Apr<br />

States / BC Task Force Meeting Portl<strong>and</strong>, OR 22-23 Apr<br />

NOAA STOCS Course Seattle, WA 26-30 Apr<br />

NOSC Course Newport, RI 4-7 May<br />

BIO '99 Intl Conf <strong>of</strong> the Biotechnology Industry<br />

Seattle, WA<br />

Computer Aided Mgmt. <strong>of</strong> Emerg. Ops. (CAMEO) Workshop<br />

Phoenix, AZ<br />

16-20 May<br />

24-28 May<br />

CANUSLANT '99 Exercise Eastport, ME 7-10 Jun<br />

Waste Expo '99 Dallas, TX 8-10 Jun<br />

Water & Enviro Resources Mgmt for Asia & the Pacific<br />

Honolulu, HI<br />

29 Jun-3 Jul<br />

NOSC Course Yokosuka, Japan 20-23 Jul<br />

ASCE-CSCE Environmental Engineering Conference<br />

Norfolk, VA<br />

25-28 Jul<br />

Oceans '99 Conference Seattle, WA 13-16 Sep<br />

For more information on these <strong>and</strong> other “UPCOMING EVENTS”,<br />

contact PCCI at (703)684-2060<br />

10<br />

Spring 1999

<strong>SUPSALV</strong> <strong>Skimmer</strong><br />

MSC<br />

In<br />

San Diego<br />

Spring 1999 11