2005 - College of Engineering - Oregon State University

2005 - College of Engineering - Oregon State University

2005 - College of Engineering - Oregon State University

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

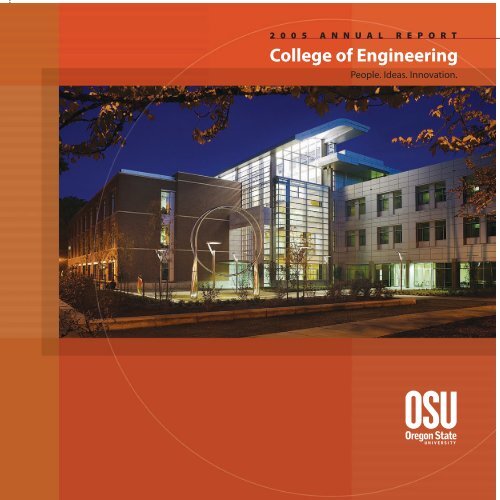

2 0 0 5 A N N U A L R E P O R T<br />

<strong>College</strong> <strong>of</strong> <strong>Engineering</strong><br />

People. Ideas. Innovation.

It is good to<br />

have an end<br />

to journey<br />

toward;<br />

but it is the journey<br />

that matters, in the end.<br />

— U R S U L A K . L e G U I N

A Message from the Dean<br />

Here at <strong>Oregon</strong> <strong>State</strong> <strong>University</strong>,<br />

the <strong>College</strong> <strong>of</strong> <strong>Engineering</strong><br />

is in the midst <strong>of</strong> an<br />

incredible journey—<br />

a journey that is leveraging our long tradition<br />

<strong>of</strong> excellence and our culture <strong>of</strong> innovation,<br />

collaboration, and creativity to build a truly great<br />

engineering program made up <strong>of</strong> extraordinary<br />

people doing astonishing, innovative work.<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

2<br />

Like most journeys, ours takes persistence and<br />

passion. The path includes high points with<br />

sweeping vistas, as well as lows where the going<br />

can be tough. But we welcome the challenges as<br />

we move toward the next milestones; this balance<br />

gives us energy for the next stage <strong>of</strong> the journey<br />

as we climb steadily toward becoming one <strong>of</strong> the<br />

top-25 engineering programs in the nation.<br />

During the last year, the people here at the <strong>College</strong><br />

have taken a great number <strong>of</strong> steps, working hard<br />

LEFT: In front <strong>of</strong> the new Kelley <strong>Engineering</strong><br />

Center, Dean Ron Adams sits behind the<br />

wheel <strong>of</strong> a prototype solar car designed by<br />

a multidisciplinary team <strong>of</strong> OSU students<br />

including Kathy VanWormer, Leif Schneider,<br />

Hai Yue Han, and Peter Kurahashi.<br />

RIGHT: The deepest lake in the nation,<br />

Crater Lake, was formed by the eruption<br />

<strong>of</strong> Mount Mazama more than 7,700<br />

years ago. It is just one <strong>of</strong> <strong>Oregon</strong>’s<br />

many natural treasures.

to pass significant milestones—including one <strong>of</strong> our greatest:<br />

the opening <strong>of</strong> the 153,000-sq.-ft. Kelley <strong>Engineering</strong><br />

Center, the sparkling new home <strong>of</strong> our School <strong>of</strong> Electrical<br />

<strong>Engineering</strong> and Computer Science. This “green” building,<br />

constructed using sustainable materials (see photo essay on<br />

p. 18), is the result <strong>of</strong> vision and generosity. Martin and<br />

Judy Kelley’s $20 million lead gift, in combination with<br />

public funding and additional private support, made the<br />

Kelley <strong>Engineering</strong> Center a reality—a home for innovation<br />

that will impact thousands <strong>of</strong> lives.<br />

In the months ahead, we will begin major renovations<br />

<strong>of</strong> several other engineering buildings—including historic<br />

Apperson Hall—so that our students, staff, faculty, and<br />

industry partners can work and learn in environments<br />

that foster communication, collaboration, and creativity.<br />

All the while, we continue to build our educational<br />

programs and expand our cutting-edge research. In this<br />

report, you’ll read about our successes: microreactors used<br />

for producing biodiesel, filtering blood, and generating<br />

hydrogen for fuel cells (see p. 8); buoys that turn ocean<br />

wave action into electricity (see p. 4); structural research<br />

on bridges that is saving the state <strong>of</strong> <strong>Oregon</strong> millions<br />

<strong>of</strong> dollars (see p. 14); the development <strong>of</strong> transparent<br />

transistors—a breakthrough poised to revolutionize the<br />

electronics industry (see p. 10); and more.<br />

Our alumni like Jen-Hsun “Jensen” Huang (see p. 20)<br />

have gone on to launch major companies like NVIDIA,<br />

providing engineering innovations, economic impact, and<br />

international leadership. Like Jensen, our current entrepreneurial<br />

students, including Tyler Morita (see p. 22), are<br />

starting their own companies here on campus as part <strong>of</strong> the<br />

Austin Entrepreneurship Program at Weatherford Hall, the<br />

largest residential entrepreneurial program in the nation.<br />

Other students are doing outstanding work, too, from building<br />

autonomous vehicles to helping clean up toxic waste<br />

sites to building solar-powered cars.<br />

I’m proud <strong>of</strong> each and every one <strong>of</strong> the people who are on<br />

this journey—proud <strong>of</strong> the path we’re blazing, together. This<br />

is a journey built on our legacy <strong>of</strong> excellence and inspired<br />

by great people, bright ideas, and phenomenal innovation.<br />

Here’s to another good year… and the next milestone.<br />

Ron Adams, Dean<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

3

L A R G E - S C A L E E N E R G Y S Y S T E M S<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

<strong>College</strong> <strong>of</strong> <strong>Engineering</strong> pr<strong>of</strong>essors Annette von Jouanne and<br />

Alan Wallace are committed to involving coastal communities<br />

in the wave energy project. “It’s the collaboration that will<br />

make this project successful,” they say.

THE POWER OF<br />

TEAMWORK<br />

Creating energy from ocean waves<br />

Reedsport, a sleepy logging town on the southern <strong>Oregon</strong> coast, may<br />

be getting a shot <strong>of</strong> new energy thanks to a partnership between the<br />

community, engineers at <strong>Oregon</strong> <strong>State</strong> <strong>University</strong>, state and federal<br />

agencies, and members <strong>of</strong> private industry.<br />

This past summer, Annette von Jouanne and<br />

Alan Wallace, pr<strong>of</strong>essors in OSU’s School <strong>of</strong><br />

Electrical <strong>Engineering</strong> and Computer Science, led<br />

the first <strong>of</strong> what will be several community meetings<br />

centered around bringing wave energy to the <strong>Oregon</strong><br />

coast. In front <strong>of</strong> a standing room only crowd, they<br />

answered questions about energy potential, new<br />

jobs, environmental consequences, advanced technology,<br />

and dependence on foreign energy sources.<br />

Recognized as national leaders <strong>of</strong> ocean wave<br />

energy, von Jouanne and Wallace have developed<br />

several direct drive ocean buoys capable <strong>of</strong> converting<br />

the power in ocean waves to electrical energy.<br />

The coast near Reedsport has been identified as the<br />

optimal site in the nation for wave energy development.<br />

The overall energy potential there is enough to<br />

power about 20 percent <strong>of</strong> the state’s total electricity<br />

needs, according to von Jouanne and Wallace, and<br />

it is believed that with proper location and planning,<br />

converting wave energy to electricity may be one <strong>of</strong><br />

the most environmentally benign ways to generate<br />

electrical power.<br />

“Ocean waves have tremendous potential as an energy<br />

source,” von Jouanne says. “The energy density<br />

in water is much higher than it is in air. We can get<br />

more power with less space, and we can know within<br />

a 10-hour window what our energy capabilities are,<br />

and we can match them to the need.”<br />

The OSU-developed buoys are designed to be<br />

anchored 1-2 miles <strong>of</strong>fshore in water depths greater<br />

than 100 feet. At about 15 feet across by 12 feet<br />

tall, the buoys will sit neutrally buoyant in the water,<br />

and will be almost impossible to see from land with<br />

the naked eye. The research team pictures an array<br />

<strong>of</strong> buoys, or wave park, placed within a sectioned<br />

<strong>of</strong>f area <strong>of</strong> a yet to be determined size, however, it<br />

is estimated that 10 square miles could power the<br />

entire state <strong>of</strong> <strong>Oregon</strong>.<br />

“The key is creating a survivable, reliable, efficient<br />

system,” von Jouanne says <strong>of</strong> the buoys. “The ocean<br />

is very destructive, but we are at a point where we<br />

believe the buoys can be manufactured to survive<br />

the harsh environment.”<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report

LEFT: Reedsport, <strong>Oregon</strong><br />

already has much <strong>of</strong> the<br />

infrastructure needed for a<br />

wave energy facility intact,<br />

including this inactive<br />

paper mill north <strong>of</strong> town.<br />

BELOW: A National Science<br />

Foundation graphic <strong>of</strong><br />

OSU’s direct drive buoy.<br />

Members <strong>of</strong> the community<br />

gather to learn<br />

more about wave energy<br />

in <strong>Oregon</strong>.<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

Wallace adds that the development <strong>of</strong> wave energy is currently<br />

15-20 years behind wind energy, a technology that is just reaching<br />

its optimal performance. He says that just like wind energy,<br />

wave systems will be expensive at first then drop in price as the<br />

industry becomes competitive. Currently, there are operating<br />

wave energy systems in Europe, but the technology is different<br />

than that being developed at OSU.<br />

“This is groundbreaking research that can be <strong>of</strong> enormous value<br />

to society, and it’s amazing all <strong>of</strong> the people who want to get<br />

involved,” Wallace says.<br />

The <strong>College</strong> <strong>of</strong> <strong>Engineering</strong>, the <strong>Oregon</strong> Department <strong>of</strong> Energy,<br />

and the Electric Power Research Institute are hoping to establish<br />

a wave energy conversion research, development, and<br />

demonstration center at a disused paper mill located next to<br />

the electrical substation in Gardiner, just north <strong>of</strong> Reedsport.<br />

The mill, which has been inactive for several years, already has<br />

a number <strong>of</strong> features that could substantially reduce the cost<br />

<strong>of</strong> the project, including available power transmission capability<br />

and an existing outflow pipe. The pipe could be used to house<br />

the power cable that would run from the buoys to the Gardiner<br />

power station where the energy would enter into the grid.

“It could be a whole new<br />

industry. We could be<br />

the nation’s wave energy<br />

headquarters. In a few<br />

years time on the <strong>Oregon</strong><br />

coast there could be<br />

wave parks generating<br />

power back onto the grid<br />

and providing jobs for<br />

the people living in the<br />

region.”<br />

— ANNETTE VON JOUANNE<br />

The facility would create a need for<br />

new local jobs, both in the construction<br />

phase and in daily operations, promote<br />

development, and add to the state’s<br />

goal <strong>of</strong> energy self-sufficiency. It would<br />

receive direction and support from OSU<br />

and its Hatfield Marine Science Center<br />

in Newport. In addition, the <strong>College</strong> <strong>of</strong><br />

<strong>Engineering</strong> is home to the Motor Systems<br />

Resource Facility, the highest-power energy<br />

systems laboratory at any university in<br />

the nation, and the O. H. Hinsdale Wave<br />

Research Laboratory. Both resources would<br />

be available and used by researchers<br />

working at the site.<br />

“It could be a whole new industry,” says<br />

von Jouanne. “We could be the nation’s<br />

wave energy headquarters. In a few years<br />

time on the <strong>Oregon</strong> coast there could be<br />

wave parks generating power back onto<br />

the grid and providing jobs for the people<br />

living in the region.”<br />

The response to the project has been<br />

tremendous. Stories about the research,<br />

and the first community meetings, have<br />

been picked up by national press and run<br />

in publications ranging from engineering<br />

trade journals to the Washington Post and<br />

Popular Mechanics. Von Jouanne says she<br />

is constantly responding to phone calls<br />

and e-mails about the project, and the<br />

possibility for similar wave energy generation<br />

sites elsewhere.<br />

“The really great part is sharing the vision<br />

with others, with our students, and with<br />

the public,” von Jouanne says. “People are<br />

very receptive, and our involved students<br />

are being heavily recruited by industry.”<br />

For the past two years von Jouanne and<br />

Wallace have been funding the project<br />

with a $270,000 grant from the National<br />

Science Foundation and additional funding<br />

from the <strong>Oregon</strong> Sea Grant, the<br />

Department <strong>of</strong> Energy, Columbia Power<br />

Technologies, and regional utilities. The<br />

next phase <strong>of</strong> the project will require<br />

about $5 million. Language has been<br />

added to state and federal energy bills<br />

that could funnel money toward the<br />

project, however von Jouanne and Wallace<br />

are also actively looking for industry partners<br />

and private funding.<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report

O N A M I @ O S U<br />

Micr<strong>of</strong>luidics<br />

big things come<br />

in small packages<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

LEFT: Pr<strong>of</strong>essor Goran Jovanovic says micr<strong>of</strong>luidic systems aimed<br />

at producing alternatives to fossil fuels may provide a vehicle for<br />

energy independence in areas <strong>of</strong> the United <strong>State</strong>s.<br />

ABOVE: Examples <strong>of</strong> OSU-developed microchannels and a<br />

prototype biodiesel microprocessor.

That’s the driving force behind the <strong>Oregon</strong> Nanoscience and Microtechnologies Institute,<br />

a powerful collaboration between <strong>Oregon</strong> <strong>State</strong> <strong>University</strong>, Portland <strong>State</strong> <strong>University</strong>,<br />

<strong>University</strong> <strong>of</strong> <strong>Oregon</strong>, the Pacific Northwest National Laboratory, the state <strong>of</strong> <strong>Oregon</strong>,<br />

and the high technology industry in <strong>Oregon</strong> and southwest Washington.<br />

OSU engineering faculty, working on the micr<strong>of</strong>luidics<br />

side <strong>of</strong> ONAMI, believe that science on a small scale<br />

can achieve big results with worldwide appeal. By using<br />

microchannels developed and built in OSU’s Dept. <strong>of</strong><br />

Industrial and Manufacturing <strong>Engineering</strong> to intensify<br />

and more tightly control the processes that occur during<br />

chemical reactions, faculty are achieving unprecedented<br />

results.<br />

A few examples:<br />

• Goran Jovanovic, a pr<strong>of</strong>essor in the Dept. <strong>of</strong><br />

Chemical <strong>Engineering</strong>, is producing biodiesel by<br />

combining oil from seed crops with alcohol in tiny<br />

microchannels. The microchannels have no moving<br />

parts, do not require external energy, and can be<br />

stacked to increase production. Current data suggests<br />

that a microchannel reactor the size <strong>of</strong> a suitcase could<br />

produce one million gallons <strong>of</strong> biodiesel a year.<br />

• Jovanovic is also using microchannels to remove<br />

sulphur from conventional petroleum products like<br />

gasoline and diesel, for use in fuel cells. When burned,<br />

or combusted in an engine, sulphur produces sulphur<br />

dioxide, an environmental pollutant also know as acid<br />

rain. Removing sulphur from petroleum products may<br />

increase fuel economy, and help to reduce pollution<br />

leading to global warming.<br />

• Greg Rorrer, also a pr<strong>of</strong>essor in the Dept. <strong>of</strong> Chemical<br />

<strong>Engineering</strong>, is putting sugars and starches through a<br />

microreactor to produce hydrogen. The process gives<br />

Rorrer very tight control over the time the substances<br />

are in the reactor. This technology may help farmers<br />

make hydrogen for use in fuel cells from the very<br />

substances they are growing.<br />

• OSU engineering alumni Kay Altman and David<br />

Browning (pictured below) are helping produce a<br />

kidney dialysis unit developed by OSU engineers<br />

associated with ONAMI. The tiny device is incredibly<br />

efficient, and will enable dialysis patients to treat<br />

themselves at home while they sleep.<br />

• Rich Peterson, a pr<strong>of</strong>essor in the Dept. <strong>of</strong> Mechanical<br />

<strong>Engineering</strong>, is leading a push along with colleague<br />

Deborah Pence in the development <strong>of</strong> a personal heat<br />

pump. Previous attempts at personal cooling systems<br />

have required 10-20 lbs. <strong>of</strong> batteries. The <strong>College</strong>’s<br />

system uses waste heat from a fuel cell to drive the<br />

cooling process. This replaces the heavy battery-based<br />

power system and results in a lighter, more compact<br />

portable cooling device.<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report

O N A M I @ O S U<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

10<br />

ABOVE: Perfectly clear, see An interdisciplinary team <strong>of</strong> OSU faculty and students hold up samples <strong>of</strong> transparent<br />

electronics developed through a collaboration between OSU pr<strong>of</strong>essor <strong>of</strong> electrical engineering John Wager<br />

(second from right), OSU pr<strong>of</strong>essor <strong>of</strong> chemistry Doug Keszler (right), and others. Pictured at left are graduate<br />

student Emma Kettenring and development engineer Chris Tasker.<br />

OPPOSITE: Glass slides coated with transparent electronics sit in a petri dish, and a sputtering machine built by<br />

Chris Tasker glows purple during thin film deposition.

See-Through Electronics Will Enable a New Generation <strong>of</strong> Devices<br />

When OSU Electrical <strong>Engineering</strong><br />

pr<strong>of</strong>essor John Wager talks about his<br />

research, you can hear excitement<br />

edging his voice. No wonder. He’s in<br />

the position every researcher dreams<br />

about: standing on the threshold <strong>of</strong> a<br />

breakthrough that could revolutionize<br />

an entire industry—in this case,<br />

the electronics industry.<br />

“I think we’re onto something huge here at<br />

<strong>Oregon</strong> <strong>State</strong>,” Wager says. “And other people<br />

are beginning to sense that now.”<br />

The term “huge” doesn’t exactly fit<br />

Wager’s research, because he and<br />

his team <strong>of</strong> graduate students are<br />

working at the molecular level, and<br />

the end result is, well—invisible. But<br />

that’s the ultimate goal: electronics<br />

that are so crystal clear you can see<br />

right through them. Which makes<br />

any transparent surface a potential<br />

location for electronic devices. And<br />

that’s indeed huge.<br />

In 2003, working closely with<br />

OSU pr<strong>of</strong>essors Doug Keszler<br />

(chemistry) and Janet Tate (physics), Wager’s<br />

group developed the world’s first transparent<br />

transistor (the transistor is the most fundamental<br />

electronic component). This year, Wager and his<br />

multidisciplinary team developed the world’s first<br />

simple integrated circuit (a ring oscillator) that<br />

will also be transparent.<br />

“When we do that, I think people will realize this<br />

technology is ready for prime time,” Wager says<br />

with a smile.<br />

Already Wager’s work is drawing the attention<br />

<strong>of</strong> prestigious research journals and major news<br />

media: Nature, NPR’s Science Friday, CNN, the<br />

journal Science, Wired Magazine, and others.<br />

How did Wager, who’s been at OSU for 21 years,<br />

arrive at this research breakthrough Ever modest,<br />

Wager is quick to credit his graduate students,<br />

his OSU collaborators, his development engineer,<br />

Chris Tasker, and a good dose <strong>of</strong> luck.<br />

“You get lucky every once in a while,” he says.<br />

“We were trying to figure out how to get electrons<br />

to move through various combinations <strong>of</strong><br />

chemicals to direct electricity in electronic applications<br />

and were just in the right place at the<br />

right time asking the right questions. I also have<br />

great graduate students, and Chris Tasker—he’s<br />

the brains behind our entire lab.”<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

11

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

Inside John Wager’s lab,<br />

Celia Hung and fellow graduate<br />

students are part <strong>of</strong> a flurry<br />

<strong>of</strong> research activity that’s<br />

gained national attention.<br />

Wager (opposite page) and<br />

his students have developed<br />

the world’s first transparent<br />

integrated circuit.<br />

It is within Wager’s sprawling fourth floor<br />

lab that materials science, chemistry, physics,<br />

electrical engineering, and perseverance<br />

converged to help his team discover that<br />

common and cheap materials, zinc oxide and<br />

tin oxide, could be used to create transparent<br />

thin film transistors. They then combined<br />

these two elements and discovered that a<br />

new material, Zinc Tin Oxide (ZTO), had even<br />

greater electrical properties, including much<br />

higher electron mobility.<br />

“We just stumbled onto this new material,<br />

and although zinc tin oxide is an amorphous<br />

structure, its electrical mobility is quite<br />

good,” Wager says, ticking <strong>of</strong>f a list <strong>of</strong> other<br />

attributes: very robust (scratch resistant),<br />

high chemical stability (facilitates etching),<br />

low cost, and a smooth surface. The surface<br />

smoothness, he says, is “very, very nice from<br />

a manufacturing point <strong>of</strong> view.” Traditionally,<br />

silicon has been used for electronics because<br />

its crystalline structure facilitates efficient<br />

electron flow.<br />

12

But silicon requires high temperatures<br />

to produce, is too expensive for largearea<br />

and low-cost applications, is highly<br />

brittle, and is anything but transparent.<br />

Wager’s team has discovered that zinc<br />

tin oxide is not the only material that<br />

works well for this type <strong>of</strong> electronics.<br />

“We’ve found a sweet spot in the<br />

periodic table,”<br />

he says. “Which<br />

points to a new<br />

class <strong>of</strong> electronic<br />

materials.” His<br />

group is currently<br />

working with zinc<br />

indium oxide,<br />

another member<br />

<strong>of</strong> this new materials<br />

class.<br />

Unlike silicon, these new materials can<br />

be produced at very low temperatures<br />

and are also flexible, making them<br />

applicable to glass, plastics, and bendable<br />

materials, such as maps<br />

and foils.<br />

Wager’s work could dramatically impact<br />

organic light emitting devices, leading<br />

to displays that are brighter, crisper,<br />

and consume less power. “Our materials<br />

might be the solution to the electronic<br />

back-plane driver challenge <strong>of</strong> this projected<br />

$10-15 billion market,” he says.<br />

Solar cell technology would also be<br />

improved, as well as a myriad <strong>of</strong> other<br />

applications ranging from security and<br />

safety to energy independence.<br />

For example, the infrared or optical<br />

transparency <strong>of</strong> a coating on the<br />

window <strong>of</strong> a home or <strong>of</strong>fice could be<br />

electronically controlled, to let in more<br />

or less heat and light, depending on the<br />

weather. A warning could flash inside a<br />

car’s windshield glass if sensors detect<br />

an object in the street ahead. Invisible<br />

burglar alarms could be placed on glass.<br />

Printers and copy machines could have<br />

electronics applied on the glass, dramatically<br />

reducing<br />

their overall size.<br />

Already Wager’s work is<br />

drawing the attention <strong>of</strong><br />

prestigious research journals<br />

and major news media:<br />

Nature, NPR’s Science Friday,<br />

CNN, the journal Science,<br />

Wired Magazine, and others.<br />

“As soon as you<br />

start letting your<br />

mind wander,<br />

there are a lot <strong>of</strong><br />

potential applications<br />

out there,”<br />

Wager says. But<br />

his job, he says,<br />

is to develop the<br />

basic materials and device technology,<br />

for which he currently has six patents<br />

pending, and then let private industry<br />

incorporate this technology into new<br />

devices and products.<br />

Wager’s team has just inked an<br />

exclusive licensing agreement with<br />

Hewlett-Packard Co. and is working<br />

with the <strong>Oregon</strong> Nanoscience and<br />

Microtechnologies Institute (ONAMI) to<br />

help commercialize the OSU research.<br />

What else could Wager wish for at this<br />

point in his career He’d like to secure<br />

funding to hire another faculty member<br />

with expertise in his research area.<br />

This would speed development <strong>of</strong> his<br />

“invisible” research, which is already<br />

casting a growing shadow across the<br />

electronics industry.<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

13

T H E K I E W I T C E N T E R F O R I N F R A S T R U C T U R E + T R A N S P O R T A T I O N<br />

Strong Research,<br />

Stable Structures<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

Chris Higgins and his team <strong>of</strong><br />

research students build their<br />

own concrete girders at the<br />

Large-Scale Structural Testing<br />

Laboratory. The <strong>College</strong> <strong>of</strong><br />

<strong>Engineering</strong> is working toward<br />

expanding the lab to include<br />

a strong wall and other<br />

testing features.<br />

14

Keeping <strong>Oregon</strong>’s Infrastructure Up and Running<br />

During regular inspections in 2000, <strong>Oregon</strong> Department <strong>of</strong> Transportation (ODOT) personnel<br />

noticed something disturbing about the vintage concrete bridges all over <strong>Oregon</strong>. From the<br />

Powder River in the northeast to the Rogue River in southern <strong>Oregon</strong>, the bridges were cracked.<br />

Of the 1,800 concrete girder bridges listed in the state<br />

database roughly 500 showed visible cracks, many <strong>of</strong> those<br />

on Interstate 5 and Interstate 84, the main north-south<br />

and east-west corridors in the state.<br />

“From just about anywhere in the state, you can’t<br />

travel east or west, north or south without crossing<br />

one <strong>of</strong> these bridges,” says Chris Higgins, a pr<strong>of</strong>essor<br />

in OSU’s Dept. <strong>of</strong> Civil, Construction, and Environmental<br />

<strong>Engineering</strong>. “It has a large scope and is an expensive<br />

problem.”<br />

ODOT took immediate action. The agency imposed load<br />

limitations on several bridges, closed others, and commissioned<br />

Higgins and his team at the <strong>College</strong> <strong>of</strong> <strong>Engineering</strong><br />

to help the state analyze the severity <strong>of</strong> the cracks, assess<br />

the remaining capacity, and predict the remaining life <strong>of</strong><br />

these bridges.<br />

“I was pleased to partner with OSU in development <strong>of</strong> the<br />

testing plan, and to be part <strong>of</strong> the technical advisory committee<br />

for the research project,” says Ray Mabey, deputy<br />

director <strong>of</strong> ODOT’s OTIA III <strong>State</strong> Bridge Delivery Program.<br />

“Some <strong>of</strong> the research methods and results <strong>of</strong> this study<br />

will be recognized nationally.”<br />

The majority <strong>of</strong> the bridges affected were built in the<br />

1950s. At the time, engineers were employing very lean<br />

and efficient designs, specifying only that material which<br />

was necessary. When they began using standardized<br />

deformed reinforcing bars, a new technology at the time,<br />

they deviated from their past successful practice when<br />

detailing the reinforcing within the bridges, Higgins says.<br />

Prior to cracking, the concrete carries the load on the<br />

bridge. Once cracked, the load is transferred to the steel<br />

rebar imbedded in the structure. As trucks became heavier<br />

and more frequent, the load on the bridges increased and<br />

large diagonal cracks formed. Because the bridges contain<br />

less steel than required by current codes, the structures<br />

were <strong>of</strong> concern to engineers.<br />

“We undertook field work and full-scale laboratory<br />

testing and analysis to determine how the<br />

bridge members were behaving,” Higgins says.<br />

“We studied the load effects and found that it<br />

was a matter <strong>of</strong> both shear and moment acting<br />

on the section. The problem was a conspiracy <strong>of</strong><br />

two force effects, and not a lone gunman.”<br />

Higgins and his research team completed field data collection<br />

on four <strong>Oregon</strong> bridges, and built 44 full-size concrete<br />

girders to 1950s specifications for testing at the Large-<br />

Scale Structural Testing Laboratory housed in the <strong>College</strong><br />

<strong>of</strong> <strong>Engineering</strong>’s O.H. Hinsdale Wave Research Laboratory.<br />

The laboratory contains a strong-floor that enabled the<br />

team to carry out full-scale experimental tests on the fourfoot<br />

thick girders, and the first-ever tests <strong>of</strong> real-size bridge<br />

girders failing under moving loads.<br />

Higgins’ team developed a reliability-based assessment<br />

methodology for ODOT to use on a bridge-by-bridge basis,<br />

and provided ODOT tools to determine the<br />

residual load carrying capacity.<br />

“Once you make that assessment you can decide what<br />

needs to be done, if anything, to ensure the safety <strong>of</strong> the<br />

structure,” Higgins said. “All this work is about protecting<br />

the safety <strong>of</strong> the traveling public, making the best use <strong>of</strong><br />

public transportation investments, and keeping <strong>Oregon</strong> up<br />

and running.”<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

15

F A C U L T Y<br />

José Reyes<br />

Managing Major Growth in Nuclear <strong>Engineering</strong><br />

OSU Nuclear <strong>Engineering</strong> faculty,<br />

José Reyes, Brian Woods, Qiao<br />

Wu, and Todd Palmer enjoy a light<br />

moment near campus. This faculty<br />

team, their staff, and a burgeoning<br />

number <strong>of</strong> students have helped<br />

the OSU Nuclear <strong>Engineering</strong> program<br />

gain a No. 9 national ranking.<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

16<br />

After a sabbatical in Vienna, Austria working with the<br />

United Nations to develop safer passive nuclear reactors,<br />

José Reyes, the Henry W. and Janice J. Schuette Chair in<br />

Nuclear <strong>Engineering</strong> and Radiation Health Physics, returned<br />

to OSU last winter to a flurry <strong>of</strong> good news:<br />

• U.S. News and World Report ranked OSU’s<br />

nuclear engineering program No. 9 in the nation<br />

• student enrollment in the department was way up,<br />

and climbing<br />

• national interest in nuclear power was the<br />

highest in decades<br />

• and the <strong>College</strong> selected Reyes as the new<br />

department head<br />

To top it <strong>of</strong>f, OSU was selected as one <strong>of</strong> five universities<br />

to play a key role in a research collaboration with the<br />

Idaho National Laboratory (INL), which will bring the<br />

department approximately $12 million in funding<br />

over 10 years.<br />

“That was quite a coup,” says Reyes, who will be<br />

co-director, along with pr<strong>of</strong>essor Todd Palmer, <strong>of</strong><br />

the Academic Center <strong>of</strong> Excellence for Thermal<br />

Fluids and Reactor Safety — the OSU part <strong>of</strong> the<br />

INL project.<br />

All the growth and good news is stretching the department,<br />

both physically and personnel wise. So Reyes<br />

and colleagues are making big plans to meet the<br />

growing demand for nuclear engineering graduates.<br />

“The average age <strong>of</strong> workers at the nation’s 102 nuclear<br />

power plants is 52,” Reyes says. “There’s a tremendous need<br />

for new nuclear engineers and for medical physicists, who<br />

design radiation therapies.”<br />

Reyes’s department is soliciting funds to construct a new<br />

wing on the OSU Radiation Center to house a new Medical<br />

Physics program, a 300-seat auditorium, larger classrooms,<br />

and faculty <strong>of</strong>fices. The new wing would also free up existing<br />

space for desperately needed laboratories.<br />

“We’ve been converting lab space to <strong>of</strong>fice space to accommodate<br />

growth,” he says. “But we can’t keep doing that.”<br />

The ultimate change The department will be renamed the<br />

OSU School <strong>of</strong> Nuclear Science and <strong>Engineering</strong> to better<br />

reflect its leadership position as one <strong>of</strong> the top nuclear<br />

programs in the world.

F A C U L T Y<br />

MusicStrands<br />

Sing Loud, Sing Proud<br />

Cranking up the volume at the <strong>College</strong> <strong>of</strong> <strong>Engineering</strong><br />

I love rock n’ roll<br />

So put another dime<br />

in the jukebox, baby<br />

I love rock n’ roll<br />

So come an’ take your<br />

time an’ dance with me<br />

Joan Jett, the musical bombshell popular<br />

during the 1980s, sang “I Love Rock n’<br />

Roll,” and thousands <strong>of</strong> rock fans loved<br />

her for it. She belted out the lyrics in a<br />

loud unapologetic voice accompanied by<br />

a fast guitar, heavy base, and memorable<br />

drumbeat. Her music filled a niche in the<br />

male dominated world <strong>of</strong> rock and roll<br />

punk. Today, Jett’s unique sound is largely<br />

confined to the classic rock station, and<br />

the potential fans who just might love her<br />

music may never even hear her sing.<br />

MusicStrands, a new music recommendation<br />

s<strong>of</strong>tware company, could change that.<br />

The s<strong>of</strong>tware, which<br />

began as an idea at the<br />

<strong>College</strong> <strong>of</strong> <strong>Engineering</strong>,<br />

uses artificial intelligence<br />

to identify an individual’s<br />

listening patterns and<br />

generate new musical<br />

recommendations.<br />

“It’s all about music discovery,” says<br />

Jon Herlocker, a pr<strong>of</strong>essor in the School<br />

<strong>of</strong> Electrical <strong>Engineering</strong> and Computer<br />

Science, and one <strong>of</strong> the masterminds<br />

behind MusicStrands. “We asked, ‘How can<br />

we help people discover new music’ and<br />

what we’ve come up with is a way to assist<br />

in the creation <strong>of</strong> communities <strong>of</strong> interest<br />

around music.”<br />

Matt McLaughlin, Herlocker’s former<br />

master’s student and the current vice<br />

president <strong>of</strong> product innovations at<br />

MusicStrands, adds that the company<br />

is centered around helping individuals<br />

connect with one another through music.<br />

MusicStrands has <strong>of</strong>fices in Barcelona,<br />

Spain, and Corvallis, Ore. It employs<br />

44 people, several <strong>of</strong> whom graduated,<br />

taught, or conducted research at <strong>Oregon</strong><br />

<strong>State</strong> <strong>University</strong>’s <strong>College</strong> <strong>of</strong> <strong>Engineering</strong>.<br />

“OSU is where we all met,”<br />

says 25-year-old McLaughlin.<br />

“The <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> is<br />

very important as a connecting<br />

point for new ideas.”<br />

Matt McLaughlin (left) and Jon<br />

Herlocker describe the combination<br />

<strong>of</strong> music and artificial intelligence<br />

in MusicStrands.com as “fun.”<br />

The company continues to receive<br />

national media attention.<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

17

Kelley <strong>Engineering</strong> Center<br />

A NEW HOME FOR INNOVATION, DESIGNED FOR COLLABORATION AND CREATIVITY.<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

18<br />

Thanks to a $20 million lead gift from Judy and Martin Kelley<br />

(Civil <strong>Engineering</strong>, 1950), an additional $20 million in matching<br />

public funds from the citizens <strong>of</strong> <strong>Oregon</strong>, and $5 million<br />

in private gifts, the 153,000-sq.-ft. Kelley <strong>Engineering</strong> Center<br />

provides a dynamic new working and learning<br />

environment for students, faculty, and staff <strong>of</strong><br />

the OSU School <strong>of</strong> Electrical <strong>Engineering</strong><br />

and Computer Science.

A L U M N I<br />

Visualizing the Big Picture<br />

Jen-Hsun Huang<br />

CEO, President, and Co-founder<br />

It was in a circuit design class taught by <strong>Oregon</strong> <strong>State</strong> pr<strong>of</strong>essor<br />

Donald Amort that Jen-Hsun “Jensen” Huang<br />

(BS, 1984) first learned how to see and understand the<br />

big picture before diving into the details. It’s a lesson he<br />

uses everyday as co-founder and CEO <strong>of</strong> NVIDIA, the world<br />

leader in graphics processing technologies.<br />

“We had a hunch 13 years ago when we founded NVIDIA,<br />

that visualizing information—the visual experience you have<br />

with your computer, or any digital device—was going to be<br />

as important, if not more important, than the computational<br />

experience,” Huang says. “That hunch was right. We’ve<br />

now entered the post-computer era, the experiential era.”<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

“I was a sophomore engineering student, trained to analyze<br />

things down to three decimal points, and here was pr<strong>of</strong>essor<br />

Amort up at the board using such rough numbers that<br />

it was incredibly<br />

uncomfortable<br />

for me,” Huang<br />

says. “But in a<br />

way, how he<br />

taught that<br />

class really<br />

set me free.”<br />

“<strong>Oregon</strong> <strong>State</strong> is a wonderful<br />

school. The pr<strong>of</strong>essors have<br />

a balance <strong>of</strong> practicality and<br />

theory. They teach the theory,<br />

but are always trying to help<br />

you apply it.”<br />

As leader <strong>of</strong> a wildly successful semiconductor<br />

company with more than 2,500 employees and annual<br />

sales in excess <strong>of</strong> $2 billion, Huang says he has to focus on<br />

the big picture, and credits Amort with teaching him how<br />

to do that.<br />

“In my job, I have to analyze problems very quickly,” Huang<br />

says. “If you focus on the most important variables and<br />

don’t get bogged down by the minutia, it’s amazing what<br />

you can accomplish.”<br />

In his 42 years, Huang has accomplished much. The graphics<br />

processing units his company produces are found in<br />

products ranging from Micros<strong>of</strong>t’s Xbox and Motorola’s new<br />

3G cell phones to NASA workstations that help navigate<br />

the Mars Rover.<br />

Huang was raised in Taiwan and Thailand, son <strong>of</strong> an<br />

engineering father. At age 10, he came to the U.S., where<br />

an aunt and uncle in Tacoma, Wash. selected what they<br />

thought was a prep school in eastern Kentucky for Huang<br />

to attend. The school turned out to be closer to a reform<br />

school, where Huang shared a dorm room with a tattooed<br />

17-year-old who sported scars from knife wounds and<br />

couldn’t read. It was there that Huang learned about work<br />

ethic, scrubbing toilets and sweeping the halls every day<br />

after school.<br />

But it was at <strong>Oregon</strong> <strong>State</strong>, in an electromagnetics class<br />

taught by pr<strong>of</strong>essor Phil Magnuson, where Huang met his<br />

20

Jen-Hsun Huang’s journey from standout <strong>Oregon</strong><br />

<strong>State</strong> engineering student to leader <strong>of</strong> a highly<br />

successful Silicon Valley company is an example<br />

<strong>of</strong> what can happen when engineering and<br />

entrepreneurship come together.<br />

wife, Lori, when they were paired <strong>of</strong>f as lab partners. “That was the most important, single<br />

event <strong>of</strong> OSU, and <strong>of</strong> my life,” he says.<br />

Huang believes the <strong>College</strong>’s emphasis on basic principles, work ethic, collaboration, and<br />

business acumen are all important assets in the drive toward becoming a top-25 engineering<br />

program. “<strong>Oregon</strong> <strong>State</strong> is a wonderful school. The pr<strong>of</strong>essors have a balance <strong>of</strong> practicality<br />

and theory. They teach the theory, but are always trying to help you apply it.”<br />

As an engineer and entrepreneur, Huang has obviously done an extraordinary job<br />

applying what he’s learned.<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

21

O U T S T A N D I N G S T U D E N T S<br />

<strong>Engineering</strong><br />

Entrepreneur<br />

A student business makes a mark<br />

in the personal amplifier business<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

22<br />

Originally built in 1928, Weatherford Hall has been through two distinct renovations.<br />

The picturesque building is the current home <strong>of</strong> the Austin Entrepreneurship Program,<br />

a collaboration between the <strong>College</strong> <strong>of</strong> <strong>Engineering</strong>, the <strong>College</strong> <strong>of</strong> Business, and<br />

<strong>University</strong> Housing and Dining Services.

Most people who want to get a<br />

better sound out <strong>of</strong> their stereo<br />

systems buy a better stereo. Not<br />

Tyler Morita. He looked into the<br />

situation, discovered that an<br />

amplifier could solve the problem,<br />

then proceeded to build one—<br />

in an Altoid box—that worked so<br />

well he launched a new company<br />

to sell the devices.<br />

Morita, a junior in the School <strong>of</strong> Electrical<br />

<strong>Engineering</strong> and Computer Science, is<br />

founder, owner, and sole employee <strong>of</strong><br />

Z-audio, a company that produces<br />

customized musical amplifiers for personal music devices<br />

and stereo systems.<br />

“I wanted something to make the music sound better, richer,<br />

and more real,” he says <strong>of</strong> his initial wanderings into the<br />

world <strong>of</strong> amplifiers. “But it had to add quality, not just<br />

volume. After looking at commercial amps and doing a<br />

bunch <strong>of</strong> reading, I built my own and loved it. It actually<br />

ended up working better than the store-bought amp. Soon<br />

my friends were all asking me to build them one, and I just<br />

saw the potential in the market.”<br />

When Morita started Z-audio he was a double major in<br />

biology and music. The company led him to change his major<br />

to engineering, and to move into Weatherford Hall, home <strong>of</strong><br />

the Austin Entrepreneurship Program, the largest residential<br />

entrepreneurship program in the country.<br />

“I switched to engineering to learn more<br />

about building amplifiers,” Morita says.<br />

“I want to have the best product out there.”<br />

At Weatherford, Morita was given one <strong>of</strong><br />

the incubator suites, a large research and<br />

development space reserved for highly<br />

motivated students. Justin Craig,<br />

assistant pr<strong>of</strong>essor <strong>of</strong> entrepreneurship<br />

in the <strong>College</strong> <strong>of</strong> Business, took Morita<br />

under his wing and began introducing<br />

him to students enrolled in the business<br />

program. With students Brad Hubbard<br />

and Jared Yeck, Morita entered the<br />

Round Table Competition for business,<br />

winning second place and $1,000.<br />

The money went straight into the<br />

business along with investments made<br />

by Morita’s grandfather, Hubbard,<br />

and Yeck.<br />

“Once the business was really up and running, I bought out<br />

Brad and Jared’s shares,” Morita says. “Right now, I’m working<br />

on paying <strong>of</strong>f my initial investors. Each amp that I sell is<br />

broken into parts cost, payments, and living expenses.”<br />

Along with a second job at Starbucks to help pay the bills,<br />

Morita spends about 30-40 hours a week building amps<br />

and conducting Z-audio business. He prides himself on his<br />

customer service, and says that when someone makes a purchase<br />

from him they receive not only a high quality product,<br />

but also unlimited access to his expertise. His amplifiers have<br />

a devoted following, especially on the web, where he is known<br />

as a bit <strong>of</strong> a maverick. He says his next step is to focus on the<br />

marketing side <strong>of</strong> the business.<br />

“I hope to take this business as far as I can go,” he says.<br />

“At the very least I’d like to pay back<br />

my investors and have the business<br />

financially stable. I’m trying to make<br />

a name for myself.”<br />

Visit Z-audio on the web at:<br />

http://www.z-audio.com/<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

23

O U T S T A N D I N G S T U D E N T S<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

Home is Where<br />

the Heart Is<br />

This engineering student<br />

knows just where she’s<br />

supposed to be<br />

In her 20 years, Kremena Diatchka has called three countries<br />

on three different continents home. Diatchka, a senior in<br />

the School <strong>of</strong> Electrical <strong>Engineering</strong> and Computer Science<br />

was born in Bulgaria, moved to Zimbabwe when she was<br />

eight, then came to <strong>Oregon</strong> when she was 17 to study at the<br />

<strong>College</strong> <strong>of</strong> <strong>Engineering</strong>.<br />

She speaks English, Bulgarian, and a<br />

bit <strong>of</strong> Shona, the local language spoken<br />

in Harare, Zimbabwe, but claims<br />

her speech is imperfect in all <strong>of</strong> them.<br />

“Whenever I go back to Bulgaria to<br />

visit my relatives, they always ask me<br />

why I’m so quiet, or why I’m talking<br />

so slow,” she says. “Once I’m there a<br />

while, it’s a lot easier.”<br />

Diatchka is not the first member <strong>of</strong><br />

her family to pursue engineering.<br />

Her mother is a pr<strong>of</strong>essor <strong>of</strong> civil<br />

engineering and worked for several<br />

years at the <strong>University</strong> <strong>of</strong> Zimbabwe<br />

before transferring to the <strong>University</strong><br />

<strong>of</strong> Botswana, and her older brother<br />

graduated with a bachelor’s degree in<br />

computer science from the <strong>University</strong><br />

<strong>of</strong> Cape Town. He is currently working<br />

on a doctorate at Portland <strong>State</strong><br />

<strong>University</strong>.<br />

“In Bulgaria, your work doesn’t dictate<br />

who you are,” Diatchka says.<br />

“Whatever your career is, you can still<br />

be a fun sociable person. Here there is<br />

more <strong>of</strong> an ‘engineering personality.’<br />

A stereotype exists about nerdy boys<br />

being the only ones who are good at<br />

engineering.”<br />

Diatchka is proving that stereotype<br />

false. She is enrolled in OSU’s Honors<br />

<strong>College</strong> and is highly successful in<br />

her engineering coursework, maintaining<br />

a 4.0 GPA. Last summer, she<br />

spent several months at <strong>University</strong> <strong>of</strong><br />

Washington working with pr<strong>of</strong>essor<br />

Linda Shapiro on a bioinformatics<br />

project as part <strong>of</strong> the Distributed<br />

Mentor Project. At OSU she is part<br />

<strong>of</strong> the Computer Systems option in<br />

EECS, and she has briefly worked<br />

with pr<strong>of</strong>essor Jon Herlocker.<br />

The flexibility in the computer science<br />

program appeals to Diatchka, and she<br />

says two areas she’d like to explore<br />

are applying computer science to<br />

biological sciences and computational<br />

biology. Ultimately, she says she’d like<br />

to pursue a doctoral degree, before<br />

moving back to Bulgaria.<br />

“Living on three different continents<br />

gives you a unique perspective,”<br />

Diatchka says. “I’ve gotten to see all<br />

different cultures, and it’s really made<br />

me think about the world in a more<br />

open minded way. I’m really glad I<br />

came here—it’s been great for me.”<br />

24

O U T S T A N D I N G S T U D E N T S<br />

Cleaning Up What’s Left Behind<br />

A doctoral student from rural <strong>Oregon</strong><br />

works toward helping the planet<br />

Lots <strong>of</strong> people end up in jobs that create messes. Stephanie Harrington<br />

is working toward a career that cleans them up. As a doctoral student<br />

in the Dept. <strong>of</strong> Civil, Construction, and Environmental <strong>Engineering</strong>,<br />

Harrington’s passions, and her studies, revolve around cleaning up<br />

contaminations associated with radioisotopes, or radioactive materials.<br />

Harrington, who earned a bachelor’s in chemical engineering<br />

from <strong>Oregon</strong> <strong>State</strong>, first became interested in radiation<br />

and its associated complications as an OSU master’s student<br />

in environmental engineering. Her thesis project was on<br />

uranium transport, specifically how uranium moves through<br />

different media, like soils and groundwater.<br />

“I became so interested in my project that I realized this is<br />

what I wanted to do with my life,” Harrington says. “I love<br />

research. I like the hands-on, doing stuff in the lab. I like<br />

working on something that may make a difference. I think<br />

it’s fascinating. I love it.”<br />

For her doctoral research, Harrington is working under<br />

Brian Wood, a pr<strong>of</strong>essor <strong>of</strong> environmental engineering,<br />

studying contaminate transport <strong>of</strong> non-radioactive materials.<br />

Harrington says the work is applicable to her interest<br />

in radioisotopes, and it is easier to conduct the research<br />

when she doesn’t have to obtain special permissions.<br />

“Right now, we’re doing lab research, 3-D computer simulations,<br />

and mathematical modeling to see if we can come up<br />

with a good estimation <strong>of</strong> how long it takes a contaminate<br />

to reach the water system,” she says. “Hopefully we can help<br />

people better deal with spills in the real world.”<br />

Harrington grew up on five acres outside King’s Valley, Ore.,<br />

a small rural community west <strong>of</strong> Corvallis. Although she was<br />

always interested in science,<br />

even conducting experiments<br />

with a child’s science kit, she<br />

thought she would become a<br />

teacher. She claims she sort <strong>of</strong><br />

fell into engineering, and now<br />

spends a lot <strong>of</strong> time explaining<br />

to her family and friends what<br />

she does, and why she does it.<br />

Stephanie Harrington uses spheres<br />

made <strong>of</strong> heated sand to model the<br />

paths <strong>of</strong> contaminates through the<br />

environment.<br />

“My family is baffled—they have<br />

no idea what I’m talking about<br />

most <strong>of</strong> the time—they’re just<br />

proud <strong>of</strong> me,” she says, smiling.<br />

“My friends all joke with me about how I’m going to grow<br />

four arms and glow in the dark. It’s great.”<br />

Harrington estimates that finishing her doctoral degree<br />

will take about five years, but she’s in no hurry. She knows<br />

the work she’s doing has the potential to make the world a<br />

safer, healthier place for everyone.<br />

“Somebody has to figure out how to clean up all the messes<br />

we make,” she says. “We need to live in harmony with the<br />

environment, and growing up in <strong>Oregon</strong> that’s all I know.<br />

Being an environmental engineer is sort <strong>of</strong> like being a<br />

doctor, only to the planet, not to people.”<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

25

Team named semifinalist for $2 million prize in driverless race<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

26<br />

Members <strong>of</strong> the <strong>Oregon</strong> WAVE autonomous vehicle team pose with their<br />

driverless car in front <strong>of</strong> the OSU Valley Library. The team includes engineering<br />

students from a range <strong>of</strong> different disciplines, as well as pr<strong>of</strong>essional<br />

engineers.

It’s called “The Grand Challenge” for good reason. The <strong>of</strong>f-road course stretches 175<br />

grueling miles across the desert between LA and Las Vegas. Race teams don’t know the<br />

exact coordinates <strong>of</strong> the course until two hours before the start. And—here’s the kicker—<br />

each vehicle must be totally autonomous: no driver, no remote control, no human<br />

intervention <strong>of</strong> any kind once it leaves the starting line.<br />

Sound daunting<br />

It is. But the $2 million prize that DARPA<br />

(Defense Advanced Research Projects Agency)<br />

is <strong>of</strong>fering to the first vehicle to finish the race<br />

within 10 hours has attracted the best and brightest<br />

engineering talent from across the nation—<br />

including an OSU-based team <strong>of</strong> students,<br />

faculty, and area engineers. The <strong>Oregon</strong> WAVE<br />

(Willamette Autonomous Vehicle Enterprise) is<br />

one <strong>of</strong> 43 semifinalists winnowed from a field<br />

<strong>of</strong> almost 200 teams.<br />

“To be a semifinalist in our first year attempting<br />

this testifies to the creativity, ingenuity, and perseverance<br />

<strong>of</strong> the people involved,” says Belinda<br />

Batten, the team’s faculty advisor and head <strong>of</strong><br />

the Dept. <strong>of</strong> Mechanical <strong>Engineering</strong>. “It’s an<br />

incredible accomplishment just to have come this<br />

far. This is interdisciplinary, hands-on, teamworkdriven<br />

engineering education at its finest.”<br />

Without drivers, the vehicles must rely on hightech<br />

sensors, laser radar, and other sophisticated<br />

navigation equipment that can detect obstacles<br />

like barbed wire fences, boulders, trees, and<br />

livestock—then brake and steer clear. While some<br />

teams are using Humvees and large trucks packed<br />

with expensive electronics, the OSU team is<br />

betting that the small size and maneuverability<br />

<strong>of</strong> their vehicle will help it go the distance.<br />

“I knew this would be very tough because many<br />

<strong>of</strong> the other teams have a lot more resources<br />

than ours,” says Matt MacClary, team member<br />

and graduate student in the School <strong>of</strong> Electrical<br />

<strong>Engineering</strong> and Computer Science. “Our vehicle is<br />

one <strong>of</strong> the lightest and most fuel efficient in the<br />

running, so we’re hoping that pays <strong>of</strong>f.”<br />

The vehicle’s chassis is already a proven winner,<br />

having placed third out <strong>of</strong> 90 teams at the 2004<br />

SAE Mini-Baja West Competition, an <strong>of</strong>f-road race<br />

with human drivers. The <strong>Oregon</strong> WAVE team has<br />

spent months retr<strong>of</strong>itting the vehicle, replacing the<br />

driver’s seat, steering wheel, etc. with advanced<br />

electronics. Now the programming and algorithms<br />

must function flawlessly to successfully negotiate<br />

the course.<br />

“Whether we win or lose, this journey has been<br />

an incredible learning adventure for everyone,”<br />

Batten says.<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

27

<strong>College</strong> Pr<strong>of</strong>ile<br />

Faculty<br />

Tenured and Tenure Track________________113<br />

Other Faculty_ ________________________ 19<br />

Pr<strong>of</strong>essorships _________________________ 9<br />

Fellows <strong>of</strong> Pr<strong>of</strong>essional Societies _ _________ 25<br />

Members <strong>of</strong> National Academy ____________ 1<br />

Ocatve Levenspiel emeritus, NAE 2000<br />

Internships<br />

Approximately three-quarters <strong>of</strong> our graduates have experienced real-world<br />

internships working within industry while students. One-quarter <strong>of</strong> our<br />

bachelor’s graduates have participated in two 6-month internships through<br />

the Multiple <strong>Engineering</strong> Cooperative Program (MECOP) or the Civil<br />

<strong>Engineering</strong> Cooperative Program (CECOP), which are supported by<br />

more than 70 companies and organizations.<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

Students (Fall 2004)<br />

Undergraduate Women ________________ 370<br />

Undergraduate Men__________________ 2681<br />

Master’s Women_______________________ 67<br />

Master’s Men _______________________ 273<br />

Doctoral Women ______________________ 34<br />

Doctoral Men________________________ 168<br />

Total Students_____________3593<br />

Graduates (Spring <strong>2005</strong>)<br />

Bachelor’s Degrees ___________________ 516<br />

Master’s Degrees _____________________ 182<br />

Doctoral Degrees______________________ 25<br />

Total Degrees_______________ 723<br />

Alumni<br />

Number <strong>of</strong> Alumni _________________ 27,618<br />

Fundamentals <strong>of</strong> <strong>Engineering</strong> Pass Rate ___92%<br />

(National Average = 77%)<br />

National Academy <strong>of</strong> <strong>Engineering</strong> Members __18<br />

Rhodes Scholar: Debra Walt Johnson, BS EE 1994<br />

Financial Summary<br />

Total Revenue _____________________ $48 M<br />

Research Expenditures _______________ $24 M<br />

New Research _____________________ $26 M<br />

Research Clusters<br />

• Biological + Environmental Systems<br />

• Information Usability<br />

• Kiewit Center for Infrastructure + Transportation<br />

• Large-Scale Energy Systems<br />

• Mixed-Signal Integration<br />

• ONAMI@ OSU (<strong>Oregon</strong> Nanoscience + Microtechnologies Institute at OSU)<br />

Research Centers & Institutes<br />

• Advanced Thermal Hydraulics Research Laboratory<br />

• Center for Water + Environmental Sustainability<br />

• Center <strong>of</strong> Excellence for Advanced Materials Research<br />

• Extension Energy Program<br />

• Microproducts Breakthrough Institute<br />

• Mobile Technology Solutions Lab<br />

• Motor Systems Resource Facility<br />

• National Center for Accessible Transportation<br />

• Northwest Alliance for Computational Science + <strong>Engineering</strong><br />

• O.H. Hinsdale Wave Research Lab/Tsunami Wave Basin<br />

• <strong>Oregon</strong> Metals Initiative<br />

• <strong>Oregon</strong> Space Grant Program<br />

• Parallel Tools Consortium<br />

• Radiation Center<br />

• Western Region Hazardous Substances Research Center<br />

28

Statistics<br />

Long Range Plan<br />

700<br />

350<br />

number <strong>of</strong> degrees<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

516 545 590<br />

389<br />

’99<br />

’05<br />

GOAL<br />

Undergraduate Degrees<br />

number <strong>of</strong> degrees<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

320<br />

207 215<br />

164<br />

’99<br />

’05<br />

GOAL<br />

Graduate Degrees<br />

millions <strong>of</strong> dollars<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

24<br />

20.5<br />

12<br />

’99<br />

’05<br />

70<br />

GOAL<br />

Research Expenditures<br />

millions <strong>of</strong> dollars<br />

200<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

109<br />

’05<br />

180<br />

GOAL<br />

Top-25 Campaign Fundraising<br />

Public and private to date<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

29

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

30<br />

Leadership<br />

<strong>College</strong> <strong>of</strong> <strong>Engineering</strong> Leadership Team<br />

Ron Adams<br />

Dean, <strong>College</strong> <strong>of</strong> <strong>Engineering</strong><br />

Belinda Batten<br />

Head, Mechanical <strong>Engineering</strong><br />

Chris Bell<br />

Associate Dean<br />

John Bolte<br />

Head, Biological + Ecological<br />

<strong>Engineering</strong><br />

Bella Bose<br />

Associate Director,<br />

School <strong>of</strong> Electrical <strong>Engineering</strong><br />

+ Computer Science<br />

Terri Fiez<br />

Director, School <strong>of</strong> Electrical<br />

<strong>Engineering</strong> + Computer Science<br />

Ken Funk<br />

Interim Head, Industrial<br />

+ Manufacturing <strong>Engineering</strong><br />

Jennifer Hall<br />

Exec. Asst. for Administration<br />

Jim Lundy<br />

Associate Dean<br />

Top-25 Campaign Cabinet<br />

Ken Austin, Joan Austin<br />

A-dec, Inc.<br />

Jim B. Johnson<br />

Tripwire, Inc.<br />

Pete Johnson<br />

TEKMAX, Inc.<br />

Connie Kearney<br />

Lee Kearney<br />

Peter Kiewit Sons’, Inc. (retired)<br />

Martin Kelley<br />

Peter Kiewit Sons’, Inc. (retired)<br />

Ellen Momsen<br />

Director, <strong>Engineering</strong> Women<br />

+ Minorities Program<br />

Marnie Noble<br />

Director <strong>of</strong> Development,<br />

OSU Foundation<br />

Cherri Pancake<br />

Director <strong>of</strong> IT<br />

<strong>College</strong> <strong>of</strong> <strong>Engineering</strong><br />

Roy Rathja<br />

Assistant Dean/Head Adviser<br />

<strong>Engineering</strong> Undergraduate Programs<br />

Gordon Reistad<br />

Associate Dean<br />

José Reyes<br />

Head, Nuclear <strong>Engineering</strong> + Radiation<br />

Health Physics<br />

Steve Tesch<br />

Head, Forest <strong>Engineering</strong><br />

Ken Williamson<br />

Interim Head, Chemical <strong>Engineering</strong><br />

Head, Civil, Construction +<br />

Environmental <strong>Engineering</strong><br />

Paul Lorenzini<br />

PacifiCorp (retired)<br />

Steve Nigro<br />

Hewlett-Packard Company<br />

Jim Poirot<br />

CH2M HILL (retired)<br />

Judy Street, Jim Street<br />

Shell Oil Company (retired)<br />

<strong>College</strong> Advisory Board<br />

Kay E. Altman<br />

CFO, Altman Browning + Company<br />

JJ Cadiz<br />

Usability Engineer, Micros<strong>of</strong>t<br />

Mark Christensen<br />

President,<br />

Global Capital Management, LLC<br />

Ron Dilbeck<br />

COO, RadiSys Corporation<br />

Dwayne Foley<br />

NW Natural/OSU Alumni Assoc.<br />

(retired)<br />

James A. Johnson<br />

Vice President,<br />

Intel Communications Group<br />

Intel Corp.<br />

James B. Johnson<br />

(Board Chair)<br />

President and CEO, Tripwire, Inc.<br />

Lee Kearney<br />

Kiewit Construction Group, Inc.<br />

(retired)<br />

Martin N. Kelley<br />

Peter Kiewit Sons’, Inc. (retired)<br />

Jim Lake<br />

Associate Lab Director,<br />

Idaho National Laboratory<br />

Mark A. Lasswell<br />

President, OMI, Inc.<br />

Sue Laszlo<br />

Manager, Design Services<br />

Port <strong>of</strong> Portland<br />

Paul Lorenzini<br />

PacifiCorp (retired)<br />

Jeff Manchester<br />

Fort James Corp. (retired)<br />

Jeff Peace<br />

Program Manager, 767 Tanker<br />

The Boeing Company<br />

Jim Poirot<br />

CH2M HILL (retired)<br />

Hal Pritchett<br />

OSU Construction Engr. Mgt. (retired)<br />

Rod Quinn<br />

Director, Process Science + <strong>Engineering</strong><br />

Pacific Northwest National Laboratory<br />

Scott R. Schroeder<br />

President/CEO, Mega Tech <strong>of</strong> <strong>Oregon</strong><br />

David Skillern<br />

NetApp<br />

Milton R. Smith<br />

President<br />

Smith Investments<br />

Randall Smith<br />

IDC<br />

Jim Street<br />

Shell Oil Company (retired)<br />

Lester M. Tovey<br />

MECOP Board Chair– Rotation Term<br />

Jean Watson<br />

Chevron (retired)<br />

Mike West<br />

VP Technology, Pixelworks<br />

Robert Wilson<br />

R.C. Wilson Construction<br />

Ted Wilson<br />

HP Fellow + Technology Director<br />

Imaging + Printing Group<br />

Hewlett-Packard Company

Located in <strong>Oregon</strong>’s lush<br />

Willamette Valley, an<br />

hour south <strong>of</strong> Portland,<br />

the OSU <strong>College</strong> <strong>of</strong><br />

<strong>Engineering</strong> emphasizes<br />

innovative learning and<br />

teaching to develop<br />

graduates who are truly<br />

work-ready. The university’s<br />

location <strong>of</strong>fers easy<br />

access to some <strong>of</strong> the<br />

nation’s most breathtaking<br />

scenery, including<br />

the Pacific Ocean and the<br />

Cascade mountains.<br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

31

Mission<br />

Driven by a passion for knowledge, the people <strong>of</strong> OSU <strong>Engineering</strong><br />

are fully committed to developing extraordinary engineers,<br />

creating powerful new ideas from research, and fueling innovation<br />

that is truly visionary — all to build a better future for <strong>Oregon</strong><br />

and the world.<br />

People. Ideas. Innovation.<br />

OSU <strong>College</strong> <strong>of</strong> <strong>Engineering</strong><br />

O r e g o n S t a t e U n i v e r s i t y <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>2005</strong> Annual Report<br />

32<br />

<strong>Oregon</strong>’s highest peak, Mount Hood, rises to<br />

11,249 feet (3,429 meters) near Lost Lake..