ROwe FaRMS - Ontario Independent Meat Processors

ROwe FaRMS - Ontario Independent Meat Processors

ROwe FaRMS - Ontario Independent Meat Processors

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

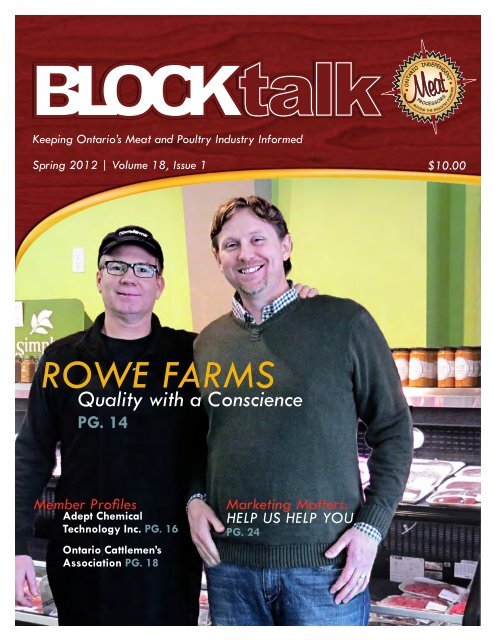

Keeping <strong>Ontario</strong>’s <strong>Meat</strong> and Poultry Industry Informed<br />

Spring 2012 | Volume 18, Issue 1 $10.00<br />

Rowe Farms<br />

Quality with a Conscience<br />

PG. 14<br />

Member Profiles<br />

Adept Chemical<br />

Technology Inc. PG. 16<br />

<strong>Ontario</strong> Cattlemen’s<br />

Association PG. 18<br />

Marketing Matters:<br />

Help US Help You<br />

PG. 24

INSIDE THE i<br />

“VC999’s new i-Series is the talk of the packaging industry for 2012!”<br />

VC999 Canada Ltd. 153 Sylvestre St. Germain De Grantham Quebec, J0C 1K0 Canada<br />

Phone 819-395-4555 Email Sales.Canada@VC999.com Website www.VC999.com<br />

NEW i-Series<br />

OPERATING<br />

SYSTEM IS<br />

IMPRESSIVE!<br />

VC999’s new i-Series Thermoformer<br />

has hit the marketplace running in 2012.<br />

The company’s new thermoformer is<br />

considered to be the most advanced in<br />

the industry.<br />

The features of the new i-Series<br />

includes a new, more reliable PLC<br />

platform. This model operates with the<br />

new i-Software design which helps to<br />

navigate the HMI machine interface, on<br />

an industrial PC, with ease.<br />

The new design also features a swingarm<br />

mounted, 12.1 LED back-lit color<br />

monitor with an HMI Machine interface<br />

which is mounted in a IP65 stainless<br />

steel enclosure.<br />

The system also operates on the Windows<br />

XPe operating system which further<br />

adds to its ease of operation. Data back<br />

ups are done via a USB memory stick.<br />

The PLC also has an intelligent Buss<br />

terminal system with diagnostics.<br />

Intelligent and comprehensive zone specific<br />

safety design, with PLC control, is<br />

another innovative feature of the i-Series<br />

Thermoformer. This new design allows<br />

for fewer connection points and less wiring<br />

resulting in reduced maintenance and<br />

easier troubleshooting for customers.<br />

The ultra-high speed of the PLC is<br />

designed with a 1 gigabyte Ethernet Field<br />

Buss CC link in an IE field. This is ten<br />

times faster communication than similar<br />

thermoformer models on the market<br />

today. This feature provides control of<br />

remote I/O field devices with essentially<br />

no transmission delay. The information<br />

management design of the new i-Series<br />

features production alarm data acquisition<br />

and data storage features that can<br />

be accessed via PC or a cellular device.<br />

An industrial LAN router design allows the<br />

new i-Series to have remote Internet access.<br />

The router detects the IP address<br />

automatically.<br />

The IP65 rated i-Cabinets are easy<br />

to access and strategically located at<br />

dedicated machine sections. The cabinet<br />

features a swing-out pneumatic panel<br />

for easy maintenance. The specially<br />

designed i-Closing mechanism assures<br />

a tight closing, IP65 wash down rating.<br />

The new i-Series has comprehensive<br />

training available at the manufacturing<br />

facility in Missouri or on-site at the<br />

installation location. Maintenance and<br />

service is even easier with access to<br />

service manuals online, on CD or in print.<br />

Real-time assembly QA documentation,<br />

maintenance logs and service history are<br />

also available online.<br />

The new i-Series even comes with its<br />

own SKYPE connection. A high-quality<br />

headset with microphone comes standard<br />

with each machine.<br />

SERIES<br />

Scan the QR Code above with your smart<br />

phone to learn more, or visit our website<br />

at www.VC999Global.info.<br />

Advertisement<br />

2 BLOCKtalk - Spring 2012<br />

www.oimp.ca

Spring 2012 | Volume. 18, Issue 1<br />

Administration<br />

Board of Directors<br />

Index<br />

EXECUTIVE DIRECTOR | Laurie Nicol<br />

laurie.nicol@oimp.ca<br />

TECHNICAL DIRECTOR | Daphne Nuys-Hall<br />

technical@oimp.ca<br />

MEAT EXTENSION SPECIALIST |<br />

Graham Delziel<br />

extension@oimp.ca<br />

MARKETING AND COMMUNICATIONS<br />

DIRECTOR | Heather Nahatchewitz<br />

heather@oimp.ca<br />

MEMBERSHIP COORDINATOR |<br />

Janet Wellwood<br />

info@oimp.ca<br />

Marketing & Design CoordinaTOR |<br />

Nikki Stager<br />

n.stager@oimp.ca<br />

<strong>Ontario</strong> <strong>Independent</strong> <strong>Meat</strong> <strong>Processors</strong><br />

7660 Mill Road<br />

Guelph, <strong>Ontario</strong> N1H 6J1<br />

Tel: (519) 763-4558<br />

Toll: (800) 263-3797<br />

Fax: (519) 763-4164<br />

www.oimp.ca<br />

news@oimp.ca<br />

BLOCKtalk is the official publication of the<br />

OIMP, distributed to over 550 OIMP members,<br />

commodity groups, and others throughout<br />

the industry, providing excellent advertising<br />

opportunities for suppliers of the meat and<br />

poultry industry to promote their newest, most<br />

innovative, supplies, equipment, and technology.<br />

BLOCKtalk encourages Associate Members and<br />

supporters of the industry to submit articleswhich<br />

would be beneficial to our members.<br />

BLOCKtalk ads must be sent electronically and<br />

properly sized high resolution (300 dpi) in<br />

either a .jpg, .tiff, or .PDF format.<br />

PUBLICATION ADVERTISING DEADLINE<br />

Spring February 15<br />

Summer May 15<br />

Fall august 15<br />

Winter November 15<br />

The information published in BLOCKtalk is<br />

compiled from a variety of sources, which we<br />

believe to be reliable; however, OIMP does not<br />

guarantee, and assumes no responsibility for, the<br />

correctness of the information.<br />

Keep Us Informed<br />

Your input is essential to produce the best<br />

newsletter possible! If you know of a newsworthy<br />

person or event, please contact us.<br />

PRESIDENT | Joe Abate<br />

Abate Packers - Arthur<br />

PAST PRESIDENT | Tony Facciolo<br />

Holly Park <strong>Meat</strong> Packers - Caledon<br />

VICE PRESIDENT | Walter Mueller Jr.<br />

Springer’s <strong>Meat</strong>s Inc. - Hamilton<br />

SECRETARY/TREASURER |<br />

Cory Van Groningen<br />

VG <strong>Meat</strong>s - Simcoe<br />

DIRECTORS<br />

Betty Dikeos<br />

D & D Poultry - Toronto<br />

Carol Goriup<br />

Florence <strong>Meat</strong> Supplies - Oakvile<br />

Richard Halenda<br />

Halenda’s Fine Foods - Oshawa<br />

John Koch<br />

Walnut Hill Farm - Gads Hill<br />

Marc Oliver<br />

Sargent Farms - Milton<br />

Luis Pavao<br />

Salsicharia Pavao - Toronto<br />

Orry Wagenhammer<br />

Wagener’s <strong>Meat</strong> Products - Toronto<br />

OIMP Vision<br />

Provide leadership for <strong>Ontario</strong>’s meat<br />

and poultry industry by fostering<br />

innovation, promoting food safety and<br />

integrity and recognizing excellence.<br />

OIMP Mission<br />

Strengthen <strong>Ontario</strong>’s meat and poultry<br />

industry by working with stakeholders,<br />

responding to challenges and identifying<br />

opportunities on behalf of the membership.<br />

OIMP Core Strategies<br />

• Member Relations<br />

• Industry and Government Relations<br />

• Industry Development<br />

• Market Development<br />

4 President’s Message<br />

4 Executive Director Report<br />

5 Welcome to the Association<br />

6 Member Achievements<br />

7 OIMP Technical Talk: Communication is a<br />

Dialogue not a Monologue<br />

9 Safety First: Repetitive Strain Injuries<br />

10 Food Handler Training Workshops<br />

11 2012 OIMP Workshop Series<br />

12 New FPS Program<br />

13 You - Yes You are an AOFP Member<br />

14 Rowe Farms, Quality with a Conscience<br />

16 Adept 3<br />

Chemical Technology Inc.<br />

18 OCA - Committed to Cattlemen<br />

19 Steak Sandwich Recipe<br />

20 Understanding Risk Management<br />

21 Funding Programs<br />

22 Changes to <strong>Meat</strong> Plant Guidelines<br />

22 CFIA Industry Information Session<br />

23 Names in the News<br />

24 Marketing Matters: Help Us Help You<br />

26 Advertiser Index<br />

3 BLOCKtalk - Spring 2012<br />

www.oimp.ca

On the ground running<br />

In their first month, our new team<br />

members Daphne Nuys-Hall, OIMP<br />

Technical Director, and Graham Dalziel,<br />

OIMP <strong>Meat</strong> Extension Specialist, have<br />

made 30 plant visits and addressed 42<br />

issues/questions, the majority of which<br />

have been regarding labelling, programs<br />

and written protocols, blueprints and<br />

construction, and licensing and new<br />

builds. This outreach is an effective way<br />

for you to get answers to your operational<br />

questions, and for OIMP to know about<br />

industry issues. Chances are someone<br />

else may be facing a similar issue and<br />

we have been able to provide assistance,<br />

or when necessary, have influenced<br />

regulatory changes. I encourage you to<br />

give them a call or invite them to your<br />

plant for a visit.<br />

At our recent Board Meeting Mike<br />

Cassidy, from OMAFRA, gave a<br />

presentation on Risk Assessment and<br />

how government uses this process,<br />

providing an example of determining<br />

frequency of inspection in meat plants.<br />

As family-owned business operators it<br />

is very important that we have a good<br />

understanding of how to evaluate risks.<br />

We need to pay close attention to: What<br />

could go wrong How likely is it to<br />

happen What would be the consequence<br />

if it did happen This will help us to make<br />

business decisions in a proactive manner<br />

and minimize our risks. Succession<br />

planning, preparing for a recall, or crisis<br />

communications management are all<br />

things we should be looking at before<br />

something happens, not in hindsight.<br />

Joe Abate<br />

OIMP President<br />

Together We’re Stronger<br />

Member Directories<br />

For a complete list of OIMP Business and Associate<br />

members please visit the Members Only section of<br />

www.oimp.ca<br />

Business Members - 190<br />

Affiliate Members - 7<br />

Associate Members - 59<br />

Contact us and ask how you can help increase our voice in<br />

the industry. If you require membership literature, please<br />

let us know.<br />

Member Help line: 1-800-263-3797<br />

info@oimp.ca * www.oimp.ca<br />

OIMP Lifetime Members<br />

OIMP presents the prestigious Lifetime Membership<br />

Award to individuals who have made outstanding<br />

contributions to the Association and <strong>Ontario</strong>’s meat and<br />

poultry industry.<br />

• Ron Deeth (1995) • Leo Rocheleau (2001)<br />

• Dr. Ron Usborne (1996) • Gerry Houtzager (2003)<br />

• Nancy Ackert (1997) • Pat Johnson (2005)<br />

• Jim Vidoczy (2000) • Tony Facciolo (2011)<br />

Make the most of your member<br />

benefits<br />

OIMP Long Time Members<br />

Thank you to our long time members who have been<br />

helping move the industry forward for over 25 years.<br />

To ensure we are continually providing<br />

the most valuable programs and services<br />

to our members we have reevaluated a<br />

number of benefits, made some positive<br />

changes, and encourage you to get<br />

involved and make the most of your<br />

membership entitlements.<br />

Within our member communications<br />

strategy, we have added new Training<br />

and Technical eBulletins, in addition<br />

to BLOCKtalk and UPDATE, and<br />

are committed to providing timely<br />

information on our website.<br />

As part of market development, we<br />

encourage Business Members to take<br />

advantage of the OIMP Branding<br />

programs including Homegrown<br />

<strong>Ontario</strong>, <strong>Ontario</strong> Finest <strong>Meat</strong><br />

Competition Award Winning Product,<br />

and <strong>Ontario</strong>’s Heritage <strong>Meat</strong>; and to<br />

help raise the profile of the association<br />

by displaying OIMP Proud Member on<br />

your website and in-store signage.<br />

OIMP hosts events throughout the<br />

year including The <strong>Meat</strong>ing Place, our<br />

annual conference, which will take<br />

place November 2-4 at Hockley Valley<br />

Resort and provide a perfect setting for<br />

networking, with a dynamic line up of<br />

educational presentations and table top<br />

displays.<br />

We look forward to seeing you at the<br />

OIMP Annual General Meeting - State<br />

of the Industry, on April 20 to see what<br />

your organization has been working on,<br />

and hear from industry professionals on<br />

issues affecting the industry.<br />

Laurie Nicol<br />

Executive Director<br />

• The Beef Way, Kincardine - Member since 1979<br />

• <strong>Ontario</strong> Pork, Guelph - Member since 1980<br />

• Gord’s Abattoir, Leamington - Member since 1982<br />

• Rudolph’s Fine <strong>Meat</strong>s, Sudbury - Member since 1982<br />

• Abattoir Brisson, Embrun - Member Since 1986<br />

• Holly Park <strong>Meat</strong> Packers, Caledon - Member Since 1986<br />

• L’Orignal Packing, L’Orignal - Member Since 1986<br />

• MMIS/MONDO, Aurora - Member Since 1986<br />

• Nitta Casings, Markham - Member Since 1986<br />

• Walnut Hill Farms, Gads Hill - Member Since 1986<br />

<strong>Meat</strong> Industry Achievement (MIA) AWARD Recipients<br />

• 2007 - Leo Rocheleau, Maidstone<br />

• 2008 - Stemmler’s <strong>Meat</strong> & Cheese, Heidelberg<br />

• 2009 - VG <strong>Meat</strong>s, Simcoe<br />

• 2010 - Springer’s <strong>Meat</strong>s, Hamilton<br />

• 2011 - Halenda’s Fine Foods, Oshawa<br />

4 BLOCKtalk - Spring 2012<br />

www.oimp.ca

Welcome to the Association<br />

Building an informed and engaged membership representing a diverse<br />

<strong>Ontario</strong> meat and poultry industry.<br />

Business Members<br />

HARRISTON PACKING COMPANY<br />

Contact:<br />

Mark Oelschlagel<br />

Address: 142 Arthur St. Box 194<br />

Harriston, ON N0G 1Z0<br />

Tel: (519) 338-3330<br />

Fax: (519) 338-3525<br />

Type of Operation: Slaughter, Processing<br />

Inspection: Provincial Abattoir Est #: 143<br />

Product Line:<br />

BBQ Hog, Beef, Lamb, Pork<br />

Value Added:<br />

Bacon, Deli Mixed, Ham,<br />

Salami, Sausage<br />

Sales Category: Wholesale, Retail, Custom<br />

Size of Operation: < 10 employees<br />

Established: 1967<br />

Associate Members<br />

ALLTECH CANADA INC.<br />

Contact:<br />

Christina Couture<br />

Address:<br />

20 Cutten Place<br />

Guelph, ON N1G 4Z7<br />

Tel: (519) 763-3331<br />

Fax: (519) 763-5682<br />

Toll: (800) 285-8617<br />

Email:<br />

ccouture@alltech.com<br />

Website:<br />

www.alltech.com<br />

Supplier Category: Other<br />

Alltech Canada Inc. has, for over 30 years, researched, developed<br />

and manufactured natural animal food ingredients. Their<br />

commitment to scientific exploration has resulted in several<br />

ground-breaking solutions to serious and costly animal health and<br />

performance problems.<br />

OIMP appreciates the strong support from our commodity partners “Working Together, Moving the Industry Forward”<br />

OIMP Annual General Meeting<br />

April 20, 2012<br />

10:30 am - 3:30 pm<br />

Cambridge, <strong>Ontario</strong><br />

OIMP Annual Conference<br />

The <strong>Meat</strong>ing Place<br />

November 2-4, 2012<br />

Hockley Valley Resort<br />

Orangeville, <strong>Ontario</strong><br />

For more information about either event contact the office, Tel: (519) 763-4558, Email: info@oimpca<br />

5 BLOCKtalk - Spring 2012<br />

www.oimp.ca

Member<br />

Achievements<br />

Fostering innovation, promoting integrity, and recognizing excellence.<br />

other opportunities; we wish him all the best and thank<br />

him for his continued support over the years. We look<br />

forward to the same long lasting relationship with the<br />

Henschels.<br />

Celebrating 50 Years of<br />

Strength, Commitment and<br />

Determination<br />

Etnico Foods in Wal-Mart<br />

Sister company to GTA <strong>Meat</strong> Supply, Etnico Foods can now be found in<br />

Wal-Mart. In the words of owner Mike Pietrantonio, “We can finally say our<br />

little ‘trippa’ company is no longer selling just ‘trippa’!” Mike also thanks all<br />

involved for making this goal a reality.<br />

Chef Bashford wins round ten of<br />

Discovered Culinary Competition<br />

Chef Michael Bashford, catering manager at Beretta Farms, is one of 16<br />

contestants to compete in the semi-finals in the Discovered Culinary<br />

Competition held at the CRFA Show, March 4 - 6.<br />

The Discovered Culinary Competition is a four-month search for the best<br />

of Canada's up-and-coming culinary stars. The winning chef will get the<br />

opportunity of a lifetime: an all-expenses-paid trip to spend a week cooking<br />

at a Michelin-star restaurant in northern Spain.<br />

The Beef Way<br />

Mike Pietrantonio, owner, GTA <strong>Meat</strong> Supply, Etnico Foods<br />

Congratulations to Rob and Melynda Henschel on the purchase of The Beef<br />

Way in Kincardine. The Beef Way has been a major part of the OIMP family<br />

since the Association’s inception in 1979.<br />

For the past 15 years, Bill Kranenburg has been the owner/operator of this<br />

custom meat processing plant and retail store. Bill has decided to pursue<br />

That was the theme of<br />

the <strong>Ontario</strong> Cattlemen’s<br />

Association’s 50th AGM,<br />

celebrated in Toronto<br />

late February. During the<br />

AGM, the association held elections for Board members<br />

and welcomed Dan Darling of Castleton as OCA<br />

President for 2012. Elected as Vice President was Bob<br />

Gordanier of Dufferin County, and two new faces were<br />

welcomed to the Board, Steve Eby of Bruce County, and<br />

Tim Fugard of Lambton County.<br />

makin’<br />

headlines<br />

Celebrating an accomplishment<br />

Or know someone who is We<br />

would love to share with the<br />

industry your special event,<br />

milestone or triumph on our<br />

Member Achievements page.<br />

Members are encouraged to<br />

submit photos and highlights to<br />

the OIMP office at<br />

news@oimp.ca, to be published<br />

in the next BLOCKtalk issue.<br />

6 BLOCKtalk - Spring 2012<br />

www.oimp.ca

- OIMP Technical Talk -<br />

Communication is a Dialogue<br />

not a Monologue<br />

By Daphne Nuys-Hall, OIMP Technical Director<br />

Communication is a key component of<br />

any business or organization. In order to<br />

sell a product or service we must be able<br />

to effectively deliver a message to our<br />

customers in order to attract their attention<br />

and convince them to purchase or utilize<br />

our product or service. Communication is<br />

essential with our suppliers as well in order<br />

to ensure that we are receiving the products<br />

and services that we need to produce our<br />

products.<br />

“For communication<br />

to be effective, the<br />

message must mean<br />

the same thing to both<br />

the sender and the<br />

receiver.”<br />

Communication is also important<br />

in developing our relationships with<br />

government agencies that are responsible<br />

for the oversight of the regulatory<br />

compliance of our businesses with key<br />

pieces of legislation. The meat industry<br />

is challenged with communication with<br />

numerous regulatory bodies on an on-going<br />

basis and it is essential for us to develop the<br />

relationships necessary to ensure business<br />

continuity and success.<br />

Communicating effectively with inspectors<br />

and other representatives at various levels<br />

of government is an essential business tool.<br />

It enables us to understand the regulatory<br />

requirements that we are required to follow,<br />

any deficiencies that require corrective<br />

actions and up-coming regulatory changes<br />

that may impact our operations.<br />

The goals between both the inspector<br />

and the operator should be the same –<br />

producing a safe and wholesome food<br />

product in the most cost effective, efficient<br />

manner in a safe working environment. By<br />

communicating on an on-going basis you<br />

can build a relationship with your inspector<br />

that can benefit not only the daily operation<br />

but the safety and quality of the products<br />

you are manufacturing and selling.<br />

7 BLOCKtalk - Spring 2012<br />

Be sure you make the most of your time<br />

with your inspector. The following are<br />

items that could be discussed in order to<br />

make the time more valuable:<br />

1. Outstanding CAP Items – It is important<br />

to keep yourself up to date on any<br />

outstanding CAP items and expected<br />

completion dates to ensure timely closure<br />

of these items.<br />

2. Inspection Report Findings – Discuss<br />

what items the inspector has identified<br />

that day as noncompliant and the ways in<br />

which they will be addressed.<br />

3. Any changes to the facility, products or<br />

processes. It is important to communicate<br />

these changes to your inspector in the<br />

event that the changes could have an<br />

impact on Food Safety or be subject to<br />

regulations.<br />

4. Ask your inspector about any upcoming<br />

changes to the regulations or guidelines<br />

that may impact your business. This<br />

timely communication will avoid any<br />

surprises that could cause potential<br />

disruption in business.<br />

Specifically in establishing your<br />

relationship with OMAFRA there are<br />

several communication vehicles available<br />

to the operator:<br />

1. FSDSS - An electronic database in which<br />

OMAFRA records Plant Information<br />

including CAP and Inspection<br />

Report findings and corrective action<br />

completion dates. FSDSS can be accessed<br />

by the Operator (request your password<br />

from OMAFRA) for review and the<br />

opportunity to input comment.<br />

2. Inspection Reports – A report that is<br />

completed by the inspector each visit to<br />

the plant noting any observations that<br />

require corrective action by the operator.<br />

This document is signed by both the<br />

inspector and operator with copies left<br />

with the operator and in the Plant Log<br />

Book.<br />

3. Plant Log Book – A binder containing<br />

pertinent information for the plant, e.g.<br />

inspection reports, approved operational<br />

controls. Review this regularly with your<br />

inspector to ensure that it is up to date<br />

and complete.<br />

4. Corrective Action Plan – A document<br />

completed at the end of the audit which<br />

records the findings of the audit and<br />

the agreed upon completion dates for<br />

corrective action by the operator.<br />

As a meat plant operator, there may be<br />

instances when you feel your concerns are<br />

not being addressed to your satisfaction<br />

after you have attempted to resolve<br />

problems or disagreements through<br />

discussion and conciliation with your<br />

meat inspector. OMAFRA wants to help<br />

you and has options in place to assist<br />

you. For more information, please refer<br />

to the Complaint Resolution Process for<br />

<strong>Meat</strong> Plant Operators Information Sheet<br />

available both on the OMAFRA website<br />

and in the Members Only Section of the<br />

OIMP website.<br />

Communication is a dialogue, not a<br />

monologue. In fact, communication is<br />

more concerned with a dual listening<br />

process. For communication to be effective,<br />

the message must mean the same thing<br />

to both the sender and the receiver. Make<br />

sure that when discussing issues with the<br />

inspector that you understand what they<br />

are asking you or telling you and that they<br />

understand your message as well. This<br />

two way communication will build long<br />

lasting, constructive relationships which<br />

will enhance your ability to effectively<br />

operate your business.<br />

Daphne Nuys-Hall<br />

OIMP Technical Director<br />

(519) 763-4558 ext. 222<br />

technical@oimp.ca<br />

www.oimp.ca

8 BLOCKtalk - Spring 2012<br />

www.oimp.ca

- Safety First -<br />

Repetitive Strain Injuries<br />

By Doug Johnson, Health & Safety Consultant<br />

For many years now we have been hearing<br />

more about ergonomic injuries such as<br />

back and shoulder strains and carpal<br />

tunnel syndrome. In <strong>Ontario</strong>, these injuries<br />

are grouped under the classification of<br />

Repetitive Strain Injuries (RSI’s).<br />

RSI’s are disorders of the bones, joints,<br />

ligaments, tendons, muscles and other<br />

soft tissues of the body. These disorders<br />

develop over time as a result of the<br />

cumulative effects of repetitive, stressful or<br />

awkward movements that wear down the<br />

musculoskeletal system. Injuries can range<br />

from very minor all the way to completely<br />

debilitating.<br />

Often described as lower back pain or<br />

other disorders of the back, carpal tunnel<br />

syndrome, bursitis, tendonitis, white finger,<br />

and sprains and strains, studies have shown<br />

that about 30% of all injuries are classified<br />

as RSI’s. In light of the frequency, WSIB has<br />

an initiative to reduce the frequency and<br />

severity of these injuries.<br />

WSIB wants employers and workers to<br />

think about the work situation and the<br />

hazards. The only way to eliminate or<br />

reduce hazards is to first recognize that<br />

hazards exist. Although we often think that<br />

this is the responsibility of the employer,<br />

it is everyone’s responsibility - employers,<br />

managers, supervisors, and workers.<br />

To be able to identify potential RSI’s,<br />

and avoid WSIB claims, every workplace<br />

participant must be aware of the types of<br />

things that could cause an RSI – things like<br />

repetitive motion that requires the use of<br />

the same muscles over and over again.<br />

It is important to look at the tasks to see<br />

if there is an excessive amount of pulling,<br />

pushing or lifting that is required to complete<br />

the job. Do the tasks require workers to<br />

adopt awkward or uncomfortable postures,<br />

including bending, reaching, or working<br />

with a wrist in an awkward position<br />

Do workers spend a lot of time sitting or<br />

standing or reaching above their shoulders<br />

Are workers exposed to hand-arm and/or<br />

whole-body vibration<br />

During your observations make note of<br />

how workers feel. Do workers tell you that<br />

their neck and/or shoulders hurt or ache<br />

Or is there an indication that workers are<br />

experiencing numbness or tingling in their<br />

hands and fingers Each human body is<br />

unique and will react differently to the<br />

stresses of work and the work environment.<br />

Workers may experience many different<br />

signs or symptoms associated with the<br />

development of RSI’s, including pain,<br />

discomfort, fatigue, swelling, tingling,<br />

numbness, and shooting pain down the legs<br />

and buttocks.<br />

The simple rule is “fit<br />

the job to the worker,<br />

not the worker to the<br />

job.”<br />

It is important to realize that the pain and<br />

suffering associated with RSI’s impairs the<br />

injured worker’s ability to work. Many<br />

early signs or symptoms of RSI’s are not<br />

recognized or reported and often workers<br />

will work in pain. They will not report the<br />

early signs of RSI’s as they either do not<br />

recognize them or they are trying to keep<br />

up with other workers.<br />

Many RSI’s are preventable. Designing<br />

work and workstations to fit worker’s<br />

physical capabilities is essential. Workers<br />

possess a great deal of knowledge about<br />

their jobs and their capabilities, so they<br />

should have input into workstation design.<br />

Workers must also be trained in proper<br />

work procedures for specific tasks. These<br />

procedures must be properly designed and<br />

should be periodically reviewed by the Joint<br />

Health and Safety Committee or health and<br />

safety representative.<br />

The simple rule is “fit the job to the worker,<br />

not the worker to the job”.<br />

If you have questions or concerns give me a<br />

call. Let’s look forward to an early spring!!<br />

Doug Johnson<br />

Health & Safety Consultant<br />

Tel: (519) 837-0997<br />

doug@safetaid.ca<br />

Resources:<br />

Ministry of Labour<br />

labour.gov.on.ca<br />

WorkSmart<strong>Ontario</strong><br />

worksmartontario.gov.on.ca<br />

Health & Safety <strong>Ontario</strong><br />

healthandsafetyontario.ca<br />

Workplace Safety<br />

Insurance Board<br />

wsib.on.ca<br />

SAFETAID<br />

safetaid.ca<br />

9 BLOCKtalk - Spring 2012<br />

www.oimp.ca

Does your staff have the skills and knowledge required to ensure<br />

safe food for your customers Does your management team have<br />

the leadership to properly develop and execute a food safety<br />

program<br />

Food Handler Training Workshops<br />

for Workers and Supervisors<br />

ABOUT THE WORKSHOP<br />

The Workshops focus on five key areas that<br />

are critical for those working in the food<br />

processing industry:<br />

1. Food Safety Responsibilities<br />

2. Food Safety Hazards<br />

3. Controlling Hazards<br />

4. Food Safety Management Systems<br />

5. Management’s Responsibilities for<br />

Food Safety<br />

The Workshop offers an interactive<br />

learning environment, is instructor led, and<br />

delivered in English.<br />

Meets the training requirements within<br />

<strong>Ontario</strong> <strong>Meat</strong> Regulation 31/05 and is<br />

We are<br />

ALL responsible<br />

for Food Safety<br />

accredited with Toronto Public Health as<br />

meeting the requirements in City of<br />

Toronto Municipal Code Chapter 545,<br />

Licensing.<br />

WORKERS AND SUPERVISORS<br />

1.5 days for workers, providing everything<br />

they need to know about food safety; and 2<br />

days for supervisors, focusing specifically<br />

on their responsibility within a food safety<br />

and management role.<br />

Presentation slides, workbook and<br />

examination are available in 10 languages:<br />

English, French, German, Italian, Polish,<br />

Portuguese, Punjabi, Simplified Chinese,<br />

Spanish and Traditional Chinese.<br />

TESTING YOUR UNDERSTANDING<br />

The Workshop prepares you for the Food<br />

Handler Training examination, taken<br />

immediately following the workshop. Upon<br />

successful completion, workers will receive<br />

a Certificate of Completion issued through<br />

the University of Guelph, Ridgetown<br />

Campus.<br />

WORKSHOP DATES<br />

April 11 - 12, 2012<br />

September 12 - 13, 2012<br />

HOW TO REGISTER<br />

To register for a Food Handler Training<br />

Workshop visit www.oimp.ca and<br />

download a registration form or call the<br />

OIMP office (519) 763-4558 to request<br />

one.<br />

TESTIMONIALS<br />

“Concise - Worth taking the time off<br />

work.”<br />

“The instructor has in-depth<br />

knowledge of the program.”<br />

“Covered the entire gamet of food<br />

safety with just the right level of<br />

information.”<br />

“Real stories about people affected by<br />

lack of food safety.”<br />

“Learning new areas of food safety.<br />

This was a great course and I would<br />

recommend it.”<br />

Helping You Put the Pieces Together<br />

10 BLOCKtalk - Spring 2012<br />

www.oimp.ca

11 BLOCKtalk - Spring 2012<br />

Get the most<br />

out of your employees!<br />

Reduce Turnover<br />

Boost Morale<br />

Increase Productivity<br />

Performance Management Workshop<br />

Wednesday March 21, 2012<br />

1:00 p.m. to 4:00 p.m.<br />

Four Points by Sheraton, Mississauga Meadowvale<br />

Who Should Attend<br />

Small business owners/managers, Human<br />

Resource personnel, Supervisors<br />

Cost<br />

$75.00 Business Members<br />

$125.00 Non-Members<br />

Register<br />

Registration is required as space is limited. To register, visit<br />

oimp.ca and download a form, or email info@oimp.ca.<br />

Registration Deadline<br />

Wednesday, March 14, 2012<br />

Key Learning Objectives<br />

• Understand performance management essentials<br />

• Learn components of an effective<br />

performance appraisal system<br />

• Discover how to have meaningful performance appraisal<br />

discussions with different types of performers<br />

• Find out how to give feedback in a way<br />

that improves performance<br />

Presented by<br />

Jeff Fila, Manager, Professional Development<br />

Conestoga College Institute of Technology and<br />

Advanced Learning<br />

Alliance of <strong>Ontario</strong> Food <strong>Processors</strong><br />

Do you know how<br />

to determine shelf life<br />

Meet Regulatory Requirements<br />

Ensure Product Quality<br />

Guarantee Consumer Satisfaction<br />

Design a Shelf Life Study Workshop<br />

Wednesday, April 18, 2012<br />

1:00 p.m. to 4:00 p.m.<br />

Guelph, ON<br />

Who Should Attend<br />

Small business owners/operators, HACCP<br />

Coordinators, Quality Assurance personnel<br />

Cost<br />

$75.00 Business Members<br />

$125.00 Non-Members<br />

Register<br />

Registration is required as space is limited. To register, visit<br />

oimp.ca and download a form, or email info@oimp.ca.<br />

Registration Deadline<br />

Wednesday, April 11, 2012<br />

Key Learning Objectives<br />

• Recognize which micro-organisms could<br />

impact the shelf life of products<br />

• Learn how to develop and execute<br />

reliable in-house shelf life studies<br />

• Find out what type of data to collect<br />

• Understand how to use the information collected<br />

to establish the shelf life of products<br />

Presented by<br />

Maxxam Analytics<br />

Upcoming Workshops<br />

Product Costing and Accounting, May 16<br />

Social Media, June 15<br />

Allergen Control, July 18<br />

Fermentation and Dry Curing, August 15<br />

www.oimp.ca

New<br />

FPS Program<br />

Designed to meet the needs of industry,<br />

Conestoga’s new Food Processing<br />

Supervisor (FPS) program, the first of<br />

its kind in <strong>Ontario</strong>, is now accepting<br />

applications for its second intake beginning<br />

in May 2012.<br />

Designed to provide individuals with the<br />

knowledge and skills essential to effectively<br />

conduct supervisory activities in a food<br />

processing environment, the part-time<br />

continuing education program is the only<br />

certificate program in the province catering<br />

specifically to the industry.<br />

According to Susan McLachlan,<br />

Communications Officer for IFPT, the<br />

demand for such a program has never been<br />

higher.<br />

“The food processing industry has<br />

identified the need for such a program in<br />

different studies conducted in the last 3-5<br />

years,” she said. “Many current middle<br />

management positions are filled with<br />

employees that were promoted based on<br />

performance, but who were not further<br />

trained for the specific needs of the<br />

positions. Our program is designed to fill<br />

that gap.”<br />

The program, which will use case studies<br />

and practical application of supervisory<br />

skills related to the food processing<br />

environment, will benefit individuals<br />

new to the industry, as well as those with<br />

previous experience who are looking to<br />

gain a competitive advantage.<br />

Luis Garcia, Chair of IFPT, said the<br />

program will not only prepare graduates<br />

for the challenges they will encounter on a<br />

day-to-day basis, but will also give them the<br />

skills and experience required to manage<br />

an entire team.<br />

“The program will<br />

provide them with tools<br />

to complement their<br />

previous experience and/<br />

or education, for growth<br />

into senior management<br />

positions.”<br />

“The program will provide them with tools<br />

to complement their previous experience<br />

and/or education, for growth into senior<br />

management positions,” he said. “The<br />

industry recognizes a need for enhancing<br />

the soft skill base of their supervisors<br />

and middle management through formal<br />

training to add value to their operation and<br />

improve their competitiveness.”<br />

The program consists of ten mandatory<br />

courses and can be completed in as few as 16<br />

months. The courses, which were designed<br />

around the most current trends in the food<br />

processing industry, include everything<br />

from Food Safety 101 and Employment<br />

Law to Developing Effective Teams and<br />

Project Management. All of the program’s<br />

instructors have extensive, hands-on<br />

managerial experience in the industry, and<br />

small class sizes ensure a more interactive<br />

and hands-on learning environment.<br />

“Graduates will have been exposed to case<br />

studies and real-life examples that will<br />

enhance their ability to secure a qualified<br />

position in industry,” said Garcia. “The<br />

program will provide graduates with a<br />

certificate that will enhance their resume<br />

when looking for interview opportunities.”<br />

For more information about the program<br />

please contact the Institute of Food<br />

Processing Technology.<br />

Taken from a story by Ryan Bowman, a firstyear<br />

student in Conestoga’s Journalism-Print<br />

program.<br />

850 Fountain Street South<br />

Cambridge, ON N3H 0A8<br />

Tel: (519) 748-5220<br />

ifpt@conestogac.on.ca<br />

12 BLOCKtalk - Spring 2012<br />

www.oimp.ca

YOU - YES YOu<br />

are an AOFP Member<br />

In 2003, the Alliance of <strong>Ontario</strong> Food <strong>Processors</strong> (AOFP) was<br />

created to address issues of common concern across the food and<br />

beverage processing industry.<br />

OIMP, along with the <strong>Ontario</strong> Dairy Council, the Association<br />

of <strong>Ontario</strong> Chicken <strong>Processors</strong>, the <strong>Ontario</strong> Fruit and Vegetable<br />

<strong>Processors</strong> Association, the <strong>Ontario</strong> Wine Council, and the Baking<br />

Association of Canada, are the founding members of AOFP.<br />

What that means is all business members of OIMP are automatically<br />

members of AOFP, receiving all the benefits of AOFP membership.<br />

Associate members of OIMP can join as associate members of<br />

AOFP at a reduced rate. Individual processing companies are also<br />

welcome to join.<br />

Benefits of being an AOFP member are numerous. With over 650<br />

members, AOFP is a credible voice to government, advocating on<br />

behalf of the industry and raising its profile as an economic driver in<br />

<strong>Ontario</strong>. AOFP offers tools and resources addressing key concerns<br />

for the industry including business management, environment,<br />

and human resources. Additionally, events and seminars are held<br />

throughout the year giving processors the opportunity to network<br />

with other leaders in the industry.<br />

Among AOFP’s successes are the creation of the Institute of<br />

Food Processing Technology at Conestoga College; the Food<br />

and Beverage Innovation Fund, a $3 million federal/provincial<br />

program to support innovation and skills development; and the<br />

Southern <strong>Ontario</strong> Development Program for Food <strong>Processors</strong>,<br />

which provided $20 million to support growth of the sector.<br />

AOFP Road Show<br />

In January, members of the industry met in Leamington, <strong>Ontario</strong> at<br />

the first AOFP Road Show event. The event focussed on providing<br />

“... all business members of OIMP<br />

are automatically members of AOFP,<br />

receiving all the benefits of AOFP<br />

membership.”<br />

processors with information about AOFP and industry, the recently<br />

released Labour Market Report conducted by the Canadian Food<br />

<strong>Processors</strong> Human Resource Council, and information about<br />

human resources management tools.<br />

2012 Golf Tournament<br />

Save the date! The <strong>Ontario</strong> Food Industry Golf Tournament will<br />

be held May 29 at Whistle Bear Golf Club in Cambridge. Hosted<br />

annually by AOFP and the <strong>Ontario</strong> Fruit and Vegetable <strong>Processors</strong><br />

Association, the golf tournament is a great opportunity to network<br />

with leaders in the food and beverage processing industry and<br />

enjoy a fun day of golf. Sponsorship and registration information is<br />

available at www.aofp.ca.<br />

For more information about how your membership in AOFP can<br />

benefit you and your business, visit www.aofp.ca or call our office<br />

at (519) 650-3741.<br />

850 Fountain Street South<br />

Cambridge, ON N3H 0A8<br />

Tel: (519) 650-3741<br />

info@aofp.ca<br />

Taste the Future<br />

Opportunities in <strong>Ontario</strong>’s Food & Beverage Processing Industry<br />

Post your jobs for FREE at<br />

Contact Mary Feldskov at AOFP to learn how.<br />

Tel: (519) 650-3741 * Email: mfeldskov@aofp.ca<br />

13 BLOCKtalk - Spring 2012<br />

www.oimp.ca

- Business Member Spotlight -<br />

Left to right: Doug Whyte, COO and Jamie Cooney, CEO<br />

Rowe Farms<br />

Quality with a Conscience<br />

Rowe Farms’ Guelph location is small and<br />

unobtrusive in its corner location of the<br />

plaza. In fact, if you’re not looking for it,<br />

you could miss it. But that doesn’t matter<br />

as the majority of Guelph’s clientele isn’t<br />

walk-in. The customers coming to Rowe<br />

already know what they want and make it<br />

a destination when shopping for their meat<br />

and poultry products, some coming from<br />

as far as Windsor, and often for special<br />

occasion purposes.<br />

Guelph is just one retail location of seven,<br />

the rest primarily in the GTA, including<br />

the St. Lawrence Market (Saturday’s only).<br />

From a logistics perspective, when asked<br />

why they would keep a Guelph location, the<br />

answer was simple, “because this is where it<br />

14 BLOCKtalk - Spring 2012<br />

all started” on a 150 acre<br />

beef farm, just northeast<br />

of Guelph in 1973. And<br />

the Guelph community<br />

repays that loyalty with<br />

their own.<br />

Following in his father, veterinarian Dr.<br />

Ken Rowe’s, tradition, John Rowe started<br />

farming because he wanted “to grow<br />

food he felt safe about”. A little over five<br />

years ago, when John was just 60, he took<br />

on equity partners in order to grow the<br />

business. Today, under the direction of<br />

Jamie Cooney, CEO, and Doug Whyte,<br />

COO, the business is thriving with further<br />

expansion in the GTA planned for the retail<br />

platform.<br />

“Membership with the OIMP is<br />

important because it connects us<br />

with processors and suppliers we can<br />

develop partnerships with, and learn<br />

from.”<br />

-Jamie Cooney, CEO<br />

When asked about their impressive titles,<br />

jean-clad Jamie and Doug both laughed.<br />

Although they hold important positions<br />

critical to the growing business, the two<br />

are much more laid back then you might<br />

expect from partners. All said, the pride<br />

and passion in the business was undeniable<br />

and the willingness to step in wherever<br />

necessary to ensure a smooth operation was<br />

apparent. Having both come from Loblaws,<br />

www.oimp.ca

they also have experience and insight necessary to compete in the<br />

incredibly competitive grocery business.<br />

When Jamie was asked what he would tell his younger self of five<br />

years ago, the answer came quick, “Be patient and positive. It’s a<br />

slow process and a long haul.” An interesting juxtaposition to his<br />

response regarding his personal philosophy, “Believe in what you<br />

do.”<br />

So what does Rowe Farms believe in Rowe believes in managing<br />

the animal from farm to store to ensure their strict standards are<br />

adhered to at every step. With 25 farms to keep track of, Rowe<br />

employs a Director of Farm Relations, responsible for farm<br />

communications and issues management. The Director is also<br />

in charge of the animal welfare audits, with standards written<br />

by Rowe, but based on the EU. To ensure compliance for other<br />

health claims and to meet CFIA labelling requirements, Rowe<br />

also has third party audits performed as required on all farms.<br />

Rowes’ meat and poultry is processed at various plants across<br />

<strong>Ontario</strong> and are under similar scrutiny as the farmers growing<br />

the animals. For example, processors are required to process<br />

Rowe meats during the first shift of the day to ensure Rowe<br />

product is not mixed with conventionally-raised protein, lending<br />

further integrity to claims including antibiotic and growth<br />

hormone-free.<br />

The business position is that local has become an even bigger<br />

food movement than organic. “Our customers want to connect<br />

with their food. As long as they know and trust the farmer,<br />

they are less concerned about whether the product is organic,”<br />

says Cooney. Walking the walk, Rowe believes in carrying<br />

complementary products from local artisan companies that follow<br />

the same philosophy of ensuring sustainable farms and supporting<br />

the local economy - even if that means stocking vegan soup in a<br />

butcher shop!<br />

Although the flattened, pre-seasoned chicken is a big hit with<br />

Toronto consumers, Whyte’s personal favourite product is a bonein<br />

pork chop from a Tamworth hog. His response couldn’t have<br />

been more genuine as Whyte enthusiastically went on to describe<br />

the process involved in producing a Tamworth, the fact that it’s<br />

raised outdoor and forage fed leading to a fattier breed with great<br />

marbling. Cooney readily concurred.<br />

The profile of Rowe’s best customer is a soccer mom, aged 30-45,<br />

looking for healthier options for her family and is willing to spend<br />

a bit more on something she feels good about serving. Rowe’s<br />

philosophies and business practices ensure that not only these,<br />

but all <strong>Ontario</strong> consumers have the option to choose ‘quality with<br />

a conscience’.<br />

1027 Gordon Street<br />

Guelph, ON N1G 4X1<br />

Tel: (519) 822-2171<br />

info@rowefarms.ca<br />

www.rowefarms.ca<br />

15 BLOCKtalk - Spring 2012<br />

www.oimp.ca

- Associate Member Spotlight -<br />

ADEPT 3 Chemical Technology INC.<br />

Specialists in Food Plant Sanitation and in-Process Food Safety<br />

“Adept mantra -<br />

Opportunity is missed by most<br />

because it is dressed in overalls<br />

and looks like work.”<br />

But how can you have the best of both worlds Simple. Adept has<br />

adopted a utilitarian business model where spending only adds<br />

value to the customer or the program and costs are controlled by<br />

eliminating the wasteful practices of unnecessary management,<br />

packaging, warehousing, inefficient distribution, blue skies<br />

research, and flashy marketing.<br />

Mike Brock, President, Adept Chemical Technology<br />

One might assume a company that offers premium chemical<br />

systems is focused more on product than service, more about the<br />

literature and less about relationship building, but with Adept you<br />

get both. Mike Brock, President and CEO feels, “we are letting the<br />

electronic age play a slightly too important role in our lives,” and<br />

goes on to say, “I believe in personal contact with people, getting to<br />

know them as people, not just as an email address. I truly believe if<br />

you put others first you will be rewarded for it in time.”<br />

And an impressive client list including Maple Leaf, Cargill, Pinty’s<br />

Delicious Foods and Lilydale Poultry proves Adept is advanced<br />

enough to work with the big guns but small enough to appreciate the<br />

great value in serving the needs of independent meat processors.<br />

In fact, in Brock’s words, “It is a simple synergy equation, we need<br />

you to help us grow and survive, and you need us to help compete<br />

with the major processors and process safe foods.”<br />

Their best kept secret Due in part to a strategic decision to focus on<br />

product and program development that pertained more to daytime<br />

food safety issues and a little less on simple sanitation products,<br />

Adept has become experts in chlorine dioxide technologies and<br />

have since worked with Health Canada and the CFIA to bring<br />

state of the art peroxyacetic acid technologies to the carcass<br />

Chlorine Dioxide Dip Tank<br />

Raw Storage<br />

16 BLOCKtalk - Spring 2012<br />

www.oimp.ca

At ADEPT 3 We Believe:<br />

Your best interest is served by utilizing premium quality products combined with proven application techniques, and supported by<br />

professional services. This enables controlled costs, high performance, and high value in your program.<br />

Our best interest is served by providing the appropriate products and services to support your requirements as defined together.<br />

This facilitates both of our Adept goals; satisfied customers and our mutual sustainability.<br />

Our collective best interest is served by creating an atmosphere of trust and constant diligence towards achieving the common<br />

goals of our program. This fosters the building of long-standing relationships by providing high value and exemplary performance<br />

every day.<br />

treatment forefront. Plants are converting<br />

to these two technologies at a very rapid<br />

rate as the technical effect now achieved<br />

enables compliance with the most stringent<br />

regulations at well under the maximum<br />

allowable CFIA limit.<br />

When asked to describe the future of the<br />

industry Brock responded, “It is clear that<br />

an even more thorough focus on food<br />

safety will be required by all processors<br />

as we address an ever increasing number<br />

of pathogenic organisms of concern,<br />

combined with ever increasing more<br />

stringent regulations to address these<br />

organisms. I believe strongly that those<br />

who embrace this challenge will survive,<br />

and those who do not will vanish from our<br />

landscape... There is no silver bullet and no<br />

real “easy” answers. Nothing will be more<br />

important than the processors’ dedication<br />

to food safety over the coming decades.”<br />

505 McGregor Ave.<br />

London, ON N6J 2S9<br />

Tel: (519) 645-9999<br />

Toll: (888) 990-2999<br />

www.adeptchemical.com<br />

.<br />

,<br />

i<br />

S<br />

17 BLOCKtalk - Spring 2012<br />

www.oimp.ca

- Affiliate Member Spotlight -<br />

Committed to<br />

CattlemEn<br />

and retain a group of visionary organization<br />

leaders who are capable of moving the<br />

<strong>Ontario</strong> beef industry forward. The pilot<br />

program will increase the leadership<br />

skills of existing or potential organization<br />

leaders, and better prepare leaders to move<br />

the industry forward in times of change or<br />

challenge.<br />

The <strong>Ontario</strong> Cattlemen’s Association (OCA)<br />

is a grassroots organization representing<br />

all beef producers in the province and<br />

provides leadership to cattlemen from all<br />

sectors of the industry. OCA is involved in<br />

a number of initiatives to assist producers in<br />

improving the longevity and success of their<br />

individual operations, as well as the entire<br />

beef industry in the province.<br />

<strong>Ontario</strong>’s Risk Management Insurance<br />

Program (RMIP)<br />

Perhaps OCA’s most significant<br />

accomplishment in 2011 was the<br />

establishment and implementation of a<br />

permanent Risk Management Insurance<br />

Program (RMIP) for all non-supply<br />

managed commodities. For over two<br />

years the OCA memberships’ number one<br />

priority with government was to establish<br />

a permanent RMIP. Premiums have been<br />

announced for the 2012 program and<br />

applications will be due in March for those<br />

producers wishing to participate in the<br />

insurance based program.<br />

Government Relations<br />

OCA will be working closely with the<br />

Minister of Agriculture, Food and Rural<br />

Affairs, The Honourable Ted McMeekin,<br />

and all MPPs to discuss plans for agriculture<br />

and the beef sector moving forward and to<br />

ensure they are up to speed on the issues<br />

facing our members.<br />

Federally, OCA continues to be involved<br />

in an MP Working Group with a number<br />

of other <strong>Ontario</strong> agricultural commodities.<br />

The MPs involved have an interest in<br />

<strong>Ontario</strong> agriculture and desire to represent<br />

<strong>Ontario</strong> farming and its unique needs<br />

to Minister Ritz and their urban and<br />

rural caucus. This collaboration allows<br />

all participants to discuss and explore<br />

avenues for improving<br />

the business risk<br />

management programs<br />

that are available to<br />

<strong>Ontario</strong> producers.<br />

Leadership<br />

Development<br />

Program<br />

In collaboration with<br />

the Rural <strong>Ontario</strong><br />

Institute (ROI), OCA<br />

has committed to<br />

the development and<br />

implementation of a<br />

pilot program to recruit<br />

The concept of this program arose from<br />

a county resolution brought forward to<br />

OCA. The program will be accepting 40<br />

participants in 2012 (20 in the spring and<br />

20 in the fall) and training will be provided<br />

on effective communications, meeting<br />

management, organization governance, and<br />

beef industry issues. The spring program<br />

began in January and will wrap-up in April.<br />

OCA will be accepting applications for the<br />

fall program in the summer of 2012.<br />

<strong>Ontario</strong> Corn-Fed Beef<br />

OCA continues to support the <strong>Ontario</strong><br />

Corn-Fed Beef Program, established to<br />

provide a high-quality, premium branded,<br />

beef program for the <strong>Ontario</strong> marketplace.<br />

OCA was pleased to see that one of Canada’s<br />

largest grocery retailers introduced <strong>Ontario</strong><br />

Corn-Fed Beef in over 150 retail locations<br />

across the province in the summer of 2011.<br />

With retail sales exceeding expectations,<br />

this is a great opportunity to grow and<br />

strengthen our entire beef industry.<br />

<strong>Ontario</strong> Corn Fed Beef display in Loblaws stores across <strong>Ontario</strong><br />

18 BLOCKtalk - Spring 2012<br />

www.oimp.ca

Biosecurity<br />

OCA continues to work with the sheep, veal,<br />

goat and rabbit commodities on Phase II of<br />

a biosecurity gap analysis project, which<br />

assesses the on-farm biosecurity practices<br />

and emergency response capabilities for the<br />

cow-calf, backgrounder and feedlot sectors<br />

in <strong>Ontario</strong>. A new cost calculator model is<br />

now available to help the livestock industry<br />

put a price tag on disease outbreaks. The<br />

program, built in an Excel spreadsheet, will<br />

calculate the cost of moderate or severe<br />

outbreaks of specific diseases on beef, veal,<br />

sheep, goat, and rabbit<br />

farms. This includes Bovine<br />

Viral Diarrhea (BVD) and<br />

mycoplasmosis in cattle.<br />

Producers can visit www.<br />

agbiosecurity.ca for more<br />

information.<br />

Supporting the<br />

Development of<br />

Calf Clubs to Foster<br />

Improved Margins for<br />

Cow Calf Producers<br />

The <strong>Ontario</strong> feedlot sector<br />

requires approximately 600,000 feeder<br />

cattle per year. With the <strong>Ontario</strong> beef cow<br />

herd being less than 350,000, there is a great<br />

potential for <strong>Ontario</strong> cow-calf producers to<br />

meet an obvious need.<br />

Since 2010, OCA has worked with selected<br />

cow-calf producers to develop (and expand<br />

existing) calf clubs that will raise similartype<br />

cattle under defined protocols with<br />

the intent of placing attractive sized lots<br />

of preconditioned <strong>Ontario</strong> calves into<br />

special calf sales. Participating producers<br />

have been encouraged to get involved<br />

in benchmarking surveys and grazing<br />

mentorship relationships. We have been<br />

building upon the premise ID information<br />

that has been gathered through past<br />

programs to enhance the traceability aspect<br />

of these calf clubs. This project will give us<br />

documented evidence to show <strong>Ontario</strong>’s<br />

cow-calf producers that being proactive and<br />

working together can result in improved<br />

profitability. It will show producers clear<br />

steps they can take in order to increase their<br />

returns, and meet the needs of <strong>Ontario</strong>’s<br />

feedlots.<br />

130 Malcolm Rd.<br />

Guelph, ON N1K 1B1<br />

Tel: (519) 824-0334<br />

www.cattle.guelph.on.ca<br />

Steak SandwichES<br />

Quick and easy to prepare, they offer the perfect weeknight meal for families on the go.<br />

Ingredients:<br />

2 8 oz (250 g) <strong>Ontario</strong> strip<br />

loin steaks, trimmed<br />

2 tsp (10 mL) olive oil<br />

1/2 tsp (2 mL) salt<br />

1/2 tsp (2 mL) cracked black pepper<br />

1 tbsp (15 mL) butter<br />

2 large onions, sliced<br />

2 tsp (10 mL) chopped fresh thyme<br />

1 red bell pepper, sliced<br />

6 crusty buns<br />

3 oz (75 g) crumbled blue cheese<br />

Preheat oven to 350°F (180°C).<br />

Rub steaks with olive oil and season with salt and<br />

pepper. Leave out at room temperature for 30<br />

minutes.<br />

In large heavy skillet, melt butter over mediumhigh<br />

heat. Add onions and thyme, cook until<br />

onions are golden, about 10 minutes. Add<br />

red pepper, cook one minute. Reduce heat to<br />

medium-low, stirring occasionally, until peppers<br />

are very tender, about 15 minutes.<br />

Transfer to oven and cook until desired doneness,<br />

about 5 minutes for medium rare. Let rest for 10<br />

minutes before thinly slicing.<br />

Slice buns in half lengthwise. Divide steak over<br />

each bottom bun and top with onion mixture.<br />

Sprinkle evenly with crumbled cheese. Cover with<br />

bun tops. Serve with a crisp green salad.<br />

Makes 6 servings.<br />

Meanwhile, heat ovenproof skillet over mediumhigh<br />

heat, add steaks and sear on both sides until<br />

well browned, about 2 minutes per side.<br />

19 BLOCKtalk - Spring 2012<br />

To use OIMP recipes and photos in your own<br />

communications contact media@oimp.ca<br />

www.oimp.ca

Understanding<br />

Risk Management<br />

Risk management, or risk assessment, are terms used by businesses<br />

and governments around the world to describe a process of<br />

identification, assessment, and prioritization of events that may<br />

have an impact, negative or positive, on the goals or outcomes of<br />

the business.<br />

The following diagram illustrates the Food Safety Risk Management<br />

Framework OMAFRA utilizes.<br />

Risk Management requires forward thinking and a proactive<br />

approach to management that focuses on prevention, rather than<br />

reaction. Organizations that manage risks have a greater likelihood<br />

of achieving their objectives and desired results.<br />

The aim is not to eliminate risk. It is to assist people to manage<br />

the risks involved in all activities to maximize opportunities and<br />

minimize adverse consequences.<br />

Business is not alone in the utilization of Risk Management Tools<br />

and the Board of Directors of OIMP was fortunate to have a<br />

presentation delivered by Mike Cassidy, Coordinator from the Food<br />

Safety Science Unit of the Food Inspection Branch of OMAFRA, on<br />

what is Risk Management and how the <strong>Ontario</strong> Government uses<br />

Risk Management tools as a Regulatory Agency to evaluate, assess,<br />

and manage risk.<br />

The <strong>Ontario</strong> Public Service believes:<br />

• that the adoption of a formal approach to risk management will<br />

improve decision-making, performance and accountability; and<br />

• that success in managing risk will result in improvements in the<br />

quality of government services and the effectiveness of public<br />

policy.<br />

More specifically, the benefits of effective risk management include:<br />

• improved transparency in decision-making (thereby increasing<br />

accountability);<br />

• effective and efficient allocation of resources;<br />

• more creative and innovative management practice;<br />

• increased standards of client service; and<br />

• the capacity to manage in the face of competing obligations.<br />

Risk management refers to a systematic and explicit approach used<br />

for identifying, analyzing and controlling risk.<br />

The risk management process produces two main outputs:<br />

• Understanding about risks.<br />

• Controlling actions.<br />

Risk management is an important element of overall good<br />

management and will continue to be an integral part of management<br />

processes in many governments in Canada and abroad. The goal<br />

is better decisions, supported by a risk management process and<br />

rigour.<br />

20 BLOCKtalk - Spring 2012<br />

The Risk Management Process traditionally begins with<br />

establishing context:<br />

1. State or clarify your objective.<br />

2. Identification and description of issues, problems or<br />

scenarios potentially posing a risk to that objective.<br />

May arise through a variety of means, e.g. program<br />

review, incident reports, or audit results.<br />

3. Risk Assessment is undertaken to answer three basic questions:<br />

• What could go wrong (Risk identification)<br />

• How likely is it to happen (Probability/<br />

likelihood of occurrence)<br />

• What would be the consequence if it did happen (Impact)<br />

• Risk = Likelihood of Occurrence x Impact<br />

4. Results of the Risk Assessment are evaluated and<br />

analyzed. The Risk Assessment guides decisions to<br />

be made respecting the need for risk mitigation or<br />

changes to existing risk mitigation approaches.<br />

5. The risks are monitored and reviewed and will cycle<br />

through again periodically for continuous improvement.\<br />

Mike Cassidy demonstrated to the Board of Directors the use of<br />

the Risk Assessment process utilized by OMAFRA to determine<br />

the Frequency of Inspection of FSMPs. The following are the steps<br />

that OMAFRA used:<br />

Risk Identification:<br />

• Consideration for previous OMAFRA ‘informal’ work<br />

(Category 1 and 2 already based on risk) and work of others<br />

www.oimp.ca

FUNDING PROGRAMS<br />

A list of current funding programs available to the industry.<br />

• Consideration of various risk factors<br />

and assessed risk associated with each<br />

(so weighting could be assigned)<br />

• Split into<br />

▶ ▶‘Intrinsic’ risk factors:<br />

• Processes used and type of<br />

meat products produced<br />

• Volume<br />

• Potential for crosscontamination<br />

(with RTE)<br />

• Distribution<br />

• Source of meat<br />

▶▶Risk mitigation factors:<br />

• Inspection compliance history<br />

• Operator & staff food safety<br />

knowledge and application<br />

• Regulatory water and<br />

RTE testing results<br />

• Manufacturing controls or<br />

food safety programs practiced<br />

• Audit history<br />

Risk Assessment and Prioritization of<br />

Plants:<br />

Area managers, coordinators, and<br />

inspectors assessed each plant resulting in a<br />

relative risk score for each. The plants were<br />

then assigned a level of inspection based on<br />

their level of risk.<br />

Risk management provides a clear and<br />

structured approach to identifying risks.<br />

Having a clear understanding of all risks<br />

allows a business to measure and prioritize<br />

them and take the appropriate actions to<br />

reduce losses. It would be beneficial for<br />

industry to incorporate risk management<br />

in every day decision making.<br />

Special thanks to Mike Cassidy, Ph. D, Food<br />

Inspection Branch OMAFRA for assistance in,<br />

and content for, this article.<br />

1 Stone Road, West<br />

Guelph, ON N1G 4Y2<br />

AIME Global initiative<br />

- Yves Landry<br />

The Yves Landry Foundation (YLF) is<br />

making available up to $50,000 per company<br />

in the form of a grant to foster training that<br />

will lead to advancements in innovation<br />

within the manufacturing sector in <strong>Ontario</strong>.<br />

All projects for consideration must lead to<br />

new global export opportunities or create<br />

new global markets.<br />

If you have received federally supported<br />

AIME funding from the Yves Landry<br />

Foundation in the past three years, you are<br />

not eligible to participate in this new round<br />

of funding. Please check with YLF staff to<br />

confirm your eligibility.<br />

See www.yveslandryfoundation.com for<br />

full details.<br />

Prosperity Now program<br />

- CME SMART<br />

CME SMART Prosperity Now program<br />

has an Assessment stream and a Project<br />

Funding stream. You can apply for funding<br />

for one assessment and one project.<br />

Assessments: Eligible companies can<br />

receive 50% of the cost, up to $5,000, for<br />

assessments of Market, Commercialization<br />

of New Technology, and Productivity.<br />

Only one assessment per company will be<br />

funded.<br />

Projects: Eligible companies can receive<br />

33% of the eligible costs, up to $75,000, for<br />

eligible projects.<br />

SMEs previously supported through CME<br />

SMART programming will be considered<br />

eligible; however, cumulative funding<br />

between previous SMART program and<br />

the new Prosperity Now cannot exceed<br />

$100,000.<br />

Application forms are now available. Visit<br />

www.cme-smart.ca for more information.<br />

CAAP calls for sustainability<br />

proposals<br />

The Agricultural Adaptation Council<br />

(AAC) issued a Call for Proposals (CFP)<br />

December 2011, to encourage projects<br />

that address agricultural sustainability in<br />

<strong>Ontario</strong>.<br />

Eligible projects must be consistent with<br />

the objectives and principles of Canadian<br />

Agricultural Adaptation Program (CAAP)<br />

as outlined in the AAC CAAP Guide.<br />

Proposals submitted under the CFP<br />

will focus on one or more of the three<br />

defined areas of sustainability – economic,<br />

environmental and/or social.<br />

Sustainability is defined as follows for the<br />

purposes of this CFP:<br />

• Economic sustainability – participants<br />

in the value chain have reasonable and<br />

equal opportunity to prosper<br />

• Environmental sustainability – the<br />

industry conserves, protects and<br />

regenerates resources and is resilient to<br />

climate and ecological conditions<br />

• Social sustainability – the industry<br />

generates goods and services reflecting<br />

demographic trends of the general<br />

population<br />

Funding comes from Agriculture and<br />

Agri-Food Canada in the form of either a<br />

non-repayable or repayable contribution,<br />

to a maximum of 85 per cent of total<br />

project costs. Funding levels of $100,000<br />

to $250,000 are encouraged, but higher<br />

levels of funding may be provided when<br />

projects involve partnerships of two or<br />

more organizations and result in significant<br />

benefits to the agriculture and agri-food<br />

industry. CAAP is a five-year (2009-2014),<br />

$163-million program.<br />

Proposal Submission Deadline:<br />

Thursday, March 15, 2012 at 4:00 p.m.<br />

For more information, please visit<br />

www.adaptcouncil.org.<br />

21 BLOCKtalk - Spring 2012<br />

www.oimp.ca

<strong>Meat</strong> Plant Guidelines<br />

Provincially licensed meat plants Regulatory Guide<br />

<strong>Meat</strong> Plant Guidelines (MPGs) are offered as a tool to understanding<br />

a plant operator’s regulatory requirement under <strong>Ontario</strong> <strong>Meat</strong><br />

Regulation 31/05 of the Food Safety and Quality Act. These<br />

guidelines are similar to the <strong>Meat</strong> Hygiene Manual of Procedures<br />

for Canada, <strong>Meat</strong> Inspection Act and Regulations 1990. When you<br />

are uncertain of a request made by an inspector, it is important to<br />

refer to the <strong>Meat</strong> Plant Guidelines and understand your regulatory<br />

responsibilities. Sometimes there may be a number of different<br />

solutions that will achieve the same regulatory outcome.<br />

One of the efforts to improve the consistency of delivering<br />

OMAFRA’s inspection program, the Food Inspection Branch has<br />

implemented a thorough review of the <strong>Meat</strong> Plant Guidelines.<br />

The Policy Review Committee which meets on a monthly basis<br />

provides a multidisciplinary approach from within government<br />

(food scientist, food safety advisors, audit, engineering, operations,<br />

field staff, policy) and includes two members from OIMP (staff<br />

and a plant operator). This is important to balance the perspective<br />

when updating these documents.<br />

Changes to the guidelines, with effective dates, will be<br />

communicated to both industry and inspection staff quarterly:<br />

January 1, April 1, July 1, and October 1. Guidelines are available<br />

on OMAFRA’s website at www.omafra.gov.on.ca/english/food/<br />

inspection/meatinsp/manual/index.htm.<br />

January 1 Changes to <strong>Meat</strong> Plant Guidelines<br />