effectivity: md900 - MD Helicopters

effectivity: md900 - MD Helicopters

effectivity: md900 - MD Helicopters

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BENDIXIKING" IFR AVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

HONEYWELL - CONFIDENTIAL<br />

THlS DOCUMENT AND ALL INFORMATION AND EXPRESSION CONTAINED HEREIN ARE THE<br />

PROPERTY OF HONEYWELL INTERNATIONAL INC., ARE PROVIDED IN CONFIDENCE, AND<br />

MAY BE USED BY PERSONS REQUIRED BY 14 CFR 21.50 TO COMPLY WITH ANY OF THE<br />

TERMS OF THESE INSTRUCTIONS. EXCEPT AS SET FORTH ABOVE, NO PERSON MAY, IN<br />

WHOLE OR IN PART, USE, DUPLICATE OR DISCLOSE THlS INFORMATION FOR ANY<br />

PURPOSE WITHOUT THE PRIOR WRITTEN PERMISSION OF HONEYWELL INTERNATIONAL<br />

INC.<br />

BENDlXlKlNGQ and WINGMANO are registered Trademarks of Honeywell International Inc.<br />

For further information contact Honeywell at:<br />

Honeywell International Inc.<br />

One Technology Center<br />

23500 West 105'~ Street<br />

Olathe KS 66061<br />

Telephone: (913) 712-0400.<br />

Prior to Export of this Document, review for export license requirement is needed.<br />

Revisions to this manual may be ordered from the Technical Publicafions section of the<br />

www. bendixkinn.com website

BENDIX/KINGG" IFRAVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

<strong>MD</strong> <strong>Helicopters</strong> <strong>MD</strong>900 Rotorcraft<br />

Maintenance Manual Supplement<br />

IFR Avionics with KFC 900<br />

Automatic Flight Control System (AFCS)<br />

Registration. No.<br />

Serial. No.<br />

This supplement shall be attached to the Model <strong>MD</strong>900 Rotorcraft Maintenance Manual when the<br />

BendixlKing IFR Avionics with KFC 900 Automatic Flight Control System is installed per STC<br />

SR00436WI-D. The information contained herein supplements or supersedes the basic<br />

Maintenance Manual only in those areas listed herein. For Limitations, Procedures and<br />

Performance Data not contained in this supplement, consult the basic Maintenance Manual.<br />

I EFFECTIVITY: <strong>MD</strong>900<br />

I<br />

I<br />

I TITLE<br />

T-I<br />

Revision AD

BENDIX/KlNG@ IFR AVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

THIS PAGE INTENTIONALLY LEFT BLANK<br />

T-2<br />

Revision AD<br />

TITLE<br />

EFFECTIVITY: <strong>MD</strong>900

BENDIXIKING" IFR AVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

I<br />

FAA APPROVED MAINTENANCE MANUAL SUPPLEMENT<br />

for the<br />

BENDIWKING KFC 900 AFCS AND IFR AVIONICS PACKAGE<br />

in the<br />

<strong>MD</strong> <strong>Helicopters</strong> Model <strong>MD</strong>900<br />

(including the 902 configuration)<br />

Serial Numbers 900-00010 and Subsequent<br />

Log of Revisions<br />

I Rev. I Page($) I Description<br />

0<br />

I<br />

AA<br />

AB<br />

AC<br />

-<br />

AD<br />

All<br />

All<br />

All<br />

All<br />

All<br />

Original Issue<br />

Deleted chapters 22, 23, 24 and 34. Added Chapters 96 and 97 to include<br />

autopilot maintenance information.<br />

Revised all pages to Rev AA due to format change. Revised pages as<br />

required due to company name changes.<br />

Revised chapters 96 and 97 to include 902 configuration (sln 52 and<br />

subsequent) and Category A equipment.<br />

Changed AlliedSignal to Honeywell.<br />

Added new power distribution schematics to 96-00-00.<br />

Added ~haiter 98, subchapters 98-10-00 and 98-40-00.<br />

Minor changes were incorporated to all sections. Added Section 11-00-00.<br />

Section 97-00-00 and subparts changed to add part numbers and<br />

I procedures for the configuration, alignment and checkout of 1<br />

1 1 repairedtreplaced avionics components. Section 98-40-00 was completely I I<br />

All<br />

cover<br />

changed to add new formatting for the wiring diagrams.<br />

Changed all sheets to revision AD.<br />

Revised Honeywell Confidential statement.<br />

Made minor revisions to section 98-40-00.<br />

Date<br />

4-15-96<br />

10-30-96<br />

1-4-99<br />

12-1 7-00<br />

5-3-02<br />

02-06-07<br />

I I<br />

LOR<br />

LOR-1<br />

Revision AD

BENDIX/KlNG@ IFRAVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

THIS PAGE INTENTIONALLY LEFT BLANK<br />

LOR-2<br />

Revision AD

BENDIXIKINGIG IFRAVIONICSI KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

Discrepancy Notification<br />

This manual is maintained by Honeywell Certification Engineering Department. This manual supports the maintenance<br />

of the BENDIX/KlNG@ equipment and systems for the aircraft type and Supplemental Type Certificate designated on the<br />

cover of this manual. If a discrepancy is found in this manual, please mail or fax this form (or a copy) as well as copy of<br />

the page(s) with the discrepancy noted. The recommended change(s) will be evaluated and incorporated into the manual<br />

as necessary at the time of the next revision.<br />

Name:<br />

Company:<br />

Phone:<br />

Fax:<br />

Address:<br />

Honeywell<br />

Electronic & Avionics Systems<br />

One Technology Center<br />

23500 W 105'~ Street<br />

Olathe, KS 66061<br />

Attention: Certification Engineering<br />

Mail Drop # 1<br />

FAX (9 13) 782-0345 or (9 13) 7 12-6099<br />

Manual Number and Revision:<br />

Discrepancy:

BENDIXIKING" IFR AVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

THIS PAGE INTENTIONALLY LEFT BLANK<br />

DN-2<br />

Revision AD

BENDIX/KlNG@ IFRAVIONICSI KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

Table of Contents<br />

Section Title Page<br />

Title ..................................................................................................................................................... T-1<br />

Log of Revisions ........................................................................................................................... LOR-1<br />

Discrepancy Notification ................................................................................................................ DN-1<br />

01-00-00 Introduction . Description and Operation ..................................................................... 1<br />

1 . Description ............................................................................................................. 1<br />

2 . Aircraft Configuration ............................................................................................ 1<br />

A Configuration A ..................................................................................................... 1<br />

B . Configuration B ...................................................................................................... 1<br />

C . Configuration C ...................................................................................................... 1<br />

3 . Type Design Change .............................................................................................. 1<br />

A . Major Components ................................................................................................. 1<br />

B . Rotorcraft Flight Manual Supplement(s) ................................................................ 2<br />

4 . Manual Revisions ................................................................................................... 2<br />

01-00-00 Introduction - Maintenance Practices ......................................................................... 201<br />

1 . Maintenance and Operational Test Requirements and Precautions .................... 201<br />

2 . Operational Tests ............................................................................................... 201<br />

3 . Cleaning and Lubrication ................................................................................... 201<br />

4 . Inspections ...................................................................................................... 2 1<br />

5 . Maintenance Information Requests .................................................................... 201<br />

04-00-00 Airworthiness Limitations ................................................................................................ 1<br />

1 . Airworthiness Limitations ...................................................................................... 1<br />

05-00-00 Continued Airworthiness Inspections .............................................................................. 1<br />

1 . General ................................................................................................................... 1<br />

2 . Scheduled Inspection Program Overview .............................................................. 1<br />

3 . Documentation ....................................................................................................... 1<br />

4 . Electrical Bonding .................................................................................................. 1<br />

5 . Special Tools .......................................................................................................... 2<br />

05-20-00 Continued Airworthiness Scheduled Inspection ............................................................. 1<br />

1 General ................................................................................................................... 1<br />

2 . Scheduled Inspections ............................................................................................ 1<br />

A . Airframe Periodic Inspection Program ................................................................... 1<br />

B . Airframe Segmented Inspection Program .............................................................. 1<br />

3 . Definitions .............................................................................................................. 2<br />

05-20-20 Airframe Periodic Inspection ........................................................................................... 1<br />

05-20-50 Airframe Segmented Inspection Program ....................................................................... 1<br />

11-00-00 Placards and Markings ..................................................................................................... 1<br />

1 . General ................................................................................................................... 1<br />

2 . Decals and Placard ................................................................................................. 1<br />

A . Decal and Placard Application ............................................................................... 1<br />

...............................................................<br />

96-00-00 Electrical Power - Description and Operation 1<br />

1 . Electrical System .................................................................................................... 1<br />

A . Aircraft S/N 900-00010 thru 900-00051 ............................................................. 1<br />

B . Aircraft S/N 900-00052 and Subsequent ................................................................ 1<br />

C . External Power Box Assembly (S/N 900-00010 thru 900-00051 only) ................. 6<br />

D . Essential Bus Circuit Breaker Panel ....................................................................... 6<br />

E . Electrical Load Center ........................................................................................... 7<br />

. .....................................................................................<br />

.<br />

................................................................................<br />

.<br />

........................................................................<br />

............................................................................<br />

2 Battery Power Subsystem 10<br />

3 External Power Subsystem 1 0<br />

4 DC Power Generation Subsystem 10<br />

5 . DC Power Distribution System 10<br />

EFFECTIVITY: <strong>MD</strong>900<br />

CONTENTS<br />

Page i<br />

Revision AD

BENDIX/KINGG" IFRAVIONICSI KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

Page ii<br />

Revision AD<br />

Table of Contents (continued)<br />

Section Title Page<br />

A Essential Busses .................................................................................................. 12<br />

B . Battery Bus .......................................................................................................... 12<br />

C . Lighting Bus ...................................................................................................... 13<br />

D . Left Generator Bus ............................................................................................. 13<br />

E . Right Generator Bus ............................................................................................ 13<br />

F . Left Avionics Bus ............................................................................................ 13<br />

G . Right Avionics Bus .............................................................................................. 13<br />

H . 26VAC 400 HZ Bus ............................................................................................ 13<br />

96-30-00 DC Power Systems - Fault Isolation ........................................................................... 101<br />

.............................................................<br />

.<br />

........................<br />

A . PCRl Failure Verification Procedure ................................................................ 104<br />

B . PCR2 Failure Verification Procedure ................................................................ 105<br />

1 Power Busses System Troubleshooting 101<br />

2 Verification of Rectifiers, Essential Bus Circuit Breaker Panel 104<br />

..............................................................<br />

96-30-00 DC Power Systems - Removal I Installation 401<br />

1 . Circuit Breaker Panel ....................................................................................... 401<br />

A . Circuit Breaker Panel Removal ....................................................................... 401<br />

B . Circuit Breaker Panel Installation ...................................................................... 401<br />

C . Side Circuit Breaker Panel Removal (sln 900-00052 and subsequent) ............. 402<br />

D . Side Circuit Breaker Panel Installation (sln 900-00052 and subsequent) .......... 402<br />

.<br />

..........................................................................................<br />

A Rectifier PCRlICRI Removal ........................................................................... 406<br />

B . Rectifier PCRIICRI Installation ....................................................................... 406<br />

C . Rectifier PCR2lCR2 Removal ........................................................................... 406<br />

D . Rectifier PCR2lCR2 Installation ....................................................................... 407<br />

.<br />

..........................................................................................<br />

A . Master Switch Panel Removal ........................................................................... 407<br />

B . Master Switch Panel Installation ....................................................................... 407<br />

C . RT EFS Master Switch Removal ...................................................................... 408<br />

D . RT EFS Master Switch Installation ................................................................... 409<br />

E . AP Master Switch Removal ............................................................................... 409<br />

F . AP Master Switch Installation ........................................................................... 409<br />

G LT EFS Master Switch Removal (Four Tube configured aircraft only) ............ 409<br />

H . LT EFS Master Switch Installation (Four Tube Configured Aircraft Only) ...... 410<br />

. ..................................................................................<br />

A . Left Generator Field RCCB Removal ............................................................... 410<br />

B . Left Generator Field RCCB Installation ............................................................ 411<br />

C . Right Generator Field RCCB Removal ............................................................. 411<br />

D . Right Generator Field RCCB Installation .......................................................... 411<br />

. .........................................................<br />

A . Left Generator Field Control Circuit Breaker Removal .................................... 412<br />

B . Left Generator Field Control Circuit Breaker Installation ................................. 412<br />

C . Right Generator Field Control Circuit Breaker Removal .................................. 413<br />

D . Right Generator Field Control Circuit Breaker Installation ............................ 413<br />

2 Rectifier PCRlICRl 406<br />

3 Master Switch Panel 407<br />

4 Generator Field RCCB's 410<br />

5 Generator Field Control Circuit Breakers 412<br />

.......................................................................<br />

96-30-00 DC Power Systems - Inspection / Test 601<br />

1 . DC Power Systems Inspections ......................................................................... 601<br />

A . Essential Bus Circuit Breaker Panel .................................................................. 601<br />

B . Master Switch Panel .......................................................................................... 601<br />

97-00-00 Avionics - Description and Operation ............................................................................ 1<br />

..................................................................................................................<br />

. ..................................................................................................<br />

.<br />

.....................................<br />

1 General 1<br />

2 Avionics Systems 1<br />

3 VHF Navigation And Communications (NAVICOMM) 12<br />

EFFECTIVITY: <strong>MD</strong>900

BENDIX/KING" IFR AVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

Table of Contents (continued)<br />

Section Title Page<br />

A . KX 1651165A VHF NAVICOMM Transceiver ................................................... 14<br />

B KN 40 NAV Converter ....................................................................................... 15<br />

C . KI 206 Navigation Indicator ............................................................................... 15<br />

D . Navigation Antennas .......................................................................................... 1 6<br />

4 . Distance Measuring Equipment (DME)...............................................................<br />

16<br />

5 . Marker Beacon Receiver ...................................................................................... 16<br />

6 . Automatic Direction Finder (ADF)...................................................................... 17<br />

A KR 87 ADF Receiver .......................................................................................... 17<br />

B . KA 44B ADF Antenna ........................................................................................ 19<br />

7 . Global Positioning System (GPS) ........................................................................ 19<br />

A . KLN 90B GPS Receiver ...................................................................................... 20<br />

B . KA 92 GPS Antenna ............................................................................................ 22<br />

8 . Radar Altimeter .................................................................................................... 22<br />

A . KRA 4051405B Radar Altimeter Transceiver ...................................................... 22<br />

B . KA 54A Radar Altimeter Antenna ....................................................................... 23<br />

9 . Transponder (XPDR) ........................................................................................... 23<br />

10 . Attitude and Heading Reference System (pAHRS) ............................................. 25<br />

A . LCR-92s AHRU .................................................................................................. 25<br />

B . KMT 112 Flux Valve ........................................................................................... 28<br />

11 . Digital Air Data System ....................................................................................... 29<br />

A . KAV 485 AltimeterIVertical Speed Indicator ...................................................... 29<br />

B . KDC 481 T Air Data Computer ............................................................................ 31<br />

12 . Electronic Flight Information System (EFIS or EFS) .......................................... 31<br />

A . SG 465 Symbol Generator ................................................................................... 34<br />

B . ED 461 EHSI Display .......................................................................................... 34<br />

C . ED 462 EADI Display ......................................................................................... 37<br />

D . CP 470 Control Panel ........................................................................................... 40<br />

E . Composite Switch ................................................................................................ 40<br />

F . Pitch Sync Switch ................................................................................................. 40<br />

13 . Automatic Flight Control System (AFCS) ........................................................... 40<br />

A . KCP 520 Flight Control Computer ...................................................................... 45<br />

B . KCM 100 Configuration Module ......................................................................... 45<br />

C . KMS 540 Mode Select Panel ............................................................................... 45<br />

D . KSM 575 Linear Actuator .................................................................................... 46<br />

E . Trim Actuators ..................................................................................................... 47<br />

F . Cable Transducer And KSC 573 Yaw Spring Cartridge ...................................... 47<br />

G . Position Resolvers ................................................................................................ 47<br />

H . KRG 333 Triaxial Rate And Acceleration Sensor ............................................... 48<br />

I . APISAS Annunciator Panel .................................................................................. 48<br />

J . Flight Director LeWRight Switch ......................................................................... 49<br />

K . Diagnostic Plug .................................................................................................... 49<br />

14 . Weather Radar System ......................................................................................... 49<br />

A . ART 2000 Transceiver ......................................................................................... 51<br />

B . Flat Plate Antenna ................................................................................................ 52<br />

C . CM 2000 Configuration Module .......................................................................... 52<br />

D . K<strong>MD</strong> 540 MFD .................................................................................................... 52<br />

E . IN- 182A Indicator ................................................................................................ 53<br />

15 Avionics Cooling Fans ......................................................................................... 53<br />

16 . Standby Attitude Indicator and Standby Altimeter ............................................... 56<br />

EFFECTIVITY: <strong>MD</strong>900<br />

A . STANDBY ATTITUDE INDICATOR ............................................................... 56<br />

B . STANDBY ALTIMETER ................................................................................... 56<br />

CONTENTS<br />

Page iii<br />

Revision AD

BENDIX/KINGGe IFRAVIONICSI KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

Page iv<br />

Revision AD<br />

Section<br />

Table of Contents (continued)<br />

Title<br />

Page<br />

17 . Mechanical Gyro System .................................................................................... 56<br />

A . Attitude Gyro ....................................................................................................... 57<br />

B . Directional Gyro .................................................................................................. 58<br />

C . KI 525A Pictorial Navigation Indicator (or HSI) ................................................ 58<br />

D . Slaving Accessory ............................................................................................... 59<br />

E . KMT 112 Flux Valve .......................................................................................... 59<br />

18 . AC Power System ..............,............................................................................... 59<br />

A . SPC-5(B) Static Inverter ..................................................................................... 60<br />

19 . Category A Equipment ........................................................................................ 61<br />

A . Aural Warning Generator .................................................................................... 61<br />

B . GH-3000 Indicator .............................................................................................. 61<br />

C . DCM-3000 Configuration Module ...................................................................... 61<br />

D . ADC-3000 Air Data Computer ........................................................................... 62<br />

E . MAG-3000 Magnetometer .................................................................................. 62<br />

20 . Emergency Locator Transmitter (ELT) ............................................................... 63<br />

.............................................................<br />

Avionics - Fault Isolation 1 Troubleshooting 101<br />

1 . General ............................................................................................................ 101<br />

2 . Attitude and Heading Reference System (pAHRS)........................................... 101<br />

A . TROUBLESHOOTING .................................................................................... 101<br />

3 . Digital Air Data System .................................................................................... 103<br />

A . KAV 485 POWER UP TEST SEQUENCE ..................................................... 103<br />

B . SELF TEST SEQUENCE (Push-to-Test) ......................................................... 103<br />

C . LOOPBACK TEST ........................................................................................... 104<br />

D . PITOT - STATIC SYSTEM CHECKS ............................................................. 104<br />

4 . Electronic Flight Instrumentation System (EFIS or EFS) .................................. 105<br />

A . EFS 40 SYSTEM FAILURES .......................................................................... 105<br />

B . TROUBLESHOOTING .................................................................................... 106<br />

C . MAINTENANCE PAGES ................................................................................ 109<br />

5 . Automatic Flight Control System (AFCS)......................................................... 120<br />

A . TROUBLESHOOTING ................................................................................... 120<br />

B . FCC ANNUNCIATIONS ................................................................................. 124<br />

C . AFCS DISCONNECT AURAL ALERT ........................................................... 127<br />

D . MANUAL TESTS ............................................................................................. 127<br />

E . FCC ERROR CODES ....................................................................................... 131<br />

F . FAILURE ANNUNCIATION .......................................................................... 166<br />

6 . Avionics Cooling Fans ...................................................................................... 174<br />

7 . Annunciators and Bulb Replacement ................................................................ 174<br />

A . AnnunciatorISwitches ........................................................................................ 174<br />

. ....................................................................................................<br />

B Annunciators 175<br />

Avionics - Removal / Installation ...................................... , ......................................... 401<br />

1 . General .............................................................................................................. 401<br />

2 . VHF Navigation and Communications (NAVICOMM).................................... 401<br />

A . KX 165lKX 165A NAVICOMM ...................................................................... 401<br />

B KI 206 NAV Indicator ....................................................................................... 402<br />

C . CI-1 125 Quadraplexer ....................................................................................... 402<br />

D . CI- 120 VORILOCIGS Antenna ....................................................................... 402<br />

E . CI-29 1 COMM Antenna (either antenna) .......................................................... 403<br />

3 . Distance Measuring Equipment (DME) ............................................................ 403<br />

A . KN 63 DME ...................................................................................................... 403<br />

B . CI- 105-6 DME Antenna .................................................................................. 404<br />

4 . Marker Beacon Receiver ................................................................................... 404<br />

EFFECTIVITY: <strong>MD</strong>900

BENDIX/KlNG@' IFR AVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

Table of Contents (continued)<br />

Section Title Paqe<br />

A . KMR 675 Marker Beacon Receiver ................................................................... 404<br />

B . KA 26 Marker Antenna ...................................................................................... 404<br />

5 . Automatic Direction Finder (ADF)....................................................................<br />

405<br />

A . KR 87 ADF Receiver ......................................................................................... 405<br />

B . KA 44B ADF Antenna ....................................................................................... 405<br />

6 . Global Positioning System (GPS) ...................................................................... 406<br />

A . KLN 90B GPS Receiver .................................................................................... 406<br />

B . KA 92 GPS Antenna .......................................................................................... 406<br />

7 . Radar Altimeter .................................................................................................. 407<br />

A . KRA 405lKRA 405B Radar Altimeter .............................................................. 407<br />

B . KA 54A Antenna ................................................................................................ 407<br />

8 . Transponder (XPDR).........................................................................................<br />

408<br />

A . KT 70 I KT 71 Transponder .............................................................................. 408<br />

B . CI- 105-6 XPDR Antenna ................................................................................... 408<br />

9 . Attitude and Heading Reference System (pAHRS) ........................................... 408<br />

A . LCR-92s AHRU ................................................................................................ 408<br />

B Calibration Prom (either unit) ............................................................................ 409<br />

C . KMT 112 Flux Valve ......................................................................................... 409<br />

10 . Digital Air Data System ..................................................................................... 410<br />

A KDC 481T Adapter Module .............................................................................. 410<br />

B . KDC 481T Air Data Computer .......................................................................... 412<br />

C . KAV 485 AltimeterNSI .................................................................................... 412<br />

D . Temperature Probe ............................................................................................. 413<br />

11 . Electronic Flight Instrumentation System (EFIS or EFS) .................................. 413<br />

A . SG 465 Symbol Generator ................................................................................. 413<br />

B . ED 4611462 EHSIIEADI ................................................................................ 1 3<br />

12 . Automatic Flight Control System (AFCS) ......................................................... 414<br />

A . KCP 520 Flight Control Computer .................................................................... 414<br />

B . KMS 540 Mode Select Panel ............................................................................. 415<br />

C . KRG 333 Triaxial Rate And Acceleration Sensor ............................................. 415<br />

D . KSM 575 Linear Actuator (Lateral Axis) .......................................................... 416<br />

E . KSM 575 Linear Actuator (Longitudinal Axis) ................................................. 418<br />

F . KSA 572 Trim Actuator ..................................................................................... 420<br />

G Pitch Position Resolver ...................................................................................... 420<br />

H . Roll Position Resolver ....................................................................................... 421<br />

I . Directional Position Resolver ............................................................................ 421<br />

J . Collective Position Resolver .............................................................................. 421<br />

K . Cable Transducer ............................................................................................... 422<br />

L . Directional Spring Cartridge .............................................................................. 422<br />

M . T-BAR Trim Switching Relay ............................................................................ 423<br />

N . LEDEX Trim Switch .......................................................................................... 423<br />

0 . APISAS Annunciator Panel ................................................................................ 423<br />

P . Cyclic Trim Switch Assembly ............................................................................ 424<br />

13 . Weather Radar System ....................................................................................... 424<br />

A . ART 2000 Transceiver ....................................................................................... 424<br />

B Flat Plate Antenna .............................................................................................. 425<br />

C . CM 2000 Configuration Module ........................................................................ 425<br />

D . IN- 182A Weather Radar Indicator ..................................................................... 425<br />

E . K<strong>MD</strong> 5501850 Multi-Function Display .............................................................. 426<br />

14 . Avionics Cooling Fans ....................................................................................... 426<br />

A . No . 1 KA 33 Cooling Fan .................................................................................. 426<br />

EFFECTIVITY: <strong>MD</strong>900<br />

CONTENTS<br />

Page v<br />

Revision AD

BENDIXlKIN6" IFRAVIONICSI KFC 900<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

Page vi<br />

Revision AD<br />

Table of Contents (continued)<br />

Section Title Page<br />

B . No . 2 KA 33 Cooling Fan ................................................................................. 427<br />

C . Instrument Panel Forward Cooling Fan ............................................................. 427<br />

D . Instrument Panel Lower Cooling Fan ................................................................ 427<br />

E . KCP 520 Cooling Fan ....................................................................................... 428<br />

15 . Standby Attitude Indicator and Standby Altimeter ............................................ 428<br />

A . Standby Attitude Indicator ................................................................................ 428<br />

B . Standby Altimeter .............................................................................................. 428<br />

16 . Mechanical Gyro System .................................................................................. 429<br />

A . Attitude Indicator .............................................................................................. 429<br />

B . KI 525A HSI .................................................................................................... 429<br />

C . KA 51 B Slaving Accessory ............................................................................... 429<br />

D . KG 102A Directional Gyro ............................................................................... 430<br />

E . KMT 112 Flux Valve ........................................................................................ 430<br />

17 . AC Power System .............................................................................................. 431<br />

A . SPC-5(B) Inverter ............................................................................................. 431<br />

18 . Accessories ....................................................................................................... 431<br />

A . Annunciator Power Supply ................................................................................ 431<br />

B . Avionics Switch Panel ....................................................................................... 431<br />

19 . Category A ........................................................................................................ 432<br />

A . Aural Warning Generator .................................................................................. 432<br />

B . GH-3000 Standby Indicator .............................................................................. 432<br />

C . ADC-3000 Air Data Computer .......................................................................... 432<br />

D . MAG-3000 Magnetometer ................................................................................ 433<br />

20 . ELT ................................................................................................................... 433<br />

.........................................................................................<br />

97-00-00 Avionics - Inspection / Test 601<br />

1 . General .............................................................................................................. 601<br />

2 . VHF Navigation and Communications (NAVICOMM)....................................<br />

601<br />

A . NAVICOMM Inspection ................................................................................... 601<br />

B . COMM Operational Test ................................................................................... 601<br />

C . NAV Operational Test ....................................................................................... 602<br />

3 . Distance Measuring Equipment (DME) ............................................................ 602<br />

A . DME Inspection ................................................................................................ 602<br />

B . DME Operational Test ...................................................................................... 602<br />

4 . Marker Beacon Receiver ................................................................................... 603<br />

A . Marker Beacon Inspection ................................................................................. 603<br />

B . Marker Operational Test ................................................................................... 603<br />

5 . Automatic Direction Finder (ADF) ................................................................... 603<br />

A . ADF Inspection ................................................................................................. 603<br />

B ADF Operational Test ....................................................................................... 603<br />

C . ADF Quadrantal Error Adjustment ................................................................... 604<br />

6 . Global Positioning System (GPS) ..................................................................... 605<br />

A . GPS Inspection .................................................................................................. 605<br />

B . GPS Operational Test ........................................................................................ 606<br />

7 . Radar Altimeter System (RALT)....................................................................... 607<br />

A . RALT Inspection ............................................................................................... 607<br />

B . KRA 405 Operational Test ................................................................................ 607<br />

C . KIM 405B Operational Test ............................................................................. 607<br />

8 . Transponder (XPDR) ........................................................................................ 607<br />

A . XPDR Inspection ............................................................................................... 607<br />

B . XPDR Operational Test .................................................................................... 607<br />

C . XPDR Ramp Test .............................................................................................. 608<br />

EFFECTIVITY: <strong>MD</strong>900

BENDIXIKING" IFRAVIONICSI KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

Table of Contents (continued)<br />

Section Title Pane<br />

D . EEPROM Test ................................................................................................... 608<br />

9 . Attitude and Heading Reference System (AHRS)..............................................<br />

609<br />

A AHRS Inspection ............................................................................................... 609<br />

B . AHRS Operational Test .................................................................................. 1 0<br />

C . MSU and CAL PROM Operational Test ........................................................... 610<br />

10 . Digital Air Data System (DADS)....................................................................<br />

6 3<br />

A . DADS Inspection ............................................................................................... 613<br />

B . DADS Operational Test ..................................................................................... 614<br />

C . Air Data Computer Operational Test ................................................................. 614<br />

D . TEMPERATURE PROBE ................................................................................. 615<br />

11 . Electronic Flight Information System (EFIS).....................................................<br />

615<br />

A . EFIS Inspection .................................................................................................. 615<br />

B . EFIS Operational Test ........................................................................................ 615<br />

C . SG 465 Symbol Generator Configuration ...................................................... 6 16<br />

D . CP 470 Operational Test .................................................................................... 618<br />

E . EFIS Configuration Procedure ...................................................................... 6 18<br />

12 . Automatic Flight Control System (AFCS) ......................................................... 621<br />

A . AFCS Inspection ................................................................................................ 621<br />

B . AFCS Operational Test ...................................................................................... 622<br />

C . AFCS Configuration .......................................................................................... 624<br />

13 . Weather Radar System (WX).............................................................................<br />

645<br />

A . WX Inspection ................................................................................................... 645<br />

B . WX Operational Test ......................................................................................... 645<br />

C . CM 2000 CONFIGURATION MODULE PROGRAMMING .......................... 646<br />

14 . Weather Radar System (WX).............................................................................<br />

649<br />

A . WX Inspection ................................................................................................... 649<br />

B . WX Operational Test ......................................................................................... 649<br />

C . CM 2000 CONFIGURATION MODULE PROGRAMMING .......................... 650<br />

D . MFD Configuration Operational Test ................................................................ 651<br />

15 . Avionics Cooling Fans ....................................................................................... 659<br />

A . Inspection ........................................................................................................... 659<br />

B . Avionics Cooling Fan Operation ........................................................................ 660<br />

16 . Standby Attitude Gyro ....................................................................................... 660<br />

A . Inspection ........................................................................................................... 660<br />

B . Standby Attitude Operation ................................................................................ 660<br />

17 . Mechanical Gyro System ................................................................................... 661<br />

A . Inspection ........................................................................................................... 661<br />

B . Mechanical Gyro System Operation .............................................................. 661<br />

18 . AC Power System ............................................................................................ 663<br />

A . Inspection ........................................................................................................... 663<br />

B . AC Power System Operation ............................................................................. 663<br />

19 . Avionics Accessories ......................................................................................... 664<br />

A Inspection ........................................................................................................... 664<br />

B . Avionics Accessories Operation ........................................................................ 664<br />

C . Avionics Switch Panel Operation ....................................................................... 665<br />

20 . Instrument and Console Lighting ....................................................................... 666<br />

A . Instrument and Console Lighting Operation ...................................................... 666<br />

2 1 . Aural Warning Generator ................................................................................... 667<br />

A . Inspection ........................................................................................................... 667<br />

B . Aural Warning Unit Operation ........................................................................... 667<br />

22 . Electronic Standby Instrument System (ESIS)...................................................<br />

668<br />

EFFECTIVITY: <strong>MD</strong>900<br />

_I<br />

I<br />

CONTENTS<br />

Page vii<br />

3 Revision AD

BENDIXIKING" IFR AVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

Table of Contents (continued)<br />

Section Title Page<br />

A Ins~ection .......................................................................................................... 668<br />

B . ESIS Operation .................................................................................................. 668<br />

23 . Emergency Locator Transmitter (ELT).............................................................<br />

674<br />

...........................................................................<br />

98-00-00 WIRING . Description and Operation 1<br />

1 . Effectivity .............................................................................................................. 1<br />

A . Aircraft S/N 900-00010 thru 900-00051 ............................................................. 1<br />

B . Aircraft S/N 900-00052 and Subsequent ............................................................... 1<br />

2 . Chapter Content ..................................................................................................... 1<br />

3 . Section Content ..................................................................................................... 1<br />

4 Illustration Layout Convention .............................................................................. 1<br />

5 . Wiring Diagram Symbology .................................................................................. 2<br />

................................................................................................<br />

..................................................................................................<br />

............................................................................................<br />

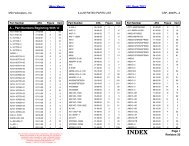

98-10-00 Electrical Equipment List 1<br />

1 . Equipment List Usage .......................................................................................... 1<br />

98-40-00 System Wiring Diagrams 1<br />

Index to Wiring Diagrams 129<br />

Page viii<br />

Revision AD<br />

I EFFECTIVITY: <strong>MD</strong>900<br />

CONTEWTS 1 s '<br />

I

BENDIX/KINGG" IFRAVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

01 -00-00<br />

Introduction -<br />

Description and Operation<br />

1. Description<br />

The <strong>MD</strong> Explorer (<strong>MD</strong>900) is a light twin engine utility helicopter manufactured by <strong>MD</strong> <strong>Helicopters</strong>, Inc.<br />

The basic aircraft is certified for Visual Flight Rules operation only. The incorporation of the IFR avionics<br />

and KFC 900 Rotorcraft Flight Control System installation (STC No. SR00436WI-D) allows the <strong>MD</strong><br />

Explorer to be operated in the IFR environment.<br />

2. Aircraft Configuration<br />

The STC No. SR00436WI-D approves the following three configurations:<br />

A. Configuration A<br />

The Configuration A approval is for VFR operations only. All aircraft previously approved under this<br />

configuration have been upgraded to either Configuration B or Configuration C.<br />

B. Configuration B<br />

The Configuration B approval is for Category B Helicopter lnstrument Flight. Configuration B applies<br />

to the <strong>MD</strong>900 serial numbers 900-0010 and subsequent.<br />

C. Configuration C<br />

The Configuration C approval is for Category A Helicopter Instrument Flight. Configuration C applies<br />

to the <strong>MD</strong>900 serial numbers 900-0052 and subsequent.<br />

Type Design Change<br />

The incorporation of the IFR avionics and KFC 900 Automatic Flight Control System requires<br />

modifications to the basic aircraft DC electrical system and the aircraft structure. A majority of the<br />

required DC electrical system changes have already been incorporated into the basic aircraft DC electrical<br />

system on <strong>MD</strong>900 serial numbers 900-0052 and subsequent. Reference Sections 96-00-00 and 97-00-00<br />

for a complete description of the changes.<br />

A. Major Components<br />

Electrical System - The IFR avionics installation incorporates a splitlredundant bussing structure that<br />

can accommodate IFR operations. Modifications have been made to the Electrical Load Center, the<br />

External Power Box Assembly and the Essential Bus Circuit Breaker Panel. Existing DC power bus<br />

wires were replaced and new DC power bus wiring was added. Reference Section 96-00-00 for a<br />

complete description of the changes.<br />

Avionics Systems - The avionics systems installed as part of the IFR STC enable the aircraft to be<br />

operated in the IFR environment. Reference Section 97-00-00 for a complete description of changes.<br />

Configurations B and C require the installation of the following avionics systems: Dual VHF<br />

NAVICOMM transceivers, a single DME transceiver, a single marker receiver, a single ABF receiver,<br />

a radar altimeter, a Two-Tube EFS 40 with EADIIEHSI, a single AHRS attitude and heading reference<br />

EFFECTIVITY: <strong>MD</strong>900<br />

Page I<br />

@yi~iqn AD

BENBIX/KING" IFR AVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

system, a GPS long range NAV sensor, a single digital air data system, a standby attitude indicator, a<br />

standby altimeter and an inverter powering the AC power system.<br />

The following existing aircraft systems are also part of the IFR avionics package: a single nondiversity<br />

Mode S transponder or a ATCRBS transponder (Modes A and C), an audio system with ICS<br />

capability and a dual vertical stabilizer control system (VSCS).<br />

Configurations B and C require the installation of the KFC 900 Automatic Flight Control System<br />

(AFCS) that includes the following: flight control computer, mode select panel, rate sensor, linear<br />

actuators, trim actuator, position resolvers, cable transducers, directional spring cartridge, trim switch<br />

and annunciator panel.<br />

The following systems are optional: a second EFS 40 system with a second AHRS or a mechanical<br />

gyro system for the copilot (AD1 and HSI), a weather radar system, a Multi-Function Display System<br />

and an emergency locator transmitter (ELT).<br />

Configuration C requires these additional systems: a standby altimeter, an aural warning tone<br />

generator (and an electronic standby instrument system for 2-Tube configurations.)<br />

B. Rotorcraft Flight Manual Supplement(s)<br />

There are three (3) rotorcraft flight manual supplements for the IFR avionics installation. A<br />

supplement for the standard Category B IFR operation and limitations, a supplement for the Category<br />

A IFR operation and limitations (902 configuration only) and a supplement for the KLN 90B GPS<br />

operations and limitations.<br />

4. Manual Revisions<br />

Changes to this manual are incorporated by issuing a complete manual revision. A List of Effective Pages<br />

(LEP) is not necessary because all pages are at the same revision level. Temporary revisions are not<br />

used.<br />

There is no program for the distribution of changes to this manual. It is the responsibility of the<br />

maintenance facility to use the most current manual when performing aircraft maintenance. The revision<br />

level of this document may be found in the Technical Publicafions section on the www.bendixking.com<br />

website. Revisions to this manual can be obtained by calling Honeywell Order Administration (1-800-757-<br />

8999 USA) or by accessing the BendixIKing website at www.bendixking.com.<br />

Page 2<br />

Revision AD<br />

I EFFECTIVITY: <strong>MD</strong>9OO<br />

I

BENDIX/KINGG" IFRAVIONICSI KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

01 -00-00<br />

Introduction -<br />

Maintenance Practices<br />

1. Maintenance and Operational Test Requirements and Precautions<br />

In addition to the <strong>MD</strong> <strong>Helicopters</strong>, Inc. Rotorcraft Maintenance Manual(s) (RMM), all avionics maintenance<br />

is to comply with the following requirements and precautions.<br />

This manual is intended to be a supplement to the RMM provided by <strong>MD</strong> <strong>Helicopters</strong>, Inc. for the model<br />

<strong>MD</strong>900 (<strong>MD</strong> Explorer). The information provided here is for the items, which have been added by the<br />

Honeywell lnternational Inc. certification for the IFR avionics. This manual will supersede information from<br />

<strong>MD</strong> <strong>Helicopters</strong>, Inc. only for the specific items addressed.<br />

2. Operational Tests<br />

After maintenance, modification, removal, installation, inspection, test or repair; the affected parts,<br />

assemblies, installations or systems must be examined and an operational test must be performed before<br />

release of the helicopter for flight.<br />

3. Cleaning and Lubrication<br />

There are no cleaning or lubrication requirements associated with this design change.<br />

4. lnspections<br />

Inspection requirement procedures are supplied in the appropriate chapter text. lnspections must be<br />

made in accordance with Chapter 05, Continued Airworthiness.<br />

lnspections in this manual are visual inspections for cracks, corrosion, distortion, correct installation and<br />

other obvious defects or damage.<br />

Replace components that exhibit damage or wear, or that change the correct operation or integrity of an<br />

assembly.<br />

5. Maintenance Information Requests<br />

Address all questions regarding the IFR avionics maintenance to the Honeywell Field Service<br />

Representative assigned to the geographical area in which the helicopter is operated. If a representative<br />

is not available, refer all questions to Honeywell lnternational Inc. Product Support, (USA) 913-782-0400<br />

or by accessing the BendixIKing website at www.bendixking.com.<br />

When any of the IFR avionics systems exhibit a failure not described in the following sections, it must be<br />

taken to an Honeywell lnternational Inc. Approved Sales and Service Center for repair. These Approved<br />

Sales and Service Centers have maintenance manuals, test sets, tools and trained personnel approved by<br />

Honeywell lnternational Inc. to perform troubleshooting and repair on the equipment on which they are<br />

rated. Maintenance and troubleshooting information available at ttiese Approved Sales and Service<br />

Centers is not duplicated in this document. A list of Honeywell lnternational Inc. Approved Sales and<br />

Service Centers can be obtained from Honeywell lnternational Inc. Product Support, (USA) 913-782-0400<br />

or by accessing the BendixIKing website www.bendixking.com.<br />

I EFFECTIVITY: <strong>MD</strong>900<br />

I<br />

Page 201<br />

Revision AD

BENDIXIKING" IFR AVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

THIS PAGE INTENTIONALLY LEFT BLANK<br />

Page 202<br />

Revision AD<br />

EFFECTIVITY: <strong>MD</strong>900

BENDIXIKING" IFRAVIONICSI KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

04-00-00<br />

Airworthiness Limitations<br />

1. Airworthiness Limitations<br />

No airworthiness limitations associated with this type design change.<br />

EFFECTIVITY: <strong>MD</strong>900<br />

Page 1<br />

Revision AD

BENDIX/KINGG" IFRAVIONICSI KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

THIS PAGE INTENTIONALLY LEFT BLANK<br />

Page 2<br />

Revision AD<br />

EFFECTIVITY: <strong>MD</strong>900

BENDIXIKING" IFR AVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

05-00-00<br />

Continued Airworthiness Inspections<br />

1. General<br />

This section contains scheduled inspections for the KFC 900 AFCS and IFR avionics in the <strong>MD</strong>900. This<br />

section is to be added to the approved scheduled inspection for the aircraft. It is assumed that the aircraft<br />

access panels are open for inspection.<br />

2. Scheduled lnspection Program Overview<br />

There are two inspection programs for the KFC 900 AFCS and IFR avionics in the <strong>MD</strong>900 which align with<br />

the manufacturer developed airframe inspection programs. They are the Periodic lnspection and<br />

Segmented lnspection Programs.<br />

The ownerloperator is responsible for the selection of an inspection program and for its approval by the<br />

governing aviation authority.<br />

3. Documentation<br />

For Category B Helicopter Instrument Flight aircraft, ensure that the Rotorcraft Flight Manual Supplements<br />

006-00845-0000 (IFR AvionicsIKFC 900) and 006-00845-0001 (KLN 90B) are inserted in the Pilot's<br />

Operating Handbook and accessible to the pilot during flight.<br />

For Category A Helicopter Instrument Flight aircraft, ensure that the Rotorcraft Flight Manual Supplements<br />

006-00845-0004 (Category A IFR AvionicsIKFC 900) and 006-00845-0001 (KLN 90B) are inserted in the<br />

Pilot's Operating Handbook and accessible to the pilot during flight.<br />

4. Electrical Bonding<br />

Electrical bonding is important for the reliable and continued safe use of many components of the IFR and<br />

AFCS equipment. Several of the following inspections require visual inspection of units for general<br />

condition and security. These examinations should include checking the unit rack and all brackets for<br />

security. Loose and chaffing brackets will increase the resistance between parts. Also check for signs<br />

that the racks or brackets have been removed or otherwise tampered with. If any of these indications are<br />

present, an electrical bonding test should be performed. An electrical bonding test requires the use of a<br />

milli-ohm meter to confirm that there is a maximum resistance of 2.5 milli-ohms between the unit rack and<br />

airframe ground. If a resistance is found to be too high, disassembly of the brackets will be required.<br />

Check each metal mating surface to be sure it is clear of paint and primer. If necessary, lightly sand the<br />

mating areas to clean them. Always treat bare aluminum with a corrosion preventative, such as Alodine or<br />

Iridite, before reassembly.<br />

EFFECTIVITY: <strong>MD</strong>900<br />

05-00-00<br />

Page 1<br />

Revision AD

BENDIXIKINNG" IFR AVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

5. Special Tools<br />

There are no special tools required to perform the normal inspection on the IFRIAFCS equipment or<br />

installation. Special tools may be required to perform some maintenance on components of the system<br />

on an as-required basis. These tools are as follows:<br />

TOOL: Biddell Milliohm Meter<br />

REASON: Electrical bonding checks<br />

TOOL: Laptop Computer wl RS232 connection<br />

REASON: For AFCS Installation Setup procedures. Example, replacing a failed position resolver will<br />

require running the setup procedure.<br />

Page 2<br />

Revision AD 05-00-00<br />

EFFECTIVITY: <strong>MD</strong>900

BENDIXIKING" IFR AVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

05-20-00<br />

Continued Airworthiness Scheduled lnspection<br />

General<br />

This section contains requirements for scheduled inspection. This section is to be added to the approved<br />

scheduled inspection for the aircraft. It is assumed that the aircraft access panels are open for inspection.<br />

Scheduled Inspections<br />

This section contains requirements for scheduled inspection<br />

A. Airframe Periodic lnspection Program<br />

The Airframe Periodic lnspection Program must be completed within twelve (12) calendar months of<br />

the last Airframe Periodic lnspection or initial certification of the helicopter.<br />

This inspection can be used when aviation authority regulations require periodic inspections such as<br />

an annual or 100 hour inspection.<br />

B. Airframe Segmented lnspection Program<br />

The Airframe Segmented lnspection Program may be used in place of the Airframe Periodic<br />

lnspection Program. If the Airframe Segmented lnspection Program is used, it must be used in its<br />

entirety.<br />

Routine lnspection -A Routine lnspection is to be performed at one hundred (100) hour intervals.<br />

Performance Schedule - The Airframe Segmented lnspection Program is implemented on a twentyfour<br />

month completion cycle.<br />

Month 2 - inspection 7 is to be completed.<br />

Month 3 - inspection 1 is to be completed.<br />

Month 5 - inspection 2 is to be completed.<br />

Month 6 - inspection 4 is to be completed.<br />

Month 7 - inspection 5 is to be completed.<br />

Month 8 - inspection 7 is to be completed.<br />

Month 10 - inspection 3 is to be completed.<br />

Month 12 - inspection 6 is to be completed.<br />

Month 14 - inspection 7 is to be completed.<br />

Month 15 - inspection 1 is to be completed.<br />

Month 17 - inspection 2 is to be completed.<br />

Month 18 - inspection 4 is to be completed.<br />

Month 19 - inspection 5 is to be completed.<br />

Month 20 - inspection 7 is to be completed.<br />

Month 22 - inspection 3 is to be completed.<br />

Month 24 - inspection 6 is to be completed.<br />

I EFFECTIVITY: <strong>MD</strong>900<br />

I<br />

Page 1<br />

, Revision AD

BENDIX/KINGGe IFRAVIONICSI KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

3. Definitions<br />

This section defines the inspection criteria listed in the periodic and segmented inspection programs.<br />

General Condition - This term refers to the overall appearance of the item(s) under consideration.<br />

lnspect for chafing, rubbing, interference to surrounding structure, corrosion, wear, etc. Make any<br />

necessary repairs.<br />

Security - This term refers to installed equipment, wiring harnesses, hoses and tubes. lnspect for<br />

loose attaching and/or mounting hardware, Adel clamps, broken Ty-raps, etc. Make any necessary<br />

repairs.<br />

Electrical Bonding - This term refers to the electrical bonding of equipment, mounting trays or racks,<br />

shelves and other structure that supports the avionics equipment. lnspect for loose attaching<br />

hardware or mounting hardware and evidence of corrosion or deterioration of hardware, sheet metal<br />

etc. Refer to section 05-00-00 for electrical bonding testing methods. Make any necessary repairs.<br />

Page 2<br />

, Revision AD<br />

I EFFECTIVITY: <strong>MD</strong>908<br />

I

BENDIXIKING" IFRAVIONICSI KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

05-20-20<br />

Airframe Periodic Inspection<br />

Model<br />

900<br />

900<br />

General<br />

Ensure all placards and markings are installed<br />

Review and correct operational squawks on aircraft<br />

related to the IFR and AutopilotISAS systems<br />

RMMS Section<br />

1 1-00-00<br />

Initial<br />

Model<br />

900<br />

900<br />

Electrical Bus<br />

Ensure that it is safe to put electrical power on aircraft<br />

Perform the following procedure to test the power<br />

rectifiers in the Essential Circuit Breaker Panel:<br />

I. Apply ground power to the aircraft.<br />

2. Place the power switch in the "BATIEXT" position.<br />

3. Verify that the right and left essential busses are<br />

powered. Verify the right and left DC busses are<br />

powered.<br />

4. Pull the 40 amp "RH BUS FDR and "LH BUS FDR"<br />

circuit breakers located in the Electrical Load Center.<br />

5. Verify that the right and left DC busses have no<br />

power.<br />

On ships sln 900-000 10 thru 900-0005 1, the<br />

transponder, GPS, avionics annunciators, No. 2<br />

NAVICOMM, L VSCS, and the instrument flood<br />

lights should not be operational.<br />

On ships sln 900-00052 and subsequent, the<br />

transponder, bleed air heat, avionics annunciators,<br />

No. 2 NAVICOMM, L VSCS, and the instrument<br />

flood lights should not be operational.<br />

6. Verify that the right and left essential busses are still<br />

powered.<br />

7. If either one or both of the DC busses have power,<br />

replace the appropriate rectifier per the procedures<br />

outlined in section 96-30-00 DC Power Systems<br />

RemovalIInstallation.<br />

8. Otherwise, reset the 40 amp "RH BUS FDR" and "LH<br />

BUS FDR" circuit breakers located in the Electrical<br />

Load Center. Place the power switch in the "OFF"<br />

position and remove ground power from the aircraft<br />

RMMS Section<br />

N/A<br />

96-30-00<br />

Initial<br />

I EFFECTIVITY: <strong>MD</strong>900<br />

I

BENDX/KINGG" IFR AVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

AIRFRAME PERIODIC INSPECTION (CONT'D)<br />

Model<br />

900<br />

900<br />

900<br />

900<br />

900<br />

Air Data System<br />

Visually inspect pitotlstatic lines for general condition and<br />

security<br />

Visually inspect the KDC 48 1 T for general condition,<br />

security and evidence of poor electrical bonding<br />

Visually inspect the KAV 485 for general condition,<br />

security and evidence of poor electrical bonding<br />

Visually inspect the temperature probe for general<br />

condition and security.<br />

Test the pitotlstatic system and transponder per FAR<br />

91.41 1 and FAR 91.413.<br />

RMMS Section<br />

97-00-00<br />

97-00-00<br />

97-00-00<br />

97-00-00<br />

Initial<br />

Model I CNI & Miscellaneous Cockpit Instruments I RMMS Section I Initial<br />

J;**J;* DO NOT USE MAGNETIZED TOOLS NEAR THE<br />

ED 4611462 DISPLAY UNITS<br />

900 Remove glare shield and top panel, and visually inspect:<br />

glare shield and top panel for general condition and<br />

apparent defects<br />

e KLN 90B GPS unit and cooling hose for general<br />

condition and security<br />

annunciators1switches for general condition and<br />

security<br />

cooling fans for general condition and security<br />

e electrical wiring installation for proper installation<br />

and security<br />

900 Visually inspect the KI 206 CDI for proper markings,<br />

general condition and security of instrument mounting:<br />

900 Visually inspect the K<strong>MD</strong> 540 MFD (if installed) for<br />

general condition and security of instrument mounting:<br />

900 Visually inspect electrical wiring installation within<br />

console for chafing and security<br />

900 Visually inspect installation of the following console<br />

installed equipment for proper markings, general<br />

condition, and security:<br />

0 KX 165lA NAVICOMM (2 units)<br />

KR 87 ADF receiver<br />

KT 70171 transponder<br />

Avionics switch panel<br />

Master switch panel<br />

Circuit breaker panel<br />

Side circuit breaker panel (if installed)<br />

Generator field RCCB -<br />

*****J~**J;<br />

97-00-00<br />

97-00-00<br />

97-00-00<br />

97-00-00<br />

97-00-00<br />

97-00-00<br />

97-00-00<br />

97-00-00<br />

96-30-00<br />

96-30-00<br />

96-30-00<br />

96-30-00<br />

Page 2<br />

Revision AD

BENDIX/KlNG@ IFRAVIONICS I KFC goo<br />

006-00757-0000 MAINTENANCE MANUAL SUPPLEMENT<br />

AIRFRAME PERIODIC INSPECTION (CONT'D)<br />

Model I Autopilot/SAS I RMMS Section I Initial<br />

FOLLOW THE <strong>MD</strong> HELICOPTERS RECOMMENDED<br />

1 ***** PROCEDURE FOR OPERATING THE FLIGHT *********<br />

I<br />

CONTROLS USING A HYDRAULIC MULE<br />

1 Linear Actuators (KSM 575) I<br />

Visually inspect for apparent defects, evidence of<br />

failure or interference, and general condition and<br />

security<br />

With hydraulic pressure on, visually inspect for<br />

clearance through the operating range of both the<br />

longitudinal and lateral KSM 575 linear actuators<br />

Visually inspect the harnesses for general condition<br />

and security<br />

Visually inspect the roof structure surrounding the<br />

KSM 575 actuators for security<br />

Trim<br />