Download - METZNER Maschinenbau GmbH

Download - METZNER Maschinenbau GmbH

Download - METZNER Maschinenbau GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

nylon tube converting line<br />

p r o d u c e e c o n o m i c a l l y s i n g l e p a r t p r o d u c t i o n a n d j u s t - i n - t i m e<br />

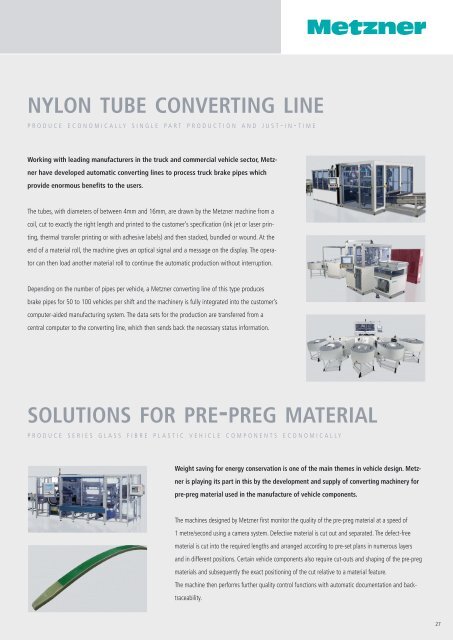

Working with leading manufacturers in the truck and commercial vehicle sector, Metzner<br />

have developed automatic converting lines to process truck brake pipes which<br />

provide enormous benefits to the users.<br />

The tubes, with diameters of between 4mm and 16mm, are drawn by the Metzner machine from a<br />

coil, cut to exactly the right length and printed to the customer’s specification (ink jet or laser printing,<br />

thermal transfer printing or with adhesive labels) and then stacked, bundled or wound. At the<br />

end of a material roll, the machine gives an optical signal and a message on the display. The operator<br />

can then load another material roll to continue the automatic production without interruption.<br />

Depending on the number of pipes per vehicle, a Metzner converting line of this type produces<br />

brake pipes for 50 to 100 vehicles per shift and the machinery is fully integrated into the customer’s<br />

computer-aided manufacturing system. The data sets for the production are transferred from a<br />

central computer to the converting line, which then sends back the necessary status information.<br />

solutions for pre-preg material<br />

p r o d u c e s e r i e s g l a s s f i b r e p l a s t i c v e h i c l e c o m p o n e n t s e c o n o m i c a l l y<br />

Weight saving for energy conservation is one of the main themes in vehicle design. Metzner<br />

is playing its part in this by the development and supply of converting machinery for<br />

pre-preg material used in the manufacture of vehicle components.<br />

The machines designed by Metzner first monitor the quality of the pre-preg material at a speed of<br />

1 metre/second using a camera system. Defective material is cut out and separated. The defect-free<br />

material is cut into the required lengths and arranged according to pre-set plans in numerous layers<br />

and in different positions. Certain vehicle components also require cut-outs and shaping of the pre-preg<br />

materials and subsequently the exact positioning of the cut relative to a material feature.<br />

The machine then performs further quality control functions with automatic documentation and backtraceability.<br />

27