barrage naga hammadi - VINCI Construction Grands Projets

barrage naga hammadi - VINCI Construction Grands Projets

barrage naga hammadi - VINCI Construction Grands Projets

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

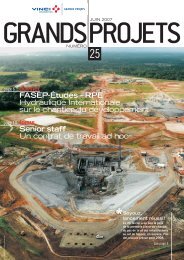

NAGA<br />

HAMMADI<br />

BARRAGE<br />

Harnessing the forces of the Nile for the coming century<br />

grands projets

The players behind the project<br />

The Clients: The Naga Hammadi <strong>barrage</strong> was commissioned<br />

by the Arab Republic of Egypt’s Ministry of Water<br />

Resources and Irrigation, and Ministry of Electricity and<br />

Energy, advised by a group of consultants comprising<br />

Lahmeyer International (Germany), Electrowatt (Switzerland)<br />

and Sogreah (France).<br />

Funding was provided by the Egyptian government, with<br />

financing by the European Investment Bank and the<br />

German Entwicklungsbank, KfW.<br />

The Contractors: <strong>VINCI</strong> <strong>Construction</strong> <strong>Grands</strong> <strong>Projets</strong><br />

(leader), Bilfinger Berger and Orascom <strong>Construction</strong> Industries,<br />

acting in Joint-Venture, were awarded the civil<br />

works contract.<br />

<strong>VINCI</strong> <strong>Construction</strong> <strong>Grands</strong> <strong>Projets</strong><br />

(France) designs and builds major civil<br />

engineering structures and buildings<br />

throughout the world. The company<br />

combines its engineering and project<br />

management expertise with the<br />

proactive creation of local partnerships<br />

when deploying solutions for its public<br />

and private-sector clients.<br />

Bilfinger Berger (Germany) is<br />

a leading international construction<br />

and service company. As a Multi Service<br />

Group, Bilfinger Berger delivers<br />

comprehensive solutions in the areas<br />

of real estate, infrastructure and industrial<br />

services. Its business activities range<br />

from consulting, development, design,<br />

financing and turnkey construction<br />

through to operation and maintenance.<br />

Orascom <strong>Construction</strong> Industries<br />

(Egypt) provides engineering,<br />

procurement and construction services<br />

on large-scale infrastructure, industrial<br />

and commercial projects principally<br />

across the Middle East, North Africa<br />

and Central Asia. OCI is a leader<br />

in the regional construction market.

A multi-purpose structure<br />

Irrigation: the new dam (3.5 km downstream from<br />

the original dam) was designed to increase the existing<br />

irrigation system, a task for which rehabilitation of the<br />

previous 80-year-old structure was deemed insufficient.<br />

By raising the level of the Nile upstream by approximately<br />

one meter, the new <strong>barrage</strong> irrigates 60,000 additional<br />

hectares for agriculture land.<br />

Regulation of the Nile: the new Naga Hammadi<br />

<strong>barrage</strong> will manage regular seasonal variations in the<br />

river’s level, as well as cope with the maximum<br />

emergency output if the Aswan dam were to be opened<br />

upstream (7,000 m 3 /second).<br />

Electricity production: four turbines with total output<br />

of 64 MW enough to power 200,000 Egyptian households<br />

with environmentally friendly, renewable energy.<br />

Increased shipping capacity: two high capacity<br />

navigation locks accommodate even the largest Nile<br />

cruise ships, carrying visitors to Luxor and the other sites<br />

of Upper Egypt.<br />

7,000 m 3 /second<br />

maximum flow capacity<br />

200,000<br />

households powered<br />

with clean hydroelectric energy<br />

60,000 ha<br />

of additional agricultural land<br />

NAGA HAMMADI - 3

A force for regional<br />

development<br />

CAIRO<br />

LUXOR<br />

Naga <strong>hammadi</strong><br />

ASWAN<br />

The Nile river valley is Egypt’s breadbasket and home<br />

to 97% of the country’s population, although the site<br />

chosen for construction of the new <strong>barrage</strong> is itself very<br />

isolated. Naga Hammadi lies in Upper Egypt, about midway<br />

between Aswan, upstream to the South, and Cairo,<br />

some 500 km distant to the Nile river delta.<br />

The Naga Hammadi Barrage has major regional impact<br />

by increasing land available for cultivation, providing<br />

clean energy and improving floodwater regulation.<br />

The Egyptian Clients also wanted the project itself to contribute<br />

to local added value and economic development.<br />

The Joint-Venture partners worked closely with local<br />

staff and labourers to ensure positive impact on the<br />

natural and economic environment of the region. An<br />

awareness campaign directed by the Ministry of Water<br />

Resources and Irrigation towards the local population<br />

provided information about the many benefits to be<br />

provided by the new dam.<br />

Workers from the local sugar cane farming operations<br />

were trained as the main source of manpower<br />

for the project, which employed close to 2,000 workers<br />

during peak phases, most coming from the surrounding<br />

villages. A dedicated transport service by bus and boat<br />

brought workers to the construction site.<br />

Land which was temporarily reclaimed for construction<br />

of the diversion canal and other project elements was<br />

renaturalized before restoration to farmers.<br />

Certain specific activities have been sub-contracted<br />

to local companies such as Arab Contractors (dredging<br />

and riverbed protection), Bauer Egypt (diaphragm walls),<br />

Bekheet and Awad (earthworks), Rowad (steel reinforcement)<br />

and Harb (Electromechanical).<br />

Specific design and operating measures were implemented<br />

to protect groundwater quality and prevent Nile<br />

River from soil pollution.<br />

2,500<br />

local jobs created

Strong technical expertise and complex logistics<br />

The Clients awarded contracts in packages corresponding<br />

to the technical expertise required for the various<br />

facets of the dam’s construction:<br />

Diversion canal and cofferdam,<br />

Civil engineering for the <strong>barrage</strong> structures,<br />

Hydromechanical and electrical equipment,<br />

Permanent housing and operation services building.<br />

The civil works Joint-Venture comprising <strong>VINCI</strong><br />

<strong>Construction</strong> <strong>Grands</strong> <strong>Projets</strong> / Bilfinger Berger / Orascom<br />

<strong>Construction</strong> Industries handled all these works except<br />

equipment.<br />

Cofferdam: a 1,650 m circular cofferdam reinforced<br />

with diaphragm walls of plastic concrete to a depth of up<br />

to 59 m was designed to withstand any tensions resulting<br />

from drainage, excavation and construction, without<br />

loss of waterproof properties.<br />

Barrage structures: the 336 m length dam includes:<br />

- the sluiceway with seven bays, each 17 m in width,<br />

- dual 17 m x 160 m navigation locks,<br />

- the hydroelectric plant housing four turbines and<br />

generators.<br />

The Joint-Venture delivered multiple structures on a<br />

tight deadline.<br />

Diversion canal: full diversion of the Nile river is a<br />

procedure only used once before, during construction<br />

of the Aswan dam. 3.1 million m 3 of earth were removed<br />

through dry excavation and dredging of the right<br />

bank. The canal bed was reinforced with 300,000 m 2 of<br />

geotextile and a 200,000 m 3 stone layer, to withstand<br />

erosion even under strong current.<br />

NAGA HAMMADI - 5

<strong>Construction</strong><br />

phases<br />

1. Diversion canal<br />

(June 2002 – Dec. 2003)<br />

Situation with cofferdam and sealing element<br />

Measuring 1.1 km in<br />

length, 10 m deep with a<br />

minimum navigable width of<br />

100 m, the canal served to<br />

divert the Nile in full for the<br />

duration of the project with no<br />

disruption in fluvial transport.<br />

Shipping was transferred to<br />

the canal in October 2003.<br />

After finishing structures within the pit<br />

6.6<br />

million m 3 of earth removed<br />

Final stage

Cofferdam<br />

<strong>Construction</strong> pit<br />

Diversion canal<br />

2. Cofferdam and<br />

construction pit<br />

(Nov. 2003 – Nov. 2004)<br />

Cofferdam reinforced with excavation<br />

of the plastic concrete cut-off walls created<br />

a construction pit on the bed of the Nile.<br />

Measuring 240,000 m 2 and 1,815 m in<br />

circumference, the pit was fully drained<br />

including lowering of ground water levels,<br />

to prepare the riverbed surface for the<br />

next phase.<br />

NAGA HAMMADI - 7

<strong>Construction</strong><br />

phases<br />

3. Concrete<br />

structures<br />

(Dec. 2004 – Oct. 2006)<br />

The main concrete<br />

structures were completed on a<br />

tight deadline, 18 months from<br />

start to finish. Meeting this<br />

schedule required proactive<br />

team management and careful<br />

logistical planning, to achieve a<br />

high daily cadence of 1,000 m 3 .<br />

400,000<br />

m 3 of concrete poured

4. Impounding<br />

(Oct. 2006)<br />

The construction pit was refilled following completion<br />

of the <strong>barrage</strong>, using pumps for a controlled impounding<br />

to avoid erosion of the cofferdam walls before their<br />

removal. Once the new locks were opened to navigation<br />

(February 2007), backfill of the diversion canal and<br />

construction of service buildings completed the project,<br />

on schedule in May 2008.<br />

NAGA HAMMADI - 9

Specific<br />

characteristics<br />

The Joint-Venture successfully<br />

negotiated the multiple strategic<br />

and technical challenges imposed<br />

by the nature of the project and the<br />

requirements of the Clients.<br />

Extremely tight calendar:<br />

63 key dates over 2 years imposed<br />

by the Clients to ensure coordination<br />

of the project lots.<br />

Rapid pace of concrete work:<br />

25,000 m 3 of concrete in average<br />

per month, during the 8 months<br />

peak period.<br />

<strong>Construction</strong> of the <strong>barrage</strong><br />

in a single piece on the riverbed,<br />

without disruption to Nile<br />

shipping.<br />

High density of reinforcement<br />

steel: 48,000 tons required for a<br />

confined space necessitated expert<br />

engineering.<br />

Curved geometry, in particular of<br />

the powerhouse inflow and outflow<br />

structures, required complex and<br />

technically challenging formwork<br />

(265,000 m 2 of formwork in all).

NAGA HAMMADI - 11

Specific<br />

characteristics<br />

Significant engineering design<br />

modifications introduced by the<br />

Consultant after start of construction,<br />

requiring the rapid implementation of<br />

additional equipment and manpower.<br />

Environmental protection:<br />

measures to maintain groundwater<br />

quality, renaturalization of farmland,<br />

etc.<br />

Regional added value: local<br />

manpower used for the bulk of the<br />

work, requiring specific, intensive<br />

training programmes. Small<br />

management teams from Cairo, local<br />

staff and labourers.<br />

Logistics: transport of materials to<br />

the site’s remote location took<br />

several days.<br />

Weather conditions: temperatures<br />

more than 40°C during the summer<br />

months required the use of a special<br />

cooling system and ice flake to<br />

maintain the concrete at a<br />

temperature not exceeding 25°C.

NAGA HAMMADI - 13

NAGA HAMMADI - 15

grands projets<br />

08/09 - 2000 copies - Photos: Cyrille Dupont, Thierry Duvivier/Trilogi’c, Francis Vigouroux, photo libraries of <strong>VINCI</strong><br />

and subsidiaries, all rights reserved - Design and layout: