type approval certificate - admin bac valves

type approval certificate - admin bac valves type approval certificate - admin bac valves

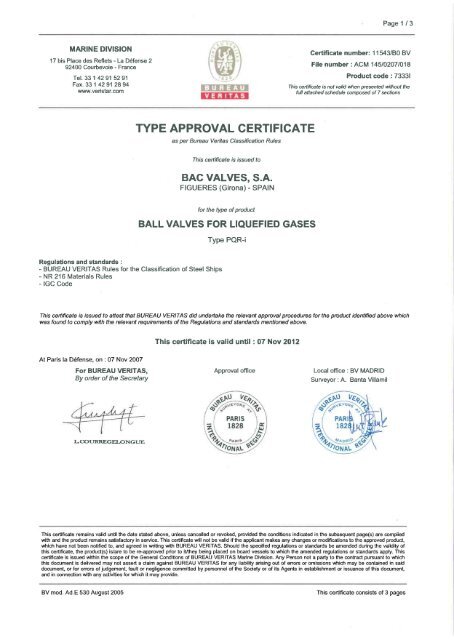

- Page 10 and 11: Page 1 / 3 Certificate number: 0702

- Page 12 and 13: Page 3 / 3 Certificate number: 0702

- Page 14 and 15: Page 2 / 3 Certificate number: 0702

Page 1 / 3<br />

Certificate number: 07023/D0 BV<br />

File number: ACM 145/2209/001<br />

Product code: 7334I<br />

This <strong>certificate</strong> is not valid when presented without the<br />

full attached schedule composed of 7 sections<br />

www.veristar.com<br />

TYPE APPROVAL CERTIFICATE<br />

This <strong>certificate</strong> is issued to<br />

BAC VALVES, S.A.<br />

FIGUERES (Girona) - SPAIN<br />

for the <strong>type</strong> of product<br />

BUTTERFLY VALVES FOR LIQUEFIED GASES<br />

High Performance Butterfly Valves, Lugged and Wafer <strong>type</strong>s, Metal Seat<br />

Requirements:<br />

- BUREAU VERITAS Rules for the Classification of Steel Ships<br />

- IGC Code<br />

This <strong>certificate</strong> is issued to attest that BUREAU VERITAS did undertake the relevant <strong>approval</strong> procedures for the product identified above which<br />

was found to comply with the relevant requirements mentioned above.<br />

This <strong>certificate</strong> will expire on: 25 Apr 2017<br />

For BUREAU VERITAS,<br />

At BV MADRID, on 25 Apr 2012,<br />

Montserrat Espin<br />

This <strong>certificate</strong> remains valid until the date stated above, unless cancelled or revoked, provided the conditions indicated in the subsequent page(s) are complied<br />

with and the product remains satisfactory in service. This <strong>certificate</strong> will not be valid if the applicant makes any changes or modifications to the approved product,<br />

which have not been notified to, and agreed in writing with BUREAU VERITAS. Should the specified regulations or standards be amended during the validity of<br />

this <strong>certificate</strong>, the product(s) is/are to be re-approved prior to it/they being placed on board vessels to which the amended regulations or standards apply. This<br />

<strong>certificate</strong> is issued within the scope of the General Conditions of BUREAU VERITAS Marine Division available on the internet site www.veristar.com. Any<br />

Person not a party to the contract pursuant to which this document is delivered may not assert a claim against BUREAU VERITAS for any liability arising out of<br />

errors or omissions which may be contained in said document, or for errors of judgement, fault or negligence committed by personnel of the Society or of its<br />

Agents in establishment or issuance of this document, and in connection with any activities for which it may provide.<br />

BV Mod. Ad.E 530 May 2009<br />

This <strong>certificate</strong> consists of 3 page(s)

Page 2 / 3<br />

Certificate number: 07023/D0 BV<br />

1. PRODUCT DESCRIPTION<br />

High Performance Butterfly Valve<br />

> Body design: wafer and lugged<br />

> Operator <strong>type</strong>: handlever <strong>type</strong> and manual gear <strong>type</strong><br />

> Seat: metal seated (Fire safe seat <strong>type</strong> tested)<br />

> Commercial designation<br />

Valve <strong>type</strong> ANSI DIN<br />

Lugged <strong>type</strong>,<br />

Stainless steel<br />

Lugged <strong>type</strong>,<br />

Carbon steel<br />

Wafer <strong>type</strong>,<br />

Stainless steel<br />

Wafer <strong>type</strong>,<br />

Carbon steel<br />

HPBFV LD1 # 150 CF8M 316 METAL FS<br />

HPBFV LD3 # 300 CF8M 316 METAL FS<br />

HPBFV LD1 # 150 WCC 316 METAL FS<br />

HPBFV LD3 # 300 WCC 316 METAL FS<br />

HPBFV WR1 # 150 CF8M 316 METAL FS<br />

HPBFV WR3 # 300 CF8M 316 METAL FS<br />

HPBFV WR1 # 150 WCC 316 PTFE FS<br />

HPBFV WR3 # 300 WCC 316 PTFE FS<br />

THE SCHEDULE OF APPROVAL<br />

HPBFV LD PN 10 1.4408 316 METAL FS<br />

HPBFV LD PN 16 1.4408 316 METAL FS<br />

HPBFV LD PN 25 1.4408 316 METAL FS<br />

HPBFV LD PN 40 1.4408 316 METAL FS<br />

HPBFV LD PN 10 1.0619 316 METAL FS<br />

HPBFV LD PN 16 1.0619 316 METAL FS<br />

HPBFV LD PN 25 1.0619 316 METAL FS<br />

HPBFV LD PN 40 1.0619 316 METAL FS<br />

HPBFV WR PN 10 1.4408 316 METAL FS<br />

HPBFV WR PN 16 1.4408 316 METAL FS<br />

HPBFV WR PN 25 1.4408 316 METAL FS<br />

HPBFV WR PN 40 1.4408 316 METAL FS<br />

HPBFV WR PN 10 1.0619 316 PTFE FS<br />

HPBFV WR PN 16 1.0619 316 PTFE FS<br />

HPBFV WR PN 25 1.0619 316 PTFE FS<br />

HPBFV WR PN 40 1.0619 316 PTFE FS<br />

1.1 Rating<br />

- Size: DN 80 to DN 300<br />

- Class range: ANSI Class 150, ANSI Class 300, PN 10, PN 16, PN 25, PN 40<br />

- Design pressure (bar): 10 to 50<br />

Schedule range with maximum working pressures:<br />

Class 150 Class 300 PN 10 PN 16 PN 25 PN 40<br />

20 50 10 16 25 40<br />

- Temperature range (°C): -196 to 500<br />

Materials Class ranges Max. working<br />

temperature (°C)<br />

Stainless Steel<br />

HPBFV LD/SS/FS and HPBFV WR/SS/FS<br />

Stainless Steel<br />

HPBFV LD/SS/FS and HPBFV WR/SS/FS<br />

Carbon Steel<br />

HPBFV LD/CS/FS and HPBFV WR/CS/FS<br />

Carbon steel<br />

HPBFV LD/CS/FS and HPBFV WR/CS/FS<br />

1.2 Material specification<br />

Body Stainless steel ASTM A351 CF8M - DIN 17445 1.4408<br />

Carbon steel WCC - DIN 17245 1.0619<br />

Class 150<br />

PN 10, PN 16, PN 25<br />

Class 300<br />

PN 40<br />

Class 150<br />

PN10, PN 16, PN 25<br />

Class 300<br />

PN 40<br />

Min. working<br />

temperature (°C)<br />

500 -196<br />

500 -196<br />

500 -30<br />

500 -30<br />

Disc Stainless steel ASTM A351 CF8M E.N.P.- DIN 17445 1.4408 E.N.P.<br />

Seat Inconel 718 - Inconel/PTFE<br />

Gaskets Nickel reinforced graphite - Graphite<br />

When other choices of materials are used per manufacturer's instructions, the BV agreement will be obtained.<br />

2. DOCUMENTS AND DRAWINGS<br />

Manufacturer's drawings Ref. N° Date<br />

Butterfly Valve Wafer-Lugged Metal Seat ANSI 150 06-2026 25/03/1996<br />

Butterfly Valve Wafer-Lugged Metal Seat ANSI 300 06-2027 25/03/1996<br />

Butterfly Valve Wafer Metal Seat DIN PN 10/16 06-2008 06/10/1995<br />

Butterfly Valve Wafer Metal Seat DIN PN 25/40 06-2010 09/10/1995<br />

Butterfly Valve Lugged Metal Seat DIN PN 10/16 06-2012 09/10/1995<br />

Butterfly Valve Lugged Metal Seat DIN PN 25/40 06-2014 09/10/1995<br />

‘BAC’ HP Butterfly Valve Wafer Metal Seat CL 300 CF8M Cryogenic Service -80°C to -200°C 06-2806 11/07/1996<br />

‘BAC’ HP Butterfly Valve Wafer Metal Seat CL 150 CF8M Cryogenic Service -80°C to -200°C 06-2805 11/07/1996<br />

‘BAC’ HP Butterfly Valve Lugged Metal Seat CL 300 CF8M Cryogenic Service -80°C to -200°C 06-2804 08/07/1996<br />

‘BAC’ HP Butterfly Valve Lugged Metal Seat CL 150 CF8M Cryogenic Service -80°C to -200°C 06-2803 11/07/1996<br />

- Manual instructions HPBFV<br />

BV Mod. Ad.E 530 May 2009<br />

This <strong>certificate</strong> consists of 3 page(s)

Page 3 / 3<br />

Certificate number: 07023/D0 BV<br />

3. TEST REPORTS<br />

3.1 Fire tests according to BS6755 Part 2 (1987) and API Spec. 6FA (1985) and API Std. 607 (1985) carried out and witnessed<br />

by a Classification Society's Surveyor and found in order.<br />

3.2 Pressure tests and cryogenic tests carried out according to the technical specification N° P-04-510-B and witnessed by a<br />

Bureau Veritas's Surveyor:<br />

- Test report N° F-04-004/03 dated 04/07/1996. Test specimen HPBFV LD 4" (flat side) 300# Seat material Inconel.<br />

- Test report N° F-04-004/04 dated 05/07/1996. Test specimen HPBFV LD 4" (key side) 300# Seat material Inconel.<br />

4. APPLICATION / LIMITATION<br />

4.1 May be used in cargo handling systems of liquefied gas carrier (not below minus 165 °C).<br />

4.2 The <strong>valves</strong> intended to be used for handling of Propylene Oxide or Ethylene Oxide/ Propylene Oxide mixtures shall be of a<br />

fire safe design.<br />

4.3 The <strong>valves</strong> belong to class I according to the relevant requirements stated in Part D, Ch 9, Sec 5 of the Bureau Veritas Rules<br />

applicable to liquefied gas tankers.<br />

4.4 When required in Part D, Ch 9, Sec 6 of the Bureau Veritas Rules applicable to liquefied gas tankers, Charpy V-notch<br />

impact test shall be carried out for castings. Castings in steel grades 316 and 316L at any temperature will be impact tested at<br />

-196 °C. A reduction may be granted for design temperature above -60 °C after examination by the Society.<br />

4.5 The <strong>valves</strong> body, disc and sealing should be of a suitable <strong>type</strong> for use with cargoes intended to be carried.<br />

4.6 The <strong>approval</strong> does not include any operating gear for remote control of the <strong>valves</strong>.<br />

4.7 The valve is to be installed according to manufacturer's instructions and Society's rule requirements.<br />

5. PRODUCTION SURVEY REQUIREMENTS<br />

5.1 The <strong>valves</strong> are to be manufactured, tested and inspected according to the requirements of Bureau Veritas Rules for the<br />

Classification of Steel Ships. Arrangements shall be made for a Society's Surveyor to carry out surveys at manufacturer's works<br />

or relevant audits when an alternative survey scheme, BV Mode I, has been arranged.<br />

5.2 Bureau Veritas Certificates are required for materials of valve housings of Class I (DN>=50). Materials of valve housings of<br />

Class I (DN

Page 1 / 3<br />

Certificate number: 07024/D0 BV<br />

File number: ACM 145/2209/002<br />

Product code: 7334I<br />

This <strong>certificate</strong> is not valid when presented without the<br />

full attached schedule composed of 7 sections<br />

www.veristar.com<br />

TYPE APPROVAL CERTIFICATE<br />

This <strong>certificate</strong> is issued to<br />

BAC VALVES, S.A.<br />

FIGUERES (Girona) - SPAIN<br />

for the <strong>type</strong> of product<br />

BUTTERFLY VALVES FOR LIQUEFIED GASES<br />

High Performance Butterfly Valves, Lugged and Wafer <strong>type</strong>s, Soft Seat<br />

Requirements:<br />

- BUREAU VERITAS Rules for the Classification of Steel Ships<br />

- IGC Code<br />

This <strong>certificate</strong> is issued to attest that BUREAU VERITAS did undertake the relevant <strong>approval</strong> procedures for the product identified above which<br />

was found to comply with the relevant requirements mentioned above.<br />

This <strong>certificate</strong> will expire on: 25 Apr 2017<br />

For BUREAU VERITAS,<br />

At BV MADRID, on 25 Apr 2012,<br />

Montserrat Espin<br />

This <strong>certificate</strong> remains valid until the date stated above, unless cancelled or revoked, provided the conditions indicated in the subsequent page(s) are complied<br />

with and the product remains satisfactory in service. This <strong>certificate</strong> will not be valid if the applicant makes any changes or modifications to the approved product,<br />

which have not been notified to, and agreed in writing with BUREAU VERITAS. Should the specified regulations or standards be amended during the validity of<br />

this <strong>certificate</strong>, the product(s) is/are to be re-approved prior to it/they being placed on board vessels to which the amended regulations or standards apply. This<br />

<strong>certificate</strong> is issued within the scope of the General Conditions of BUREAU VERITAS Marine Division available on the internet site www.veristar.com. Any<br />

Person not a party to the contract pursuant to which this document is delivered may not assert a claim against BUREAU VERITAS for any liability arising out of<br />

errors or omissions which may be contained in said document, or for errors of judgement, fault or negligence committed by personnel of the Society or of its<br />

Agents in establishment or issuance of this document, and in connection with any activities for which it may provide.<br />

BV Mod. Ad.E 530 May 2009<br />

This <strong>certificate</strong> consists of 3 page(s)

Page 2 / 3<br />

Certificate number: 07024/D0 BV<br />

THE SCHEDULE OF APPROVAL<br />

1. PRODUCT DESCRIPTION<br />

High Performance Butterfly Valve<br />

- Body design: wafer and lugged<br />

- Operator <strong>type</strong>: handlever <strong>type</strong> and manual gear <strong>type</strong><br />

- Seat: soft seated and fire safe metallic ring (Fire safe seat <strong>type</strong> tested)<br />

- Commercial designation<br />

Valve <strong>type</strong> ANSI DIN<br />

Lugged <strong>type</strong>,<br />

Stainless steel<br />

HPBFV LD1 # 150 CF8M 316 PTFE FS<br />

HPBFV LD3 # 300 CF8M 316 PTFE FS<br />

HPBFV LD PN 10 1.4408 316 PTFE FS<br />

HPBFV LD PN 16 1.4408 316 PTFE FS<br />

HPBFV LD PN 25 1.4408 316 PTFE FS<br />

Lugged <strong>type</strong>,<br />

Carbon steel<br />

Wafer <strong>type</strong>,<br />

Stainless steel<br />

Wafer <strong>type</strong>,<br />

Carbon steel<br />

HPBFV LD1 # 150 WCC 316 PTFE FS<br />

HPBFV LD3 # 300 WCC 316 PTFE FS<br />

HPBFV WR1 # 150 CF8M 316 PTFE FS<br />

HPBFV WR3 # 300 CF8M 316 PTFE FS<br />

HPBFV WR1 # 150 WCC 316 PTFE FS<br />

HPBFV WR3 # 300 WCC 316 PTFE FS<br />

HPBFV LD PN 40 1.4408 316 PTFE FS<br />

HPBFV LD PN 10 1.0619 316 PTFE FS<br />

HPBFV LD PN 16 1.0619 316 PTFE FS<br />

HPBFV LD PN 25 1.0619 316 PTFE FS<br />

HPBFV LD PN 40 1.0619 316 PTFE FS<br />

HPBFV WR PN 10 1.4408 316 PTFE FS<br />

HPBFV WR PN 16 1.4408 316 PTFE FS<br />

HPBFV WR PN 25 1.4408 316 PTFE FS<br />

HPBFV WR PN 40 1.4408 316 PTFE FS<br />

HPBFV WR PN 10 1.0619 316 PTFE FS<br />

HPBFV WR PN 16 1.0619 316 PTFE FS<br />

HPBFV WR PN 25 1.0619 316 PTFE FS<br />

HPBFV WR PN 40 1.0619 316 PTFE FS<br />

1.1 Rating<br />

- Size: DN 80 to DN 600 (NPS 3" to NPS 24")<br />

- Class range: ANSI Class 150, ANSI Class 300, PN 10, PN 16, PN 25, PN 40<br />

- Design pressure (bar): up to 50<br />

Schedule range with maximum working pressures:<br />

Class 150 Class 300 PN 10 PN 16 PN 25 PN 40<br />

20 50 10 16 25 40<br />

- Temperature range (°C): -104 to 200<br />

Materials Class ranges Max. working<br />

Temperature (°C)<br />

Min. working<br />

Temperature (°C)<br />

Stainless Steel<br />

Class 150, 300<br />

200 -104<br />

HPBFV LD/SS/FS and HPBFV WR/SS/FS<br />

Carbon Steel<br />

HPBFV LD/CS/FS and HPBFV WR/CS/FS<br />

PN 10, PN 16, PN 25, PN 40<br />

Class 150, 300<br />

PN10, PN 16, PN 25, PN 40<br />

200 -30<br />

1.2 Material specification<br />

Body Stainless steel ASTM A351 CF8M - DIN 17445 1.4408<br />

Carbon steel WCC - DIN 17245 1.0619<br />

Disc Stainless steel ASTM A351 CF8M E.N.P.- DIN 17445 1.4408 E.N.P.<br />

Metal seat Inconel 625<br />

PTFE seat Virgin PTFE<br />

Gaskets Nickel reinforced graphite - Graphite<br />

When other choices of materials are used per manufacturer's instructions, the BV agreement is to be obtained.<br />

2. DOCUMENTS AND DRAWINGS<br />

Manufacturer's drawings Ref. N° Date<br />

Butterfly Valve Wafer-Lugged Soft Seat ANSI 150 06-2024 25/03/1996<br />

Butterfly Valve Wafer-Lugged Soft Seat ANSI 300 06-2025 25/03/1996<br />

Butterfly Valve Wafer PTFE Seat DIN PN 10/16 06-2007 06/10/1995<br />

Butterfly Valve Wafer PTFE Seat DIN PN 25/40 06-2009 06/10/1995<br />

Butterfly Valve Lugged PTFE Seat DIN PN 10/16 06-2011 09/10/1995<br />

Butterfly Valve Lugged PTFE Seat DIN PN 25/40 06-2013 09/10/1995<br />

BAC HP Butterfly Valve <strong>type</strong> Wafer Soft Seat CL 150 CF8M Cryogenic Service -104°C 06-2017 25/10/1995<br />

BAC HP Butterfly Valve <strong>type</strong> Lugged Soft Seat CL 300 CF8M Cryogenic Service -104°C 06-2018 31/10/1995<br />

HPBFV WR LD ANSI Rev. 1 and HPBFV WR LD CRYO-104 ANSI Rev. 1 - 31/01/2008<br />

HPBFV WR LD DIN Rev. 1 and HPBFV WR LD CRYO-104 DIN Rev. 1 - 31/01/2008<br />

- Manual instructions HPBFV<br />

BV Mod. Ad.E 530 May 2009<br />

This <strong>certificate</strong> consists of 3 page(s)

Page 3 / 3<br />

Certificate number: 07024/D0 BV<br />

3. TEST REPORTS<br />

3.1 Fire tests according to BS6755 Part 2 (1987) and API Spec. 6FA (1985) and API Std. 607 (1985) carried out and witnessed<br />

by a Classification Society's Surveyor.<br />

- Fire-safe test report N° F-04-003/14 dated 27-28/07/1992. Test specimen HPBFV LD DN 150 Soft seated material<br />

- Fire-safe test report N° F-04-003/22 dated 07/11/1994. Test specimen HPBFV LD 3" Soft seated material<br />

- Fire-safe test report N° F-04-003/23 dated 07/11/1994. Test specimen HPBFV LD 12" Soft seated material<br />

3.2 Fire test report dated 25/06/2008 according to ISO 10497:2004 witnessed by a Society's Surveyor. Test specimen HPBFV<br />

WR 300# CF8M 316 PTFE DN 80 and WR 150# CF8M 316 PTFE DN 200.<br />

3.3 Pressure tests and cryogenic tests carried out according to the technical specification N° P-04-512-A and standard BS 6364<br />

and witnessed by a Bureau Veritas's Surveyor:<br />

- Test report N° F-04-006-A dated 06/08/1996. Test specimen HPBFV LD 300# CF8M 316 PTFE DN 150<br />

- Test report dated 25/06/2008. Test specimen HPBFV WR 300# CF8M 316 PTFE DN 80 and DN 300<br />

4. APPLICATION / LIMITATION<br />

4.1 May be used in cargo handling systems of liquefied gas carrier (not below minus 104 °C).<br />

4.2 The <strong>valves</strong> intended to be used for handling of Propylene Oxide or Ethylene Oxide/ Propylene Oxide mixtures shall be of a<br />

fire safe design.<br />

4.3 The <strong>valves</strong> belong to class I according to the relevant requirements stated in Part D, Ch 9, Sec 5 of the Bureau Veritas Rules<br />

applicable to liquefied gas tankers.<br />

4.4 When required in Part D, Ch 9, Sec 6 of the Bureau Veritas Rules applicable to liquefied gas tankers, Charpy V-notch<br />

impact test shall be carried out for castings. Castings in steel grades 316 and 316L at any temperature will be impact tested at<br />

-196 °C. A reduction may be granted for design temperature above -60 °C after examination by the Society.<br />

4.5 The <strong>valves</strong> body, disc and sealing should be of a suitable <strong>type</strong> for use with cargoes intended to be carried.<br />

4.6 The <strong>approval</strong> does not include any operating gear for remote control of the <strong>valves</strong>.<br />

4.7 The valve is to be installed according to manufacturer's instructions and Society's rule requirements.<br />

5. PRODUCTION SURVEY REQUIREMENTS<br />

5.1 The <strong>valves</strong> are to be manufactured, tested and inspected according to the requirements of Bureau Veritas Rules for the<br />

Classification of Steel Ships. Arrangements shall be made for a Society's Surveyor to carry out surveys at manufacturer's works<br />

or relevant audits when an alternative survey scheme, BV Mode I, has been arranged.<br />

5.2 Bureau Veritas Certificates are required for materials of valve housings of Class I (DN>=50). Materials of valve housings of<br />

Class I (DN