Compression Fitting Assembly Procedure - Franklin Fueling Systems

Compression Fitting Assembly Procedure - Franklin Fueling Systems

Compression Fitting Assembly Procedure - Franklin Fueling Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Compression</strong> <strong>Fitting</strong> <strong>Assembly</strong> <strong>Procedure</strong><br />

On occasion it is necessary to use compression fittings<br />

to extend or terminate UPP pipe work. This can be<br />

achieved using the following assembly procedures.<br />

Note: <strong>Compression</strong> fittings must only be used inside<br />

containment, i.e. Sumps and Chambers, and<br />

NOT direct-buried or used in contact with soil.<br />

General Rules for All <strong>Fitting</strong>s<br />

1. Pipe ends must be cut square and smooth, i.e.<br />

Perpendicular to axis.<br />

2. Cut pipe to length allowing for correct insertion<br />

depth into fitting.<br />

3. Chamfer pipe bore.<br />

4. Remove all burrs and swarf from pipe.<br />

11-50x / 63x Series models<br />

Model<br />

Description<br />

11-501M BSPT Termination, 50 mm /1.5" BSPT<br />

11-503F BSPT 90º 50 mm/1.5" BSPT Female<br />

11-508F BSPT TEE 1.5" BSPT Female<br />

11-50X OL Olive (<strong>Compression</strong> Ring) for 11-50X<br />

11-631M BSPT Termination, 63 MM 2" BSPT<br />

11-631M-1 BSPT Termination, 63 MM 1.5" BSPT<br />

11-63X OL Olive (<strong>Compression</strong> Ring) for 11-63X<br />

<strong>Compression</strong> Termination<br />

1. Measure the pipe insertion depth of the fitting.<br />

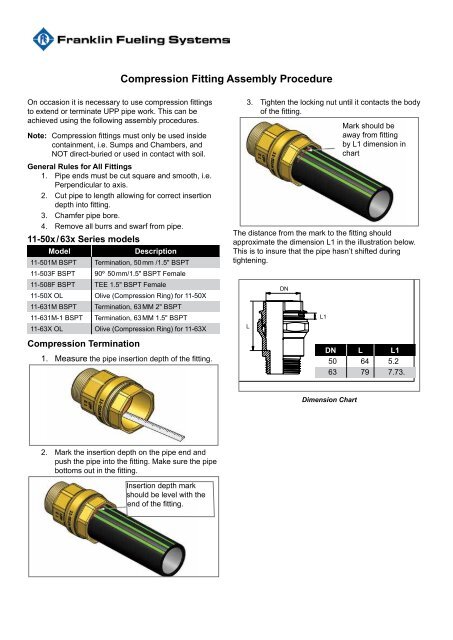

3. Tighten the locking nut until it contacts the body<br />

of the fitting.<br />

Mark should be<br />

away from fitting<br />

by L1 dimension in<br />

chart<br />

The distance from the mark to the fitting should<br />

approximate the dimension L1 in the illustration below.<br />

This is to insure that the pipe hasn’t shifted during<br />

tightening.<br />

L<br />

DN<br />

L1<br />

DN L L1<br />

50 64 5.2<br />

63 79 7.73.<br />

Dimension Chart<br />

2. Mark the insertion depth on the pipe end and<br />

push the pipe into the fitting. Make sure the pipe<br />

bottoms out in the fitting.<br />

Insertion depth mark<br />

should be level with the<br />

end of the fitting.

<strong>Compression</strong> Terminations (11.321)<br />

1. Fully insert support collar into pipe end.<br />

<strong>Compression</strong> Terminations (11-032-EC)<br />

1. Cut the pipe square, allowing for correct<br />

insertion depth into fitting and remove all burs.<br />

2. Seal is supplied pre-greased.<br />

2. Disassemble fitting and slide locking nut and<br />

sealing ring on to the pipe.<br />

3. Mark the insertion depth on the pipe.<br />

3. Fully insert pipe into fitting.<br />

4. Push the pipe into the fitting through the clamp<br />

ring until the first stop, meaning you have<br />

reached the seal. Push the pipe through the<br />

seal until you reach the pipe stop of the fitting.<br />

Check the mark of the insert depth of the pipe<br />

for correct assembly.<br />

4. Tighten locking nut hand tight then wrench<br />

tighten a further two and a half turns.<br />

5. Tighten the nut hand tight plus one turn.

<strong>Compression</strong> <strong>Fitting</strong>s<br />

1. Cut the pipe square, allowing for correct insertion depth into fitting.<br />

2. Chamfer the tubing and remove all burrs, paying particular attention to the bore of the pipe.<br />

3. Remove the outer sleeve.<br />

4. Insert the bolt head between the clamp bosses.<br />

3<br />

4<br />

5. Mount the outer sleeve onto the pipe.<br />

6. Lubricate the O-ring and insert coupling into pipe.<br />

5<br />

7. Slide the outer sleeve up to rear face of the coupling.<br />

8. Lubricate the bolt / nut and faces of the clamp bosses.<br />

9. Tighten the fitting until the clamp bosses meet.<br />

6<br />

7<br />

8

© 2011 FFS 408001015 rev 1<br />

<strong>Franklin</strong> <strong>Fueling</strong> <strong>Systems</strong> LTD<br />

8 Olympus Close • Whitehouse Industrial Estate<br />

Ipswich, Suffolk IP1 5LN • United Kingdom<br />

Tel: +44 1473 243300 • Fax: +44 1473 243301