processing & packaging equipment for breakfast cereal processing

processing & packaging equipment for breakfast cereal processing

processing & packaging equipment for breakfast cereal processing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

order<br />

SALEBy<br />

FOR SALE<br />

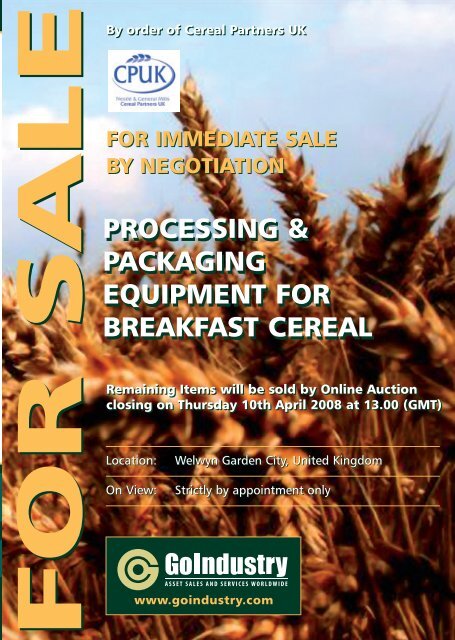

By order of Cereal Partners UK<br />

FOR IMMEDIATE SALE<br />

BY NEGOTIATION<br />

PROCESSING &<br />

PACKAGING<br />

EQUIPMENT FOR<br />

BREAKFAST CEREAL<br />

Remaining Items will be sold by Online Auction<br />

closing on Thursday 10th April 2008 at 13.00 (GMT)<br />

Location: Welwyn Garden City, United Kingdom<br />

On View: Strictly by appointment only<br />

www.goindustry.com

To view the lots visit www.goindustry.com<br />

GRAIN HANDLING<br />

RECEPTION & STORAGE<br />

REDLER 60m Long Wheat Intake<br />

System<br />

Grain Storage Silos, Capacity 60<br />

Tonne (Qty 2)<br />

SAMPLEX ‘CS90’ Wheat Sampler<br />

CLEANING PLANT<br />

MAXIMUM CAPACITY:<br />

12.5 TON/HOUR<br />

BÜHLER ‘MWBL’ Batch Weighers with<br />

Metal Detectors (Qty 5)<br />

BÜHLER ‘Combi-Cleaner’ Wheat<br />

Separator<br />

BÜHLER Gravity Pneumatic Tables (Qty 2)<br />

BÜHLER Vibratory De-Stoners (Qty 2)<br />

BÜHLER ‘MPS’ Dust Extraction Units<br />

(Qty 2)<br />

ULTRATRIEUR ‘UTRN-498’ Wheat<br />

Indent Cylinders<br />

FLAKES PROCESSING<br />

BRAN & WHEAT<br />

PREPARATION<br />

BÜHLER ‘DBAA’ Twin-Wheel Wheat<br />

Cracking Mill with Five Wheat &<br />

Bran Storage Bins with Reverse Jet<br />

Filters and DCE Dust Collectors<br />

BÜHLER ‘DBZD’ Wheat Cracking Mill<br />

with Four BÜHLER Storage Hoppers<br />

with Reverse Jet Filter and DCE Dust<br />

Collectors<br />

SS Liquor Drums with DAVY Weigh<br />

Systems (Qty 2) and a SS Holding<br />

Vessel with Mixing Drum<br />

STEAM COOKING &<br />

DRYING<br />

BAKER PERKINS ‘BS 5500’ Rotating<br />

Ovens, max 144˚C, with Feed<br />

Hopper with Reverse Jet Filter and<br />

Dust Control (Qty 3)<br />

Lump Breakers with KMG Vibratory<br />

Conveyors (Qty 2)<br />

APV MITCHELL Wheat Dryers (Qty 2),<br />

4 & 6 Zones, with Internal Lump<br />

Breaker & Cooling System<br />

FLAKING & TOASTING<br />

LAUHOFF (Qty 3) & BÜHLER ‘DNQB’<br />

(Qty 4) Flaking Roller Mills (to 1994)<br />

WOLVERINE Jetzone ‘9325-01’ SS<br />

Toaster, 2-Sections (2001)<br />

SLUIS Jetzone ‘86039’ SS 2-Stage<br />

Toaster<br />

ULTRATRIEUR ‘UTRN-498’ Wheat Indent Cylinders<br />

BÜHLER Wheat Cracking Mill<br />

or Telephone +44 (0)20 7098 3700<br />

BÜHLER Batch Weighers/Metal Detectors<br />

BÜHLER Wheat Separator BÜHLER Vibratory De-Stoners

BÜHLER Flaking Mill<br />

To view the lots visit www.goindustry.com<br />

CERMEX ‘SM 7500’ Case Packer<br />

Flake Coating Line with Slurry Mixing & Coating Drums<br />

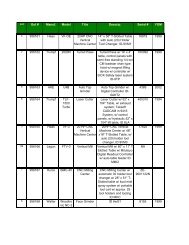

1994 1995<br />

1992<br />

SASIB / BAKER PERKINS 8 Zone Double Deck Oven<br />

QTY 3 1988 1998<br />

BÜHLER-Miag ‘OTW-300C’ Wheat Dryers<br />

KTRON ‘50der WF300AK3FT’ Dried Fruit Dispensing System<br />

or Telephone +44 (0)20 7098 3700

JetZone Flake Toaster<br />

To view the lots visit www.goindustry.com<br />

SASIB / BAKER PERKINS 8-Zone Single Deck Oven<br />

SIG ‘HSU’ Flow Wrapping Machines<br />

QTY 8<br />

1995<br />

2001<br />

or Telephone +44 (0)20 7098 3700<br />

COATING & MIXING<br />

SS Coating Drum with Holding Tank,<br />

Slurry Spray Mixing Drum and<br />

Conveyors<br />

PROCTOR & SCHWARZ Coating Dryer<br />

Fruits & Nuts Dispensing and Mixing<br />

System, with KMG Big Bag<br />

Dispenser, KTRON Weigh Belt Feeder<br />

and Three KMG Vibratory Bucket<br />

Conveyors<br />

SHREDDED BISCUIT<br />

PROCESSING<br />

WHEAT PREPARATION<br />

DMN ‘AI 250’ Batch Weigh Hoppers<br />

(Qty 3) (2004)<br />

INTEG Tempering Bins, 10 Ton<br />

Capacity (Qty 2)<br />

WHEAT DRYING<br />

BÜHLER ‘OTW 300C’ Fluid-Bed Dryers<br />

/ Coolers, with Weigh Feed Hoppers<br />

and Dust Extraction System (Qty 3)<br />

(1998)<br />

BISCUIT BAKING<br />

DIXEN Gravure Unit Paper Coating Line<br />

SASIB / BAKER PERKINS SS Gas-Fired<br />

Double-Deck Oven, 8 Zones (1995)<br />

SASIB / BAKER PERKINS SS Gas-Fired<br />

Oven, 8 Zones, with Elevated<br />

Conveyors<br />

Gas-Fired Oven, 10 Zones<br />

SPOONER Gas-Fired Oven, 10 Zones<br />

SUH SYSTEMS & SAPAL Cooling<br />

Systems (Qty 2) each with Conveyors<br />

and an Outfeed Reject Table

To view the lots visit www.goindustry.com<br />

BISCUIT & FLAKE<br />

PACKAGING<br />

FLOW WRAPPING<br />

SIG Flow Wrapping Lines (Qty 8)<br />

POWER TEC De-Packer, with KEMCO<br />

Infeed Conveyor and Hopper Loader<br />

DIXEN Gravure Unit Surface Coating<br />

Machine<br />

DIXEN ‘5300’ Paper Splitting<br />

Machine, Variable Size<br />

FEEDERS & IN-LINE<br />

STORAGE<br />

ISHIDA ‘CCW-S-212’ 14-Head Batch<br />

Weighers (Qty 7) (1988-91)<br />

KMG ‘Storveyor’ SS Storage Hoppers<br />

(Qty 6) with built-in Vibratory<br />

Feeding Conveyor<br />

KMG Van Scan Vibrating Spiral<br />

Elevators (Qty 2) (2000)<br />

BAGGING MACHINES<br />

SANDIACRE ‘TG235B’ Vertical Form,<br />

Fill, Seal and Bagging Machine<br />

(Qty 2) (1988)<br />

ROVEMA ‘VPX 250/400’ Vertical Form<br />

Fill Seal (Qty 3) (1991)<br />

CARTON & CASE<br />

PACKING<br />

RA JONES 4-Lane Collating Machines<br />

(Qty 3)<br />

RA JONES Carton Erectors & Loaders<br />

(Qty 3) each with NORDSON Glue<br />

Dispenser, MARKEM or SWEDOT Bar<br />

Code Printerr<br />

SAFELINE and CINTEX Metal Detectors<br />

(Qty 3)<br />

PROVIT ‘2200’ or CINTEX Check<br />

Weighers (Qty 3)<br />

FOCKE ‘484’ or ‘464’ Case Packers,<br />

(Qty 3) (1983)<br />

BRADMAN LAKE & JONES Box<br />

Erectors & Loaders (Qty 2) each<br />

with Glue Dispenser, Bar Code<br />

Printer, Metal Detector, Check-<br />

Weigher and Rejection System<br />

KANEPACK ‘CP1’ Case Packers (Qty 2)<br />

& KANEPACK Glue Case Sealers<br />

(Qty 2) (to 1993)<br />

CERMEX ‘SM 7500’ Case Packer<br />

(1992)<br />

ISHIDA Weigh Belt Conveyor (2005);<br />

CINTEX X-Ray Machine (2000)<br />

DOMINO ‘78800’ Barcode Interface<br />

Assistants (Qty 2)<br />

QTY 7 1988-91<br />

ISHIDA ‘CCW-S-212’ 14 Head<br />

Batch Weigher<br />

SANDIACRE ‘TG235B’ Vertical Form,<br />

Fill, Seal and Bagging Machine<br />

or Telephone +44 (0)20 7098 3700<br />

2005<br />

SAFELINE Metal Detector & ISHIDA<br />

Check-Weigher<br />

QTY 2 1991 QTY 2 2000<br />

ROVEMA End-Load Cartoner<br />

SCAN VIBRO Spiral Vibratory<br />

Elevators

QTY 3<br />

To view the lots visit www.goindustry.com<br />

RA JONES Carton Erecting Machines<br />

2x60 Tonne Capacity Grain<br />

Storage Silos<br />

OCME Palletiser with Pallet De-<br />

Stacker<br />

COCHRAN Dual Fuel Boiler<br />

For Further Details contact Ms Christine Daniélou<br />

Mobile +44 (0)7774 417 225 email christine.danielou@goindustry.com<br />

www.goindustry.com<br />

FOCKE ‘484’ & ‘464’ Box Erectors<br />

New London Bridge House,<br />

25 London Bridge Street, London SE1 9BQ<br />

Tel: +44 (0)20 7098 3700 Fax: +44 (0)20 7098 3795<br />

email: sales@goindustry.com<br />

QTY 3 1983<br />

2001<br />

WAREHOUSE & FACTORY<br />

UTILITIES<br />

OCME Palletising Machine with Pallet<br />

De Stacker<br />

OCTOPUS Shrink Wrapper with Max<br />

Wright Control<br />

ITALCO Pallet Elevator with Siba Delta<br />

Light Guards with Max Wright<br />

Control<br />

ATLAS COPCO ‘ZT 200’ Air Rotary<br />

Screw Air Compressor<br />

COCHRAN Dual Fuel Boiler (2001)<br />

Terms & Conditions:<br />

A Buyers Premium of 15% is charged on all sales.<br />

VAT @ 17.5% is payable on the sale and buyers<br />

premium amount. Refunds or Exemptions<br />

may apply.<br />

All items are sold on a "As is, Where is, with all<br />

Faults" basis without representations, guarantee<br />

or warranties as to condition, quality, quantity,<br />

merchantability or fitness <strong>for</strong> a particular<br />

purpose or any use whatsoever.<br />

Payment by Bank Transfer, in GBP only.<br />

No dismantling nor removal will be allowed until<br />

full cleared funds have been received.<br />

All removals will have to comply with<br />

CDM regulations.<br />

Full terms and conditions available on request or on<br />

www.goindustry.com<br />

LOCAL SERVICE – GLOBAL REACH<br />

The details within this brochure are <strong>for</strong> guidance only and do not <strong>for</strong>m any part of any contract.

![UTILITY PIPE BENT EASEMENT AGREEMENT [PE-UB5] THIS ...](https://img.yumpu.com/5265493/1/190x245/utility-pipe-bent-easement-agreement-pe-ub5-this-.jpg?quality=85)