42-Table Saw Safety3.indd - Woodcraft Magazine

42-Table Saw Safety3.indd - Woodcraft Magazine

42-Table Saw Safety3.indd - Woodcraft Magazine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

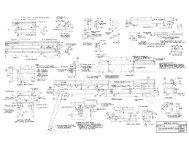

9"<br />

5"<br />

3"<br />

C<br />

Rip the sole straight before shaping<br />

the pushstick. Complete the cut at<br />

the heel using a jigsaw or bandsaw.<br />

This ensures that stock is<br />

held to the fence when ripping<br />

and eliminates the chance<br />

of kickback once the board<br />

contacts the splitter or knife.<br />

Make sure your blade guard is<br />

in place and operating smoothly.<br />

Yes, I know a guard can get in<br />

the way when cutting narrow or<br />

small pieces, so you’re going to<br />

remove it at times. Nonetheless,<br />

use it whenever you possibly<br />

can. If you’ve “lost” your original<br />

guard, various aftermarket<br />

models can be retrofitted to most<br />

saws (see the opening photo).<br />

D<br />

When ripping, stand to the<br />

left of the blade with your legs<br />

splayed for good footing.<br />

Prepare your stock<br />

Trying to guide a crooked edge<br />

against the rip fence invites<br />

kickback. Similarly, struggling<br />

to hold a crooked edge against<br />

a miter gauge or crosscut sled<br />

fence can cause a workpiece<br />

to jump when it hits the blade.<br />

To prevent this, joint and plane<br />

stock straight and flat before<br />

bringing it to the saw. Also<br />

inspect your stock for solidity<br />

before sawing. Don’t cut through<br />

loose knots or deep cracks, which<br />

can cause parts of a board to<br />

suddenly break free mid-cut.<br />

Safe ripping basics<br />

Safe ripping requires a suitable<br />

pushstick, sure-footed balance,<br />

and a smooth, deliberate feed<br />

technique. For best control, use a<br />

“shoe-style” pushstick (Photo C).<br />

Its long sole helps hold a<br />

workpiece against the table, while<br />

its heel pushes the work forward.<br />

I make my own pushsticks from<br />

1⁄ 2"- and 1 ⁄ 4"-thick plywood, using<br />

the latter for ripping narrow<br />

stock. Make sure the sole is<br />

dead-straight for good contact<br />

with the workpiece. (Attaching<br />

a strip of 150-grit sandpaper<br />

helps for applying sideways<br />

pressure against the fence.) When<br />

sawing, keep the pushstick at<br />

the ready for easy retrieval.<br />

Make sure to use an outfeed<br />

table or other support to prevent<br />

workpieces from tipping up at<br />

the trailing end and/or crashing<br />

to the floor as you complete the<br />

cut. If using a friend as a receiver,<br />

have him support the board<br />

palms-up only, never pulling on it.<br />

To rip, stand to the left of the<br />

blade with your legs splayed<br />

roughly parallel to it and your<br />

torso facing the fence (Photo D).<br />

Turn on the saw, and lay the board<br />

Understanding Kickback<br />

So what causes kickback? It’s<br />

really pretty simple: It’s the<br />

rising rear saw teeth grabbing<br />

the edge of the board and<br />

hurling it upward and backward<br />

at fierce speeds. When ripping,<br />

the feed force encounters<br />

diagonal resistance from the<br />

blade, causing the board to<br />

rotate toward the rear teeth,<br />

instigating the problem. The<br />

fix? Use a properly aligned<br />

splitter or riving knife to keep<br />

the stock against the fence and<br />

away from the rear teeth.<br />

The<br />

Principle:<br />

Pushing<br />

against<br />

opposing<br />

corners<br />

causes<br />

board to<br />

rotate.<br />

Spinning<br />

blade<br />

Resistance<br />

from blade<br />

Kickback<br />

Rotational force<br />

drives board<br />

against rising<br />

rear teeth,<br />

which lift and<br />

throw board.<br />

40 woodcraftmagazine.com Aug/Sept 2011<br />

Feed force