Dräger Polytron 3000 - ancb.it

Dräger Polytron 3000 - ancb.it

Dräger Polytron 3000 - ancb.it

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

D<br />

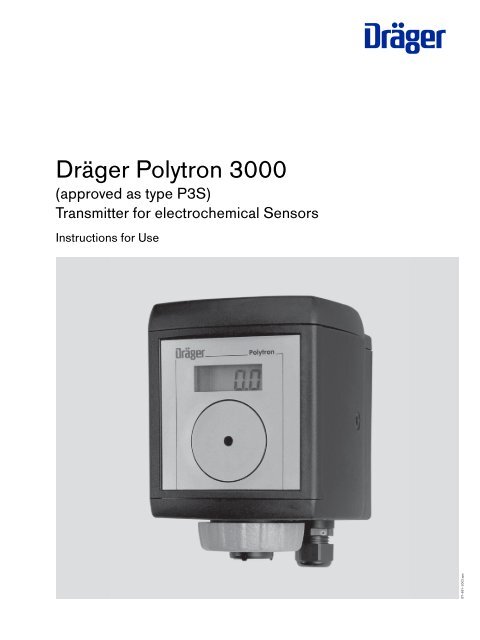

<strong>Dräger</strong> <strong>Polytron</strong> <strong>3000</strong><br />

(approved as type P3S)<br />

Transm<strong>it</strong>ter for electrochemical Sensors<br />

Instructions for Use<br />

ST–691–2002.eps

Contents<br />

Contents<br />

For Your Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5<br />

Installing the transm<strong>it</strong>ter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6<br />

Installing the docking station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7<br />

How to install the electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8<br />

Installing the 4 to 20 mA current loop on the transm<strong>it</strong>ter . . . . . . . . . . . . . . . . . . . . 8<br />

Connecting to the central un<strong>it</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8<br />

Installing the transm<strong>it</strong>ter in areas subject to explosion hazards of zone 0<br />

or zone 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Installing the transm<strong>it</strong>ters in explosion-hazard areas of zone 2 or 22,<br />

or in areas not subject to explosion hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Installing the transm<strong>it</strong>ters in non-explosion-hazard areas . . . . . . . . . . . . . . . . . . . . 10<br />

Installing the measuring un<strong>it</strong> <strong>Dräger</strong> <strong>Polytron</strong> <strong>3000</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . 10<br />

F<strong>it</strong>ting the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11<br />

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Un<strong>it</strong> calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14<br />

Calibrating the zero point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16<br />

Calibrating the sens<strong>it</strong>iv<strong>it</strong>y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16<br />

Replacing the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17<br />

Fault – Cause – Remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19<br />

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20<br />

Order List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23<br />

ATEX approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26<br />

IECEx approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31<br />

UL approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35<br />

CSA - Approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38<br />

Declaration of Conform<strong>it</strong>y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43<br />

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47<br />

Drilling templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51<br />

<strong>Dräger</strong> docking station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51<br />

2

For Your Safety<br />

For Your Safety<br />

Strictly follow the Instructions for Use<br />

Any use of the apparatus requires full understanding and strict observation of<br />

these instructions. The apparatus is only to be used for purposes specified here.<br />

Maintenance<br />

The un<strong>it</strong> must be inspected and serviced regularly by su<strong>it</strong>ably qualified persons.<br />

Repair and general overhaul of the apparatus may only be carried out by trained service<br />

personnel.<br />

We recommend that a service contract be obtained w<strong>it</strong>h <strong>Dräger</strong>Service and that<br />

all repairs also be carried out by them. Only authentic <strong>Dräger</strong> spare parts may be<br />

used for maintenance.<br />

Observe chapter "Maintenance Intervals".<br />

Use in areas subject to explosion hazards<br />

Equipment and components which are used in explosion-hazard areas and which<br />

have been inspected and approved in accordance w<strong>it</strong>h international or European<br />

explosion-protection regulations may be used only under the specified cond<strong>it</strong>ions.<br />

The equipment or components may not be modified in any manner. The use of faulty<br />

or incomplete parts is forbidden.<br />

The appropriate regulations must be observed at all times when carrying out repairs<br />

on the equipment or components.<br />

If the transm<strong>it</strong>ter has been installed w<strong>it</strong>h a su<strong>it</strong>able safety barrier, <strong>it</strong>s case may be<br />

opened or the sensor may be changed while the transm<strong>it</strong>ter is operating.<br />

Caution:<br />

— When the transm<strong>it</strong>ter is installed in Ex areas zone 22 or Class II, Div. 1 & 2,<br />

Group E, F, G the opening of the housing (inclusive sensor replacement)<br />

must not be done when connected to power (power must be turned off or<br />

the area has to be declassified). Explosion hazard!<br />

Accessories<br />

Use only accessories shown in the Ordering List.<br />

Liabil<strong>it</strong>y for proper function or damage<br />

The liabil<strong>it</strong>y for the proper function of the apparatus is irrevocably transferred to the<br />

owner or operator to the extent that the apparatus is serviced or repaired by personnel<br />

not employed or authorized by <strong>Dräger</strong>Service or if the apparatus is used in a<br />

manner not conforming to <strong>it</strong>s intended use.<br />

<strong>Dräger</strong> cannot be held responsible for damage caused by non-compliance w<strong>it</strong>h the<br />

recommendations given above. The warranty and liabil<strong>it</strong>y provisions of the terms of<br />

sale and delivery of <strong>Dräger</strong> are likewise not modified by the recommendations given<br />

above.<br />

<strong>Dräger</strong> Safety AG & Co. KGaA<br />

3

Intended Use<br />

Intended Use<br />

<strong>Dräger</strong> <strong>Polytron</strong> ® <strong>3000</strong> Transm<strong>it</strong>ter for electrochemical sensors<br />

— For stationary, continuous mon<strong>it</strong>oring of gas concentrations in ambient air, w<strong>it</strong>h<br />

built-in <strong>Dräger</strong>Sensor ® .<br />

— For indoor and outdoor use<br />

— For installation alternatively in Ex areas zone 0, 1, 2 or 22 corresponding to device<br />

category 1G, 2G, 3G, 3D or Class I, Class II, Div. 1 & 2 hazardous area.<br />

For further details, see the installation notes.<br />

Notes on use in zone 22:<br />

Valid for all <strong>Dräger</strong> <strong>Polytron</strong> <strong>3000</strong> versions (see II 3D identification marking on the identification tag) and the accessories Duct<br />

Mount K<strong>it</strong> (Order No. 8317150).<br />

ST–691–2002–1.eps<br />

Identification marking and safety data concerning dust explosion protection:<br />

0158 II 3D, IP6x T65 o C (–40 o C Ta +65 o C)<br />

Maximum supply voltage: 30 V DC<br />

As electrical equipment of the device class and category II 3D according to directive 94/9/EC, the transm<strong>it</strong>ter <strong>Dräger</strong> <strong>Polytron</strong><br />

<strong>3000</strong> can be installed and operated w<strong>it</strong>hout safety barriers in the ATEX Zone 22 (dust), if the following notes concerning safe<br />

use are taken into account.<br />

1. The category II 3D is only valid for the accordingly marked <strong>Dräger</strong> <strong>Polytron</strong> <strong>3000</strong> transm<strong>it</strong>ter.<br />

2. According to EN 50281-1-2, the transm<strong>it</strong>ter may not be installed in areas which are endangered by conductive, combustible<br />

dusts.<br />

3. The Transm<strong>it</strong>ter and the accessories must be enclosed according to IP 6x rating. Especially the locking screw (2 mm Allen<br />

screw) of the sensor bayonet ring tight enough to ensure that the bayonet ring is secured against unintended loosening.<br />

4. The <strong>Dräger</strong> <strong>Polytron</strong> <strong>3000</strong> transm<strong>it</strong>ter and the accessories have a maximum surface temperature of 65 o C and the IP 6x rating.<br />

The transm<strong>it</strong>ter must be installed and maintained according to valid regulations (e.g. in European countries according to EN<br />

50281-1-2).<br />

5. The transm<strong>it</strong>ter and the accessories may only be opened when off-circu<strong>it</strong> or outside the Ex area. This must always be observed<br />

when replacing the sensor!<br />

— Calibration by one person even in areas subject to explosion hazards.<br />

— For connection to <strong>Dräger</strong> central un<strong>it</strong>s or to a programmable logic controller (PLC) to warn against physiologically harmful<br />

gas concentrations.<br />

— The optional display on the transm<strong>it</strong>ter indicates the actual gas concentration and makes calibration easier.<br />

False alarms during calibration are avoided by a special maintenance mode w<strong>it</strong>h output of a maintenance signal.<br />

_______________<br />

® <strong>Polytron</strong> is a registered trademark of <strong>Dräger</strong>.<br />

<strong>Dräger</strong>Sensor is a registered trademark of <strong>Dräger</strong>.<br />

4

Design<br />

Design<br />

<strong>Polytron</strong> <strong>3000</strong> is designed for connection to the <strong>Dräger</strong> <strong>Polytron</strong>, Regard,<br />

QuadGard or Unigard central un<strong>it</strong>s.<br />

The <strong>Polytron</strong> <strong>3000</strong> transm<strong>it</strong>ter may also be connected to other central un<strong>it</strong>s if the following<br />

cond<strong>it</strong>ions are met:<br />

— Industrial standard 4 to 20 mA input signal<br />

— Operating voltage at the transm<strong>it</strong>ter 12 to 30 V DC.<br />

On delivery, <strong>Polytron</strong> <strong>3000</strong> is configured for the measuring range and gas to be<br />

measured. This information can be found on a sticker below the service port and on<br />

the back of the measuring un<strong>it</strong>. The Order No. of the sensor to be used is also specified<br />

there.<br />

Two different versions of the <strong>Polytron</strong> <strong>3000</strong> transm<strong>it</strong>ter are available:<br />

<strong>Polytron</strong> <strong>3000</strong> transm<strong>it</strong>ter w<strong>it</strong>h display<br />

This version is intended for installations requiring local indication of the measured<br />

value.<br />

The transm<strong>it</strong>ter is calibrated w<strong>it</strong>h the aid of two potentiometers and the display.<br />

<strong>Polytron</strong> <strong>3000</strong> transm<strong>it</strong>ter w<strong>it</strong>hout display<br />

This version is intended for installations in which local indication of the measured<br />

value is not required.<br />

A dig<strong>it</strong>al voltmeter is required for calibration.<br />

ST–691–2002–2.eps<br />

ST–691–2002–1.eps<br />

5

Installing the transm<strong>it</strong>ter<br />

Installing the transm<strong>it</strong>ter<br />

Preparing for installation<br />

The performance and effectiveness of the entire system depends essentially on the<br />

pos<strong>it</strong>ion chosen for installing the transm<strong>it</strong>ter.<br />

The following should be noted during installation:<br />

— Local requirements and regulations governing the installation of gas measuring<br />

systems.<br />

— Relevant regulations concerning the connection and routing of electric power<br />

supply and signal lines.<br />

— The full scope of environmental factors to which the transm<strong>it</strong>ter may be exposed<br />

(ambient cond<strong>it</strong>ions: see Technical data, page 20).<br />

— Physical properties of the gas to be measured:<br />

For gases w<strong>it</strong>h a dens<strong>it</strong>y lower than that of air, the transm<strong>it</strong>ter must be located<br />

above any possible leak or at the highest point at which large concentrations of<br />

gas may occur.<br />

For gases and vapours w<strong>it</strong>h a dens<strong>it</strong>y greater than that of air, the transm<strong>it</strong>ter must<br />

be located below a possible leak or at the lowest point at which such gases and<br />

vapours may occur.<br />

— The specific uses (e.g. possible leaks, ventilation cond<strong>it</strong>ions, etc.).<br />

— Accessibil<strong>it</strong>y for the necessary maintenance work (see Installation instructions for<br />

the <strong>Polytron</strong> docking station).<br />

— All other factors and cond<strong>it</strong>ions which could have a negative effect on the installation<br />

and operation of the system (such as vibrations or varying temperatures).<br />

— We recommend installing a reflective shield if the un<strong>it</strong> is exposed to strong sunlight.<br />

— The transm<strong>it</strong>ter must be installed vertically (sensor facing downwards).<br />

— The transm<strong>it</strong>ter has been tested w<strong>it</strong>h regard to <strong>it</strong>s weather-resistance and may be<br />

installed out of doors. Use of a splash guard is recommended to protect the sensor<br />

from splashing water, dust and wind.<br />

In explosion-hazard areas:<br />

Observe the national regulations concerning electrical equipment in<br />

explosion-hazard areas.<br />

The <strong>Dräger</strong> <strong>Polytron</strong> <strong>3000</strong> transm<strong>it</strong>ter consists of two main components:<br />

— <strong>Dräger</strong> docking station<br />

This can be pre-installed anywhere and contains the electrical installation components.<br />

— The measuring un<strong>it</strong> <strong>Dräger</strong> <strong>Polytron</strong> <strong>3000</strong><br />

contains the electronics of the transm<strong>it</strong>ter.<br />

If the measuring un<strong>it</strong> is not f<strong>it</strong>ted immediately after installing the docking station, the<br />

latter should be covered w<strong>it</strong>h the raincover provided (dust and water protection) to<br />

protect against dust and splashing water.<br />

6

Installing the transm<strong>it</strong>ter<br />

Installing the docking station<br />

— If the transm<strong>it</strong>ter is to be installed in a Zone 2 explosion-hazard area, select a location<br />

w<strong>it</strong>h low exposure to mechanical risk.<br />

— Docking station is installed vertically (transm<strong>it</strong>ter w<strong>it</strong>h sensor facing down) in an<br />

area w<strong>it</strong>h low vibrations and stable temperatures – near the possible leak.<br />

— A space of at least 15 cm (6") must be maintained above the transm<strong>it</strong>ter for installation<br />

of the measuring un<strong>it</strong>.<br />

— A space of at least 10 cm (4") – preferably 30 cm (12") – must be maintained below<br />

the docking station to perm<strong>it</strong> access for maintenance.<br />

● Unpack the docking station.<br />

1 Remove raincover (protection against dust and splashing water).<br />

1<br />

00123758_1.eps<br />

2 Remove the 4-pole terminal block (Part No. 83 16 268), keep <strong>it</strong> in a safe place and<br />

insert <strong>it</strong> again after completion of the installation work.<br />

● A drilling template is provided on page 51. The mounting holes are 66 ±4 mm (2.6<br />

± 0.16") apart.<br />

●<br />

Attention:<br />

Spacers (e.g. mounting bracket 68 09 772) must be used to prevent any<br />

twisting of the housing when installed on uneven surfaces.<br />

If the measuring un<strong>it</strong> is not to be mounted at this time:<br />

ref<strong>it</strong> the raincover (protection against dust and splashing water).<br />

2<br />

00223758_1.eps<br />

7

Installing the transm<strong>it</strong>ter<br />

How to install the electrical connections<br />

— The electrical wiring may be laid and connected only by a qualified electrician,<br />

who must also comply w<strong>it</strong>h the appropriate regulations – a screened or unscreened<br />

cable (such as LiY, LiYCY) may be used.<br />

— Connection to central device w<strong>it</strong>h at least 2-wire cable, 0.5 to 2.5 mm 2 .<br />

— For currents of 0 to 22 mA, a DC voltage between 12.0 V DC and 30 V DC must<br />

be present at the transm<strong>it</strong>ter.<br />

Installing the 4 to 20 mA current loop on the transm<strong>it</strong>ter<br />

● F<strong>it</strong> 2-wire connecting cable in cable gland, cut to length and strip ends<br />

(approx. 80 mm / 3.15").<br />

● Shorten the shield (if installed) to prevent short-circu<strong>it</strong>ing:<br />

● Connect cable<br />

1 2-pin terminal for <strong>Polytron</strong> <strong>3000</strong> – check polar<strong>it</strong>y (marking in the docking station).<br />

Cut excess wires short or<br />

2 Fasten in 4-pin terminal.<br />

1 Slide connecting terminal back into holder.<br />

● Secure cable in holder.<br />

● Fold up the installation notes and place them in the <strong>Dräger</strong> docking station for future<br />

use during commissioning.<br />

● Ref<strong>it</strong> raincover (protection against dust and splashing water).<br />

Connecting to the central un<strong>it</strong><br />

●<br />

Connect shield to earth of central un<strong>it</strong> (e.g. housing, earth bar, etc.).<br />

1<br />

2<br />

00323758_1.eps<br />

Connecting the <strong>Dräger</strong> <strong>Polytron</strong> <strong>3000</strong> transm<strong>it</strong>ter to a <strong>Dräger</strong> control un<strong>it</strong><br />

(such as Regard, QuadGard, Unigard or <strong>Polytron</strong>):<br />

— Further information about the connection can be found in the instructions for<br />

the <strong>Dräger</strong> control un<strong>it</strong>.<br />

Connecting the <strong>Dräger</strong> <strong>Polytron</strong> <strong>3000</strong> transm<strong>it</strong>ter to control un<strong>it</strong>s w<strong>it</strong>h<br />

a 4 to 20 mA interfaced made by other manufacturers:<br />

— For operation together w<strong>it</strong>h control un<strong>it</strong>s made by other manufacturers, care must<br />

be taken that the voltage at the transm<strong>it</strong>ter does not drop below 12 V. The supply<br />

voltage, the resistance of the cable and the load and the resistance of any installed<br />

safety barrier must be taken into account.<br />

— Further information about the connection can be found in the instructions for the<br />

control un<strong>it</strong> being used.<br />

8

Installing the transm<strong>it</strong>ter<br />

Installing the transm<strong>it</strong>ter in areas subject to explosion hazards of zone 0 or<br />

zone 1<br />

● Install a safety barrier w<strong>it</strong>h the appropriate explosion protection approval (category<br />

1, 2 or Div. 1) between the transm<strong>it</strong>ter and the control un<strong>it</strong>.<br />

— Only safety barriers w<strong>it</strong>h the following characteristics may be used: U o (V oc ) ≤30<br />

V, I o (Isc) ≤0.3 A, P o ≤700 mW.<br />

— Take care that the maximum permissible capac<strong>it</strong>ance and inductance of connections<br />

to the safety barrier are not exceeded, also taking the cable into account.<br />

The safety-related input parameters of the transm<strong>it</strong>ter are: C i = 0 nF, Li = 50 μH.<br />

Transm<strong>it</strong>ter supply un<strong>it</strong>s<br />

(w<strong>it</strong>hout HART-communication between Ex/Non-Ex area)<br />

The following safety barriers are provided as examples only. Selected barriers must<br />

be acceptable to the author<strong>it</strong>y having jurisdiction and comply w<strong>it</strong>h the assigned P3S<br />

ent<strong>it</strong>y parameters also taking the cable into account.<br />

Manufacturer Type su<strong>it</strong>able for Line (Loop)<br />

MTL MTL 5041 Zone 0, Div. 1 ≤190 Ω<br />

Pepperl & Fuchs KFD2–STC4–Ex1 Zone 0, Div. 1 ≤140 Ω<br />

KFD2–STC1–Ex1 Zone 0, Div. 1 ≤140 Ω<br />

Steel 1)<br />

9160 / 13 – 11 – 11 Zone 0 ≤220 Ω<br />

1)<br />

Only use the steel safety barrier as of a cable length of 100 m.<br />

— Connect shielding to earth point and/or 0 V (Ex i).<br />

Explosion-hazard area, zone 0, 1 or Div. 1<br />

Non-explosion-hazard area<br />

Safety barrier<br />

Ex i<br />

+<br />

4 ... 20 mA<br />

+<br />

0 V<br />

–<br />

4 to 20 mA<br />

+24 V<br />

PA<br />

Earth point<br />

Control un<strong>it</strong><br />

00433020_1_en.eps<br />

Installing the transm<strong>it</strong>ters in explosion-hazard areas of zone 2 or 22, or in areas<br />

not subject to explosion hazards<br />

— Use only supply un<strong>it</strong>s of the device category 3.<br />

— Take care that the maximum permissible capac<strong>it</strong>ance and inductance of connections<br />

to the supply un<strong>it</strong> are not exceeded, also taking the cable into account.<br />

The safety-related input parameters of the transm<strong>it</strong>ter are:<br />

C i = 0 nF, Li = 50 μH.<br />

Caution:<br />

The category 1 marking has to be cut out from the rating-plate label. Once<br />

the un<strong>it</strong> has been used after installation in the above manner, <strong>it</strong> may never<br />

be installed in explosion-hazard areas of zone 0 or zone 1 (device category<br />

1 or 2). Explosion hazard!<br />

9

Installing the transm<strong>it</strong>ter<br />

Installing the transm<strong>it</strong>ters in non-explosion-hazard areas<br />

Caution:<br />

The explosion-protection markings has to be removed from the transm<strong>it</strong>ter. Once the transm<strong>it</strong>ter has been used after<br />

installation in this manner, <strong>it</strong> may never be installed in explosion-hazard areas.<br />

Ex-hazard area, zone 2 or non explosion-hazard area<br />

Non-explosion-hazard area<br />

+<br />

4 ... 20 mA<br />

+<br />

0 V<br />

–<br />

+24 V<br />

4 to 20 mA<br />

Control un<strong>it</strong><br />

00533020_1_en.eps<br />

Installing the measuring un<strong>it</strong> <strong>Dräger</strong> <strong>Polytron</strong> <strong>3000</strong><br />

● Remove the rain cover from the previously installed docking station.<br />

● Examine seal for signs of dirt and clean if necessary.<br />

1 Check pos<strong>it</strong>ion of eccentric catches and correct if necessary.<br />

The eccentric opening must point upwards, engaged pos<strong>it</strong>ion.<br />

Attention:<br />

Use only a 5 mm Allen key w<strong>it</strong>hout a ball head.<br />

2<br />

● Check the polar<strong>it</strong>y (marking in the docking station) and cable routing and check<br />

that the connector is securely seated; rectify as necessary (see the installation<br />

notes for the <strong>Polytron</strong> docking station).<br />

● Unpack the measuring un<strong>it</strong> <strong>Dräger</strong> <strong>Polytron</strong> <strong>3000</strong>.<br />

3 1<br />

2 Insert the measuring un<strong>it</strong> about halfway up the docking station and slide <strong>it</strong> in as<br />

far as <strong>it</strong> will go.<br />

3 Lower the un<strong>it</strong> along the front edge of the docking station. About 5 mm before <strong>it</strong>s<br />

h<strong>it</strong>s the stop, the resistance will increase as the connector engages w<strong>it</strong>h the socket<br />

on the printed circu<strong>it</strong> board.<br />

Note!<br />

Check that the terminals in the docking station are correctly aligned if the<br />

connector does not engage correctly!<br />

00623758_1.eps<br />

Note:<br />

Ensure that the front bottom of the measuring un<strong>it</strong> is flush w<strong>it</strong>h the bottom<br />

of the Docking Station. Apply pressure to the measuring un<strong>it</strong> until <strong>it</strong><br />

"clicks" into place. If the fronts are not flush, the measuring un<strong>it</strong> is not<br />

completely sealed and could get water inside the transm<strong>it</strong>ter!<br />

1 Turn the eccentric catches clockwise w<strong>it</strong>h an Allen key to lock the measuring un<strong>it</strong><br />

( ⇒ = approx. 180 o ).<br />

10

Installing the transm<strong>it</strong>ter<br />

F<strong>it</strong>ting the sensor<br />

1 Remove bayonet ring from transm<strong>it</strong>ter, remove dummy plate.<br />

2 Open the front cover of the service port w<strong>it</strong>h an Allen key by turning anticlockwise<br />

(approx. 60 o ).<br />

Attention:<br />

Use only a 5 mm Allen key w<strong>it</strong>hout a ball head.<br />

<strong>Polytron</strong><br />

3 Only use the <strong>Dräger</strong>Sensor specified on the sticker on the <strong>Polytron</strong> <strong>3000</strong> measuring<br />

un<strong>it</strong>.<br />

● Remove sensor from packaging.<br />

● Remove short-circu<strong>it</strong> jumper from sensor if installed.<br />

● There is a coded connector on the back of the sensor. Place the sensor in the<br />

opening w<strong>it</strong>h the connector at the back and the <strong>Dräger</strong> logo at the front.<br />

Before plugging the connector in the socket, ensure that they are identically coded.<br />

Incorrect connection can damage the sensor!<br />

● Secure sensor in transm<strong>it</strong>ter w<strong>it</strong>h bayonet ring.<br />

Attention:<br />

For use in Zone 22, tighten the locking screw (2 mm Allen screw) of the<br />

sensor bayonet ring tight enough to ensure that the bayonet ring is<br />

secured against unintended loosening.<br />

1<br />

2<br />

00723758_1.eps<br />

If the manufacturer's calibration setting for the sensor is to be used:<br />

● Open the front cover of the service port w<strong>it</strong>h an Allen key by turning anticlockwise<br />

(approx. 60 o ). The maintenance sw<strong>it</strong>ches and potentiometers for calibration are<br />

now revealed.<br />

4 Jumper J1 must be set over the two left-hand pins or removed completely.<br />

If the transm<strong>it</strong>ter is specifically to be calibrated w<strong>it</strong>h calibration gas:<br />

● Open the front cover of the service port w<strong>it</strong>h an Allen key by turning anticlockwise<br />

(approx. 60 o ). The maintenance sw<strong>it</strong>ches and potentiometers for calibration are<br />

now revealed.<br />

5 Jumper J1 must be set over the two right-hand pins.<br />

3<br />

<strong>Polytron</strong><br />

4<br />

5<br />

00823758_1.eps<br />

11

Start-up<br />

Start-up<br />

●<br />

Sw<strong>it</strong>ch on power supply.<br />

The transm<strong>it</strong>ter begins <strong>it</strong>s warm-up routine.This is indicated by a flashing display.<br />

The warm-up phase takes between 5 minutes and 12 hours, depending on the<br />

sensor installed. Note the information in the sensor data sheet. The warm-up<br />

phase may take longer in extremely high or low temperatures. It is completed<br />

when the display stops flashing.<br />

When the sensor has warmed up:<br />

— Transm<strong>it</strong>ters set for specific calibration w<strong>it</strong>h calibration gas<br />

● Calibrate sensor, page 14.<br />

— Transm<strong>it</strong>ters set for use of the manufacturer's calibration setting for the sensor<br />

● Transm<strong>it</strong>ter is ready for use.<br />

● Check signal transmission to the central un<strong>it</strong> and alarm output.<br />

Analogue signal<br />

— A current between 4 and 20 mA flows through the transm<strong>it</strong>ter during normal operation.<br />

This current is proportional to the gas concentration.<br />

— <strong>Polytron</strong> <strong>3000</strong> uses various current values to indicate the operating status of the<br />

transm<strong>it</strong>ter:<br />

Display (optional)<br />

Current<br />

Meaning<br />

4 mA Zero point<br />

20 mA Full-scale value<br />

Maintenance<br />

Maintenance<br />

Maintenance intervals<br />

Before starting operation:<br />

● Check the calibration, see page 14.<br />

● Check the transmission of signals to the control un<strong>it</strong> and the triggering of alarms.<br />

At regular intervals,<br />

to be defined by the person responsible for the gas warning installation:<br />

● Check the transmission of signals to the control un<strong>it</strong> and the triggering of alarms.<br />

If a selective filter specific to the sensor is being used:<br />

● Replace the selective filter –<br />

See the related operating instructions for the sensor for details of the capac<strong>it</strong>y<br />

of the selective filter being used.<br />

At regular intervals defined in accordance w<strong>it</strong>h the sensor being used by the<br />

person responsible for the gas warning system:<br />

● Calibrate the sensor, see page 14.<br />

The interval for regular calibration depends on the sensor being used and on the<br />

operating cond<strong>it</strong>ions.<br />

Specific calibration data for the sensor, see the operating instructions for the sensor.<br />

Every six months:<br />

● Inspection by specialists.<br />

The inspection intervals must be established in each individual case and shortened<br />

if necessary, depending on technical safety considerations, engineering<br />

cond<strong>it</strong>ions and the technical requirements of the equipment.<br />

We recommend that a service agreement be concluded w<strong>it</strong>h <strong>Dräger</strong>Service<br />

and that repairs also be carried out by them.<br />

As required:<br />

● Replace sensor, page 17.<br />

13

Maintenance<br />

Un<strong>it</strong> calibration<br />

Caution:<br />

— When the transm<strong>it</strong>ter is installed in Ex areas zone 22 or Class II, Div. 1 & 2,<br />

Group E, F, G the opening of the housing (required for calibration) must not<br />

be done when connected to power (power must be turned off or the area<br />

has to be declassified). Explosion hazard!<br />

— Ensure that the sensor is warmed up before <strong>it</strong> is calibrated. See the sensor data<br />

sheet for the warming-up time.<br />

— Only the zero point is checked if an oxygen sensor has been f<strong>it</strong>ted. The zero point<br />

of an oxygen sensor does not require calibration.<br />

— The transm<strong>it</strong>ter can be calibrated by the operator on s<strong>it</strong>e.<br />

— For cr<strong>it</strong>ical applications, the calibration intervals should be defined in accordance<br />

w<strong>it</strong>h the recommendations in EN 50073 1) , EN45544-4 2) and national regulations.<br />

Note the calibration sequence!<br />

● First check the zero point and correct <strong>it</strong> necessary, Immediately after this, check<br />

the sens<strong>it</strong>iv<strong>it</strong>y and adjust <strong>it</strong> as necessary.<br />

— Never calibrate the sens<strong>it</strong>iv<strong>it</strong>y before calibrating the zero point.<br />

— Zero gas and test gas: see the information in the sensor data sheet.<br />

Caution:<br />

Test gas must not be inhaled. Risk to health! Care must be taken about the<br />

risks which can arise when using test gas; hazard instructions and safety advice<br />

must be observed.<br />

For details, see appropriate DIN Safety Data Sheets.<br />

<strong>Polytron</strong><br />

●<br />

Open the front cover of the service port w<strong>it</strong>h an Allen key by turning anticlockwise<br />

(approx. 60 o ). The maintenance sw<strong>it</strong>ch and potentiometers for calibration are now<br />

revealed.<br />

Attention!<br />

Use only a 5 mm Allen key w<strong>it</strong>hout a ball head.<br />

Note:<br />

The <strong>Dräger</strong> <strong>Polytron</strong> <strong>3000</strong> does not support the storage of calibration data<br />

in the sensor data base.<br />

01323785_1.eps<br />

Measuring / maintenance mode<br />

1 Maintenance sw<strong>it</strong>ch w<strong>it</strong>h two pos<strong>it</strong>ions.<br />

2 Measuring mode pos<strong>it</strong>ion (left-hand pos<strong>it</strong>ion) – measured values are relayed to<br />

the analogue output.<br />

3 Maintenance mode pos<strong>it</strong>ion (right-hand pos<strong>it</strong>ion) – a maintenance signal (3.4 mA<br />

±0.2 mA constant) is relayed to the analogue output and prevents alarms being<br />

triggered.<br />

1)<br />

EN 50073 – Guidelines for selection, installation, use and maintenance of devices for the<br />

detection and measurement of flammable gases and oxygen.<br />

2) EN 45544-4 – Electrical devices for the direct detection and direct concentration measurement<br />

of toxic gases and vapours – Part 4: Guidelines for selection, installation, use and<br />

maintenance.<br />

1<br />

2<br />

3<br />

01423758_1.eps<br />

14

Maintenance<br />

Output for calibration<br />

4 Connect voltmeter (mV setting, Ri > 10 M) to test points TP1 and TP2 (required<br />

for the version w<strong>it</strong>hout display).<br />

Caution:<br />

— For operation in explosion-hazard areas:<br />

Only use intrinsically safe voltmeters w<strong>it</strong>h electrical parameters to the following<br />

specifications:<br />

U i (V max ) 7.6 V; I i (I max ) 1 mA; U o (V oc ) 10.4 V; C i 2.5 μF; L i 10 mH (C o (C a )<br />

and L o (L a ) are not relevant as C i and L i of the test point circu<strong>it</strong> are zero)<br />

MiniGrabber © Test Clips from Pomona Electronics (order no. 4723 or<br />

4826) shall be used for connecting the voltmeter.<br />

The jumper J1 must be connected to the right-hand pin, when connecting<br />

the voltmeter.<br />

–<br />

TP1<br />

+<br />

TP2<br />

mV<br />

4<br />

01523758_1.eps<br />

— If a fault is detected, the voltmeter shows –200 mV.<br />

— Voltage output –200 to 1100 mV:<br />

–200 mV corresponds to a fault<br />

–0 mV corresponds to zero concentration<br />

–1000 mV corresponds to the 100 % measuring range end value<br />

Jumper<br />

5 Jumper J1 can be set to two pos<strong>it</strong>ions.<br />

6 The left-hand pos<strong>it</strong>ion or complete removal of jumper J1 in order to use the manufacturer's<br />

calibration setting for the sensor.<br />

7 The right-hand pos<strong>it</strong>ion for calibration w<strong>it</strong>h calibration gas and the potentiometers<br />

for zero point and sens<strong>it</strong>iv<strong>it</strong>y.<br />

— Only the manufacturer's calibration setting for the sensor can be used when jumper<br />

J1 is set over the two left-hand pins.<br />

— Calibration w<strong>it</strong>h calibration gas can be performed when jumper J1 has been set<br />

over the two right-hand pins.<br />

6<br />

7<br />

5<br />

J1<br />

01623758_1.eps<br />

Operating elements<br />

8 Potentiometer (left) for calibration of the zero point.<br />

9 Potentiometer (right) for calibration of the sens<strong>it</strong>iv<strong>it</strong>y.<br />

8 9<br />

01723758_1.eps<br />

15

Maintenance<br />

Calibrating the zero point<br />

For all sensors except oxygen sensor:<br />

The zero point can be calibrated w<strong>it</strong>hout the use of n<strong>it</strong>rogen (zero gas) when the<br />

ambient air is free from measuring gas and other interfering gases. Alternatively:<br />

<strong>Polytron</strong><br />

1 Use the calibration adapter.<br />

● Set maintenance sw<strong>it</strong>ch to maintenance pos<strong>it</strong>ion, see page 14.<br />

● Let n<strong>it</strong>rogen flow through the calibration adapter at a rate of approx. 0.5 L/min.<br />

Synthetic air may also be used, except when calibrating oxygen sensors.<br />

● Wa<strong>it</strong> for the measured value to stabilise – approx. 3 minutes. Note the information<br />

in the sensor data sheet.<br />

2 Set potentiometer for zero point so that the display shows 0 and the dig<strong>it</strong>al voltmeter<br />

0 mV ±2 mV.<br />

Oxygen sensors:<br />

The zero point cannot be calibrated for these sensors. The zero point is merely<br />

checked.<br />

1<br />

2<br />

01823758_1.eps<br />

● Sw<strong>it</strong>ch off calibration gas and remove calibration adapter.<br />

● Set maintenance sw<strong>it</strong>ch to measuring pos<strong>it</strong>ion, see page 14.<br />

Calibrating the sens<strong>it</strong>iv<strong>it</strong>y<br />

Caution:<br />

Test gas must not be inhaled. Risk to health!<br />

Care must be taken about the risks which can arise when using test gas;<br />

hazard instructions and safety advice must be observed.<br />

For details, see appropriate Safety Data Sheets.<br />

— The recommended calibration gas concentration for optimum accuracy is between<br />

40 % and 100 % of the measuring range end value.<br />

1 Use the calibration adapter.<br />

● Set maintenance sw<strong>it</strong>ch to maintenance pos<strong>it</strong>ion, see page 14.<br />

● Let calibration gas flow through the calibration adapter at a rate of approx. 0.5 L/<br />

min.<br />

— Wa<strong>it</strong> for the measured value to stabilise – approx. 3 minutes. Note the information<br />

in the sensor data sheet.<br />

<strong>Polytron</strong><br />

3 Set the potentiometer for sens<strong>it</strong>iv<strong>it</strong>y so that the display shows the concentration<br />

of the calibration gas or the dig<strong>it</strong>al voltmeter shows the calculated voltage mV.<br />

Calculation of the voltage V exp between test points TP1 and TP2:<br />

V exp = Concentration of calibration gas ÷ Measuring range x 1000 mV<br />

3<br />

Example:<br />

Concentration of calibration gas 250 ppm CO<br />

Measuring range 0 to 300 ppm CO<br />

Calculated voltage: 250 ppm<br />

V exp = x 1000 mV = 833 mV<br />

300 ppm<br />

1<br />

01923758_1.eps<br />

16

Maintenance<br />

● Sw<strong>it</strong>ch off calibration gas and remove calibration adapter.<br />

● Wa<strong>it</strong> until the measured value drops below the alarm threshold set on the central<br />

un<strong>it</strong>. Otherwise an alarm will be triggered when the maintenance sw<strong>it</strong>ch is returned<br />

to the measuring pos<strong>it</strong>ion immediately after calibration.<br />

1 Set maintenance sw<strong>it</strong>ch to measuring pos<strong>it</strong>ion, left-hand pos<strong>it</strong>ion. The 4 to 20 mA<br />

output changes to measuring mode.<br />

● Ref<strong>it</strong> the front cover of the service port and lock <strong>it</strong> in place by turning clockwise<br />

w<strong>it</strong>h an Allen key (approx. 60 o ).<br />

<strong>Polytron</strong><br />

1<br />

Replacing the sensor<br />

The sensor can be replaced, if necessary, w<strong>it</strong>hout interrupting the power supply in<br />

the explosion-hazard area.<br />

Use only <strong>Dräger</strong>Sensors which are approved for use w<strong>it</strong>h the <strong>Dräger</strong> <strong>Polytron</strong> <strong>3000</strong><br />

transm<strong>it</strong>ter.<br />

Caution:<br />

— When the transm<strong>it</strong>ter is installed in Ex areas zone 22 or Class II, Div. 1 & 2,<br />

Group E, F, G the opening of the housing (inclusive sensor replacement)<br />

must not be done when connected to power (power must be turned off or<br />

the area has to be declassified)! Explosion hazard!<br />

●<br />

Open the front cover of the service port w<strong>it</strong>h an Allen key by turning anticlockwise<br />

(approx. 60 o ). The maintenance sw<strong>it</strong>ch and potentiometers for calibration are now<br />

revealed.<br />

Attention!<br />

Use only a 5 mm Allen key w<strong>it</strong>hout a ball head.<br />

1 Set maintenance sw<strong>it</strong>ch to right-hand pos<strong>it</strong>ion. The 4 to 20 mA output changes to<br />

maintenance mode. In this pos<strong>it</strong>ion, a maintenance signal is relayed to the analogue<br />

output and prevents alarms being triggered.<br />

<strong>Polytron</strong><br />

1<br />

02023758_1.eps<br />

02123758_1.eps<br />

2 Remove bayonet ring from transm<strong>it</strong>ter; pull out old sensor.<br />

3 Remove sensor from packaging. Ensure that the sensor is of the same type as that<br />

specified on the sticker on the measuring un<strong>it</strong>.<br />

● Remove the short-circu<strong>it</strong> strap from the sensor (if <strong>it</strong> is f<strong>it</strong>ted).<br />

● There is a coded connector on the back of the sensor. Place the sensor in the<br />

opening w<strong>it</strong>h the connector at the back and the <strong>Dräger</strong> logo at the front.<br />

Before plugging the connector in the socket, ensure that they are identically coded.<br />

Incorrect connection can damage the sensor!<br />

2 Secure sensor in transm<strong>it</strong>ter w<strong>it</strong>h bayonet ring.<br />

Attention:<br />

For use in Zone 22, tighten the locking screw (2 mm Allen screw) of the<br />

sensor bayonet ring tight enough to ensure that the bayonet ring is<br />

secured against unintended loosening.<br />

2<br />

3<br />

<strong>Polytron</strong><br />

02223758_1.eps<br />

●<br />

Wa<strong>it</strong> until the measured value drops below the alarm threshold set on the central<br />

un<strong>it</strong>. Otherwise an alarm will be triggered when the maintenance sw<strong>it</strong>ch is returned<br />

to the measuring pos<strong>it</strong>ion immediately after the sensor replacement.<br />

17

Maintenance<br />

1 Set maintenance sw<strong>it</strong>ch to left-hand pos<strong>it</strong>ion.<br />

The 4 to 20 mA output changes to measuring mode.<br />

● Ref<strong>it</strong> the front cover of the service port and lock <strong>it</strong> in place by turning clockwise<br />

w<strong>it</strong>h an Allen key (approx. 60 o ).<br />

<strong>Polytron</strong><br />

1<br />

When the sensor has warmed up:<br />

— Transm<strong>it</strong>ters set for specific calibration w<strong>it</strong>h calibration gas<br />

● Calibrate sensor, page 14.<br />

— Transm<strong>it</strong>ters set for use of the manufacturer's calibration setting for the sensor.<br />

● Transm<strong>it</strong>ter is ready for use.<br />

02323758_1.eps<br />

Disposal of electrochemical sensors:<br />

— Sensors must be disposed of as special waste.<br />

Caution:<br />

— Do not throw sensors into the fire – explosion hazard.<br />

— Do not open sensors forcibly – risk of caustic burns.<br />

Note the relevant waste disposal regulations.<br />

Further information can be obtained from the relevant local author<strong>it</strong>y and from appropriate<br />

waste disposal companies.<br />

18

Fault – Cause – Remedy<br />

Fault – Cause – Remedy<br />

Fault Cause Remedy<br />

Flashing display Sensor warms up Wa<strong>it</strong> for warm-up phase to end.<br />

Display<br />

Equipment fault,<br />

e.g. wrong sensor installed<br />

Only use a sensor w<strong>it</strong>h the gas type, Part No.<br />

and measuring range indicated on the sticker.<br />

Display Measuring range end value exceeded Wa<strong>it</strong> until the gas concentration is w<strong>it</strong>hin the<br />

measuring range.<br />

Display Value too far below zero point Calibrate zero point if fault occurs frequently.<br />

19

Technical Data<br />

Technical Data<br />

The measuring range and the measuring properties depend on which type of sensor is installed – see the operating instructions<br />

for the sensor being used.<br />

CE markings — Devices and protective systems for use for the intended purpose in explosion-hazard<br />

area (Directive 94/9/EC)<br />

— Electromagnetic compatibil<strong>it</strong>y (Directive 89/336/EEC) max. influence on sensor: 2<br />

x repeatabil<strong>it</strong>y<br />

Ingress protection IP 66 / IP 67, according to EN 60 529 / IEC 529 (NEMA 4)<br />

Approvals<br />

ATEX<br />

<strong>Polytron</strong> <strong>3000</strong> is certified as type P3S.<br />

Device markings in accordance w<strong>it</strong>h 94/9/EC<br />

P3S<br />

0158 II 1G<br />

EEx ia IIC T4 (–40 o C Ta +65 o C)<br />

EEx ia IIC T6 (–40 o C Ta +40 o C)<br />

0158 II 3G<br />

EEx nL IIC T4 (–25 o C Ta +65 o C)<br />

EEx nL IIC T6 (–25 o C Ta +40 o C)<br />

BVS 03 ATEX E 406 X<br />

Power Supply: U i = 30 V, I i = 0,3 A, P i = 700 mW, C i = 0 nF, L i = 50 μH<br />

Meter Circu<strong>it</strong>, II 1G/3G: Uo = 7.6 V, Io = 1 mA, Ui = 10.4 V, Co = 2.5 μF, Lo = 10 mH<br />

0158 II 3D<br />

IP6x T65 o C (–40 o C Ta +65 o C)<br />

maximum supply voltage 30 V DC<br />

Year of manufacture (indicated by Serial No.) 1)<br />

<strong>Dräger</strong> Safety, 23560 Lübeck, Germany<br />

Safety parameters for the supply-voltage and signalling circu<strong>it</strong> (centre terminals of the<br />

docking station):<br />

U i = 30 V, I i = 0,3 A, P i = 700 mW, C i = 0 nF, L i = 50 mH<br />

IECEx<br />

P3S<br />

EEx ia IIC T4 (–40 o C Ta +65 o C)<br />

EEx ia IIC T6 (–40 o C Ta +40 o C)<br />

IECEx BVS 04 0003 X<br />

Power Supply: U i = 30 V, I i = 0,3 A, P i = 700 mW, C i = 0 μF, L i = 50 μH<br />

Year of construction (via serial number) 1)<br />

<strong>Dräger</strong> Safety, 23560 Lübeck, Germany<br />

1) The year of manufacture is indicated by the third letter in the serial number shown on the rating plate: T = 2003, U = 2004, W = 2005,<br />

X = 2006, Y = 2007, Z = 2008, A = 2009, B = 2010, C = 2011, etc.<br />

Example: Serial No. ARUH-0054: the third letter is U, which means that the un<strong>it</strong> was manufactured in 2004.<br />

20

Technical Data<br />

UL (Underwr<strong>it</strong>ers Laboratories Inc.)<br />

CSA (Canadian Standards Association)<br />

P3S<br />

Only as to Intrinsic Safety for use in Hazardous Locations<br />

Class I, Div. 1, Groups A, B, C, D<br />

Class II, Div. 1, Groups E, F, G<br />

Use in accordance w<strong>it</strong>h <strong>Dräger</strong> Control Drawing SE20105.<br />

T4: –40 ≤ Ta ≤ +65 o C, T6: –40 ≤ Ta ≤ +40 o C.<br />

Not tested in oxygen enriched atmospheres (>21 % O 2 ).<br />

Power Supply: V max = 30 V, I max = 0.3 A, P i = 700 mW,<br />

C i = 0 nF, L i = 50 μH<br />

Meter circu<strong>it</strong>: V oc = 7.6 V, I sc = 1 mA, V max = 10.4 V, C a = 2.5 μF, L a = 10 mH,<br />

C i = 0, L i = 0<br />

P3S<br />

Intrinsic safe<br />

®<br />

Class I, Div. 1, Groups A, B, C, D<br />

LR97594<br />

Class II, Div. 1, Groups E, F, G<br />

Ex ia T4 (–40 o C Ta +65 o NRTL/C<br />

C),<br />

Ex ia T6 (–40 o C Ta +40 o C)<br />

Signal transmission to central un<strong>it</strong><br />

Analogue<br />

— Measured-value signal 4 mA to 20 mA<br />

— Drift below zero point 3.8 mA to 4 mA<br />

— Full-scale value exceeded 20 mA to 20.5 mA<br />

— Un<strong>it</strong> fault

Order List<br />

Order List<br />

Part name and description<br />

Order No.<br />

<strong>Dräger</strong> Docking Station 83 17 990<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>s and <strong>Dräger</strong>Sensors<br />

Overview,<br />

page 23 and page 25<br />

Accessories:<br />

Splash guard 68 07 549<br />

Splash guard AC sensor 68 09 379<br />

Transm<strong>it</strong>ter feed un<strong>it</strong>, U0 = 28 V, I0 = 91 mA<br />

18 90 212<br />

Messrs. Stahl, type 9303 / 15 – 22 – 11<br />

Safety barriers are not designed for installation in the<br />

explosion-hazard area<br />

Duct Mount K<strong>it</strong> 83 17 150<br />

Assembly set 68 09 951<br />

Calibration accessories:<br />

Calibration w<strong>it</strong>h ampoules:<br />

Calibration flask 68 03 407<br />

Test-gas ampoules and calibration gas, see operating<br />

instructions for the <strong>Dräger</strong>Sensor being used<br />

Calibration w<strong>it</strong>h test gas cylinder:<br />

Calibration adapter 68 06 978<br />

Calibration adapter V 68 10 536<br />

Remote calibration adapter 68 07 955<br />

AC calibration adapter 68 09 380<br />

Pressure reducer<br />

on request<br />

Test gas cylinder<br />

Test gas = Target gas in n<strong>it</strong>rogen in concentrations between<br />

40 % and 100 % of the measuring range end value<br />

Test gas cylinder 99.9 % N 2 , (zero gas), 4 L, 200 bar<br />

Order from gas<br />

supplier<br />

– note delivery<br />

period of<br />

6 – 8 weeks and<br />

use-by date<br />

on request<br />

Spare parts:<br />

Dust filter for <strong>Dräger</strong>Sensor ...<br />

Selective filter for <strong>Dräger</strong>Sensor ...<br />

see<br />

sensor data sheet<br />

see<br />

sensor data sheet<br />

22

Order List<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>s<br />

Part name and description<br />

Order No.<br />

w<strong>it</strong>h display<br />

Order No.<br />

w<strong>it</strong>hout display<br />

Order No.<br />

<strong>Dräger</strong>Sensor<br />

For measuring ammonia (NH 3 ):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 100 ppm NH 3 , for <strong>Dräger</strong>Sensor NH 3 LC<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,,<br />

Measuring range 0 to 300 ppm NH 3 , for <strong>Dräger</strong>Sensor NH 3 HC<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 1000 ppm NH 3 , for <strong>Dräger</strong>Sensor NH 3 HC<br />

For measuring carbon monoxide (CO):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 100 ppm CO, for <strong>Dräger</strong>Sensor CO<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 300 ppm CO, for <strong>Dräger</strong>Sensor CO<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 1000 ppm CO, for <strong>Dräger</strong>Sensor CO<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 300 ppm CO, for <strong>Dräger</strong>Sensor CO LS<br />

83 16 637 83 16 737 68 09 680<br />

83 16 638 83 16 738 68 09 645<br />

83 16 639 83 16 739 68 09 645<br />

83 16 632 83 16 732 68 09 605<br />

83 16 631 83 16 731 68 09 605<br />

83 16 630 83 16 730 68 09 605<br />

83 16 633 83 16 733 68 09 620<br />

For measuring chlorine (Cl 2 ):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

83 16 647 83 16 747 68 09 665<br />

Measuring range 0 to 1 ppm Cl 2 , for <strong>Dräger</strong>Sensor Cl 2<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

83 16 648 83 16 748 68 09 665<br />

Measuring range 0 to 10 ppm Cl 2 , for <strong>Dräger</strong>Sensor Cl 2<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 25 ppm Cl 2 , for <strong>Dräger</strong>Sensor Cl 2<br />

83 16 649 83 16 749 68 09 665<br />

For measuring hydrogen sulphide (H 2 S):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 20 ppm H 2 S, for <strong>Dräger</strong>Sensor H 2 S<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 50 ppm H 2 S, for <strong>Dräger</strong>Sensor H 2 S<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 100 ppm H 2 S, for <strong>Dräger</strong>Sensor H 2 S<br />

For measuring n<strong>it</strong>rogen monoxide (NO):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 50 ppm NO, for <strong>Dräger</strong>Sensor NO LC<br />

83 16 634 83 16 734 68 10 435<br />

83 16 635 83 16 735 68 10 435<br />

83 16 636 83 16 736 68 10 435<br />

83 16 640 83 16 740 68 09 625<br />

For measuring n<strong>it</strong>rogen dioxide (NO 2 ):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

83 16 641 83 16 741 68 09 655<br />

Measuring range 0 to 10 ppm NO 2 , for <strong>Dräger</strong>Sensor NO 2<br />

23

Order List<br />

Part name and description<br />

Order No.<br />

w<strong>it</strong>h display<br />

Order No.<br />

w<strong>it</strong>hout display<br />

Order No.<br />

<strong>Dräger</strong>Sensor<br />

For measuring oxygen (O 2 ):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

83 16 642 83 16 742 68 09 720<br />

Measuring range 0 to 5 Vol.-% O 2 , for <strong>Dräger</strong>Sensor O2<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

83 16 643 83 16 743 68 09 720<br />

Measuring range 0 to 25 Vol.-% O 2 , for <strong>Dräger</strong>Sensor O 2<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

83 16 644 83 16 744 68 09 720<br />

Measuring range 0 to 100 Vol.-% O 2 , for <strong>Dräger</strong>Sensor O 2<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 25 Vol.-% O 2 , for <strong>Dräger</strong>Sensor O 2 LS<br />

83 16 645 83 16 745 68 09 630<br />

For measuring sulphur dioxide (SO 2 ):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

83 16 646 83 16 746 68 09 660<br />

Measuring range 0 to 10 ppm SO 2 , for <strong>Dräger</strong>Sensor SO 2<br />

For the measurement of acidic compounds<br />

(SiCl 4 , BCl 3 , ClF 3 , HBr, SiF 4 ):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 3 ppm, for <strong>Dräger</strong>Sensor AC<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 10 ppm, for <strong>Dräger</strong>Sensor AC<br />

For the measurement of boron trichloride (BCl 3 ):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 10 ppm BCl 3 , for <strong>Dräger</strong>Sensor AC<br />

83 16 652 83 16 752 68 10 595<br />

83 16 657 83 16 757 68 10 595<br />

83 16 666 83 16 766 68 10 595<br />

For the measurement of boroethane (B 2 H 6 ):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 0.5 ppm B 2 H 6 , for <strong>Dräger</strong>Sensor Hydride SC<br />

For the measurement of ethylene oxide (C 2 H 4 O):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 50 ppm C 2 H 4 O, for <strong>Dräger</strong>Sensor OV<br />

For the measurement of hydride (PH 3 , SiH 4 ):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 0.3 ppm, for <strong>Dräger</strong>Sensor Hydride<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 1 ppm, for <strong>Dräger</strong>Sensor Hydride<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 10 ppm, for <strong>Dräger</strong>Sensor Hydride<br />

For the measurement of hydrogen chloride (HCl):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 30 ppm HCI, for <strong>Dräger</strong>Sensor HCI<br />

83 16 656 83 16 756 68 09 980<br />

83 16 658 83 16 758 68 09 615<br />

83 16 653 83 16 753 68 09 635<br />

83 16 667 83 16 767 68 09 635<br />

83 16 668 83 16 768 68 09 635<br />

83 16 670 83 16 770 68 09 640<br />

24

Order List<br />

Part name and description<br />

Order No.<br />

w<strong>it</strong>h display<br />

Order No.<br />

w<strong>it</strong>hout display<br />

Order No.<br />

<strong>Dräger</strong>Sensor<br />

For the measurement of hydrogen (H 2 ):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

83 16 669 83 16 769 68 09 685<br />

Measuring range 0 to 1000 ppm, for <strong>Dräger</strong>Sensor H 2<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to <strong>3000</strong> ppm, for <strong>Dräger</strong>Sensor H 2<br />

83 16 655 83 16 755 68 09 685<br />

For the measurement of hydrazine (N 2 H 4 ):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 1 ppm N 2 H 4 , for <strong>Dräger</strong>Sensor Hydrazine<br />

83 16 650 83 16 750 68 10 180<br />

For the measurement of ozone (O 3 ):<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range 0 to 1 ppm O 3 , for <strong>Dräger</strong>Sensor O3<br />

For the measurement of further gases:<br />

<strong>Polytron</strong> <strong>3000</strong> measuring un<strong>it</strong>,<br />

Measuring range and <strong>Dräger</strong>Sensor<br />

83 16 665 83 16 765 68 10 290<br />

on request on request on request<br />

25

ATEX approval<br />

ATEX approval<br />

26

ATEX approval<br />

27

ATEX approval<br />

28

ATEX approval<br />

29

ATEX approval<br />

30

IECEx approval<br />

IECEx approval<br />

31

IECEx approval<br />

32

IECEx approval<br />

33

IECEx approval<br />

34

UL approval<br />

UL approval<br />

35

UL approval<br />

36

UL approval<br />

37

CSA - Approval<br />

CSA - Approval<br />

38

CSA - Approval<br />

39

CSA - Approval<br />

40

CSA - Approval<br />

41

CSA - Approval<br />

42

Declaration of Conform<strong>it</strong>y<br />

Declaration of Conform<strong>it</strong>y<br />

43

Declaration of Conform<strong>it</strong>y<br />

44

Declaration of Conform<strong>it</strong>y<br />

45

Declaration of Conform<strong>it</strong>y<br />

46

Index<br />

Index<br />

4 to 20 mA current loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8<br />

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3, 22<br />

Ambient cond<strong>it</strong>ions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21<br />

Analogue signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20<br />

Areas subject to explosion hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3, 6<br />

ATEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20<br />

ATEX approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26, 31<br />

Cable inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8, 21<br />

Calibrating the sens<strong>it</strong>iv<strong>it</strong>y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16<br />

Calibrating the zero point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16<br />

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Calibration accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22<br />

Calibration adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16<br />

Calibration gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16<br />

capac<strong>it</strong>y of the selective filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Category 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Category 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

CE markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20<br />

Central un<strong>it</strong>s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5<br />

Coded pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17<br />

Connecting to the central un<strong>it</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8<br />

Declaration of Conform<strong>it</strong>y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43<br />

Dens<strong>it</strong>y of gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5<br />

Device category 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Device markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20<br />

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

Disposal of electrochemical sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18<br />

Docking station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7, 51<br />

Drilling templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51<br />

Dust and water protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6, 7, 10<br />

Earth point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8<br />

electrochemical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18<br />

Environmental factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Equipment faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19<br />

Explosion-hazard areas of zone 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Explosion-hazard areas of zone 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19<br />

F<strong>it</strong>ting the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

47

Index<br />

Ingress protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20<br />

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3, 13<br />

Installation in potentially explosive atmospheres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Installation location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Installing in non-explosion-hazard areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10<br />

Installing the 4 to 20 mA current loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8<br />

Installing the transm<strong>it</strong>ter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

Liabil<strong>it</strong>y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

Local requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3, 13<br />

Maintenance Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3, 13<br />

Maintenance sw<strong>it</strong>ch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11, 14<br />

Maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Manufacturer's calibration setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

Measurement Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14<br />

Measuring / maintenance mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14<br />

Measuring range exceeded . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

Measuring range too negative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

Measuring un<strong>it</strong>, installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10<br />

Mon<strong>it</strong>oring of gas concentrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

Operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

Order List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22<br />

Performance data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Physical properties of the gas to be measured . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21<br />

Polar<strong>it</strong>y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10<br />

Potentiometer for calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

Potentiometer for sens<strong>it</strong>iv<strong>it</strong>y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

Potentiometer for the calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

Potentiometer for zero point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21<br />

Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Programmable logic controller (PLC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

Raincover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6, 7<br />

Reflective shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

replace the selective filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Replacing the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13, 17<br />

48

Index<br />

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

Safety barriers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Sensor drift below zero point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Short-circu<strong>it</strong> strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17<br />

Signal transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21<br />

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22<br />

Splash guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Splashing water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21<br />

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20<br />

Terminal strip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7<br />

Test gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14<br />

The measuring un<strong>it</strong> <strong>Dräger</strong> <strong>Polytron</strong> <strong>3000</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Transm<strong>it</strong>ter supply un<strong>it</strong>s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />