You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

QM Corner<br />

If it is unsafe - don’t do it!<br />

Prevention is better than cure<br />

It’s all about the little things!<br />

By Leif Gunnar Alvær<br />

All business activities, not least in the<br />

chemical trade, involve an element<br />

of risk. Therefore proactive risk<br />

management is needed in all units.<br />

− Identification of hazards<br />

− Risk assessment<br />

− Risk prevention, and<br />

− Risk protection<br />

Risk management in everyday life<br />

When crossing the street we usually do a<br />

quick risk evaluation.<br />

Hazard: May get hit by a car.<br />

Assessment: Consequence may<br />

be serious. Without<br />

precautions the probability<br />

is high.<br />

Prevention: Run quickly. Look out.<br />

Move to a safer place.<br />

Wait for green light.<br />

Avoid crossing.<br />

Protection: Use helmet, boots and<br />

gloves. Have good medical<br />

care. Have insurance.<br />

As you see there are many possibilities.<br />

In most cases reducing the probability<br />

of an adverse occurrence is better than<br />

reducing its consequences.<br />

Perception of what is an acceptable risk<br />

level is individual, and it could be difficult<br />

to judge how safe is “safe enough”.<br />

It may be better to ask yourself: “Is it<br />

unsafe”? If the answer is: “Yes”, don’t<br />

do it!<br />

More formal everyday risk management<br />

activities are referred to as Safe Job<br />

Analysis (SJA) or Task Risk Assessment<br />

(TRA).<br />

Systematic risk management<br />

There are many threats to consider<br />

in our global business, and their<br />

consequences may be serious injury,<br />

fire, groundings, pollution, lost clients,<br />

fines or ruin. But, hazards need not<br />

be as dangerous if we apply active and<br />

systematic risk management to handle<br />

them. Good knowledge, best practices,<br />

experience feedback and proper working<br />

procedures reduce the probability of<br />

something going wrong. Personal<br />

protection, life saving equipment,<br />

contingency preparedness and insurance<br />

are factors that may reduce the possible<br />

consequences if something nevertheless<br />

should go wrong.<br />

To avoid accidents or even disasters<br />

we must make sure that what we have<br />

decided to do to manage the risk is<br />

implemented. Ensuring compliance with<br />

plans and procedures is another piece of<br />

the same story – quality management.<br />

CORPORATE QUALITY<br />

MANAGEMENT MANUAL<br />

Table of Contents<br />

Definitions<br />

Introduction<br />

2006 Q2<br />

Mission and Policies<br />

Organisational structures<br />

<strong>2008</strong> Q1<br />

Responsibilities<br />

2006 Q4<br />

Human Resource Management 2007 Q2<br />

Common Directives<br />

2007 Q4<br />

Processes and elements of<br />

Quality Management<br />

2007 Q3<br />

Quality Management System 2007 Q3<br />

Quality Assurance and Improvement 2006 Q3<br />

Event Analysis<br />

<strong>2008</strong> Q2<br />

HSE Management<br />

2007 Q1<br />

Risk Management<br />

<strong>2008</strong> Q4<br />

In today’s tough market it’s an objective<br />

in itself to operate as effective as<br />

possible, something we all aim for on a<br />

daily basis. The brokers strive towards<br />

maximum tonnage utilisation, the<br />

operators for voyage and port turnaround<br />

optimisation. Our port captains<br />

further assist our agents with ensuring<br />

maximum efficiency in our port calls.<br />

The same applies for our vessels,<br />

where masters and chiefs all work to<br />

achieve the most efficient usage of their<br />

respective vessels. Small adjustments<br />

can mean huge savings.<br />

An example of the latter; one of our<br />

vessels had an ETA Port Said 06:00 am.<br />

To reach the convoy she was not required<br />

to arrive before 19:00 hrs, with that<br />

meant a waiting time at the anchorage<br />

for about 13hrs. However, the operator<br />

in agreement with the captain decided<br />

to reduce the speed, causing the vessel<br />

to arrive at 15:30 instead of 06:00. The<br />

vessel had a net saving of more than 45<br />

mt fuel which amounts to thousands of<br />

US dollars. All because the master and<br />

the operator were alert and focused.<br />

Energy saving is good for the<br />

environment and the economy<br />

Energy saving is obviously targeted<br />

throughout our organisation, and <strong>Odfjell</strong><br />

Tankers recognises the need for a<br />

common strategy on how to utilise the<br />

energy. <strong>Odfjell</strong> Tankers has therefore<br />

proactively initiated a project called<br />

Energy Management Project (EMP). The<br />

purpose of this project is to work towards<br />

a common Energy Management Strategy.<br />

A great deal of the EMP will then be to<br />

identify best practices and distribute this<br />

knowledge to all vessels. Moreover, the<br />

better we become to utilize the energy,<br />

we are not only saving the environment,<br />

we are also saving costs.<br />

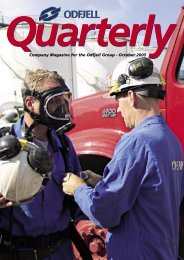

Members of the EMP: From left Leif Gunnar Alvær, Siri Anne Mjåtvedt, Tony Martin Fjellanger,<br />

Erik Hjortland. Sigmund Larsen, Geir Bjørndalen and Geir Almestad were not present when the<br />

photo was taken.<br />

A multi-disciplinary project<br />

The EMP is multi disciplinary with<br />

members from operations, chartering,<br />

ship management and technology.<br />

A significant key success factor of<br />

the project is of course an open and<br />

constructive communication with our<br />

seafarers. We therefore encourage<br />

everyone with questions, possible<br />

initiatives or just plain criticism, to<br />

contact us. We have already received<br />

good initiatives from some of our vessels<br />

and superintendents. As a wise man<br />

once said; “Don’t reinvent the wheel, just<br />

realign it.”<br />

Weather routing<br />

Currently we have started a few<br />

initiatives, and more are to follow.<br />

Firstly we are testing weather routing.<br />

Weather routing is based on the master<br />

informing a third party provider with<br />

voyage relevant data. This includes<br />

departure/arrival, trim etc. The master<br />

then receives a recommended route<br />

suggestion based on actual weather data<br />

and weather forecasts. This will ensure<br />

that the vessel can choose not only the<br />

safest route, but also the route with the<br />

shortest sailing time. Better information,<br />

shorter and safer voyages not only<br />

lightens the master’s burden onboard<br />

but also saves us energy.<br />

“Energy Management is all about the<br />

little things.”<br />

For feedback, questions or good<br />

suggestions, please use<br />

energy.management@odfjell.com<br />

16 <strong>Odfjell</strong> <strong>Quarterly</strong> <strong>December</strong> <strong>2008</strong> <strong>Odfjell</strong> <strong>Quarterly</strong> <strong>December</strong> <strong>2008</strong> 17