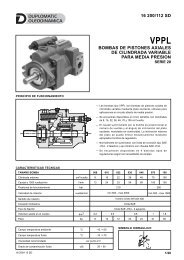

62 300/110 ED PILOT OPERATED PRESSURE ... - Duplomatic

62 300/110 ED PILOT OPERATED PRESSURE ... - Duplomatic

62 300/110 ED PILOT OPERATED PRESSURE ... - Duplomatic

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

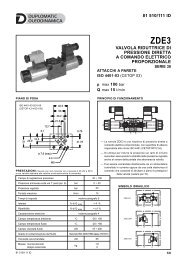

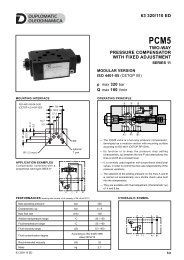

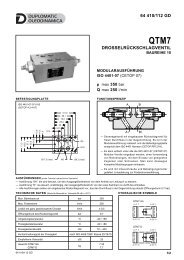

<strong>62</strong> <strong>300</strong>/<strong>110</strong> <strong>ED</strong><br />

Z4M<br />

<strong>PILOT</strong> OPERAT<strong>ED</strong><br />

<strong>PRESSURE</strong> R<strong>ED</strong>UCING VALVE<br />

SERIES 50<br />

MODULAR VERSION<br />

ISO 4401-05 (CETOP 05)<br />

p max 320 bar<br />

Q max (see table of performances)<br />

MOUNTING INTERFACE<br />

OPERATING PRINCIPLE<br />

ISO 4401-05-04-0-05<br />

(CETOP 4.2-4-05-320)<br />

P<br />

T<br />

54<br />

50.8<br />

37.3<br />

27<br />

46<br />

32.5<br />

21.4<br />

6.3<br />

16.7<br />

3.2<br />

T<br />

P<br />

A<br />

B<br />

M6<br />

P1<br />

T1<br />

— The Z4M valve is a piloted pressure reducing valve made<br />

as a modular version with mounting surface according to<br />

the ISO 4401 (CETOP PR 121H) standards.<br />

— It is used to reduce pressure on secondary circuit<br />

branches, assuring stability of the controlled pressure and<br />

even changing the flow that runs through the valve.<br />

Ø11.2 (max)<br />

— It can be assembled quickly under the ISO 4401-05<br />

(CETOP 05) directional solenoid valves without use of<br />

pipes.<br />

CONFIGURATIONS (see hydraulic symbols table)<br />

— Z4M*-I: pressure reduction on line P - drainage connected to line T.<br />

— Z4M*-A: pressure reduction on line A and full pressure on line B.<br />

— Z4M*-B: pressure reduction on line B and full pressure on line A.<br />

PERFORMANCES (measured with mineral oil of viscosity 36cSt at 50°C)<br />

Maximum operating pressure bar 320<br />

— It is normally supplied with a countersunk hex adjustment<br />

screw, locking nut and maximum adjustment travel<br />

limiting device.<br />

— It is available in four different pressure adjustment ranges<br />

up to 320 bar.<br />

HYDRAULIC SYMBOLS<br />

Z4M*-I PT AB<br />

M<br />

Maximum flow rate in the controlled line P<br />

Maximum flow rate in the free lines<br />

Drainage flow rate<br />

l/min<br />

80<br />

100<br />

≤ 0,07<br />

Ambient temperature range °C -20 / +50<br />

Z4M*-A<br />

M<br />

P1 T1<br />

PT<br />

A1 B1<br />

AB<br />

Fluid temperature range °C -20 / +80<br />

Fluid viscosity range cSt 10 ÷ 400<br />

P1 T1<br />

A1 B1<br />

Fluid contamination degree<br />

According to ISO 4406:1999<br />

class 20/18/15<br />

Z4M*-B<br />

M<br />

PT<br />

AB<br />

Recommended viscosity cSt 25<br />

Mass kg 2,7<br />

P1 T1<br />

A1 B1<br />

<strong>62</strong> <strong>300</strong>/<strong>110</strong> <strong>ED</strong> 1/2

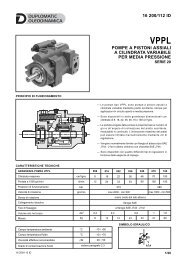

Z4M<br />

SERIES 50<br />

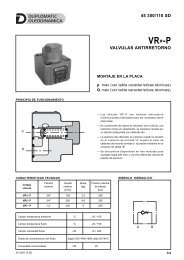

1 - IDENTIFICATION CODE<br />

Z 4 M - / / 50 /<br />

Pressure reducing valve<br />

Size: ISO 4401-05 (CETOP 05)<br />

Modular version<br />

Pressure adjustment range:<br />

3 = 5 ÷ 70 bar<br />

4 = 8 ÷ 140 bar<br />

5 = 10 ÷ 210 bar<br />

6 = 15 ÷ 320 bar<br />

Seals: omit for mineral oils<br />

V = viton for special fluids<br />

Series No. (the overall and mounting<br />

dimensions remain unchanged from 50 to 59)<br />

M1 = Adjustment knob<br />

(omit for adjustment with countersunk hex screw)<br />

Configurations: I: pressure reduction on line P. Internal drainage connected to line T<br />

A: pressure reduction on line A and full pressure on line B<br />

B: pressure reduction on line B and full pressure on line A<br />

2 - CHARACTERISTIC CURVES (values obtained with viscosity of 36 cSt at 50°C)<br />

ADJUSTMENT<br />

<strong>PRESSURE</strong> DROPS ∆p - Q<br />

1) pressure drops<br />

P 1 →P<br />

2) pressure drops<br />

on free lines<br />

(ex. A→A 1 )<br />

3 - HYDRAULIC FLUIDS<br />

Use mineral oil-based hydraulic fluids HL or HM type, according to ISO 6743-4. For these fluids, use NBR seals. For fluids HFDR type<br />

(phosphate esters) use FPM seals (code V). For the use of other kinds of fluid such as HFA, HFB, HFC, please consult our technical<br />

department. Using fluids at temperatures higher than 80 °C causes a faster degradation of the fluid and of the seals characteristics.<br />

The fluid must be preserved in its physical and chemical characteristics.<br />

4 - OVERALL AND MOUNTING DIMENSIONS<br />

4<br />

1<br />

2<br />

dimensions in mm<br />

25<br />

66<br />

72<br />

26<br />

50<br />

23.5<br />

3<br />

1 Locking nut<br />

spanner 17<br />

2 Countersunk hex<br />

adjustment screw:<br />

Spanner 5.<br />

Rotate clockwise to<br />

increase pressure<br />

5<br />

ø32<br />

70<br />

12<br />

T<br />

P<br />

A B<br />

T<br />

117<br />

185<br />

50<br />

3 Mounting surface<br />

with sealing rings:<br />

5 OR type 2050<br />

(12.42x1.78)<br />

90 Shore<br />

4 Pressure gauge port<br />

1/4” BSP<br />

DUPLOMATIC OLEODINAMICA S.p.A.<br />

20015 PARABIAGO (MI) • Via M. Re Depaolini 24<br />

Tel. +39 0331.895.111<br />

Fax +39 0331.895.339<br />

www.duplomatic.com • e-mail: sales.exp@duplomatic.com<br />

<strong>62</strong> <strong>300</strong>/<strong>110</strong> <strong>ED</strong> REPRODUCTION IS FORBIDDEN. THE COMPANY RESERVES THE RIGHT TO APPLY ANY MODIFICATIONS.<br />

2/2