Overview Presentation - Canusa-CPS

Overview Presentation - Canusa-CPS Overview Presentation - Canusa-CPS

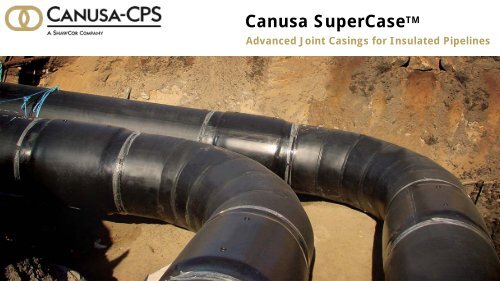

Canusa SuperCase TM Advanced Joint Casings for Insulated Pipelines Advanced Thermal and Corrosion Protection

- Page 2 and 3: Seven Industry Leading Business Uni

- Page 4 and 5: The Global Leader in Field Applied

- Page 6 and 7: Traditional Crosslinked Joint Casin

- Page 8 and 9: Introducing… Canusa SuperCase TM

- Page 10 and 11: Canusa SuperCase TM , type CSC-XP

- Page 12 and 13: Canusa SuperCase TM , type CSC-XP

- Page 14 and 15: CSC-XP 450-750 in Sandbox

- Page 16 and 17: Absolute No Moisture Ingress (At an

- Page 18 and 19: Canusa SuperCase TM , type CSC-XP

- Page 20 and 21: Insulated Pipe Joint Ready (PE 450

- Page 22 and 23: Abrasion of HDPE Jacket Pipe Surfac

- Page 24 and 25: CSC-XP Slid on Pipe Prior to Weldin

- Page 26 and 27: Preheating (to 40°C) of HDPE Jacke

- Page 28 and 29: Casing Positioned over Cutback Area

- Page 30 and 31: CSC-XP Joint Casing Application Com

- Page 32 and 33: Foam Injection (Hand Pour Method Sh

- Page 34 and 35: Preheating of Hole for Plug Welding

- Page 36 and 37: Completed CSC-XP Joint Casting Casi

<strong>Canusa</strong> SuperCase TM<br />

Advanced Joint Casings for Insulated Pipelines<br />

Advanced Thermal and<br />

Corrosion Protection

Seven Industry Leading<br />

Business Units<br />

Pipeline and Pipe Services<br />

Bredero Shaw<br />

The global leader in pipe coatings specializing in coating<br />

systems to provide integrity for land and marine pipelines<br />

<strong>Canusa</strong>-<strong>CPS</strong><br />

The global leader in field applied anti-corrosion and<br />

insulation coatings and services for land and marine pipeline<br />

networks with a focus on the oil and gas, district energy and<br />

water transmission industries<br />

Shaw Pipeline Services<br />

Petrochemical and Industrial<br />

DSG-<strong>Canusa</strong><br />

A leading global supplier of heat shrink tubing for<br />

sealing and protection for the electrical/utility,<br />

communications, automotive and electronics markets.<br />

ShawFlex<br />

Specialized control and instrumentation cable for<br />

advanced applications in the petrochemical, power<br />

generation, pulp and paper, primary metals, automation,<br />

robotics and automotive industries<br />

The world’s leading supplier of advanced weld inspection<br />

technolgies and services for oil and gas and other pipelines<br />

Flexpipe Systems<br />

Flexible composite pipe for oil and gas and other distribution<br />

and gathering applications<br />

Guardian<br />

A leading supplier of Inspection, repair and inventory<br />

management services for drill pipe

The Global Leader in Field<br />

Applied Coatings and Services<br />

Coating Rehabilitation<br />

District Energy Networks<br />

Onshore Oil & Gas Pipelines<br />

Full Range of Installation<br />

Equipment and Services<br />

High Temperature<br />

Coating Systems<br />

Water Pipelines<br />

Offshore Pipelines

The Global Leader in Field<br />

Applied Coatings and Services<br />

Coating Rehabilitation<br />

District Energy Networks<br />

Onshore Oil & Gas Pipelines<br />

Full Range of Installation<br />

Equipment and Services<br />

High Temperature<br />

Coating Systems<br />

Water Pipelines<br />

Offshore Pipelines

<strong>Canusa</strong> SuperCase TM System<br />

• Over a million joints successfully coated<br />

• Traditionally, <strong>Canusa</strong> has supplied two versions:<br />

Type CSC<br />

▪<br />

▪<br />

<strong>Canusa</strong> SuperCase, type CSC:<br />

1. Edge Recovery/Sealing<br />

2. Pressure Testing as per EN 489<br />

3. PU Foam Injection into Applied Casing<br />

<strong>Canusa</strong> SuperCase, type CSC-X:<br />

1. PU foam applied using a removable mould<br />

2. PU foam Inspection<br />

3. Fully Shrinkable CSC-X (and Shrink Film for Double Seal)<br />

Applied over Foam<br />

Type CSC-X

Traditional Crosslinked Joint Casing Systems<br />

• Traditionally, crosslinked PE sheet materials were limited to relatively<br />

low thickness and to standard PE raw material grades<br />

– Due to challenges with irradiation and expansion process<br />

– This also allowed the material to be easily wrapped and handled.<br />

• Thicker, pressure testable crosslinked joint casings have therefore<br />

typically been manufactured by bonding thin layers of crosslinked<br />

HDPE material on a mandrel inside an oven to get desired thickness<br />

• This ‘batch’ process is slower, less efficient and more expensive.

Next Generation Crosslinked Joint Casing System<br />

• In 2009-10, <strong>Canusa</strong>-<strong>CPS</strong> invested and developed next generation<br />

extrusion, irradiation and expansion equipment and techniques<br />

• Allowed for centralized manufacturing of thicker, advanced multilayered<br />

crosslinked HDPE materials<br />

• Formed basis for development of next generation of crosslinked joint<br />

casings<br />

• Provides leading edge performance with lower cost to end user

Introducing… <strong>Canusa</strong> SuperCase TM , type CSC-XP

<strong>Canusa</strong> SuperCase TM , type CSC-XP<br />

• HybridPEX TM Technology<br />

• Advanced Sealing Performance<br />

• Efficient Design / Manufacturing<br />

• Strongest Resistance to Soil Stress<br />

• Fastest Installation<br />

• Flexible Installation

<strong>Canusa</strong> SuperCase TM , type CSC-XP<br />

• HybridPEX TM Technology<br />

▪<br />

Rugged, rigid and crack resistant bimodal<br />

HDPE meeting EN 253 standards<br />

(same rating as mainline HDPE jacket)<br />

▪<br />

Crosslinked on the outside<br />

▪ Faster application, improved productivity<br />

▪ Resists premature shrinking<br />

▪ Maintains long term tightness and seal<br />

▪<br />

Uncrosslinked on the inside<br />

▪ Maximum adhesion, weldability and<br />

compatibility<br />

Offering the best of crosslinked<br />

and uncrosslinked casings!

<strong>Canusa</strong> SuperCase TM , type CSC-XP<br />

• Advanced Adhesive Technology<br />

▪<br />

Minimum preheats for more consistent<br />

installation and speed<br />

▪<br />

Highest shear strength for maximum<br />

resistance to forces associated with preinsulated<br />

pipelines<br />

▪<br />

Proven long term resistance to water<br />

immersion

<strong>Canusa</strong> SuperCase TM , type CSC-XP<br />

• Efficient Design / Manufacturing<br />

HybridPEX TM Sheet Cut to Length<br />

Sheet Bonded When Required<br />

Casing Ready with Short Lead Time<br />

▪<br />

▪<br />

▪<br />

▪<br />

Bulk sheet supplied from <strong>Canusa</strong>-<strong>CPS</strong> manufacturing facility with built-in consistency/quality<br />

No need to bond layers of thin sheet using ovens (inconsistent, slow batch process)<br />

Allows for short lead times (casings made quickly upon order receipt)<br />

Results in lower installed cost for end user

<strong>Canusa</strong> SuperCase TM , type CSC-XP<br />

• Strongest Resistance to Soil Stress<br />

▪<br />

▪<br />

Advanced adhesive and crosslinked bimodal HDPE<br />

materials maximize rigidity and shear strength<br />

Easily meets EN 489:2009 and even much more severe<br />

requirements for soil stress resistance<br />

Prior to Testing<br />

After Soil Stress Test<br />

FFI (Hanover) Sandbox Testing<br />

EN 489:2009 test with increased requirements of 3m simulated sand overfill, 300<br />

cycles on PE 450 and PE 225 sized pipe samples

CSC-XP 450-750 in Sandbox

Casing Completely Intact at Edges<br />

(Both Top and Bottom and on Each Side)

Absolute No Moisture Ingress<br />

(At any Point on All Samples)<br />

PE 450 Size – 12:00 PE 450 Size – 6:00<br />

PE 225 Size – 12:00 PE 225 Size – 6:00

<strong>Canusa</strong> SuperCase TM , type CSC-XP<br />

• Fastest Installation<br />

▪<br />

Outer crosslinked bimodal HDPE allowing for<br />

fastest material response time<br />

▪<br />

Low preheat adhesive reduces installation<br />

time and improves consistency<br />

▪<br />

No requirement for additional shrink collars<br />

on the edges to meet requirements for soil<br />

stress resistance

<strong>Canusa</strong> SuperCase TM , type CSC-XP<br />

• Flexible Installation<br />

Seal, Pressure Test, Then Foam<br />

1. Seal Edges then Foam (Pressure Testable)<br />

▪ Casing is applied (edges recovered)<br />

▪ Then pressure-tested<br />

▪ Then PU foam is injected into the cavity<br />

OR<br />

2. Foam then Apply Casing (Fully Shrinkable)<br />

▪ PU foam is applied first using a removable mould<br />

▪ The PU foam can then be fully inspected<br />

▪ Then the full-shrinkable casing is applied over the foam<br />

Foam, Inspect, then Seal

<strong>Canusa</strong> SuperCase TM , type CSC-XP<br />

Installation Procedure<br />

Pressure Testable Method

Insulated Pipe Joint Ready (PE 450 Size Shown)

Cleaning of HDPE Jacket Pipe Surface

Abrasion of HDPE Jacket Pipe Surface

HDPE Jacket Pipe Cleaned and Abraded<br />

(Ready for Application of Joint Casing System)

CSC-XP Slid on Pipe Prior to Welding

Cleaning and Abrasion of Joint Casing Inner Surface

Preheating (to 40°C) of HDPE Jacket Pipe Surface

Adhesive Application<br />

(Separately Applied to Eliminate Potential for Contaminants)

Casing Positioned over Cutback Area<br />

Heat Shields Applied for Controlled Application

Casing Application<br />

(Medium Intensity Torch Application Shown)

CSC-XP Joint Casing Application Complete<br />

(Ready for Pressure Testing and Foam Injection)

Pressure Testing (0.2 BAR)

Foam Injection (Hand Pour Method Shown)

Foam Expansion

Preheating of Hole for Plug Welding

Foam Plug Welding<br />

(Enhanced by Uncrosslinked Portion of HybridPEX TM )

Completed CSC-XP Joint Casting Casing<br />

(Seal then Foam Method with Pressure Testing)

<strong>Canusa</strong> SuperCase TM<br />

Advanced Joint Casings for Insulated Pipelines<br />

For additional information, contact:<br />

<strong>Canusa</strong>-<strong>CPS</strong> Product Management<br />

Attention: Pascal Laferriere or Paul Boczkowski<br />

Telephone: +1 416 743 7111<br />

Email: plaferriere@canusa.com or pboczkowski@canusa.com