Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

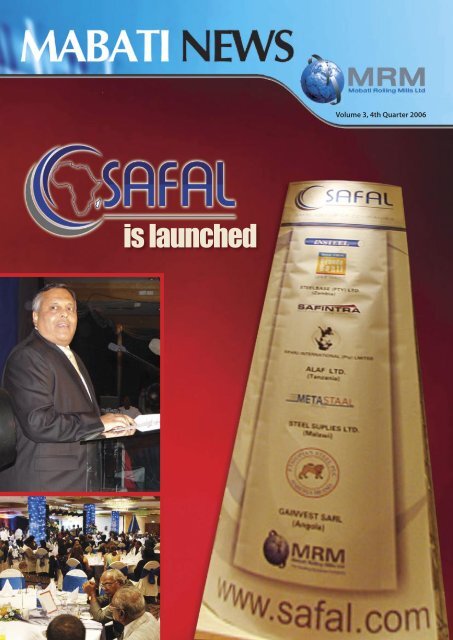

Volume 3, 4th Quarter 2006<br />

is launched<br />

M A B A T I N E W S<br />

1

FROM THE EDITOR<br />

As the year takes its<br />

sundown dive, the<br />

<strong>Mabati</strong> News Editorial<br />

Board pauses to look<br />

back at 2006 as the year<br />

that was. As a team and<br />

as a Company we join<br />

hands to review our<br />

performance objectives<br />

in terms of delivery.<br />

Therefore it is time to<br />

celebrate whatever<br />

achievements we have<br />

realised and review those<br />

areas where we did not<br />

succeed as expected.<br />

This is a moment of<br />

truth. It is the time our<br />

readers take the centre<br />

stage because they are<br />

the ones to tell us on the<br />

face whether we lived<br />

up to their expectations<br />

or fell short. It is time to<br />

Members of the Editorial Board<br />

set higher delivery goals<br />

for the coming year.<br />

We would like to reassure our readers of an improvement taking into account<br />

your concerns and suggestions. We certainly share your sentiments of making<br />

every issue of <strong>Mabati</strong> News the most awaited publication by all our readers.<br />

However, 2006 will be remembered with nostalgia. It is the year when <strong>MRM</strong><br />

became an international family member - the Safal Group. The Safal Group, Horn<br />

of Africa Region, was officially launched amidst pomp, colour and pageantry at a<br />

spectacular function at a Nairobi hotel this year (see the lead story). It is also the<br />

year in which <strong>MRM</strong> staff participated in the Nairobi Marathon and brought home<br />

a number of medals. It is the year when the <strong>MRM</strong>’s caring nature witnessed the<br />

inauguration of the <strong>Mabati</strong> Technical Training Institute at Mariakani, a significant<br />

contribution to society through the corporate social responsibility initiatives. It<br />

is the year in which the multi-million US dollar investment in the Pickling Line<br />

was officially commissioned. It is also the year in which <strong>MRM</strong> launched a number<br />

of new products, including the revolutionary roofing concept - SAFLOK700.<br />

What an eventful year. One can reflect, but for <strong>MRM</strong> it is just the beginning of<br />

greater things. The <strong>Mabati</strong> family is now focusing on the strategies of delighting<br />

all our customers through creative and customer-focused products and services.<br />

There is greater focus on empowering every <strong>MRM</strong> employee with target training<br />

opportunities to sharpen their talents and competencies in order to shift<br />

company performance to the next level in the true spirit of better performance<br />

and leadership.<br />

We take this opportunity to thank all our readers for their support and useful<br />

pieces of advice. We salute the <strong>MRM</strong> management for sponsoring the <strong>Mabati</strong><br />

News publication. We congratulate Mr. Kaushik Shah for becoming the first CEO<br />

of the SAFAL Group, Horn of Africa Region. We also take this opportunity to wish<br />

<strong>MRM</strong> customers, staff members, families and friends and all our readers a Merry<br />

Christmas and a prosperous 2007.<br />

Cheers!<br />

Contents<br />

2 - From the Editor<br />

3 - The launch of SAFAL, Horn of Africa<br />

5 - Chairman's Message<br />

6 - COO’s Message<br />

7 - Interview<br />

8 - <strong>Mabati</strong> News<br />

9 - Staff corner<br />

10 - Pictorial<br />

<strong>MRM</strong> NEW STAFF<br />

Pochiraju Hanumantha Rao<br />

(Imports Officer, Mariakani)<br />

Reuben Kimaru Murguiyia<br />

(Production Supervisor)<br />

Daniel Kiptoo Arusei<br />

(Training Engineetr)<br />

2<br />

M A B A T I N E W S

THE LAUNCH OF SAFAL, HORN OF AFRICA REGION<br />

MABATINEWS<br />

Amid pomp and fireworks, SAFAL Group<br />

was officially launched on the 26th of<br />

October, 2006 in a colourful ceremony<br />

in Nairobi. In attendance were both local and<br />

foreign guests. The unveiling ceremony was<br />

carried out by Dr Manu Chandaria, Chairman<br />

of the Comcraft Group of Companies,<br />

accompanied by his wife Aruna, and<br />

Mr. D.P. Shah, Senior Director, together<br />

with his wife.<br />

SAFAL incorporates four clusters<br />

mainly Horn of Africa region, Great<br />

Lakes Region, Southern Africa and<br />

South Africa. The Great Lakes Region<br />

launch was carried out in August 2006,<br />

in Kampala.<br />

SAFAL Horn of Africa region includes<br />

<strong>Mabati</strong> <strong>Rolling</strong> <strong>Mills</strong> Ltd., Athi River,<br />

Nairobi and Mariakani, Insteel Limited<br />

and Ethiopian Steel PLC. Mr. Kaushik<br />

Shah is the CEO. In his welcoming<br />

address, he had the following message<br />

to share:<br />

“In today’s business environment,<br />

more than at any one time in history,<br />

the only constant is change. Markets,<br />

Products, Technology and Competitive<br />

Conditions are rapidly changing ... What this<br />

means for us and, indeed for all organizations,<br />

is that we must possess the capacity and<br />

goodwill to adapt to these changes effectively.<br />

Indeed, any organization, large or small, that<br />

fails to change could pay a very heavy cost,<br />

which could impact on its very survival!<br />

On the other hand, organizations that<br />

effectively manage change by continuously<br />

adapting their bureaucracies, strategies,<br />

systems, products and cultures to survive<br />

the shocks of change; should benefit and<br />

prosper.<br />

Reality today is that leaders and managers<br />

MUST become Masters of Change and<br />

Renewal to effectively lead their organizations<br />

to greater levels. Those who do not will<br />

continue to struggle.<br />

Tonight, Ladies and Gentlemen, we will be<br />

celebrating the results of our organizations’<br />

renewal … As my role was to welcome you, I<br />

will not delve into the details of this important<br />

step that we have taken.”<br />

Mr. Sarit Shah, Director for South and<br />

Southern Africa Region, took the audience<br />

through the genesis, current state and future<br />

of SAFAL.<br />

Dr. Manu Chandaria, in his usual jovial<br />

mood, gave an inspiring address, highlights<br />

of which are reproduced here:<br />

“The recent World Bank report<br />

on Africa says that Africa is listed<br />

as the most difficult place in the<br />

world to do business. However<br />

there are lots of opportunities<br />

and some of the companies are<br />

doing extremely well in spite of<br />

all the problems of insecurity,<br />

famine, HIV/aids and difficult<br />

political situations. All of us<br />

who are here know all this and<br />

yet we are running successful<br />

businesses. This is largely due to<br />

our commitment, dedication and<br />

hard work. SAFAL is no exception.<br />

Thanks to all of you for your support<br />

to us, the SAFAL Group is now in a number<br />

of countries in eastern Africa and southern<br />

Africa and hope it will have its presence<br />

in many more countries in Africa. In my<br />

various speeches I keep on addressing the<br />

government that Kenya’s best resource is<br />

its human resource - its professionals and,<br />

above all, its entrepreneurs. Our workforce<br />

can be quickly trained and our professionals<br />

are equally a brand on their own not only<br />

in Kenya but also in many African countries<br />

and in Europe and the United States. Our<br />

entrepreneurs are second to none. They are<br />

not only entrepreneurs of Kenya but also<br />

of the region. Today our world<br />

is a global village;<br />

it's global<br />

in nature, it's global in<br />

manufacturing, it's global in<br />

trading, its global in services.<br />

Under these circumstances<br />

economies like China, India,<br />

Brazil and Russia are going to<br />

compete for the same Kenya<br />

shillings or any other African<br />

currencies which are in the<br />

pockets of our people. Today’s<br />

trend is that they are out to invest<br />

in Africa for natural resources<br />

and, against that, they will flood<br />

the markets of Africa with goods<br />

which are manufactured in their<br />

countries. Because of the scale<br />

of manufacturing, they are cheaper than ours.<br />

This onslaught is going to upset a number<br />

of economies unless we all get together and<br />

continue to keep our markets and propagate<br />

“made in Africa” as our first responsibility and<br />

keep jobs of our people and our children. This<br />

will require a lot of Africanness.<br />

Today in Kenya we are seeing a period<br />

of turbulent politics; but we are also seeing<br />

M A B A T I N E W S<br />

3

growth in our businesses.<br />

However, more peace, political<br />

stability and better economic<br />

management are becoming a<br />

reality. Since the establishment<br />

of Kenya Private Sector Alliance<br />

(KEPSA), which I chaired for the<br />

first two years, immediately after<br />

one year, we started propagating<br />

the idea that business must<br />

flourish in spite of politics.<br />

Businesspeople have taken this<br />

on board and business is increasing. However, business is a family of<br />

customers, bankers and financiers, suppliers of goods and services<br />

and manufacturers. Members of SAFAL management team, staff<br />

members of various group companies - it is because of you Insteel<br />

and <strong>Mabati</strong> are going places and, to you all who are present here you<br />

add to our capabilities to be what we are today. Similar is the case in<br />

other countries where SAFAL operates. I would like to thank each one<br />

of you. Asante Sana.<br />

If we have to fight to remain in the marketplace then we have to<br />

put more collective effort, more than that collective willingness to<br />

make sure we not only survive but flourish. First, let me appreciate<br />

all the support you have given to date. But, in future, we would like<br />

to create stronger partnership.<br />

We would like to share our plans of SAFAL with you. We would<br />

like your participation, help and suggestions so that we can attend<br />

to our objectives. We believe that SAFAL as a group is larger than<br />

individual<br />

companies in the group. We want<br />

you to help us build capacity<br />

not only in Kenya but also in<br />

our neighbouring countries by<br />

establishing yourself in those<br />

countries and continue to build a<br />

similar partnership that we have<br />

here in Kenya. This will give us<br />

all an opportunity to become<br />

more pan-African.<br />

I would like to raise<br />

another issue: the other<br />

major responsibility we<br />

as private sector have to<br />

accept is Corporate Social<br />

Responsibility. The private<br />

sector has a major role<br />

to play to see that the<br />

people of our country and<br />

the continent are out of<br />

poverty. Give them an<br />

opportunity to aspire<br />

for better standards<br />

of living. The United<br />

Nations has come<br />

out with Millennium<br />

Development Goals.<br />

It is a concentrated<br />

and focused effort for<br />

the poor countries’<br />

governments and the private sector to see that they meet their<br />

targets by 2015. We are already at the end of 2006, yet no country<br />

in Africa is nearer to achieving what they should have during the<br />

last six years. Our government does not have the capacity to do<br />

it alone. Private sector has to play an important role in seeing it<br />

happen. Let us take Kenya presently - our poverty level is at 60 per<br />

cent, meaning 19 million people go to sleep with one meal a day. It<br />

is a major problem but we have to be a part of the solution.<br />

SAFAL Group of Companies - <strong>Mabati</strong>, ALAF, Uganda Baati and<br />

others - we are very aware of our responsibility. In partnership<br />

with the European Investment Bank we have created EIB <strong>Mabati</strong><br />

Trust. It has set up a training institute under <strong>Mabati</strong> Technical<br />

Training Institute where young women and men of Coast Province<br />

train in Computers, Garment Manufacturing on industrial machines,<br />

Technical Wiring, Metal Fabrication and Welding. Next year we will<br />

add another two or three subjects. Presently, there are 200 young<br />

women and men under training. We are now looking at plans of<br />

how to make it sustainable. One of the things we have found is<br />

that the capacity of the students to learn reduces dramatically in<br />

the afternoons. We started giving them an afternoon meal which<br />

improved the situation tremendously. It costs 50,000 shillings a<br />

month to feed 200 students. We have started growing our own<br />

vegetables. Some of our customers have given us 50,000 shillings to<br />

provide the food under their name for a month. This way we would<br />

like more of our customers and service providers to support this<br />

project. I appeal to you to join us in providing excellent opportunity<br />

by donating to <strong>Mabati</strong> Technical Training Institute. Be a part of us and<br />

make corporate social responsibility happen.<br />

We have also set up a dispensary at <strong>Mabati</strong> in partnership with<br />

the Hindu Council. Aluminium Africa Dar es Salaam has a Health<br />

Clinic on their premises and a new clinic has just been completed at<br />

Uganda Baati in Kampala. All these provide much needed medical<br />

services not only to our staff and families but also to residents who<br />

live around. We have medical camps twice a year where our doctor<br />

friends come and give a day free of charge providing medical<br />

services. We try to make sure that all our managing directors,<br />

managers, accountants and engineers get themselves involved in<br />

some social work. Even our staff and workers in times of drought and<br />

other emergencies fully participate in serving the society.<br />

We have encouraged our senior people to personally participate<br />

in trade associations to help articulate issues facing the investors,<br />

to suggest the way forward. My request is be a part of this noble<br />

work.”<br />

4<br />

M A B A T I N E W S

CHANGING OUR COUNTRY<br />

WHO SHOULD TAKE RESPONSIBILITY?<br />

We want to change our country<br />

How can we bring about that change?<br />

We have to change our mind set.<br />

Each one of us can play a role.<br />

Dr Manu Chandaria OBE EBS<br />

We are following Gemba Kaizen<br />

in our plant. How can we<br />

introduce Gemba Kaizen in our<br />

homes and in our lives? How can we stop<br />

waste?<br />

In November, I attended a meeting<br />

called by the World Wildlife Fund (WWF).<br />

It is the largest non-governmental<br />

organization on environment. They have<br />

created a Club under the name "Eastern<br />

Africa Corporate Club" to address<br />

environmental issues. They have major<br />

corporates like Safaricom, Brookebond,<br />

Bamburi, Portland Cement, etc, as<br />

members. I am the roaming Ambassador<br />

for this Club. One of the projects they<br />

have taken up is to plant part of the Mau<br />

Forest. Quite a bit of the Mau Forest has<br />

been excised and given to individuals<br />

who have farms and dwellings there.<br />

Mau Forest is one of the watersheds out<br />

of the five in the country. Others include<br />

Mount Kenya, Amboseli and Charangani.<br />

They are also called water towers. These<br />

are the sources of the rivers in Kenya.<br />

Mau Forest is the source of the River<br />

Mara. This river flows through Masai<br />

Mara and Serengeti where we have the<br />

largest number of game. You must have<br />

read recently that the Masai Mara and<br />

the migration has been considered to<br />

be the 7th Wonder of the World. It is a<br />

heritage for the world and we Kenyans<br />

are trustees of this heritage. Due to<br />

wanton destruction of our forests most<br />

rivers that were full of water throughout<br />

the year have now become seasonal.<br />

Some rivers have already dried up.<br />

If we are not very careful and do<br />

not look after Mau Forest, the heritage<br />

that nature has given us to protect on<br />

behalf of the people of the earth, will be<br />

destroyed.<br />

That is why I ask the question, “Who<br />

should be responsible for this?”<br />

We are all responsible.<br />

Think about it. Think of what you<br />

can do and what you should do to help<br />

the situation. Be part of the solution to<br />

afforest our country to return into its<br />

former glory.<br />

OUR VISION, MISSION AND VALUES<br />

OUR VISION is<br />

“To be the TOYOTA”In Metal Roofing Solutions<br />

OUR MISSION is<br />

“To Deliver Value For Money” Metal Roofing Solutions<br />

OUR VALUES<br />

We Shall and WILL Take No Shortcuts<br />

to Ethics, Compliance and Quality; Be Fair and Caring Towards Employees,<br />

Customers, Community, Environment and Other Stakeholders.<br />

M A B A T I N E W S 5

COO's MESSAGE<br />

Managing time at work<br />

It is easily forgotten but we need to keep it in our mind<br />

at all times that time is not only scarce but a nonrenewable<br />

resource.<br />

All people should be conscious of the value of time<br />

and its non-renewable properties so that they manage<br />

it effectively. People who manage their time properly<br />

accomplish more within the same time space than their<br />

counterparts who do not. The principles of good time<br />

management are quite simple……commitment and a<br />

belief that you can do it!<br />

1. One should direct one’s efforts appropriately; by<br />

addressing what is most important.<br />

2. A person should also direct his/her efforts efficiently<br />

by maximizing the achievements for time and energy<br />

expended.<br />

3. Most importantly, a person should reduce time<br />

wastage.<br />

It is necessary to plan how to use the available time, and<br />

to monitor usage on a continuing basis to ensure that bad<br />

habits that tend to cause time wastage are systematically<br />

eliminated from your daily routine.<br />

the efforts as effective as possible. For example, avoid<br />

procrastination. Make sure that you start off on an organized<br />

platform. A lot of time is lost doing things without a clear<br />

plan from start to finish. Do not trying to do more than<br />

one thing at time. A lot of people attempt to do too many<br />

things simultaneously –<br />

this is a another common problem.<br />

Remedial actions, if your efforts are not<br />

fully effective<br />

If have an office , organize your it: It is extremely<br />

hard to concentrate when you are surrounded by a<br />

mess. There are many organizers/computer software<br />

(if you have paperless office). The system you choose is<br />

unimportant. Whatever you decide make sure that you<br />

have system.<br />

Devote efforts doing what you have planned to do:<br />

Procrastination is the thief of time. If you have a big<br />

task use the “divide and conquer approach”.<br />

Use prime time for prime jobs<br />

Make sure that you are doing what you are meant to be<br />

doing<br />

Work to deadlines<br />

Mr Mahesh Chavda,<br />

COO, <strong>MRM</strong><br />

Appropriate Direction of<br />

Your Efforts<br />

This means allocating your time in<br />

accordance with importance of various<br />

task requirements. It means avoiding<br />

doing unnecessary tasks. Typically<br />

people engage into inappropriate<br />

activities such as…<br />

Working on low priority job while a<br />

high priority job is waiting<br />

Over-supervising subordinates<br />

Aiming for perfection in performing<br />

tasks that do not require 100%<br />

accuracy<br />

Reading a document in detail when<br />

a scan would suffice<br />

Doing something by yourself when<br />

you could delegate to others<br />

Remedial actions to<br />

maximize time value<br />

1. Plan your time: Spend time to earn time<br />

2. Delegate: It may require initial time<br />

investment in training your subordinates<br />

3. Understand your over commitment<br />

4. Renounce Perfection<br />

5. Stop performing in a routine fashion : Think<br />

carefully how you spend the largest fraction<br />

of your time and rearrange the approach<br />

of doing the same thing with a view to<br />

completing the task faster.<br />

Effective Efforts<br />

Once you are sure that you are directing<br />

your efforts towards the right things, make<br />

How to minimize time wastage<br />

Keep reminding yourself about how much working time<br />

you have. Remember all the time that time is your scarcest<br />

resource, and it is your responsibility to ensure it is never<br />

wasted.<br />

Remedial actions, if time wastage is a<br />

problem<br />

Reduce meeting commitments: Prepare in advance and<br />

be objective. You will save other people’s time also.<br />

Reduce interruptions: Shorten unavoidable<br />

interruptions<br />

Putting in to practice<br />

Whatever approach you adopt enhance value for time, it is<br />

important address following:<br />

Think: In terms of telephone, visitor in terms of what<br />

you would achieve<br />

Check: Look at your day’s plan and compare with<br />

what you have achieved so far to ensure that you are<br />

progressing satisfactorily toward your deadlines<br />

Review: Compare what you have done today with<br />

what you did yesterday; have you made some<br />

improvement in time utilization?<br />

Alter: If your time is getting interfered with alter<br />

your future plans or ways of operating to ensure<br />

you accomplish in the day what you set out to<br />

complete.<br />

It is important to start improving your time management<br />

from today and to monitor your progress on continuous<br />

basis.<br />

Wish you all the best!!<br />

6<br />

M A B A T I N E W S

Japheth Ojango has been the shop steward<br />

for the <strong>Mabati</strong> Workers union<br />

Q Mr. Japheth, how long have you served as the Shop<br />

steward for the workers Union?<br />

A I have served the workers union as the shop steward<br />

for eight years.<br />

Q Eight years! That seems quite a long time. That<br />

means you must have grown along with the<br />

company!<br />

A I was among the members who did the<br />

trial run of the CCL plant, and I have seen the unit<br />

expand from a single go-down to the present<br />

three and along side this, the many profiles and<br />

products the company now offers to the market.<br />

Q You have retained this position for<br />

quite a long time, taking into account the<br />

internal politics that is synonymous with workers unions<br />

nationally.<br />

A Well, I believe I've been in this position for a long all this<br />

time due to the trust the members have had in me and the<br />

teamwork displayed by the Works Committee.<br />

Q During this time you must had some ups and<br />

downs or successes or failure. Kindly tell me about the<br />

road down the eight years!<br />

A Well, I believe under my watch, we have had more<br />

successes than failures or disputes if I may say so. I will start<br />

with the success & growth that we have had.<br />

As you know when the company shifted base from<br />

the Main Industrial Area in 1989, then known as Galsheet<br />

Resincot, it meant a fresh start. In these eight years, I initiated<br />

the following:<br />

- The Funeral Committee of which I am the chairman,<br />

- With advice from the then Chief Engineer Mr.<br />

Chaturvedi, I mobilized the workers and with KSh500<br />

shares per head we took over the running of the<br />

Canteen.<br />

- And also with the help from all members and nonunionisable<br />

staff we set up the Resincot SACCO which<br />

has been well managed to date.<br />

I am proud of all these achievements.<br />

Q That looks quite an impressive record! But there<br />

must be the other side of the story!<br />

A Disputes? Yes, but not much, whatever may have arisen<br />

we got into a discussion with the management and all issues I<br />

can say were amicably...<br />

Q As the Shop Steward how has your team contributed<br />

towards the development of <strong>MRM</strong>?<br />

A My team has been quite supportive to the company<br />

initiatives that improve the company’s performance.<br />

Q Like?<br />

A One such example is the Gemba Kaizen principles of<br />

work, which is all about ‘Continuous Improvement’ at the<br />

workplace.<br />

We have participated alongside the management to<br />

improve the company and this is clearly<br />

visible.<br />

A lot of positive changes have<br />

taken place since the introduction of<br />

Kaizen about five years ago.<br />

Q What changes are these and how<br />

do you maintain the gains?<br />

A One major change has been the<br />

cleanliness. This has been improved by<br />

the use of Kaizen tool 5K or 5S. This tool<br />

stipulates that the workplace has to be<br />

clean and well organized.<br />

To maintain the gains we have do under constant training<br />

and we ensure self-discipline and all this is made possible be<br />

good teamwork.<br />

Q What other initiatives are there?<br />

A Along side Gemba Kaizen, the company has made all<br />

aware of its direction. This is well spelt out in the company’s<br />

Mission, Vision and Core Value statements.<br />

Q What do these statements say?<br />

A Our mission is to ‘Deliver Value for metal roofing<br />

solution’ with a vision of being the ‘Toyota in Metal roofing<br />

solution’ while ‘Taking no short-cut and being caring’ being<br />

our core values.<br />

Q That’s great! But what does it mean being the<br />

‘Toyota...’<br />

A I believe Toyota cars are very affordable, reliable, easy<br />

to maintain. They keep ahead with customer trends and<br />

needs, there are variety of them to choose from and you get<br />

them in all corners of the country. I believe our products<br />

match this description already.<br />

Q Lastly, Japheth, your parting shot?<br />

A We have to maintain teamwork that has brought about<br />

these successes.<br />

We would like to be the best steel company at personal<br />

and company level; this can only be achieved if we continue<br />

working hand-in-hand with the management as we share the<br />

successes.<br />

Thank You<br />

We wish you and your team well in keeping the<br />

company’s Mission & Vision alive.<br />

Interview by Austin Okoda<br />

INTERVIEW<br />

M A B A T I N E W S 7

MABATINEWS<br />

Computer virus<br />

By Sam Kamau<br />

Systems Administrator<br />

Dear Reader, the word<br />

COMPUTER VIRUS has<br />

become a generic term that<br />

refers to all the malicious ways that<br />

your computer can be attacked.<br />

The most common blunder people<br />

make when the topic of a computer<br />

virus arise is to refer to a worm or<br />

trojan horse as a virus. While the<br />

words trojan horse, worm and virus<br />

are often used interchangeably, they<br />

are not the same. Viruses, Worms<br />

and Trojan Horses are all malicious<br />

programs that can cause damage<br />

to your computer, but there are<br />

differences among the three, and<br />

knowing those differences can help<br />

you to better protect your computer<br />

from their often damaging effects.<br />

A virus is a small program (piece of<br />

code) that piggybacks on other programs<br />

or files. A virus can be attached to a word or<br />

excel file by placing its code in the path of<br />

execution so that each time the file is run,<br />

the virus runs too hence replicating itself in<br />

the process.<br />

Since a virus is programmed to alter<br />

the way a computer operates, without the<br />

permission or knowledge of the user it can<br />

damage your programs, hardware and even<br />

delete your files. Others are not designed<br />

to do any damage, but simply to replicate<br />

themselves and make their presence<br />

known by presenting text, video, and audio<br />

messages. Even these “simple” viruses can<br />

create problems for the computer user.<br />

They typically take up computer memory<br />

used by legitimate programs. As a result,<br />

they often cause erratic behavior and can<br />

result in system crashes.<br />

A worm is similar to a virus by its design,<br />

and is considered to be a sub-class of a virus.<br />

Worms spread from computer to computer,<br />

but unlike a virus, it has the capability to<br />

travel without any help from a person.<br />

Worms replicate themselves from<br />

system to system without the use of a host<br />

file. This is in contrast with viruses, which<br />

require the spreading of an infected host<br />

file.<br />

A worm takes advantage of information<br />

transport features on your system, which<br />

allows it to travel unaided. The biggest<br />

danger with a worm is its capability to<br />

replicate itself on your system, so rather<br />

than your computer sending out a single<br />

worm, it could send out hundreds or<br />

thousands of copies of itself, creating a<br />

huge devastating effect.<br />

Due to the copying nature of a worm<br />

and its capability to travel across networks<br />

the end result in most cases is that the<br />

worm consumes too much system memory<br />

(or network bandwidth), causing network<br />

servers and individual computers to stop<br />

responding. More recent attacks such as<br />

the much-talked-about blaster worm, have<br />

been designed to tunnel into your system<br />

and allow malicious users to control your<br />

computer remotely. Others are designed<br />

using SMPT (Simple Mail Transfer Protocol)<br />

engines and will send hundreds of email<br />

from your system without your knowledge<br />

– spamming.<br />

A Trojan horse is a computer program<br />

masquerading as a benign application,<br />

game or a “cute” program.<br />

The Trojan horse, at first glance, will<br />

appear to be useful software but will<br />

actually do damage once installed or run<br />

on your computer. Those on the receiving<br />

end of a Trojan horse are usually tricked<br />

into opening them because they appear<br />

to be receiving legitimate software or<br />

files from a legitimate source. When a<br />

Trojan is activated on your computer,<br />

the results can vary. Trojans are<br />

designed to be more annoying than<br />

malicious (like changing your desktop,<br />

adding silly active desktop icons,<br />

blocking your screen with a graphic<br />

that will not go away). Trojans are also<br />

known to create a backdoor on your<br />

computer that gives malicious users<br />

access to your system, possibly allowing<br />

confidential or personal information to<br />

be compromised. Unlike viruses and<br />

worms, Trojans do not reproduce by<br />

infecting other files nor do they self-<br />

replicate.<br />

Having familiarized ourselves with<br />

the above terms we now need to be<br />

alert of messages that are normally sent<br />

by email to propagate unnecessary alarm<br />

about viruses.<br />

Virus hoaxes are messages, almost<br />

always sent by email, that amount to little<br />

more than chain letters. Following are some<br />

of the common phrases that are used in<br />

these hoaxes:<br />

If you receive an email titled [virus hoax<br />

name here], do not open it!<br />

Delete it immediately!<br />

It contains the virus [hoax name].<br />

It will delete everything on your hard<br />

drive [extreme and improbable danger<br />

specified here].<br />

This virus was announced today by<br />

[reputable organization name here e.g.<br />

CNN].<br />

Forward this warning to [everyone in<br />

your address book!]<br />

Most virus hoax warnings do not deviate<br />

far from this pattern. If you are unsure if a<br />

virus warning is legitimate or a hoax, kindly<br />

seek clarification from your system admin<br />

or from the Internet through a website like<br />

www.symantec.com .<br />

I trust and hope that this article has<br />

enlightened you on the various threats<br />

posed to our systems and you can clearly<br />

distinguish them.<br />

Thank you for taking your time to read this<br />

article.<br />

8<br />

M A B A T I N E W S

Seeing the big picture in teamwork…<br />

Assume you are the manager of a<br />

company; a supervisor calls you and<br />

says he has a breakdown (A CONVEYOR<br />

CHAIN IS BROKEN), what do you do? Similarly, at<br />

home we encounter challenges, which require<br />

solving. These challenges might be, for example,<br />

financial, social or maintenance based.<br />

When confronted with a problem at your<br />

Gemba or at home the following questions do<br />

race in most peoples minds:<br />

What happened?<br />

What do we need to do here?<br />

Why did this happen?<br />

What is the cost of this happening always?<br />

What is the real problem?<br />

How do you solve the problem?<br />

How do you ensure that it does not happen<br />

again?<br />

The first three questions can be easily<br />

answered as follows by most people:<br />

The following could be the answers from<br />

most of the people.<br />

1. What happened? The operators have caused<br />

a breakdown because we did not provide<br />

transport.<br />

2. What do we need to do here? Have the<br />

machine started and give warning letters to<br />

the operator.<br />

3. Why did this happen? Because of sabotage.<br />

4. What is the cost of this happening always?<br />

The company loses on time, customer<br />

confidence, labor, and inventories, transport,<br />

etc.<br />

5. What is the real problem? Actually that is<br />

difficulty to answer.<br />

To seek out the cause problem you need<br />

more than yourself. No wonder the Creator<br />

formed more than one being. The above<br />

answers do not solve the problem, all the<br />

answers are but finger pointing answers to one<br />

another and not solving the root cause of the<br />

problem. When confronted with a problem at<br />

your Gemba or at home we need to find the<br />

answers to the above questions using ‘5Why<br />

analysis’ and ‘2H’ technique e.g. there is a<br />

breakdown in the plant:<br />

What happened? The conveyor chain is<br />

broken.<br />

Why did the conveyor chain break? There<br />

was lack of lubrication oil in the machine.<br />

Why wasn’t the machine lubricated?<br />

Lubrication of the machine is difficult to be<br />

done.<br />

Why is the lubrication of the machine<br />

difficult to be done? Lubrication point is<br />

difficult to locate.<br />

Why is the lubrication point difficult to<br />

locate? The lubrication point is not been<br />

marked.<br />

Why wasn’t the lubrication point marked?<br />

The painter painted the lubrication indicator<br />

arrow pointer.<br />

How do you solve this? A visual sign<br />

through color-coding be assigned to all the<br />

lubrication points of the conveyors.<br />

How do you ensure this does not happen<br />

again?<br />

Training to be done to the machine operators,<br />

painter and the rest of the team on the visual<br />

management.<br />

To realize our vision of being world class we<br />

work as a mechanical chain. A chain has many<br />

links together to form a chain everyone of us<br />

including you the reader is part of the chain.<br />

Hence you are a very important member of the<br />

team. Due to the breakdown of the chain in the<br />

plant all the other team players would not do<br />

a thing.<br />

TEAM MEANS:-<br />

T-Together<br />

E-Everybody<br />

A-Achieves<br />

M-Missions<br />

WORK MEANS:-<br />

W-Winning<br />

O-Organization<br />

R-Requires<br />

K-Kaizen<br />

(Continual Improvement)<br />

Every day has its challenges, do you perceive<br />

problems to be bigger than mountains and<br />

quit trying solutions? Similarly at home we<br />

encounter challenges, which require us solving.<br />

These challenges might be financial, social or<br />

maintenance based (iron box is not working)<br />

Where do you normally operate when faced<br />

with a challenge?<br />

Where do most people operate? Looks<br />

difficult, not possible due to:<br />

Fear of rejection due to failure or loss of<br />

status<br />

Lack of vision<br />

Rules are restrictive<br />

Lack of knowledge or skill<br />

Lack of resources.<br />

Easy to do is the ultimate comfort zone where<br />

ordinary leaders can achieve their goals and<br />

objectives withought much imagination and<br />

problems, due to the reasons stated above.<br />

We need to eliminate words like "its<br />

impossible", "I cannot do it", "Goals are not<br />

attainable", and this will prompt us towards<br />

realization of our Mission and Vision.<br />

Food for thought<br />

What would you do if you were not afraid?<br />

What would you do if you had all the resources<br />

needed and all constraints removed?<br />

Not possible<br />

Looks difficult<br />

Easy to do<br />

Do not miss the next issue, as we will focus on<br />

how to generate ideas towards creativity and<br />

innovations, problem solving and many more.<br />

Carol Soi<br />

STAFFCORNER<br />

Standard Chartered Marathon<br />

<strong>MRM</strong> Sponsored 30 athletes to the Standard Chartered Marathon on<br />

Sunday October 29, 2006 at the Nyayo Stadium for the half marathon,<br />

10km race. Twenty-five gents and four women completed the marathon<br />

the first person completing at position 365 out of 15,000 participants.<br />

M A B A T I N E W S 9

P I C T O R I A L<br />

P I C T O R I A L<br />

<strong>MRM</strong>'s Standard Chartered marathon 2006 team, amongst other partcipants.<br />

MTTI students show their work during official opening of<br />

Mariakani Technical Training Institute.<br />

Head of delegation of European Union to Kenya - Mr. Eric Van Der Linden signs<br />

visitor's book as <strong>MRM</strong>, Dr. Manu Chandaria and Hirji Shah look on.<br />

Head of delegation of European Union to Kenya - Mr. Eric Van<br />

Der Linden plants a tree during official inauguration of MTTI.<br />

Trade Analysts Dawn Heuschel and Douglas Newman of the US International Trade<br />

Commission, George W. Aldridge, Economics Officer, US Embassy, Nairobi with<br />

Suresh, Mahesh and Suraj (<strong>MRM</strong>) outside <strong>MRM</strong> offices.<br />

<strong>MRM</strong> Directors, Dr. Benjamin Kipkorir and Mr. Neelesh Shah chat<br />

during SAFAL launch in a Nairobi Hotel.<br />

10<br />

M A B A T I N E W S

Dr. Manu Chandaria delivers<br />

his speech during official<br />

commissioning of Pickling line<br />

in Mariakani.<br />

Employees enjoy themselves during end-of-year staff party.<br />

<strong>MRM</strong> football team: Finalists Wavinya Cup tournament before the<br />

match - <strong>MRM</strong> clinched second position out of six participating tams.<br />

Mr. Kaushik Shah, CEO SAFAL Horn of Africa, delivers his speech at the<br />

end-of-year staff party.<br />

Dick Isiche receives his Long Service Award from the CEO during the<br />

end-of-year party.<br />

Eunice, Weru and Rispa enjoy at the end-of-year party.<br />

Happy faces in anticipation of their sumptuous lunch.<br />

M A B A T I N E W S<br />

11

MABATINEWS<br />

THE RESPONSIVE MANAGER<br />

In the recent past, the management’s<br />

development focus in most well run<br />

firms has been shifting from preparing<br />

their managers to fill higher level slots to<br />

preparing them to meet the challenges of<br />

managing in a fast-paced environment.<br />

Increasingly, therefore, the emphasis is on<br />

developing a manager’s ability to learn and<br />

make decisions under conditions of rapid<br />

change.<br />

Two experts put it this way: “As decisionmakers<br />

take on increasing responsibility<br />

across their careers, their learning needs<br />

move from the arena of task learning to<br />

behavioral learning to conceptual or policylevel<br />

learning.” For example, today’s corporate<br />

managers are under enormous pressure<br />

“to find the strategic opportunities their<br />

competitors are yet to find.” This therefore<br />

requires more emphasis and realignment<br />

on developing their conceptual ability to<br />

search for internal strategic opportunities to<br />

improve quality, service and prices. Similarly,<br />

all managers have to be well schooled in<br />

business related information, marketing and<br />

negotiation. And to manage in flatter, more<br />

empowered organizations, the leader must<br />

increasingly become a teacher, coach and<br />

consultant rather than a “boss”.<br />

The above changing scenario is causing<br />

a corresponding change in the techniques<br />

that are emphasized in management<br />

development programs. Historically, onthe-job<br />

training, coaching and rotational<br />

assignments have been the most popular<br />

management development techniques.<br />

The problem is that these techniques tend<br />

to emphasize showing managers current<br />

procedures or (at best) getting them to think<br />

about how to “do what we are doing today a<br />

little better”.<br />

However, today there is a shift<br />

towards development techniques that<br />

teach managers how to learn and how<br />

to develop the competencies they need<br />

to cope with changes, such as seizing up<br />

emerging markets and searching for new<br />

strategic opportunities. In this regard,<br />

special in-company executive development<br />

programs, action learning are examples<br />

that we in <strong>MRM</strong>, through our philosophy of<br />

“continuous improvement”, look forward to<br />

encompassing in order to stay ahead of our<br />

budding competitors.<br />

- T. M. Ngira<br />

Gender issues in management<br />

Biased impressions from an Office<br />

The Family Picture on HIS DESK.<br />

Ah, he is a solid family man<br />

HIS desk is cluttered<br />

He must be obviously a hard worker and busy man<br />

HE’s talking with his co-workers.<br />

He must be discussing the latest deal.<br />

HE’s not at his desk<br />

He must be at a meeting elsewhere<br />

HE’s not in the office<br />

He is meeting customers<br />

HE’s having lunch with the Boss<br />

He is on his way up.<br />

The boss criticized HIM<br />

He’ll improve his performance<br />

HE got an unfair deal<br />

Did he get angry?<br />

HE’s getting married<br />

HIS/ HERS<br />

He will get more settled<br />

HE’s having a baby<br />

He’ll need a salary raise<br />

HE’s going on a business trip<br />

It's good for his career<br />

HE’s leaving for a better job<br />

He knows how to recognize and seize a good opportunity<br />

The Family Picture on HER DESK<br />

Umm, her family will come before her Career<br />

HER desk is cluttered<br />

She is obviously a disorganized scatterbrain<br />

SHE’s talking with her co-workers.<br />

She must be gossiping<br />

SHE’s not at her desk<br />

She must be in the ladies room<br />

SHE’s not in the office<br />

She must be out shopping<br />

SHE’s having lunch with the Boss<br />

They must be having an affair<br />

The boss criticized HER<br />

She’ll be very upset<br />

SHE got an unfair deal<br />

Did she cry?<br />

SHE’s getting married<br />

She’ll get pregnant and leave<br />

SHE’s having a baby<br />

She’ll cost the Co. money on maternity benefits<br />

SHE’s going on a business trip<br />

What will her husband say?<br />

SHE’s leaving for a better job<br />

Women are not dependable<br />

12<br />

M A B A T I N E W S

Christmas<br />

As a Christian kid, I grew up amongst the Hindu and Muslims. I<br />

always enjoyed the celebration; the Diwali fire crackers lighting<br />

up the sky, the delicious pilau at the end of Ramadhan and finally all<br />

the Christmas goodies.<br />

But did I know what do all these people celebrate or observe?<br />

Being a Christian I thought I knew the meaning of Christmas! The<br />

birth of Jesus, Father Christmas and a day to wear new clothes!<br />

Today, reflect on the real meaning of all these celebrations<br />

including what I thought I knew - Christmas.<br />

Christmas: Christmas literally means the Mass (celebration) of<br />

Christ. “Christ” is a Greek word and title meaning “anointed” or one<br />

set apart by God for a special purpose - to deliver of the people from<br />

sin.<br />

Jesus was born in a humble stable, into a poor family. Simple<br />

shepherds were the first to witness this event. In this poverty<br />

heaven's glory was made manifest.<br />

Christians believe that it was exactly God’s plan<br />

that things happened this way. They say that<br />

it shows that Jesus came as a humble, poor<br />

person and not as a strong, rich king.<br />

The birth of Jesus was told many years<br />

before in the books of the prophets Micah<br />

and Isaiah.<br />

D<br />

Diwali<br />

iwali is the most well-<br />

D<br />

known of all Indian festivals.<br />

It is a five-day festival which occurs on the<br />

fifteenth day of Kartika (First month).<br />

During this festival, colloquially<br />

known as the “Festival of Lights”, homes<br />

are thoroughly cleaned and windows are<br />

opened to welcome Lakshmi, goddess<br />

of wealth. Candles and oil lamps (divas)<br />

are lit as a greeting to Lakshmi. The lights also illuminate the<br />

darkness of the New Year’s moon and strengthen our close<br />

friendships and knowledge<br />

Gifts such as sweets are exchanged and meals are<br />

prepared. The festival is invariably accompanied by<br />

explosion of fireworks. Everywhere, it signifies the renewal<br />

of life and, accordingly, it is common to wear new clothes<br />

on the day of the festival. Similarly, it heralds the approach<br />

of winter and the beginning of the sowing season.<br />

The<br />

Great<br />

Religious<br />

Festivals<br />

In reality, every day the real image of<br />

Christmas is exposed. As God looked down<br />

from heaven with compassion on His human<br />

creation, He sent Jesus to become like us so that<br />

through His obedience we would have the opportunity of living a life<br />

of forgiveness and hope.<br />

Scriptures say that because God so loved His people, He sent His<br />

only Son Jesus so that His people could be saved and in turn love<br />

Him (see John 3:16).<br />

The image of “people” is not one that often comes to our mind<br />

when we celebrate Christmas. But it should be. This was the image<br />

God saw when He sent Jesus to be born in that manger in Bethlehem.<br />

He saw the image of you, me and countless others who are lost,<br />

hopeless and in need of salvation.<br />

It was because of His love for what He saw that God sent His<br />

Son.<br />

As you set up your nativity scene this Christmas and as<br />

you arrange the shepherds, angels, barn animals and<br />

other figurines in the stable, don’t forget to include a<br />

portrait of yourself. After all, this was the image God<br />

saw when He looked down on Bethlehem that first<br />

Christmas day.<br />

E id-ul-Fitr<br />

Eid-ul-Fitr’<br />

id-ul-Fitr is one of the most important festivals in<br />

Islam celebrated by Muslims all over the world with<br />

great joy and festivities.<br />

‘Eid‘ means ‘a recurring happiness or festivity’ and ‘fitr’<br />

means to ‘to begin’. ‘Iftar’ means’the breaking of the fast’ and it is<br />

from this that the name ‘Eid-ul-Fitr’ seems to have been taken which<br />

means ‘festival of the breaking of the fast’.<br />

‘Eid-Ul-Fitr’ falls on the first day of Shawwal, the 10th month of the<br />

Muslim calendar, and marks the end of the fasting observed by the<br />

Muslims during the month of Ramadhan.<br />

Fasting was prescribed as an act of self-denial with a view to<br />

attaining moral and spiritual upliftment.<br />

While “Eid-ul-Fitr” is an occasion for joy and<br />

happiness, it is certainly not an occasion for<br />

over-eating, frivolity or for the pursuit of pleasure.<br />

The joy on this occasion is the spiritual joy of<br />

fulfillment.<br />

‘Eid-ul-Fitr’ also occasions an opportunity for the<br />

believers to forget all grudges and ill-feelings towards<br />

one another and start afresh in the brotherly spirit that<br />

Islam preaches.<br />

The underlying message of this happy occasion is<br />

that the believers fulfill God’s command of discipline<br />

and holiness<br />

MABATINEWS<br />

Christmas, Idd-ul- Fitr, Diwali .........<br />

so what do all these religious observance mean?<br />

The Hindu say ... 'Diwali signifies the renewal of life'<br />

The Muslims say.... The underlying message of Eid-El-Fitr is<br />

that the believers fulfil God’s command of discipline and<br />

holiness'.<br />

The Christians say..... 'With Christmas, He sent Jesus to become<br />

like us so that through His obedience we would have the<br />

opportunity of living a life of forgiveness and hope'.<br />

What do you make out of this!<br />

God bless you all!<br />

By Austin Okoda<br />

M A B A T I N E W S 13

MABATINEWS<br />

Balanced Scorecard<br />

As some of you may be aware, <strong>Mabati</strong> <strong>Rolling</strong> <strong>Mills</strong> has<br />

embraced the Balanced Scorecard philosophy alongside the<br />

Gemba Kaizen principles in the leadership and performance<br />

management strategy. Both initiatives are complementary rather<br />

than being in competition with each other. The Balanced Scorecard<br />

(BSC) is a strategic management system originated by Robert Kaplan<br />

(Harvard Business School) and David Norton in the early 1990s<br />

in the United States. It is a<br />

methodology that actualizes<br />

corporate strategy.<br />

<strong>MRM</strong> embarked on the<br />

mechanics of implementing<br />

BSC, starting with top level<br />

management this July. The<br />

plan is to initiate the concept<br />

and cascade the learning<br />

process to all key players in<br />

the supply chain loop. By<br />

embracing the BSC system,<br />

<strong>MRM</strong> is aiming at empowering<br />

all key players with appropriate<br />

competencies to develop<br />

metrics, collect data and<br />

analyze it relative to each of<br />

the following key performance<br />

perspectives:<br />

The Business Process<br />

Perspective<br />

The Customer Perspective<br />

The Financial Perspective<br />

The COO Mr. Mahesh Chavda and<br />

Manager HR Mr. Tony Nasirembe<br />

who have spearheaded the<br />

balanced scorecard initiative.<br />

The Learning, Growth and Human Resources<br />

Development Perspective<br />

<strong>MRM</strong> Employees recite<br />

the Gemba Kaizan<br />

Pledge before starting<br />

work every morning.<br />

Performance areas that need improvement will be easily<br />

identified. Appropriate training programs will purposely be designed<br />

and implemented. The result of this will be the creation of a high<br />

performance workforce.<br />

Studies have shown that by 2004 about 57% of global<br />

companies were using BSC as their strategic management tool.<br />

The companies using BSC included well known corporations such<br />

as British Telecommunications Worldwide, Caterpillar Inc.<br />

DaimlerChrysler, Defence Logistics Agency, DuPont, Ford<br />

Motor Company, General Electric Company, High Performance<br />

Systems, Inc. Hilton Hotels Corp., IBM, NCR Corp., Ricoh Corp.<br />

Royal Canadian Mounted Police and UPS.<br />

General Electric won the global leadership as the most<br />

admired corporation in (2006) taking over from Wal-Mart.<br />

Incidentally, the No. 2 position was won by Toyota Motors<br />

which applies the Kaizen principles in its management<br />

strategy.<br />

<strong>MRM</strong> has been using the Kaizen principles for sometime<br />

now. Coupled with the BSC strategy, it can be said that <strong>MRM</strong><br />

has taken advantage of a unique leadership position to use<br />

the best from both worlds.<br />

BSC goes beyond embracing management concepts.<br />

It calls for identification of the right people with the right<br />

Corporate Governance<br />

Perspective<br />

By addressing these performance perspectives the<br />

Company’s strategic performance objectives would<br />

review the vision and align all performance objectives to the mission<br />

and strategy implementation. Strategic corporate objectives will be<br />

articulated, making it possible for the departmental and individual<br />

objectives to be linked to complete the value chain loop.<br />

Balanced Scorecard and Gemba Kaizen<br />

initiatives<br />

The two perspectives provide powerful platforms for employees to<br />

link corporate vision, mission to corporate strategy. It provides a<br />

clear focus of everyone to work in tandem with the other creating a<br />

very powerful performance bond.<br />

skills, competencies and attitude for the right jobs throughout<br />

the organization structure. The result will be creation of high<br />

performance teams that deliver world-class value to customers,<br />

employees and other stakeholders.<br />

The Kemba Kaizan “alone I am weak, together we are strong”<br />

slogan is the epitome of team work. Every employee sees the<br />

strength rather than the weakness in each other. By holding<br />

hands in a circular formation every morning the energy from every<br />

individual is combined to generate powerful energy source capable<br />

of shifting the <strong>MRM</strong> performance paradigm to the next level in<br />

corporate competitiveness. Cheers!<br />

14<br />

M A B A T I N E W S

ECONOMIC PARTNERSHIP AGREEMENTS<br />

By Antony Kung'u<br />

Background<br />

A special trade relationship has existed between the European Union<br />

(EU) and African Caribbean and Pacific group (ACP) of countries since<br />

1975 when the first Lome Convention was signed. Under the Lome<br />

Conventions, the ACP countries enjoyed unilateral trade preferences<br />

into the EU market. The Fourth Lome Convention was replaced by<br />

the Cotonou Agreement in 2000, which extends the unilateral trade<br />

preferences up to December 2007. Thereafter, the parties are dutybound<br />

to negotiate and conclude World Trade Organisation (WTO)<br />

compatible reciprocal trade agreements, the Economic Partnership<br />

Agreements (EPAs), at the beginning of 2008.<br />

The EPAs are touted as the new co-operative framework under the<br />

Cotonou Agreement and are expected to adopt an integrated approach<br />

based on partnership and promoting co-operation, multilateral trade<br />

and political dialogue between the EU and the ACP countries. The key<br />

features of EPAs are their reciprocity and non-discriminatory nature.<br />

They involve the removal of all trade preferences which have been<br />

established between the EU and the ACP countries since 1975 as well<br />

as the progressive removal of trade barriers between the partners. The<br />

EPAs are open to all developing countries thereby effectively bringing<br />

down the curtain on the ACP group as the main development partner<br />

of the EU.<br />

Regional Blocs<br />

Previously, the EU negotiated with all ACP countries as a bloc. However,<br />

for EPAs’ negotiations, the EU has split the ACP countries into trading<br />

blocs, arguably undermining their solidarity, negotiating power and<br />

political power thus weakening their overall bargaining power. The<br />

ACP countries have formed six regional configurations or groupings<br />

through which to negotiate EPAs with the EU, some of which arethe<br />

Southern Africa Development Community (SADC), the Eastern<br />

and Southern Africa group (ESA), the Caribbean Community and the<br />

Economic Community of West Africa (ECOWAS). Kenya belongs to the<br />

ESA configuration.<br />

Effects of EPAs on ACP Countries<br />

Although the EPAs are aimed at supporting the on-going processes<br />

of economic integration and gradual liberalisation of trade between<br />

ACP countries and the EU, some very legitimate concerns have been<br />

raised on their effects on the ACP countries. The EU has chosen to<br />

negotiate the agreements under strict WTO rules that govern reciprocal<br />

free trade agreements (FTAs), requiring ACP countries to open their<br />

markets to "substantially all" EU imports over a limited period of time.<br />

The 10-year period given by EU to ACP countries to open their markets<br />

to substantially all trade is not adequate for the latter to develop their<br />

productive capacities and strengthen their competitiveness prior to<br />

the potential influx of EU products into the ACP markets. Inequalities<br />

resulting from the different levels of development between the EU<br />

and ACP countries make reciprocity untenable. The ACP countries also<br />

face a gargantuan task in their zeal to break into EU markets already<br />

dominated by long established, well loved and highly patronised<br />

European brands. Local producers lacking distinctive capabilities will<br />

not survive the potential onslaught to be waged by cheap imports<br />

from the EU. Furthermore, the EU is bound to apply stringent rules of<br />

origin (ROO) on imports from ACP countries, thus introducing technical<br />

barriers to market access.<br />

MABATINEWS<br />

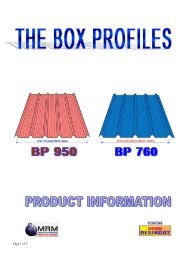

Profiling lines at CGL Mariakani<br />

By Gabriel Olukwo<br />

As part of its modernization and<br />

equipment u<strong>pg</strong>rading program in line<br />

with the developments in technology,<br />

<strong>MRM</strong> has installed and commissioned three<br />

profiling lines at the finishing department of<br />

the Continuous Galvanizing Line at Mariakani.<br />

Profiler 1 was commissioned in July 2004,<br />

while profilers 2 and 3 were commissioned<br />

in October 2006. These lines have replaced<br />

shearing lines and barrel corrugators. The<br />

profiling lines produce galvanized and<br />

aluminium-zinc coated corrugated standard<br />

profile sheets. These profiling lines and<br />

their layout are in line with Gemba Kaizen<br />

principles of lean manufacturing. Material<br />

and crane movement have been greatly<br />

reduced. Three processes have been<br />

combined into one. The order execution time<br />

has been reduced and the products from<br />

these lines do not have any variations. The<br />

profiling lines are far much superior to barrel<br />

corrugators in many ways. A higher range of<br />

materials can be processed on profilers. They<br />

can accommodate 0.20mm to 0.30mm thick<br />

material with minimum adjustments. Sheets<br />

of various lengths are produced ranging from<br />

a few centimetres to over 10 metres length<br />

to meet customer requirement. The<br />

profiling lines also produce sheets with<br />

uniform profiles. These profilers are highly<br />

automated with minimal setting time and<br />

once correct settings have been achieved, the<br />

profilers run automatically producing scratch<br />

free sheets. Since profiling lines combine<br />

three processes, (shearing, handling and<br />

corrugation), rejections are fewer and orders<br />

can be executed exactly as per requirements.<br />

Profiling lines occupy less space and do not<br />

require storage for cut plain sheets. Each<br />

Profiling line is manned by only five persons<br />

compared to 11 persons in barrel corrugators<br />

(three at shearing and eight at corrugator).<br />

Production cost of profiling lines is lower than<br />

that of lines with barrel corrugators because<br />

less manpower is utilised and less power is<br />

consumed. The profiling lines have a very<br />

high safety level as the operation position<br />

is far from moving parts and there is no<br />

manual feeding of sheets into the profiler. The<br />

operation is thus less tiresome resulting to<br />

decreased human errors as a result of fatigue.<br />

The noise levels at profiling lines are very low<br />

hence operators are not required to wear ear<br />

plugs or muffs.<br />

Conversely, barrel corrugators<br />

process only one gauge and a<br />

maximum sheet length of 3.7 metres. As<br />

the production process entails shearing,<br />

transfers and finally corrugation the rejection<br />

level is high because of the independent<br />

multiple processes involved. Continuous<br />

manual feeding leads to over dependency on<br />

humans. These lines are prone to accidents<br />

because of multiple handling of products,<br />

operation is near to moving parts and their<br />

inherent prolonged human fatigue. Lines<br />

with barrel corrugators occupy a lot of floor<br />

to accommodate the shearing lines, extra<br />

storage space for work in process plain sheets<br />

and the barrel corrugators. The noise levels at<br />

barrel corrugators are high and the operators<br />

must wear ear plugs or muffs for hearing<br />

protection.<br />

M A B A T I N E W S 15

Commisioning misioning of Pickling plant at Mariakani<br />

MABATINEWS<br />

In the true spirit of Kaizen principles of continuous improvement,<br />

<strong>MRM</strong> invested over US$9 million last year to create a new<br />

pickling line that was commissioned on October 3, 2006 this<br />

year by the Minister for Finance Hon. Amos Kimunya. In his key<br />

note address Hon. Kimunya, acknowledged the huge investment<br />

the shareholders had made into the state-of-the-art technology.<br />

He recognised that the results of the new line will shift the level of<br />

manufacturing to a completely new level of competitiveness. He<br />

noted and appreciated the advantages of the new line. <strong>MRM</strong> will<br />

now widen its raw material sources, particularly in the hot rolled<br />

coils. It was hitherto confined to a few selected suppliers. He also<br />

noted that the investment will give the company the advantage of<br />

flexibility, innovation and creativity in a very competitive market.<br />

He acknowledged that such an investment demonstrated<br />

the confidence <strong>MRM</strong> shareholders had in doing business in<br />

Kenya. Hon Kimunya noted with appreciation that the plant took<br />

into consideration environmental concerns and made further<br />

investment in Acid Regeneration Plant which allows the acid to be<br />

completely recycled. The facility has a capacity to handle and treat<br />

coils up to 200,000 tonnes per year.<br />

The minister observed that <strong>MRM</strong>’s overall business operations<br />

make a significant contribution to the country’s economic growth<br />

and development. He said that the government is committed to<br />

creating a conducive and enabling environment where businesses<br />

will find it easier and more friendly to do business.<br />

Since private sector plays and important role in the country’s<br />

economic development the government is committed to support<br />

private sector investment initiatives. Appropriate legislation and<br />

streamlining of administrative bottlenecks will continue to be<br />

introduced at various levels of operations of government to make<br />

it easier for businesses to operate.<br />

The Minister pointed out how Kenya has gained high rating<br />

by where it was rated 4th in the Sub-Saharan Africa behind<br />

Botswana, South Africa and Nigeria. The World Bank has rated<br />

Kenya 6th in Africa in respect of doing business. Obviously there<br />

is going to be increased government effort to consolidate what<br />

is good and improve on areas that can facilitate private sector<br />

investment in the country.<br />

The government is also investing in ICT and communications<br />

connectivity to make it easier for businesses to share vital<br />

information necessary for growth and global trade. The Minister<br />

spoke about refunds and said the government has scaled up from<br />

KSh614million to KSh900million. He also said there is a provision of<br />

KSh1.5billion for KRA to clear the backlog.<br />

The Minister praised the <strong>MRM</strong> management and welcomed<br />

the opportunity to officially visit the plant and commission the<br />

Pickling Line. The inauguration ceremony was attended by among<br />

others: the Board Directors,<br />

Managers, Workers,<br />

Customers, Well wishes and<br />

community leaders.<br />

After<br />

the inauguration ceremony<br />

Hon. Kimunya visited and<br />

toured the nearby Kaluworks<br />

Plant which is also owned<br />

by the same shareholders<br />

of <strong>MRM</strong>.<br />

16<br />

M A B A T I N E W S<br />

Continued on page 18>>

awards<br />

MABATINEWS<br />

OVERALL CORPORATE CP AWARD:<br />

awarded to the organization with<br />

outstanding cleaner production<br />

management initiatives<br />

CP LEADERSHIP AWARD:<br />

given to the company that demonstrates<br />

its openness and communication<br />

regarding cleaner production and other<br />

environmental matters to workers and<br />

the surrounding community<br />

SOLID WASTE REDUCTION AWARD:<br />

given to the company that has achieved<br />

significant solid waste reduction in<br />

the implementation of its cleaner<br />

production initiatives<br />

REDUCTION IN GASEOUS EMISSIONS:<br />

given to the company that has achieved<br />

significant reduction in gaseous<br />

emissions through implementation of<br />

cleaner production initiatives<br />

WASTEWATER REDUCTION AWARD:<br />

given to the company that has achieved<br />

significant wastewater reduction in<br />

the implementation of its cleaner<br />

production initiatives<br />

CP INNOVATION AWARD:<br />

given to the company that promotes voluntary<br />

complementary initiatives like designing products<br />

for environment, EMS, green supply management<br />

and other innovative eco-efficiency principles.<br />

KRA 2006 DISTINGUISHED<br />

TAXPAYER AWARD<br />

OCCUPATIONAL HEALTH AND<br />

SAFETY AWARD:<br />

given to the organization with most<br />

significant reduction in occupational<br />

health and safety risks and hazards<br />

M A B A T I N E W S 17

Cleaner Production Initiatives at<br />

<strong>Mabati</strong> <strong>Rolling</strong> <strong>Mills</strong> Ltd<br />

By Francis Muthama<br />

Cleaner production is a preventive<br />

environmental management strategy<br />

that focuses on products, processes<br />

and services. Cleaner Production aims to<br />

reduce waste generation at source leading to<br />

economic savings as well as protection of the<br />

environment. Its techniques of application can<br />

be broadly classified as waste minimization at<br />

source, on-site recovery and reuse, recycling,<br />

good house keeping, energy efficiency, risk<br />

management, equipment modification,<br />

input substitution, better process control,<br />

technology change, product modification and<br />

responsible corporate management.<br />

Cleaner Production describes a preventive<br />

approach to environmental management.<br />

It is called a “win–win” strategy, because it<br />

protects the environment, the consumer<br />

and the workers while at the same time<br />

improving industrial efficiency, profitability<br />

and competitiveness. It focuses on processes,<br />

productivity and services.<br />

Reduce the consumption of raw materials<br />

and energy<br />

Eliminate as far as possible the use of toxic<br />

and dangerous materials<br />

Reduce at source the quantity and toxicity<br />

of all emissions and waste generated and<br />

released<br />

Principles of Cleaner Production<br />

Prevention: Preventing as much as possible<br />

the generation of waste at source<br />

Source reduction: Waste is reduced at<br />

every process stage or service step<br />

Raw material optimization: Conserving<br />

raw materials and switching to renewable<br />

resources<br />

Substituting toxic inputs with less toxic<br />

ones<br />

To recover, recycle and re-use of byproducts<br />

and waste<br />

Reducing environmental, health and safety<br />

impacts<br />

<strong>MRM</strong> production processes aim for:<br />

1. Waste Management and control Systems<br />

Energy Conservation: An energy audit is<br />

performed identifying areas where there<br />

are high power consumption and giving<br />

solutions on minimizing losses.<br />

Key performance Indicators: the company<br />

has formulated objectives and targets<br />

for minimizing waste, reducing resources<br />

depletion.<br />

Methodology or a procedure for identifying<br />

areas of inefficient use of resources and<br />

poor management of waste: This is done<br />

through internal audits, Systems audits and<br />

Monitoring of consumables.<br />

Material Balance: this helps to explain<br />

unaccounted raw materials that end up as<br />

waste and the yield.<br />

Housekeeping: Implementation of Kaizen<br />

Tools such as 5K’s help control wastes and<br />

keeps the plant neat and tidy<br />

2. Process Performance, Monitoring and<br />

control<br />

Equipment performance: measured and<br />

monitored via the overall equipment<br />

efficiency analysis which takes into account<br />

the performance factor, availability & quality<br />

factors.<br />

Machine down time: Logged and analyzed<br />

with reasons.<br />

Rejections and Rework: Minimal rejections<br />

and rework is generated.<br />

Process Monitoring: Automation &<br />

computerization of the Plants, Calibration of<br />

measuring equipment / instruments, planned<br />

maintenance and in-house Laboratory<br />

analysis.<br />

3. Systems to improve services<br />

Maintenance: Autonomous Maintenance, And<br />

Periodic maintenance schedule is followed.<br />

Cross Functional Teams: These are groups<br />

working as a team on any areas of improvement<br />

i.e. different experts from different departments<br />

coming together to brainstorm on a common<br />

problems in TQM projects, Gemba – Kaizen<br />

projects / interventions ISO 14001 continual<br />

improvement programs.<br />

Computerized systems of data acquisition,<br />

storage and reporting: These include<br />