You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Hinweise Technical data<br />

Electromagnet ME 10/UV 75<br />

Electric drive for valve-gate systems<br />

The compact drive <strong>mechanism</strong> is designed for valve gate systems with drive in the clamping plate.<br />

Up to 4 needles can be controlled simultaneously and very precisely by means of an external controller (eValveControl-4).<br />

Option of 8-drop parallel operation.<br />

• For all-electric injection moulding machines<br />

• Unrestricted clean-room suitability<br />

Valve-gate technology with the five-fold ingenious solution for needle actuation.<br />

the needle can move by means of a single nozzle or in multiple systems it can be operated by means of a<br />

- Electromagnet<br />

- Single needle valve<br />

- Lifting plate <strong>mechanism</strong><br />

- <strong>Sliding</strong> <strong>cam</strong> <strong>mechanism</strong><br />

Special holes in the mould clamping plate allow the depth of the valve-gate to be adjusted individually from the outside.<br />

The selection of needle drive depends on the application, space conditions and mould size.<br />

The actuation medium can be designed for elecrical, pneumatic or hydraulic operation.<br />

Technical Data<br />

Actuation medium Electromagnet, Single needle valve, Lifting plate <strong>mechanism</strong>, <strong>Sliding</strong> <strong>cam</strong> <strong>mechanism</strong><br />

Operatin pressure The hydraulic activation of the above driving <strong>mechanism</strong> for the valve-gate system requires pressures of<br />

40-60 bar. In individual cases it might be necessary for the pressure to be >60 bar.<br />

For pneumatic activation, we recommend a pressure of 8 to 10 bar is required, a pressure intensifier will be necessary<br />

and you should contact us in that case.<br />

Electromagnet<br />

Material tube-Ø /<br />

Needle-Ø /<br />

Needle length<br />

Service<br />

Technical details Pn = 620 watts<br />

Vn = 205 VDC<br />

In = approx. 3.0 amperes<br />

connections Ip40<br />

cycle time > 0,1 s pro 10 mm stroke<br />

thermal class F = 155°C (caution: note self-heating!!!)<br />

Controller Controller “eValve Control V1.0” see. chapter controller<br />

www.guenther-hotrunner.com<br />

6/12 Subject to technical changes<br />

Material tube-Ø 4-6 mm / Needle-Ø 2 mm / Needle length L max. 260 mm<br />

Material tube-Ø 8 mm / Needle-Ø 3 mm / Needle length L max. 260 mm<br />

Material tube-Ø 10 und 12 mm/ Needle-Ø 5 mm / Needle length L max. 490 mm<br />

The stroke <strong>mechanism</strong> have to be serviced after approximately 400.000 (TPE 200.000) shots.<br />

<strong>Sliding</strong> <strong>cam</strong> <strong>mechanism</strong> lubricate: all 150.000 shots or weekly.<br />

Service intervals very depending on the processing material!<br />

Electromagnet: Maintenance-free<br />

5. 2 5. 3<br />

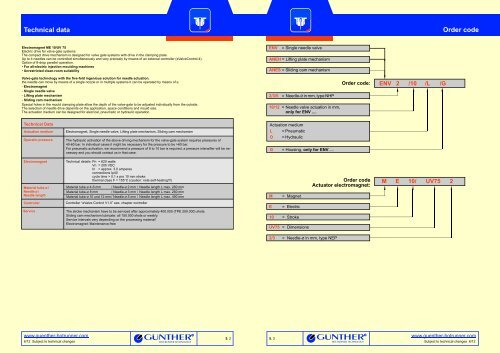

ENV = Single needle valve<br />

ANEH = Lifting plate <strong>mechanism</strong><br />

<strong>ANES</strong> = <strong>Sliding</strong> <strong>cam</strong> <strong>mechanism</strong><br />

2/3/5 = Needle-Ø in mm, <strong>type</strong> NHP<br />

10/12 = Needle valve actuation in mm,<br />

only for ENV ....<br />

Actuation medium<br />

L<br />

O<br />

= Pneumatic<br />

= Hydraulic<br />

G = Housing, only for ENV.....<br />

M = Magnet<br />

E = Electric<br />

10 = Stroke<br />

UV75 = Dimensions<br />

2/3 = Needle-Ø in mm, <strong>type</strong> NEP<br />

Order code<br />

Actuator electromagnet:<br />

Order code: ENV 2 /10 /L /G<br />

M E 10/ UV75 2<br />

Order code<br />

www.guenther-hotrunner.com<br />

Subject to technical changes 6/12

Materialabhängige Materialabhängige Düsenauswahl<br />

Düsenauswahl<br />

Hinweise<br />

a. The needle valve is coated.<br />

Blanks are available for needle valve used in special<br />

applications (e. g. exceptional lengths, gate diameter, pin diameter<br />

etc.)<br />

b.<br />

Please note<br />

c. The needle length is dependent on the nozzle length,<br />

the<br />

<strong>mechanism</strong> and the assembly of the manifold.<br />

e. Thread tightening torque to (NHP) needle adjustment<br />

Following parts must be ordered separately. Box spanner - two parts<br />

to adjust the needles, chapter 8.<br />

5. 4<br />

Needle adjustment or changing results through clampingplate/<br />

lifting plate without disassembly of the tools.<br />

d. Maximum tightening torque<br />

Regelgewinde<br />

Threads<br />

M4<br />

M5<br />

M6<br />

M8<br />

M10<br />

M12<br />

Needle-Ø<br />

Ø 2 mm<br />

Ø 3 mm<br />

Ø 5 mm<br />

Needle-Ø Thread<br />

Order code<br />

Strength class<br />

10.9 12.9<br />

3.8 Nm<br />

8 Nm<br />

13 Nm<br />

32 Nm<br />

64 Nm<br />

110 Nm<br />

Thread Tightening torque<br />

M A [Nm]<br />

M6 x 0.50<br />

15<br />

M8 x 0.50<br />

M10 x 0.75<br />

f. Thread tightening torque to (NEP) needle adjustment<br />

Ø 2 mm<br />

Ø 3 mm<br />

M6 x 0.50<br />

M8 x 0.50<br />

Bei If you Fragen have wenden any questions Sie sich please bitte an call die our technical consulting,<br />

Technische at +49 (0) 6451 Anwendungsberatung, - 50 08 0.<br />

Tel.: +49 (0) 6451 - 50 08 0.<br />

30<br />

45<br />

15<br />

30<br />

4.6 Nm<br />

9.5 Nm<br />

16.0 Nm<br />

39.0 Nm<br />

77.0 Nm<br />

135.0 Nm<br />

Tightening torque<br />

M [Nm]<br />

A<br />

ME electromagnet<br />

Hinweise Notes<br />

ME 10/UV 75 electric drive for valve-gates<br />

The ME 10 bistable heavy-duty lifting magnet serves to actuate valve<br />

needles in valve-gate systems.<br />

Excellent for all-electric injection moulding machines and for cleanroom<br />

applications.<br />

Available voltages are 48 VDC and 205 VDC (approx. 10 A and 2.5 A<br />

per magnet accordingly). The magnet is designed for thermal class F<br />

(155° C). The heat balance must be checked in individual cases,<br />

taking self-heating and heat dissipation into account.<br />

ENV single needle valve<br />

Needle actuation in single and multiple systems. Sequential opening<br />

and closing of the needles. Special holes in the mould clamping plate<br />

allow the down-stroke depth of the valve gate to be adjusted individually<br />

from the outside. Maximum working temperature is 100° C.<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

Tempering<br />

Sufficient cooling must be ensured in the lower area of needle<br />

actuation. We also urgently recommend cooling the clamping<br />

plate and frame plates or risers.<br />

Assembly height<br />

The assembly height is dependend on the dimension of the<br />

manifold height linked to the cable-Ø, the balanced and the use of<br />

nozzle <strong>type</strong>.<br />

Single needle valve<br />

ENV2/10/L, ENV2/10/L/G, ENV2/10/O, ENV2/10/O/G,(56 mm),<br />

ENV3/10/L, ENV3/10/L/G, ENV3/10/O, ENV3/10/O/G (56 mm),<br />

ENV5/12/L, ENV5/12/L/G, ENV5/12/O, ENV5/12/O/G (66 mm)<br />

Contour in details without housing<br />

In the area of the piston stroke, the surface of the cylinder hast to<br />

be flash-free and without sharp edges. Piston operating surface are<br />

honed or rolled (Ra min. 0.2).<br />

Contour in details without housing<br />

ENV2 und ENV3 ENV5<br />

R0.5<br />

R0.5<br />

3<br />

0.4<br />

0.2<br />

Edge<br />

15°<br />

Piston operating<br />

surface<br />

Ra min. 0.2<br />

Contour in details with housing<br />

0.4<br />

Edge<br />

deburred<br />

15°<br />

1.6<br />

R0.5<br />

R0.5<br />

Access supplied by the customer in the area of the fastening screw M5.<br />

4<br />

0.2<br />

7 Threads/ counterbore/ cylinder head screw<br />

ENV2/ ENV3<br />

a. Thread/ counterbore 45° rotated shown<br />

b. 4x counterbore DIN 974-1<br />

c. 4x cylinder screw M5 x 20 - 12.9 DIN EN ISO 4762<br />

ENV5<br />

a. Thread/ counterbore 30° rotated shown<br />

b. 6x counterbore DIN 974-1<br />

c. 6x cylinder screw M6 x 25 - 12.9 DIN EN ISO 4762<br />

ANEH lifting plate <strong>mechanism</strong><br />

Hinweise Notes<br />

The lifting <strong>mechanism</strong> is recommendable for a precisely<br />

simultaneous opening and closing of all needles.<br />

Special holes in the mould clamping plate allow the down-stroke depth<br />

of the valve needles to be adjusted individually from the outside.<br />

The maximum working temperature is 100° C.<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

Valve-gate nozzle, chapter 2.3<br />

The valve needle is not a component part of the valve-gate nozzle,<br />

chapter 8<br />

Manifold, chapter 4<br />

Needle guide<br />

Adjust wrench<br />

Covering<br />

Socket wrenches to adjust the valve needle, chapter 8<br />

Needle movement (stroke)<br />

Needle movement (stroke) of 10 mm is provided for nozzles<br />

with material tube-Ø (Ød) of 4-6 mm.<br />

Needle movement (stroke) of 12 mm is provided for nozzles<br />

with material tube-Ø (Ød) of 8-12 mm.<br />

Clamping plate with<br />

Supporting plate<br />

Nozzle holding plate<br />

Support pieces<br />

Guiding unit incl. guide pillar<br />

Adapter (ball)<br />

Cylinder<br />

<strong>ANES</strong> sliding <strong>cam</strong> <strong>mechanism</strong><br />

For narrow cavity spacing a sliding <strong>cam</strong> <strong>mechanism</strong> is the preferred<br />

drive.<br />

Exact opening and closing of all needles.<br />

Special holes in the mould clamping plate allow the down-stroke<br />

depth of the valve gate to be adjusted individually from the outside.<br />

Maximum working temperature is 100° C.<br />

www.guenther-hotrunner.com<br />

Subject to technical changes 6/12

<strong>Sliding</strong> <strong>cam</strong> <strong>mechanism</strong> <strong>type</strong> <strong>ANES</strong>/ L - <strong>ANES</strong>/ O<br />

Order code<br />

Example: <strong>ANES</strong>/L <strong>Sliding</strong><br />

<strong>cam</strong> <strong>mechanism</strong><br />

<strong>ANES</strong> = <strong>Sliding</strong> <strong>cam</strong> <strong>mechanism</strong><br />

L = Actuation medium: pneumatic<br />

Please indicate the actuation medium and<br />

mold dimensions in your order.<br />

Notes<br />

With tight pitches of 9-12 mm, please use the<br />

sliding <strong>cam</strong> <strong>mechanism</strong> for needle actuation.<br />

Accurate opening and closing of all needles<br />

Maximum working temperature of 100°C<br />

a Floating bearings for valve-gates<br />

Details are dependent on the actuation medium<br />

and mold size.<br />

If you have further questions please do not<br />

hesitate to contact our engineering<br />

department at +49 (0) 6451 - 50 08 0.<br />

a<br />

14<br />

Needle-Ø 2 mm = Ø8<br />

Needle-Ø 3 mm = Ø10<br />

Needle-Ø 5 mm = Ø15<br />

Signs and symbols, detailed on the yellow page:<br />

12<br />

13<br />

14<br />

15<br />

Needle<br />

Needle holder<br />

Adjusting screw nut<br />

Cover<br />

16<br />

17<br />

18<br />

19<br />

www.guenther-hotrunner.com<br />

6/12 Subject to technical changes<br />

15<br />

13<br />

12<br />

Socket wrenches<br />

Needle holding<br />

Clamping plate<br />

Lifting plate<br />

21<br />

20<br />

20<br />

21<br />

22<br />

23<br />

22<br />

19<br />

18<br />

23<br />

17<br />

Slide plate<br />

Slide bar<br />

Actuation<br />

Stop<br />

16<br />

Special openings in the clamping plate allow<br />

an individual adjustment of the valve-gate<br />

needle from the outside<br />

24<br />

25<br />

Cover plate<br />

Control rail<br />

24<br />

25<br />

5. 70<br />

<strong>ANES</strong>/ L ANEH/L<br />

<strong>ANES</strong>/ O ANEH/O<br />

ENV5/L ENV2/3/O ENV2/3/L ME 10/UV75