section d - Total Hydraulics BV

section d - Total Hydraulics BV

section d - Total Hydraulics BV

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

2012<br />

AC & DC Hydraulic<br />

Power Packs MICRO<br />

Micra 1

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

POWER PACKS MICRO series ordering code<br />

www.hydronit.com<br />

PPM2012/1-01<br />

Micro 2

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

QUICK SELECTION GUIDE<br />

AC & DC electric motors<br />

Section A<br />

DC motors<br />

0,15 12DC_T 12VDC motor - 150W - Ø 80 + thermal switch<br />

0,15 24DC_T 24VDC motor - 150W - Ø 80 + thermal switch<br />

0,5 12DC 12VDC motor - 500W - Ø 80<br />

0,5 24DC 24VDC motor - 500W - Ø 80<br />

0,5 12DC_T 12VDC motor - 500W - Ø 80 + thermal switch<br />

0,5 24DC_T 24VDC motor - 500W - Ø 80 + thermal switch<br />

0,8 12DC 12VDC motor - 800W - Ø 80<br />

0,8 24DC 24VDC motor - 800W - Ø 80<br />

0,8 12DC_T 12VDC motor - 800W - Ø 80 + thermal switch<br />

0,8 24DC_T 24VDC motor - 800W - Ø 80 + thermal switch<br />

1,6 12DC_T 12VDC motor - 1600W - Ø 114 + thermal switch<br />

2,1 12DC_T 12VDC motor - 2100W - Ø 114 + thermal switch<br />

2,2 24DC_T 24VDC motor - 2200W - Ø 114 + thermal switch<br />

AC motors: three-phase 4 poles (~1450 rpm at 50Hz)<br />

N037AC341S3 integral motor 0,37kW 3-ph 4-pole 220/380V 50/60Hz frame 71<br />

N055AC341S3 integral motor 0,55kW 3-ph 4-pole 220/380V 50/60Hz frame 71<br />

N075AC341S3 integral motor 0,75kW 3-ph 4-pole 220/380V 50/60Hz frame 71<br />

AC motors: single-phase 4 poles (~1450 rpm at 50Hz)<br />

N037ACS41S3 integral motor 0,37kW 1-ph 4-pole 220V 50Hz frame 71<br />

N055ACS41S3 integral motor 0,55kW 1-ph 4-pole 220V 50Hz frame 71<br />

2 pole and special execution motors (High starting torque, high IP, with thermal protector,... available on request<br />

No motor: B14 Flange + coupling kit<br />

NB14 63 mounting kit for B14 motors frame 63<br />

NB14 71 mounting kit for B14 motors frame 71<br />

Electric motors options<br />

DC motor options<br />

S150 12DC 80<br />

S150 24DC 80<br />

S150 12DC 112<br />

S150 24DC 112<br />

starting relay 12VDC 150A with mounting kit for Ø 80 motors<br />

starting relay 24VDC 150A with mounting kit for Ø 80 motors<br />

starting relay 12VDC 150A with mounting kit for Ø 114 motors<br />

starting relay 24VDC 150A with mounting kit for Ø 114 motors<br />

www.hydronit.com<br />

PPM2012/1-02<br />

Micra 3

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

QUICK SELECTION GUIDE<br />

Micro central manifold<br />

International execution (1/4" BSP exit ports)<br />

Section B<br />

MB<br />

MR<br />

M4<br />

Micro PPM B type body with 4 lateral cavities<br />

Micro PPM R type body for reversible circuits<br />

Micro PPM 4-way type body for 4 way cartridge valves<br />

USA execution (SAE 06 exit ports)<br />

MBUS<br />

MRUS<br />

M4US<br />

Micro PPM B type body with 4 lateral cavities US execution<br />

Micro PPM R type body for reversible circuits US execution<br />

Micro PPM 4-way type body for 4 way cartridge valves US execution<br />

Gear Pumps<br />

Standard gear pumps<br />

Section C<br />

GM0,1<br />

KM0,2<br />

KM0,4<br />

KM0,6<br />

KM0,9<br />

KM1,3<br />

KM1,5<br />

KM1,9<br />

gear pump group 0 – 0,19 cc/rev<br />

gear pump group 0 – 0,26 cc/rev<br />

gear pump group 0 – 0,38 cc/rev<br />

gear pump group 0 – 0,64 cc/rev<br />

gear pump group 0 – 0,88 cc/rev<br />

gear pump group 0 – 1,25 cc/rev<br />

gear pump group 0 – 1,54 cc/rev<br />

gear pump group 0 – 1,9 cc/rev<br />

Bi-directional gear pumps<br />

RM0,1<br />

RM0,2<br />

RM0,4<br />

RM0,6<br />

RM0,9<br />

RM1,3<br />

RM1,5<br />

reversible gear pump group 0 - 0,19 cc/rev<br />

Reversible gear pump group 0 - 0,26 cc/rev<br />

reversible gear pump - 0,38cc/rev<br />

reversible gear pump - 0,63 cc/rev<br />

reversible gear pump - 0,88cc/rev<br />

reversible gear pump - 1,25cc/rev<br />

reversible gear pump - 1,5cc/rev<br />

Integral components: Cavity 0<br />

Section D<br />

Components in central manifold cavity 0<br />

JM<br />

ML<br />

check valve ball type 5/8-18 UNF<br />

plug 5/8-18UNF basic<br />

Integral components: Cavity 1<br />

Components in central manifold cavity 1<br />

DM_60<br />

DM_280<br />

XM<br />

relief valve M14 - 10÷60 bar - socket screw adjustment<br />

relief valve M14 - 35÷280 bar - socket screw adjustment<br />

plug for relief valve cavity M14<br />

www.hydronit.com<br />

PPM2012/1-03<br />

Micro 4

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

QUICK SELECTION GUIDE<br />

Integral components: Cavity 2<br />

Components in central manifold cavity 2<br />

X<br />

A<br />

B<br />

C<br />

D<br />

E<br />

EM<br />

Z<br />

S<br />

T12DC<br />

T24DC<br />

U<br />

G<br />

H<br />

N<br />

P<br />

L<br />

J<br />

4VA11C<br />

4VA2<br />

4VB2<br />

4VC2<br />

4VE2<br />

JP<br />

MG<br />

open cavity – no valve<br />

NC solenoid 2/2 way 3/4-16UNF poppet valve<br />

NC solenoid 2/2 way 3/4-16UNF poppet valve with emergency<br />

NO solenoid 2/2 way 3/4-16UNF poppet valve with emergency<br />

NC solenoid 2/2 way 3/4-16UNF double poppet valve with emergency<br />

lever operated 2/2 way valve without micro-switch<br />

lever operated 2/2 way valve with micro-switch<br />

2 way emergency button valve<br />

flow control valve 3/4-16UNF with screw<br />

proportional flow control valve poppet type 15l/min 315 bar + coil 12VDC ED100%<br />

proportional flow control valve poppet type 15l/min 315 bar + coil 24VDC ED100%<br />

hand pump 3/4-16UNF 2 cc/stroke + suction/return line pipe 1/4”BSP 370mm<br />

closed plug 3/4-16UNF<br />

plug 3/4-16UNF with 1/4”BSPP exit port<br />

plug 3/4-16UNF open passage with 1/4”BSPP exit port<br />

plug 3/4-16UNF passing through 1/4”BSPP<br />

plug 3/4-16UNF basic<br />

check valve ball type 3/4-16UNF<br />

4/2 way solenoid directional valve, closed center transient (only for M4 manifolds)<br />

4/3 way solenoid directional valve, center P to T (only for M4 manifolds)<br />

4/3 way solenoid directional valve, closed center (only for M4 manifolds)<br />

4/3 way solenoid directional valve, H center (only for M4 manifolds)<br />

4/3 way solenoid directional valve, center A-B to T (only for M4 manifolds)<br />

check valve poppet type 5/8-18 UNF (only for MR central manifolds)<br />

Closed plug 5/8-18UNF (only for MR central manifolds)<br />

Cavity 2 option<br />

V-CSB<br />

handwheel for CSB/CSU<br />

EM9001C pressure gauge shut-off valve 90° F-F + nipples M 1/4” BSPP – M 1/4” BSPP<br />

EMIL01C pressure gauge shut-off valve F-F + nipples M 1/4” BSPP – M 1/4” BSPP<br />

F401**<br />

pressure switch 1/4” BSPP where ** = max setting pressure (050-100-200-400 bar)<br />

MIR63**EM pressure gauge Ø63 where ** = max press. (60-160-250-315 bar) + shut-off valve 90°<br />

Cavity 2 valve coil<br />

12DC_M130 Coil 12V DC 18W ED75% for MSV30-31 + Electric connector DIN 43650-A<br />

24DC_M130 Coil 24V DC 18W ED75% for MSV30-31 + Electric connector DIN 43650-A<br />

24RAC_M130 Coil 24V DC 18W ED75% for MSV30-31 + El. connector with rectifier 12-24V<br />

115_50AC_M130 Coil 115V/50Hz AC 28VA ED75% only for MSV30 + El. connector DIN 43650-A<br />

230_50AC_M130 Coil 230V/50Hz AC 28VA ED75% only for MSV30 + El. connector DIN 43650-A<br />

110RAC_M130 Coil 110V RAC 18W ED75% for MSV30-31 + El. connector with rectifier 115 V<br />

220RAC_M130 Coil 220V RAC 18W ED75% for MSV30-31 + El. connector with rectifier 230 V<br />

www.hydronit.com<br />

PPM2012/1-04<br />

Micra 5

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

QUICK SELECTION GUIDE<br />

Cavity 2 valve coil<br />

12DC_M140 Coil 12V DC 22W ED100% for MSV-MDV + Electric connector DIN 43650-A<br />

24DC_M140 Coil 24V DC 22W ED100% for MSV-MDV + Electric connector DIN 43650-A<br />

24RAC_M140 Coil 24V DC 22W ED100% for MSV-MDV + El. connector with rectifier 12-24 V<br />

110RAC_M140 Coil 110V RAC 22W ED100% for MSV-MDV + El. connector with rectifier 115 V<br />

220RAC_M140 Coil 220V RAC 22W ED100% for MSV-MDV + El. connector with rectifier 230 V<br />

12DC_M630 coil 12V DC ED100% for cartridge valves + Electric connector DIN 43650-A<br />

24DC_M630 coil 24V DC ED100% for cartridge valves + Electric connector DIN 43650-A<br />

24AC_M631 coil 24V AC ED100% for cartridge valves + integrated rectifier + Electric connector<br />

115AC_M631 coil 115V AC ED100% for cartridge valves + integrated rectifier + Electric connector<br />

230AC_M631 coil 230V AC ED100% for cartridge valves + integrated rectifier + Electric connector<br />

Integral components: Cavity 3<br />

Components in central manifold cavity 3<br />

F02<br />

F03<br />

F04<br />

F05<br />

F06<br />

F07<br />

F09<br />

F11<br />

F13<br />

F15<br />

R2<br />

R3<br />

R4<br />

R5<br />

R6<br />

R7<br />

S<br />

Z<br />

AR<br />

BR<br />

CR<br />

D<br />

J<br />

G<br />

H<br />

N<br />

P<br />

L<br />

P**12DC<br />

P**24DC<br />

V**<br />

JP<br />

MG<br />

fixed pressure compensated flow control valve 3/4-16UNF hole 0,8mm<br />

fixed pressure compensated flow control valve 3/4-16UNF hole 1mm<br />

fixed pressure compensated flow control valve 3/4-16UNF hole 1,25mm<br />

fixed pressure compensated flow control valve 3/4-16UNF hole 1,5mm<br />

fixed pressure compensated flow control valve 3/4-16UNF hole 1,75mm<br />

fixed pressure compensated flow control valve 3/4-16UNF hole 2mm<br />

fixed pressure compensated flow control valve 3/4-16UNF hole 2,5mm<br />

fixed pressure compensated flow control valve 3/4-16UNF hole 3mm<br />

fixed pressure compensated flow control valve 3/4-16UNF hole 3,5mm<br />

fixed pressure compensated flow control valve 3/4-16UNF hole 4mm<br />

compensated flow control valve 3/4-16UNF with screw 1 ÷ 2,2 l/min<br />

compensated flow control valve 3/4-16UNF with screw 1,6 ÷ 4 l/min<br />

compensated flow control valve 3/4-16UNF with screw 2,5 ÷ 5 l/min<br />

compensated flow control valve 3/4-16UNF with screw 3÷ 7 l/min<br />

compensated flow control valve 3/4-16UNF with screw 4,9 ÷ 10,8 l/min<br />

compensated flow control valve 3/4-16UNF with screw 8 ÷ 18,5 l/min<br />

flow control valve 3/4-16UNF with screw<br />

2 way emergency button valve<br />

NC solenoid 2/2 way 3/4-16UNF poppet valve, reversible flow<br />

NC solenoid 2/2 way 3/4-16UNF poppet valve with emergency, reversible flow<br />

NO solenoid 2/2 way 3/4-16UNF poppet valve with emergency, reversible flow<br />

NC solenoid 2/2 way 3/4-16UNF double poppet valve with emergency<br />

check valve ball type 3/4-16UNF<br />

closed plug 3/4-16UNF<br />

plug 3/4-16UNF with 1/4”BSPP exit port<br />

plug 3/4-16UNF open passage with 1/4”BSPP exit port<br />

plug 3/4-16UNF passing through 1/4”BSPP<br />

plug 3/4-16UNF basic<br />

proportional relief valve 3/4-16UNF 12VDC where ** = max pressure (60-210 bar)<br />

proportional relief valve 3/4-16UNF 24VDC where ** = max pressure (60-210 bar)<br />

relief valve 3/4-16UNF where ** = max pressure (110-250-350 bar) - socket screw<br />

check valve poppet type 5/8-18 UNF (only for MR central manifolds)<br />

Closed plug 5/8-18UNF (only for MR central manifolds)<br />

www.hydronit.com<br />

PPM2012/1-05<br />

Micro 6

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

QUICK SELECTION GUIDE<br />

Cavity 3 option<br />

V-CSB<br />

handwheel for CSB/CSU<br />

2 handwheel M8 for VMDC35/VMDC20/VCF6 valves<br />

EM9001C pressure gauge shut-off valve 90° F-F + nipples M 1/4” BSPP – M 1/4” BSPP<br />

EMIL01C pressure gauge shut-off valve F-F + nipples M 1/4” BSPP – M 1/4” BSPP<br />

F401**<br />

pressure switch 1/4” BSPP where ** = max setting pressure (050-100-200-400 bar)<br />

MIR63**EM pressure gauge Ø63 where ** = max press. (60-160-250-315 bar) + shut-off valve 90°<br />

Cavity 3 valve coil voltage<br />

12DC_M130 Coil 12V DC 18W ED75% for MSV30-31 + Electric connector DIN 43650-A<br />

24DC_M130 Coil 24V DC 18W ED75% for MSV30-31 + Electric connector DIN 43650-A<br />

24RAC_M130 Coil 24V DC 18W ED75% for MSV30-31 + El. connector with rectifier 12-24 V<br />

115_50AC_M130 Coil 115V/50Hz AC 28VA ED75% only for MSV30 + Electric connector DIN 43650-A<br />

230_50AC_M130 Coil 230V/50Hz AC 28VA ED75% only for MSV30 + Electric connector DIN 43650-A<br />

110RAC_M130 Coil 110V RAC 18W ED75% for MSV30-31 + El. connector with rectifier 115 V<br />

220RAC_M130 Coil 220V RAC 18W ED75% for MSV30-31 + El. connector with rectifier 230 V<br />

12DC_M140 Coil 12V DC 22W ED100% for MSV-MDV + Electric connector DIN 43650-A<br />

24DC_M140 Coil 24V DC 22W ED100% for MSV-MDV + Electric connector DIN 43650-A<br />

24RAC_M140 Coil 24V DC 22W ED100% for MSV-MDV + El. connector with rectifier 12-24 V<br />

110RAC_M140 Coil 110V RAC 22W ED100% for MSV-MDV + El. connector with rectifier 115 V<br />

220RAC_M140 Coil 220V RAC 22W ED100% for MSV-MDV + El. connector with rectifier 230 V<br />

Integral components: Cavity 4<br />

Component in central manifold cavity 4 (only for MR central manifold)<br />

DM_60<br />

DM_280<br />

XM<br />

relief valve M14 - 10÷60 bar - socket screw adjustment<br />

relief valve M14 - 35÷280 bar - socket screw adjustment<br />

plug for relief valve cavity M14<br />

Flow restrictor in central manifold cavity 5<br />

Flow restrictor in central manifold cavity 5<br />

PLUGTCE01<br />

PP01370<br />

1/4” BSPP plug with copper washer<br />

suction/return line pipe 1/4”BSP 370mm<br />

RETURN-KIT 1/4” BSP holder for SF12 + flexible plastic pipe 12 mm for return line / price per meter<br />

C34200001 return line tank immersed filter<br />

1(01) fixed pressure compensated flow control valve 1/4"BSP 1l/min<br />

2(01) fixed pressure compensated flow control valve 1/4"BSP 2l/min<br />

3(01) fixed pressure compensated flow control valve 1/4"BSP 3l/min<br />

4(01) fixed pressure compensated flow control valve 1/4"BSP 4l/min<br />

5(01) fixed pressure compensated flow control valve 1/4"BSP 5l/min<br />

6(01) fixed pressure compensated flow control valve 1/4"BSP 6l/min<br />

8(01) fixed pressure compensated flow control valve 1/4"BSP 8l/min<br />

10(01) fixed pressure compensated flow control valve 1/4"BSP 10l/min<br />

12(01) fixed pressure compensated flow control valve 1/4"BSP 12l/min<br />

15(01) fixed pressure compensated flow control valve 1/4"BSP 15l/min<br />

www.hydronit.com<br />

PPM2012/1-06<br />

Micra 7

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

QUICK SELECTION GUIDE<br />

Flow restrictor in central manifold cavity 7<br />

Flow restrictor in central manifold cavity 7<br />

0(04) closed plug Ø 12,7<br />

1(04) fixed pressure compensated flow control valve Ø 12,7 with o-ring 1l/min<br />

2(04) fixed pressure compensated flow control valve Ø 12,7 with o-ring 2l/min<br />

3(04) fixed pressure compensated flow control valve Ø 12,7 with o-ring 3l/min<br />

4(04) fixed pressure compensated flow control valve Ø 12,7 with o-ring 4l/min<br />

5(04) fixed pressure compensated flow control valve Ø 12,7 with o-ring 5l/min<br />

6(04) fixed pressure compensated flow control valve Ø 12,7 with o-ring 6l/min<br />

8(04) fixed pressure compensated flow control valve Ø 12,7 with o-ring 8l/min<br />

10(04) fixed pressure compensated flow control valve Ø 12,7with o-ring 10l/min<br />

12(04) fixed pressure compensated flow control valve Ø 12,7 with o-ring 12l/min<br />

15(04) fixed pressure compensated flow control valve Ø 12,7 with o-ring 15l/min<br />

PIL5818 pilot Ø 12,7 for PO check valve 5/8-18UNF VUC10C<br />

PIL5818DIF pilot Ø 12,7 for PO check valve 5/8-18UNF VUC10C + valve for differential cylinders<br />

Flow restrictor in central manifold cavity 8<br />

Flow restrictor in central manifold cavity 8<br />

PLUGTCE01<br />

PP01370<br />

1/4” BSPP plug with copper washer<br />

suction/return line pipe 1/4”BSP 370mm<br />

RETURN-KIT 1/4” BSP holder for SF12 + flexible plastic pipe 12 mm for return line / price per meter<br />

C34200001 return line tank immersed filter<br />

1(01) fixed pressure compensated flow control valve 1/4"BSP 1l/min<br />

2(01) fixed pressure compensated flow control valve 1/4"BSP 2l/min<br />

3(01) fixed pressure compensated flow control valve 1/4"BSP 3l/min<br />

4(01) fixed pressure compensated flow control valve 1/4"BSP 4l/min<br />

5(01) fixed pressure compensated flow control valve 1/4"BSP 5l/min<br />

6(01) fixed pressure compensated flow control valve 1/4"BSP 6l/min<br />

8(01) fixed pressure compensated flow control valve 1/4"BSP 8l/min<br />

10(01) fixed pressure compensated flow control valve 1/4"BSP 10l/min<br />

12(01) fixed pressure compensated flow control valve 1/4"BSP 12l/min<br />

15(01) fixed pressure compensated flow control valve 1/4"BSP 15l/min<br />

www.hydronit.com<br />

PPM2012/1-07<br />

Micro 8

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

QUICK SELECTION GUIDE<br />

Tanks<br />

Section E<br />

Steel tanks<br />

0,7F 0,7l cylindrical steel horizontal mounting tank + 3/8"BSPP std filler & breather plug<br />

0,7FV<br />

0,7l cylindrical steel vertical mounting tank + 3/8"BSPP std filler & breather plug<br />

1,2F 1,2l cylindrical steel horizontal mounting tank + 3/8"BSPP std filler & breather plug<br />

1,2FV<br />

1,2l cylindrical steel vertical mounting tank + 3/8"BSPP std filler & breather plug<br />

1,7H 1,7l cylindrical steel horizontal mounting tank + 3/8"BSPP std filler & breather plug<br />

1,7HV<br />

1,7l cylindrical steel vertical mounting tank + 3/8"BSPP std filler & breather plug<br />

2,4H 2,4l cylindrical steel horizontal mounting tank + 3/8"BSPP std filler & breather plug<br />

2,4HV<br />

2,4l cylindrical steel vertical mounting tank + 3/8"BSPP std filler & breather plug<br />

F80000012 steel tank adapter for PPM - to be welded on custom made tanks<br />

Plastic tanks<br />

0,4R 0,4l plastic horizontal mounting tank + 1/4"BSPP std filler & breather plug<br />

0,4RV<br />

0,4l plastic vertical mounting tank + 1/4"BSPP std filler & breather plug<br />

0,7R<br />

0,7l plastic horizontal mounting tank + 1/4"BSPP std filler & breather plug<br />

0,7RV<br />

0,7l plastic vertical mounting tank + 1/4"BSPP std filler & breather plug<br />

1,2R 1,2l plastic horizontal mounting tank + 1/4"BSPP std filler & breather plug<br />

1,2RV<br />

1,2l plastic vertical mounting tank + 1/4"BSPP std filler & breather plug<br />

Accessories<br />

Section F<br />

Accessories<br />

E60543003<br />

MIR63**<br />

EM9001C<br />

EMIL01C<br />

F16000001<br />

F401**<br />

P0201<br />

P0202<br />

VPC00<br />

BFCSAE0801<br />

BFCSAE0802<br />

foot mounting support (45mm height)<br />

pressure gauge Ø63 where ** = max press. (60-160-250-315 bar)<br />

pressure gauge shut-off valve 90° F-F + nipples M 1/4” BSPP – M 1/4” BSPP<br />

pressure gauge shut-off valve F-F + nipples M 1/4” BSPP – M 1/4” BSPP<br />

plastic Ø112-114 DC motor protection cover<br />

pressure switch 1/4” BSPP where ** = max setting pressure (050-100-200-400 bar)<br />

remote up/down control with 3m flying cable for single/double acting cylinder<br />

Remote 4 buttons control with 3m flying cable for 2 double acting cylinders<br />

electronic PWM driver for proportional valves 12/24VDC<br />

in-line manifolds for 3/4-16UNF valves 1/4” BSPP ports<br />

in-line manifolds for 3/4-16UNF valves 3/8” BSPP ports<br />

External manifolds<br />

External manifolds<br />

M60403004<br />

M60403005<br />

M60403010(US)<br />

M60413002(US)<br />

M60413001(US)<br />

M60413003(US)<br />

M50403007<br />

PM09M<br />

23mm spacer subplate<br />

90° rotation manifold<br />

NG3 MICRO parallel block - 1/4” BSPP lateral ports (opt. US execution with SAE ports)<br />

NG3 MICRO manifold with piloted check valve on A (opt. US execution with SAE ports)<br />

NG3 MICRO manifold with piloted check valve on A & B (opt. US exec. with SAE ports)<br />

NG3 MICRO manifold with piloted check valve on B (opt. US execution with SAE ports)<br />

PPM to SD01 stackable valves converter manifold<br />

hand pump 8,8 cc/stroke modular manifold<br />

www.hydronit.com<br />

PPM2012/1-08<br />

Micra 9

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

QUICK SELECTION GUIDE<br />

External valves<br />

External valves<br />

Section G<br />

SD00A11C<br />

SD00A2<br />

NG3 MICRO solenoid directional valve 4 way, 2 positions<br />

NG3 MICRO solenoid directional valve 4 way, 3 pos. center P to T<br />

SD00B2 NG3 MICRO solenoid directional valve 4 way, 3 pos. closed center<br />

SD00C2 NG3 MICRO solenoid directional valve 4 way, 3 pos. H center<br />

SD00E2 NG3 MICRO solenoid directional valve 4 way, 3 pos. center A-B to T<br />

SD01A11C Stackable solenoid directional valve 4 way, 2 positions<br />

SD01A2 Stackable solenoid directional valve 4 way, 3 pos. center P to T<br />

SD01B2 Stackable solenoid directional valve 4 way, 3 pos. closed center<br />

SD01C2 Stackable solenoid directional valve 4 way, 3 pos. H center<br />

SD01E2 Stackable solenoid directional valve 4 way, 3 pos. center A-B to T<br />

SD01A11CC Stackable solenoid directional valve 4 way, 2 positions, stack top closed<br />

SD01A2C Stackable solenoid directional valve 4 way, 3 pos. center P to T, stack top closed<br />

SD01B2C Stackable solenoid directional valve 4 way, 3 pos. closed center, stack top closed<br />

SD01C2C Stackable solenoid directional valve 4 way, 3 pos. H center, stack top closed<br />

SD01E2C Stackable solenoid directional valve 4 way, 3 pos. center A-B to T, stack top closed<br />

External SD00 valves coils<br />

12DC_M100 coil 12V DC 16W ED100% + Electric connector DIN 43650-A<br />

24DC_M100 coil 24V DC 16W ED100% + Electric connector DIN 43650-A<br />

External SD01 valves coils<br />

12DC_M120 coil 12V DC 22W ED100% + Electric connector DIN 43650-A<br />

24DC_M120 coil 24V DC 22W ED100% + Electric connector DIN 43650-A<br />

24RAC_M120 coil 24V DC 22W ED100% + El. conn. with rectifier 12-24 V black pg11<br />

220RAC_M120 coil 220V RAC 26W ED100% + El. conn. with rectifier 230 V black pg11<br />

www.hydronit.com<br />

PPM2012/1-09<br />

Micro 10

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION A<br />

AC & DC ELECTRIC MOTORS<br />

Integral AC motors: the engineered solution for compact and optimised power units from 0,25 to 1,8 kW,<br />

single or three phase. The AC motors are directly flanged on the central manifold for extra compactness.<br />

A single coupling can suit all powers. We suggest to adopt these advanced motors because of their<br />

peculiar advantages over standard B14 IEC AC motors and because they are designed specifically for use<br />

on our micro power packs, offering an higher power density and high starting torque (in HT models) than<br />

market standard motors. These motors are intendend for intermittent use (S3 40%), which is the case for<br />

most micro-power packs applications. They can be used in emergency situations continuously at a reduced<br />

rated power (about 30% less than S3 nominal power).<br />

Single phase motors should not run in any case without load for long time to avoid overheating.<br />

B14 IEC standard AC motors: the standard solution easily<br />

available on every market from 0,12 to 0,55 kW, single or three<br />

phase. These motors are normally procured by the customer<br />

itself. Hydronit provides adaptor flanges and double piece<br />

coupling for frame size: 63 and 71.<br />

Frame 80 DC motors: with or without thermal<br />

protector and running time up to 6 min. Power<br />

from 0,15kW up to 0,8kW 12 or 24VDC.<br />

The permanent magnet construction allow their<br />

use in bidirectional units.<br />

Frame 114 DC motors: power up to 2,2kW<br />

24VDC for high performances. All motors have<br />

thermal protector switch as standard.<br />

Are AC motors compliant with the European Union Minimum Energy Performance Standards?<br />

Hydronit AC motors are manufactured in Italy with the best technologies nowadays available and are specifically designed for mini<br />

power packs duties, which are typically intermittent. Hydronit motors have an higher power density, lower weight, lower cost,<br />

comparing to standard IE2 motors on the market. Due to the specific field of applications, Hydronit motors are not included in the<br />

requirements of the above mentioned normative, since they are specially and solely manufactured for mini power packs intermittent<br />

duties. For continuous duty applications IE2 motors (IEC 60034-30) must be applied. Ask our sales office.<br />

Are there special requirements to mount IEC B14 motors?<br />

No special toolings are required. Please strictly follow motor side coupling mounting dimension tolerance as per the relevant drawings.<br />

Failing in doing so may cause malfunctioning of the power pack and even the break of the coupling and pump.<br />

Can I start single phase AC motors under load?<br />

Single phase motors have a reduced starting torque due to their intrinsecal design. Normally this ranges around 30-40% of the nominal<br />

torque at full power output. When designing circuits where a single phase motor must start under load, a proper dimensioning must be<br />

done and test on field must be preliminary performed. High starting torque «HT» motors are available. Ask our technical office.<br />

How do I dimension a DC motor?<br />

These motors are normally for intermittent duty. It is important to know required flow in l/min, working pressure in bar and the duty<br />

charge. Then following A040 table instructions a proper motor/pump combination can be selected.<br />

www.hydronit.com<br />

PPM2012/1-A000<br />

Micra 11

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION A<br />

INTEGRAL DC MOTORS Ø 80<br />

Starting switch option<br />

25,5<br />

10,5<br />

Ø 7<br />

Permanent magnets<br />

Protection degree: IP54<br />

Insulation class: F<br />

Code<br />

Thermal protection option<br />

2,5 L<br />

19<br />

Weight 500W/800W: 2,6 kg (without starter)<br />

Weight 150W: 2 kg (without starter)<br />

89,5<br />

Rotation<br />

Description<br />

PPC assembly<br />

code<br />

Spare part code<br />

Nominal<br />

duty cycle<br />

Nominal<br />

speed<br />

Nominal<br />

current<br />

L<br />

150W 12V DC + thermal protector 0,15 12DC/T M46C1ST01<br />

150W 24V DC + thermal protector 0,15 24DC/T M46C2ST01<br />

500W 12V DC motor 0,5 12DC M46C1S005<br />

500W 24V DC motor 0,5 24DC M46C2S005<br />

500W 12V DC + thermal protector 0,5 12DC/T M46C1ST05<br />

500W 24V DC + thermal protector 0,5 24DC/T M46C2ST05<br />

800W 12V DC motor 0,8 12DC M46C1S008<br />

800W 24V DC motor 0,8 24DC M46C2S008<br />

800W 12V DC + thermal protector 0,8 12DC/T M46C1ST08<br />

800W 24V DC + thermal protector 0,8 24DC/T M46C2ST08<br />

Options & coupling<br />

Description PPC assembly code Spare part code<br />

12V DC 150 Amp start switch + mounting kit S150 12DC 80 M47SC0001 + M47SK0801<br />

24V DC 150 Amp start switch + mounting kit S150 24DC 80 M47SC0002 + M47SK0801<br />

Remote wired control with 2 buttons and 3m cable<br />

Remote wired control with 4 buttons and 3m cable<br />

Coupling for Ø 80 DC motors<br />

S2:25 min<br />

S3: 50% ED<br />

S2: 25 min<br />

S3: 50% ED<br />

S2: 5 min<br />

S3: 17% ED<br />

S2: 5 min<br />

S3: 17% ED<br />

S2: 5 min<br />

S3: 17% ED<br />

S2: 5 min<br />

S3: 17% ED<br />

S2: 4 min<br />

S3: 10% ED<br />

S2: 4 min<br />

S3: 10% ED<br />

S2: 4 min<br />

S3: 10% ED<br />

S2: 4 min<br />

S3: 10% ED<br />

P0201 (single acting)<br />

P0202 (double acting)<br />

E36200003<br />

1400 rpm 30 A 108 mm<br />

1400 rpm 15 A 108 mm<br />

1700 rpm 90 A 139 mm<br />

2300 rpm 45 A 139 mm<br />

1700 rpm 90 A 139 mm<br />

2300 rpm 45 A 139 mm<br />

2100 rpm 150 A 139 mm<br />

2400 rpm 75 A 139 mm<br />

2100 rpm 150 A 139 mm<br />

2400 rpm 75 A 139 mm<br />

Notes: the starting<br />

switch mounting kit is<br />

provided when<br />

specifying the /S150 as<br />

motor option in PPM<br />

assembly code.<br />

When ordering spare<br />

starting switches, it must<br />

be ordered separately<br />

(code: M47SK0801).<br />

E36200003<br />

28,5<br />

18<br />

7<br />

6,4<br />

Weight: 0,063 kg<br />

The coupling is already<br />

included when<br />

specifying the motor in<br />

PPM assembly code.<br />

It is to be indicated only<br />

when ordering PPM with<br />

no motor but with<br />

coupling.<br />

www.hydronit.com<br />

PPM2012/1-A010<br />

Micro 12

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION A<br />

INTEGRAL DC MOTORS Ø 114<br />

Starting switch option<br />

12<br />

Compound wound<br />

Protection degree: IP54<br />

Insulation class: F<br />

Weight: 7,05 kg (without starter)<br />

162<br />

90±<br />

0.2<br />

Rotation<br />

Code<br />

5,7<br />

3,5<br />

Description<br />

PPC assembly<br />

code<br />

Spare part code<br />

Nominal<br />

duty cycle<br />

Nominal<br />

speed<br />

Nominal<br />

current<br />

1600W 12V DC + thermal protector 1,6 12DC/T M46C1ST16<br />

2100W 12V DC + thermal protector 2,1 12DC/T M46C1ST21<br />

2200W 24V DC + thermal protector 2,2 24DC/T M46C2ST22<br />

Options & coupling<br />

S2: 5 min<br />

S3: 10% ED<br />

S2: 4 min<br />

S3: 12% ED<br />

S2: 2.5 min<br />

S3: 10% ED<br />

2800 rpm 210 A<br />

2400 rpm 300 A<br />

2400 rpm 130 A<br />

Description PPC assembly code Spare part code<br />

12V DC 150 Amp start switch + mounting kit S150 12DC 112 M47SC0001 + M47SK1121<br />

24V DC 150 Amp start switch + mounting kit S150 24DC 112 M47SC0002 + M47SK1121<br />

Remote wired control with 2 buttons and 3m cable<br />

Remote wired control with 4 buttons and 3m cable<br />

DC motor plastic cover<br />

Coupling for Ø114 motors<br />

P0201 (single acting)<br />

P0202 (double acting)<br />

F16000001<br />

E36200002<br />

Notes: the starting switch mounting kit is provided when specifying the /S150 as motor option in PPM assembly code.<br />

When ordering spare starting switches, it must be ordered separately (code: M47SK1121).<br />

The coupling is already included when specifying the motor in PPM assembly code.<br />

It is to be indicated only when ordering PPM with no motor but with coupling.<br />

127<br />

Motor plastic cover F16000001<br />

Coupling E36200002<br />

7<br />

6,4<br />

37<br />

180<br />

Ø148<br />

Weight: 0,27 kg<br />

Weight: 0,041 kg<br />

www.hydronit.com<br />

PPM2012/1-A020<br />

Micra 13

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION A<br />

DC MOTORS OPTIONS<br />

Remote control P0201<br />

for one single or double acting cylinder<br />

Weight: 0,58 kg<br />

Protection degree: IP65<br />

Remote control P0202<br />

for two double acting cylinders<br />

Weight: 0,60 kg<br />

Protection degree: IP65<br />

60<br />

60<br />

Spare part code<br />

P0201<br />

Spare part code<br />

P0202<br />

Electric connection schemes<br />

+<br />

-<br />

+<br />

-<br />

+ +<br />

- -<br />

+ -<br />

+ -<br />

Starting switch<br />

Single acting cylinder<br />

M<br />

Green<br />

Thermal switch<br />

Red<br />

Red<br />

MSV<br />

Black<br />

Remote control P0201<br />

White<br />

Black<br />

Starting switch<br />

+<br />

M<br />

+<br />

-<br />

+ -<br />

Starting switch<br />

Thermal switch<br />

Red<br />

Blue<br />

Brown (up)<br />

Green (down)<br />

+<br />

-<br />

Directional<br />

valve (a<br />

second<br />

directional<br />

valve for<br />

left/right<br />

movement can<br />

be attached)<br />

Double acting cylinder<br />

M<br />

Remote control P0201 (2 buttons)<br />

for one double acting cylinder<br />

or P0202 (4 buttons)<br />

for two double acting cylinders<br />

www.hydronit.com<br />

PPM2012/1-A030<br />

Micro 14

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION A<br />

DC MOTORS CHOICE AND ELECTRIC CONNECTION SCHEMES<br />

DC motors choice<br />

Once required pressure and flow and available voltage (12 or 24V DC) are known, you can select the motor checking on<br />

each provided diagram if a pump displacement is available at the inter<strong>section</strong> of pressure and flow values. On the<br />

relevant “I” curve you obtain the absorbed current. When the inter<strong>section</strong> point is not exactly on a pump curve, choose the<br />

closer smaller pump.<br />

On the right hand diagram, from the current value, you can easily obtain the maximum allowed S2 (min) and S3 (%) values.<br />

S2 gives the allowable motor continuous running time in minutes, S3 gives the allowable running time in % of the<br />

total cycle.<br />

If obtained S2 and S3 values are not enough for required duty cycle, choose a higher power or heavier duty motor and repeat<br />

the calculation on the new motor curves.<br />

Example:<br />

For our application we have following data:<br />

flow = 4 l/min, max pressure = 180 bar, not clearly defined duty cycle.<br />

-We check on 1,6 Kw 12V DC motor diagram and see there is a pump available.<br />

3<br />

-We choose from curves 1,66 pump: a 1,66 cm /rev pump. On the corresponding “I” curve we read 195 A absorbed current.<br />

In these conditions on the S2 / S3 diagram we read that the DC motor can work for maximum 5 min (S2), that<br />

is 18% (S3) of the total cycle, i.e. after 5 min working, the motor should cool down for at least 23 min.<br />

-The total cycle time is calculated adding the working time and the idle time (17% working time plus 83% idle time),<br />

in this case 28 min. If this duty cycle is not adequate for our application, we must choose a higher power or higher duty DC<br />

motor and check the relevant diagram again.<br />

Q(l/ min)<br />

M46C1ST16<br />

I (A)<br />

20<br />

18<br />

4,3 3,8<br />

3,3<br />

2,8<br />

2,17<br />

1,66 1,27<br />

250<br />

S3<br />

16<br />

14<br />

0,89<br />

200<br />

12<br />

150<br />

10<br />

8<br />

100<br />

3,3<br />

6<br />

2,8<br />

2,17<br />

4<br />

1,66<br />

1,27<br />

50<br />

2<br />

0,89<br />

0<br />

0<br />

0 50 100 150 200 250 300<br />

P(bar)<br />

S2(min) 2 4 6 8 10 12<br />

S3(%) 4 8 12 16 20 24<br />

www.hydronit.com<br />

PPM2012/1-A040<br />

Micra 15

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION A<br />

DC MOTORS Ø80 DIAGRAMS<br />

Q(l/ min)<br />

150W 12VDC<br />

M46C1S001<br />

I (A)<br />

3<br />

50<br />

45<br />

2,5<br />

2<br />

1,25<br />

1,25<br />

0,88<br />

0,64<br />

0,38<br />

0,26<br />

40<br />

35<br />

30<br />

1,5<br />

0,88<br />

25<br />

S3<br />

20<br />

1<br />

15<br />

S2<br />

0,5<br />

0,64<br />

0,38<br />

10<br />

5<br />

0,26<br />

0<br />

0<br />

0 20 40 60 80 100 120 140 160 180 200<br />

P(bar)<br />

S2(min)<br />

S3(%)<br />

24<br />

45<br />

28<br />

50<br />

32<br />

55<br />

36<br />

60<br />

40<br />

65<br />

44<br />

70<br />

Q(l/ min)<br />

150W 24VDC<br />

M46C2S001<br />

I (A)<br />

3<br />

25<br />

2,5<br />

0,64<br />

0,38<br />

20<br />

2<br />

1,25<br />

1,25<br />

0,88<br />

0,26<br />

15<br />

1,5<br />

S3<br />

10<br />

1<br />

0,88<br />

S2<br />

0,5<br />

0,64<br />

0,38<br />

5<br />

0,26<br />

0<br />

0<br />

0 20 40 60 80 100 120 140 160 180 200<br />

P(bar)<br />

S2(min)<br />

S3(%)<br />

24<br />

45<br />

28<br />

50<br />

32<br />

55<br />

36<br />

60<br />

40<br />

65<br />

44<br />

70<br />

Q (l/ min)<br />

500W 12VDC<br />

M46C1S005<br />

I (A)<br />

5<br />

100<br />

4,5<br />

4<br />

1,54<br />

1,54<br />

1,25<br />

0,88<br />

0,64<br />

0,38<br />

0,26<br />

90<br />

80<br />

3,5<br />

1,25<br />

70<br />

S2<br />

S3<br />

3<br />

60<br />

2,5<br />

50<br />

2<br />

0,88<br />

40<br />

1,5<br />

30<br />

0,64<br />

1<br />

20<br />

0,38<br />

0,5<br />

10<br />

0,26<br />

0<br />

0<br />

0 50 100 150 200 250 300<br />

P(bar)<br />

S2(min)<br />

S3(%)<br />

2 4 6 8 10 12<br />

10 14 18 22 26 30<br />

Tests made with rectified current supplied at nominal motor voltage (measured at the motor connection terminals) and oil ISO VG46 at 40°C<br />

www.hydronit.com<br />

PPM2012/1-A050<br />

Micro 16

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION A<br />

DC MOTORS Ø80 DIAGRAMS<br />

Q(l/ min)<br />

500W 24VDC<br />

M46C2S005<br />

I (A)<br />

5<br />

50<br />

4,5<br />

4<br />

1,54<br />

1,25<br />

1,54<br />

0,88<br />

0,64<br />

0,38<br />

45<br />

40<br />

3,5<br />

3<br />

1,25<br />

0,26<br />

35<br />

30<br />

S2<br />

S3<br />

2,5<br />

25<br />

2<br />

20<br />

0,88<br />

1,5<br />

15<br />

0,64<br />

1<br />

10<br />

0,38<br />

0,5<br />

5<br />

0,26<br />

0<br />

0<br />

0 50 100 150 200 250 300<br />

P(bar)<br />

S2(min)<br />

S3(%)<br />

4 6 8 10 12 14<br />

12 16 20 24 28 32<br />

Q(l/ min)<br />

800W 12VDC<br />

M46C1S008<br />

I (A)<br />

7<br />

6<br />

5<br />

1,54<br />

1,25<br />

1,54<br />

1,25<br />

0,88<br />

0,64<br />

0,38<br />

0,26<br />

140<br />

120<br />

100<br />

S2<br />

S3<br />

4<br />

80<br />

3<br />

60<br />

2<br />

0,88<br />

0,64<br />

40<br />

1<br />

0,38<br />

20<br />

0,26<br />

0<br />

0<br />

0 50 100 150 200 250 300<br />

P(bar)<br />

S2(min)<br />

S3(%)<br />

2 4 6 8 10 12<br />

8 12 16 20 24 28<br />

Q(l/ min)<br />

800W 24VDC<br />

M46C2S008<br />

I (A)<br />

7<br />

120<br />

6<br />

5<br />

4<br />

3<br />

1,54<br />

1,25<br />

0,88<br />

1,54<br />

1,25<br />

0,88<br />

0,64<br />

0,38<br />

0,26<br />

100<br />

80<br />

60<br />

S3<br />

S2<br />

2<br />

1<br />

0,64<br />

0,38<br />

40<br />

20<br />

0,26<br />

0<br />

0<br />

0 50 100 150 200 250 300<br />

P(bar)<br />

S2(min)<br />

S3(%)<br />

2 4 6 8 10 12<br />

10 14 18 22 26 30<br />

Tests made with rectified current supplied at nominal motor voltage (measured at the motor connection terminals) and oil ISO VG46 at 35°C<br />

www.hydronit.com<br />

PPC2012/1-A060<br />

Micra 17

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION A<br />

DC MOTORS Ø114 DIAGRAMS<br />

Q(l/ min)<br />

1600W 12VDC<br />

M46C1ST16<br />

I (A)<br />

9<br />

250<br />

8<br />

7<br />

6<br />

5<br />

1,54<br />

1,25<br />

0,88<br />

0,64<br />

1,54<br />

1,25<br />

0,88<br />

0,64<br />

0,38<br />

200<br />

150<br />

S3<br />

4<br />

3<br />

0,38<br />

0,26<br />

0,26<br />

100<br />

2<br />

50<br />

1<br />

0<br />

0<br />

0 50 100 150 200 250 300<br />

P(bar)<br />

S2(min) 2 6 10 14 18 22<br />

S3(%) 10 12 14 16 18 20<br />

Q(l/ min)<br />

2100W 12VDC<br />

M46C1ST21<br />

I (A)<br />

9<br />

300<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

1,54<br />

1,25<br />

0,88<br />

0,64<br />

0,38<br />

0,26<br />

1,54<br />

1,25<br />

0,88<br />

0,64<br />

0,38<br />

0,26<br />

250<br />

200<br />

150<br />

100<br />

S2<br />

S3<br />

2<br />

1<br />

50<br />

0<br />

0<br />

0 50 100 150 200 250 300<br />

P(bar)<br />

S2(min) 10 14 18 22 26 30<br />

S3(%) 8 12 16 20 24 28<br />

Q(l/ min)<br />

2200W 24VDC<br />

M46C2ST22<br />

I (A)<br />

9<br />

140<br />

8<br />

7<br />

6<br />

5<br />

4<br />

1,54<br />

1,25<br />

0,88<br />

0,64<br />

0,38<br />

1,54<br />

1,25<br />

0,88<br />

0,64<br />

0,38<br />

0,26<br />

120<br />

100<br />

80<br />

60<br />

S2<br />

S3<br />

3<br />

2<br />

40<br />

1<br />

0,26<br />

20<br />

0<br />

0<br />

0 50 100 150 200 250 300<br />

P(bar)<br />

S2(min) 6 10 14 18 22 26<br />

S3(%) 4 8 12 16 20 24<br />

Tests made with rectified current supplied at nominal motor voltage (measured at the motor connection terminals) and oil ISO VG46 at 40°C<br />

www.hydronit.com<br />

PPM2012/1-A070<br />

Micro 18

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION A<br />

INTEGRAL AC MOTORS<br />

Integral motors: single phase or three phase in frame 71, with square<br />

flange for direct connection to PPM central manifold and tang drive shaft.<br />

High starting torque single phase «HT» executions available.<br />

24<br />

72<br />

35<br />

72<br />

4 holes ø6,5<br />

2,5<br />

Drawings show<br />

typical three<br />

phase motors.<br />

Single phase<br />

motors electric<br />

have different<br />

cable wiring<br />

box (including<br />

capacitors).<br />

87,5<br />

98<br />

B<br />

25,5<br />

L<br />

Protection degree: IP54<br />

Insulation class: F<br />

PPC motor assembly code<br />

N<br />

075<br />

AC<br />

3<br />

4<br />

1<br />

S3<br />

AC integral motor<br />

Maximum Power [kW]<br />

i.e. 075 = 0,75kW<br />

Alternate current<br />

Phase: 3 = three phase<br />

S = single phase<br />

Poles: 4 = four poles<br />

2 = two poles<br />

Frame size: 0 = 63<br />

1 = 71<br />

Type of Duty: S3 = intermittent duty<br />

HT = high torque<br />

See a table of available codes on next table page<br />

A single coupling can be applied on all motor frame sizes. This is the<br />

same coupling included in B14 motors mounting kit.<br />

The coupling is already included when specifying an integral AC motor in<br />

the PPM assembly code. When ordering spare motors, the coupling is<br />

not included and must be ordered separately.<br />

Coupling spare part code<br />

18<br />

28,5<br />

E36200003<br />

7<br />

6,4<br />

Weight: 0,063 kg<br />

www.hydronit.com<br />

PPM2012/1-A080<br />

Micra 19

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION A<br />

INTEGRAL AC MOTORS<br />

Three-phase 4 poles (~1450 rpm at 50Hz)<br />

Integral AC motor<br />

frame size<br />

71<br />

Maximum Power (S3 40%) Spare motor code Ø A B C L<br />

Weight<br />

[kg]<br />

0,37kW (0,5HP) N037AC341S3 15 138 180 210 5,5<br />

0,55kW (0,75HP) N055AC341S3 15 138 180 210 5,5<br />

0,75kW (1HP) N075AC341S3 15 138 180 210 5,6<br />

Three-phase 2 poles (~2900 rpm at 50Hz)<br />

Integral AC motor<br />

frame size<br />

71<br />

Maximum Power (S3 40%) Spare motor code Ø A B C L<br />

0,55kW (0,75HP) N055AC321S3 15 138 180 210 5<br />

0,75kW (1HP) N075AC321S3 15 138 180 210 5<br />

Weight<br />

[kg]<br />

Single-phase 4 poles (~1450 rpm at 50Hz)<br />

Integral AC motor<br />

frame size<br />

71<br />

Maximum Power (S3 40%) Spare motor code Ø A B C L<br />

Weight<br />

[kg]<br />

0,37kW (0,5HP) N037ACS41S3 15 138 180 210 6,5<br />

0,55kW (0,75HP) N055ACS41S3 15 138 180 210 7,2<br />

Single-phase 2 poles (~2900 rpm at 50Hz)<br />

Integral AC motor<br />

frame size<br />

71<br />

Maximum Power (S3 40%) Spare motor code Ø A B C L<br />

0,55kW (0,75HP) N055ACS21S3 15 138 180 210 6<br />

Weight<br />

[kg]<br />

0,75kW (1HP) N075ACS21S3 15 138 180 210 6,5<br />

Other power / frame sizes and special motor types are available on request. Standard motors are for intermittent duty: S3 40% duty cycle<br />

means up to 6 switching on and off in an hour, i.e. the motors is ON for 4 min. and OFF for 6 min. They can be used in emergency situations<br />

continuously at a reduced rated power (30% less than S3 nominal power). « HT» option: available for motor spare codes marked with *.<br />

www.hydronit.com<br />

PPM2012/1-A090<br />

Micro 20

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION A<br />

B14 IEC AC MOTORS<br />

B14 IEC motors: for market compatibility, any IEC standard B14 AC motor<br />

with frame 63 and 71 can be mounted. In this case two-pieces couplings and<br />

additional adaptor flanges as per next pages tables A110 and A120 must be<br />

mounted.<br />

G<br />

D<br />

H<br />

E<br />

B<br />

Motors overall dimensions are not indicated since they can vary substantially depending on the motor manufacturer<br />

B14 IEC standard dimensions<br />

Motor<br />

frame<br />

63<br />

71<br />

Typical<br />

power range<br />

0,12 ~ 0,25 kW<br />

0,16 ~ 0,35 HP<br />

0,25 ~ 0,55 kW<br />

0,37 ~ 0,75 HP<br />

ØA B ØC D E F G H<br />

Mounting<br />

kit<br />

11 j6 23 60 75 M5 12,5 18 4 NB1463<br />

14 j6 30 70 85 M6 16 25 5 NB1471<br />

PPC B14 motor assembly code<br />

Power [kW]<br />

0,25<br />

Alternate current<br />

AC<br />

Phase: 3 = three phase<br />

3<br />

S = single phase<br />

4<br />

Poles: 4 = four pole<br />

2 = two pole<br />

0<br />

Frame size: 0 = 63<br />

1 = 71<br />

-<br />

Duty factor: - = ED 100% (S1)<br />

S3 = intermittent duty<br />

Mounting kits spare parts<br />

The B14 mounting kits are made of:<br />

- a semi-coupling E36200003 (the same used for<br />

frame 80 DC motors) on pump shaft side<br />

- a semi-coupling on motor shaft side, which is<br />

different for any frame size<br />

- an adaptor flange to suit the central manifold, which<br />

is also different for any frame size.<br />

For detailed dimensions and codes see next pages<br />

tables.<br />

The mounting kit is already included when specifying<br />

a B14 AC motor in PPM assembly code. When<br />

ordering spare motors, the relevant mounting kit is<br />

not included and must be ordered separately.<br />

www.hydronit.com<br />

PPM2012/1-A100<br />

Micra 21

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION A<br />

MOUNTING KIT FOR FRAME 63 B14 IEC MOTORS<br />

24±<br />

0,2<br />

Kit weight: 0,18 Kg<br />

23<br />

Adaptor flange<br />

Coupling<br />

Ø6,5<br />

Ø6<br />

20,5<br />

Pump group side E36100000M<br />

5<br />

15<br />

87,5<br />

100<br />

Motor side M36100011<br />

Description<br />

B14 63 motor side semi-coupling<br />

PPC<br />

assembly code*<br />

Spare part code<br />

M36100011<br />

B14 pump side semi-coupling<br />

NB1463<br />

E36100000M<br />

B14 63 adaptor flange<br />

F25030002<br />

* Note: the coupling+ flange kit is already included when specifying a B14 motor in<br />

PPM assembly code. NB1471 code to be indicated only when ordering PPM with<br />

no motor but with coupling + flange kit.<br />

14<br />

25<br />

Attention! When assembling B14 IEC motors with NB14 flange + couplings kit, please respect positioning<br />

tolerances as shown in top page drawing. Failing in doing so can cause malfunctioning or components failure.<br />

www.hydronit.com<br />

PPM2012/1-A110<br />

Micro 22

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION B<br />

MICRO CENTRAL MANIFOLD<br />

A single universal die-cast aluminium central manifold in 3 different executions is the core part to<br />

realize all power units in industrial, mobile and marine fields where extreme compactness and<br />

high power density is required. It features the highest integration and flexibility on the market,<br />

with up to seven devices which can be fitted inside, plus a wide selction of manifold blocks which<br />

can be connected externally to suit spool or cartridge type valves<br />

The interface to hose fittings<br />

or external additional<br />

manifolds is unified. The P<br />

and T ports threads for the<br />

hose fittings direct connection<br />

are 1/4" BSPP (International<br />

standard) or 9/16-18UNF<br />

(SAE06) for the American<br />

standard execution.<br />

Lateral cavities are<br />

according SAE08<br />

standard (3/4-16UNF),<br />

except for the main<br />

check valve (5/8-<br />

18UNF) and main<br />

relief valve (M14)<br />

The interfaces to tanks and<br />

motors are unified. All plastic<br />

or steel tanks have same<br />

interface and can be easily<br />

swapped.<br />

All AC or DC motors can be<br />

fitted easily either directly to<br />

the central manifold or<br />

through adaptor flanges (B14<br />

IEC standard motors)<br />

Clockwise (our standard) or counterclockwise or<br />

bidirectional rotation tang drive shaft standard gear<br />

pumps can be mounted.<br />

The maximum flow is 6 l/min,<br />

with a low pressure drop, and<br />

maximum motor power is<br />

2,2kW, well above the average<br />

of other alternative products<br />

on the market<br />

Which micro central manifold execution should I choose?<br />

MB type is the most widely applied for single acting or double acting circuits. M4 execution is recommended for compact and cost<br />

effective double acting circuits with a single cylinder while MR is for bidirectional pump schemes and integrates double relief valve and<br />

double pilot operated check valves and also an extra pilote operated check valve for differential cylinders circuits proper functionality<br />

(this extra valve discharges return flow in excess from the piston side of the cylinder).<br />

Do I need special tools to assemble the components within the central manifold?<br />

No. All valves are screw-in type in a single piece construction (no loose nuts, washers, springs,... difficult to assemble and falling apart).<br />

The components are easily assemblable with simple hand tools and hexagon keys.<br />

Is the central manifold available as loose component?<br />

Yes. We can supply either fully assembled and tested power packs or kits of loose components, which can be kept in stock by our<br />

worldwide distributors and easily assembled to satisfy local market demand quickly and effectively. Central manifolds and most other<br />

components are 100% tested even when supplied as loose parts.<br />

www.hydronit.com<br />

PPM2012/1-B000<br />

Micra 23

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION B<br />

MICRO CENTRAL MANIFOLD «MB» EXECUTION VALVE COMBINATIONS<br />

EM<br />

E<br />

CM04M<br />

CM04<br />

5<br />

8<br />

VSC01<br />

*<br />

U<br />

PMC02<br />

7<br />

VSC04<br />

*<br />

S<br />

CSB<br />

Z<br />

CPE<br />

D<br />

C<br />

MDV30E<br />

MSV31E<br />

VSC04<br />

VMPC2<br />

CSB<br />

P/*<br />

S<br />

A<br />

B<br />

MSV30<br />

MSV30E<br />

CPE<br />

Z<br />

T<br />

CSPC15<br />

E70100005<br />

G<br />

G<br />

E70100005<br />

E70100004<br />

L<br />

L<br />

H<br />

N<br />

P<br />

E70100004<br />

E70100003<br />

E70100002<br />

E70100006<br />

2<br />

0<br />

P<br />

T<br />

7<br />

5 8<br />

T1<br />

3<br />

E70100003<br />

E70100002<br />

MDV30E<br />

VMDC20<br />

H<br />

N<br />

D<br />

V/*<br />

1<br />

VFC6<br />

R<br />

JM<br />

VUC10<br />

VSC6<br />

F*<br />

ML<br />

N70200008<br />

D/*<br />

VMDC15<br />

XM<br />

N70200010<br />

Hydraulic scheme<br />

P<br />

0<br />

2 7<br />

1<br />

T<br />

5<br />

3<br />

8<br />

M<br />

www.hydronit.com<br />

PPM2012/1-B010<br />

Micro 24

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION B<br />

MICRO CENTRAL MANIFOLD «MR» EXECUTION VALVE COMBINATIONS<br />

7<br />

PIL5818<br />

PIL5818DIF<br />

MG<br />

N70200007<br />

A<br />

B<br />

N70200007<br />

MG<br />

JP<br />

VUC10C<br />

2<br />

7<br />

3<br />

VUC10C<br />

JP<br />

0<br />

1 4<br />

ML<br />

N70200008<br />

D/*<br />

VMDC15<br />

VMDC15<br />

D/*<br />

XM<br />

N70200010<br />

N70200010<br />

XM<br />

Hydraulic scheme<br />

A<br />

B<br />

2 7 3<br />

1<br />

L-S<br />

R-S<br />

L-P<br />

4<br />

www.hydronit.com<br />

PPM2012/1-B020<br />

Micra 25

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION B<br />

MICRO CENTRAL MANIFOLD «M4» EXECUTION VALVE COMBINATIONS<br />

8<br />

VSC01 *<br />

4V<br />

a<br />

b<br />

MSV4V<br />

VFC6<br />

R<br />

CSB<br />

S<br />

A<br />

B<br />

8<br />

T1<br />

E70100004<br />

L<br />

VSC6 F*<br />

JM<br />

VUC10<br />

2<br />

0<br />

3<br />

ML<br />

N70200004<br />

1<br />

D/*<br />

VMDC15<br />

XM<br />

N70200010<br />

Hydraulic scheme<br />

A B<br />

P<br />

0<br />

2<br />

T<br />

1<br />

3<br />

8<br />

M<br />

www.hydronit.com<br />

PPM2012/1-B030<br />

Micro 26

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION B<br />

MICRO CENTRAL MANIFOLD OVERALL DIMENSIONS<br />

Type<br />

Spare part code<br />

MB<br />

E60102031<br />

MR<br />

E60102032<br />

M4<br />

E60102033<br />

MBUS<br />

E60102031US<br />

MRUS<br />

M4US<br />

E60102032US<br />

E60102033US<br />

Weight: 0,60 kg (1,32 lb)<br />

Notes:<br />

- codes ending with US<br />

are intended for the<br />

American market and<br />

are machined with<br />

9/16-18 UNF (SAE06)<br />

exit ports.<br />

- all dimensions in mm<br />

+ (inches)<br />

P<br />

5<br />

8<br />

Tank side view<br />

PB<br />

Only MR type<br />

Cavity<br />

1, 4 (MR type)<br />

Threads<br />

M14x1 (relief valve)<br />

0<br />

2, 3<br />

P-T, A-B,<br />

T1 (threaded<br />

on request only)<br />

5, 8<br />

External manifold<br />

attachment<br />

Tanks<br />

attachment<br />

Integral<br />

AC Motors<br />

attachment<br />

DC Motors<br />

attachment<br />

Pump<br />

attachments<br />

Foot mounting<br />

support<br />

attachments<br />

PMC hand pump /<br />

CM lever valve<br />

cap attachments<br />

5/8-18 UNF<br />

3/4-16 UNF (SAE 08)<br />

5/8-18 UNF (MR type)<br />

1/4’’ BSPP<br />

9/16-18 UNF (US type)<br />

1/4’’ BSPP<br />

2 pcs M8 tie-rods<br />

4 pcs M5x10<br />

4 pcs M6x20<br />

2 pcs M6x14<br />

or M6 tie rods<br />

2 pcs M5<br />

(see pump lenght on<br />

the relevant tables)<br />

2 pcs M8x16<br />

4 pcs M5x45<br />

Motor side view<br />

www.hydronit.com<br />

PPM2012/1-B040<br />

Micra 27

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

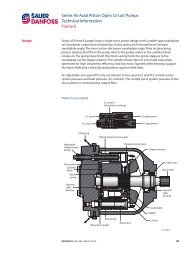

SECTION C<br />

PUMPS<br />

Group 0 with tang drive shaft and<br />

pressure balanced design for high<br />

volumetric efficiency, specifically<br />

designed for micro power packs.<br />

R series: bidirectional pumps with integrated<br />

suction check valves and two front outlet ports.<br />

They can be fitted on MR type central manifold.<br />

Why are pressure balanced gear pumps better than fixed clearings gear pumps?<br />

Pressure balanced gear pumps are built with lateral pressure plates which reduce the mechanical clearings on the gears with the<br />

increase of the pressure on the outlet, thus greatly improving the fluidodynamic efficiency, reducing heat generation and energy<br />

consumption. The mechanical efficiency is kept at optimal levels too.<br />

Why are the pump technical specifications showing three maximum pressure levels?<br />

Our pumps have three ratings for the maximum allowable pressure: 1-Peak: is the maximum one and can be allowed for a maximum<br />

cycle of 2 seconds. 2-Intermittent: it can be applied on the pump for a maximum cycle of 20 seconds; 3-Continuous: it can be applied<br />

on the pump continuously.<br />

www.hydronit.com<br />

PPM2012/1-C000<br />

Micro 28

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION C<br />

STANDARD GEAR PUMPS. GROUP 0<br />

9,5<br />

5<br />

N<br />

n.2 Ø 5,5<br />

50<br />

16<br />

Main features<br />

Oil temperature -35 ÷ +80 ° C<br />

Inlet pressure<br />

0,7 < P < 3,0 bar (absolute pressure)<br />

Fixing bolts<br />

2 x M5 8.8 class steel<br />

tightening torque: 5 Nm<br />

Pressure definition<br />

Peak pressure: cycle 2 s ON<br />

Intermittent pressure: cycle 20 s ON<br />

Continuous pressure: cycle always ON<br />

Filtration setting 25 ÷ 50 µ<br />

Standard rotation direction: clockwise rotation (from shaft side).<br />

Counterclockwise rotation pumps can be mounted on request.<br />

Ask our sales department.<br />

Spare part code<br />

PPM assembly code field<br />

E6050 ** **<br />

KM<br />

Pump type:<br />

Nominal size:<br />

50 = Group 0 see below table<br />

0,6<br />

Type:<br />

30 = G type<br />

40 = K type<br />

Pump type:<br />

GM = G type<br />

KM = K type<br />

Nominal displacement:<br />

cc/rev<br />

(see below table)<br />

Nominal<br />

displacement<br />

(cc/rev)<br />

Peak<br />

pressure<br />

(bar)<br />

Intermittent<br />

pressure<br />

(bar)<br />

Available range<br />

Continuous<br />

pressure<br />

(bar)<br />

Max<br />

speed<br />

(rpm)<br />

N (mm)<br />

Bolts*<br />

(mm)<br />

Spare parts<br />

code<br />

Weight (kg)<br />

0,1 230 210 190 7000 45,5 M5x55 E60503001 0,31<br />

0,2 200 180 160 6000 45,5 M5x55 E60504002 0,33<br />

0,4 200 180 160 6000 47,5 M5x55 E60504004 0,35<br />

0,6 200 180 160 6000 51,5 M5x60 E60504006 0,40<br />

0,9 200 180 160 5000 52,5 M5x65 E60504009 0,44<br />

1,3 200 180 160 3900 55,5 M5x65 E60504013 0,49<br />

1,5 200 180 160 3900 57,8 M5x70 E60504015 0,51<br />

1,9 150 130 110 3000 65 M5x75 E60504019 0,55<br />

* A proper washer is to be forecast to adapt bolt lenght<br />

www.hydronit.com<br />

PPM2012/1-C010<br />

Micra 29

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION C<br />

BIDIRECTIONAL GEAR PUMPS. GROUP 0<br />

9,5<br />

5<br />

N<br />

n.2 Ø 5,5<br />

50<br />

16<br />

Main features<br />

Oil temperature -35 ÷ +80 ° C<br />

Inlet pressure<br />

0,7 < P < 3,0 bar (absolute pressure)<br />

Fixing bolts<br />

2 x M5 8.8 class steel<br />

tightening torque: 5 Nm<br />

Pressure definition<br />

Peak pressure: cycle 2 s ON<br />

Intermittent pressure: cycle 20 s ON<br />

Continuous pressure: cycle always ON<br />

Filtration setting 25 ÷ 50 µ<br />

Standard rotation direction: clockwise rotation (from shaft side).<br />

Counterclockwise rotation pumps can be mounted on request.<br />

Ask our sales department.<br />

Spare part code<br />

PPM assembly code field<br />

E6050 ** **<br />

RM<br />

Pump type:<br />

Nominal size:<br />

50 = Group 0 see below table<br />

0,6<br />

Type:<br />

35 = G type<br />

45 = K type<br />

Pump type:<br />

RM = reversible type<br />

Nominal displacement:<br />

cc/rev<br />

(see below table)<br />

Nominal<br />

displacement<br />

(cc/rev)<br />

Peak<br />

pressure<br />

(bar)<br />

* A proper washer is to be forecast to adapt bolt lenght<br />

Intermittent<br />

pressure<br />

(bar)<br />

Available range<br />

Continuous<br />

pressure<br />

(bar)<br />

Max<br />

speed<br />

(rpm)<br />

N (mm)<br />

Bolts*<br />

(mm)<br />

Spare parts<br />

code<br />

Weight (kg)<br />

0,1 200 180 160 6000 45,5 M5x55 E60503501 0,44<br />

0,2 200 180 160 6000 45,5 M5x55 E60504502 0,46<br />

0,4 200 180 160 6000 47,5 M5x55 E60504504 0,48<br />

0,6 200 180 160 6000 54,5 M5x65 E60504506 0,49<br />

0,9 200 180 160 5000 62,4 M5x70 E60504509 0,50<br />

1,3 200 180 160 3900 63,2 M5x70 E60504513 0,51<br />

1,5 200 180 160 3900 64,5 M5x70 E60504515 0,52<br />

www.hydronit.com<br />

PPM2012/1-C020<br />

Micro 30

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION D<br />

INTEGRAL COMPONENTS<br />

The PMC02 cartridge hand pump SAE08 (3/4-16UNF),<br />

2cc/stroke, is an affordable and easy way to add an emergency<br />

function to your power pack.<br />

Two way no leakage solenoid valves SAE08<br />

(3/4-16UNF) are available in Normally Closed,<br />

Normally Open, single and double locking<br />

executions.Manual override also available.<br />

Pressure and flow<br />

proportional control valves are<br />

available as standard, also<br />

with integrated PWM amplifier<br />

All cartridges are supplied in<br />

single piece, easily screwable<br />

The main relief valve is fitted in a M14 cavity<br />

and has a very short external protrusion,<br />

offering excellent pressure setting stability and<br />

low noise<br />

The main check valve fits in a SAE06 (5/8-18UNF) standard cavity and<br />

can be easily unmounted from the outside for easy cleaning and servicing<br />

How does the coding of the power pack works?<br />

The power packs are coded with a speaking code, which is basically the list of subassemblies which make up the power pack (motor,<br />

pump, valves, tank,...). Integral components are those fitting inside central manifold cavities, which are numbered from 0 to 8. Each<br />

component has an assembly code, normally a single letter which compose the speaking code, and a spare part code in case they are<br />

ordered as loose components. The numbered cavities are indicated in the hydraulic scheme, so that it is easy to draw it starting from<br />

the speaking code itself, and on the central manifold casting too, to simplify assembling.<br />

There are several different coils and connectors for the cartridge solenoid valves. How do I choose the proper ones?<br />

Normally closed 2-way solenoid valves (MSV30*) use M130/M140/M63 series of coils either DC or directly AC. Normally open 2-way<br />

solenoid valves (MSV31E) can only use DC or RC (rectified current) coils due to their constructive principle. When choosing a RC coil, a<br />

rectifying bridge connector must be applied (KA132R***). MSV4V 4-way cartridge valves use the new M63*** series coils. M630 are for<br />

DC supply voltage, while M631 are rectified coils with integral rectifying bridge, to be supplied with AC current. A standard KA13200000<br />

connector must be always used in this case. On page D180 you will find the coils table for all valves.<br />

Which are the most used plugs?<br />

G or H plugs are normally fitted in cavity 2 of MB central manifold when this cavity is not used for functional valves. L type plug goes in<br />

cavity 3 of MB manifolds, when this cavity is not used. MR central manifold cavities 2 and 3 are machined according to 5/8-18UNF<br />

shape to allow the mounting of piloted operated check valves. MG plugs must be used there if P.O. check valves are not needed.<br />

www.hydronit.com<br />

PPM2012/1-D000<br />

Micra 31

Hydrauliek<br />

Pneumatiek<br />

Aandrijftechniek<br />

HEERHUGOWAARD . T: +31 (0)72 57 66 700 . WWW.TOTALHYDRAULICS<strong>BV</strong>.COM<br />

sales@hydronit.com · +39 0362 1841 210<br />

SECTION D<br />

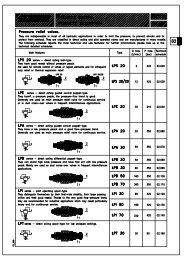

VMDC15 - DIRECT ACTING MAIN RELIEF VALVE<br />

Hex. 17<br />

Hex. 17<br />

P<br />

T<br />

Hex. 5<br />

24 25,5<br />

P<br />

Main features<br />

Max pressure<br />

Max flow<br />

Weight<br />

Recommended tightening torque: 30 Nm<br />

Recommended filtration settings: 25 ÷ 50 µ<br />

Oil temperature : -30 ÷ + 80 °C<br />

T<br />

280 bar<br />

7 l/min<br />

0,06 kg<br />

PPM assembly code field<br />

DM/*** ¨<br />

where *** stands for max setting<br />

pressure [bar]. Ex. D/280<br />

¨<br />

where stands for option other<br />

than the standard one.<br />

Mounting cavities<br />

0 1<br />

2 3 4<br />

5 7 8<br />

Note: cavity 4 only for MR type.<br />

Spare part code<br />

VMDC<br />

15<br />

B<br />

1<br />

Direct acting<br />

main relief valve<br />

Nominal size:<br />

15 = 15 l/min<br />

Working range:<br />

L = 10 ÷ 60 bar<br />

B = 20 ÷ 280 bar<br />

Option:<br />

1 = screw (std)<br />

Minimum setting pressure<br />

Pressure vs flow<br />

60<br />

50<br />

40<br />

B<br />

360<br />

300<br />

240<br />

B<br />

30<br />

20<br />

10<br />

L<br />

180<br />

120<br />

60<br />

L<br />

0<br />

0<br />

1,4 2,8 4,2 5,6 7<br />