Conservation and Restoration of Clear Coatings on Furniture and ...

Conservation and Restoration of Clear Coatings on Furniture and ... Conservation and Restoration of Clear Coatings on Furniture and ...

38 the conservation

39 The problems arise when these finishes start to break down

- Page 1 and 2: International Specialised Skills In

- Page 3 and 4: 3 Table of Content

- Page 5 and 6: 5 2.0 Introduction 2.1 About the In

- Page 7 and 8: 7 2.4 The Australian Context - Natu

- Page 9 and 10: 9 In particular; ■ To improve the

- Page 11 and 12: 11 2.7 The Skills/Knowledge Gaps Th

- Page 13 and 14: 13 3.0 The Fellowship Program 3.1 I

- Page 15 and 16: 15 3.2 List educational/Host organi

- Page 17 and 18: 17 Workshop visit with Paul Tear, c

- Page 19 and 20: 19 conservation treatments come fir

- Page 21 and 22: 21 clean materials that are traditi

- Page 23 and 24: 23 1950’s layer titanium dioxide

- Page 25 and 26: 25 passes and furt

- Page 27 and 28: 27 d) Windsor Castle furniture cons

- Page 29 and 30: 29 Research and de

- Page 31 and 32: 31 a private practice. This is her

- Page 33 and 34: 33 Material testing labs with sampl

- Page 35 and 36: 35 with Richard again demonstrating

- Page 37: 37 materials and p

- Page 41 and 42: 41 4.0 Recommendations Presently my

- Page 43 and 44: 43 ■ Both products aim for a remo

- Page 45 and 46: 45 Since my return I have already l

- Page 47 and 48: 47 Training and fu

- Page 49: 49 5. References ■ Buck, Susan. L

39<br />

The problems arise when these finishes start to break down <str<strong>on</strong>g>and</str<strong>on</strong>g> deteriorate. Not<br />

<strong>on</strong>ly do they look bad aesthetically but they stop performing their protective<br />

functi<strong>on</strong>, sometimes maybe even damaging the timber as sec<strong>on</strong>dary by-products<br />

are produced. To date neither nitro-cellulose nor polyurethanes can be<br />

successfully c<strong>on</strong>served l<strong>on</strong>g term, especially when performing a protective role<br />

during functi<strong>on</strong>al use. The <strong>on</strong>ly viable soluti<strong>on</strong> is to carefully remove the<br />

deteriorated finish, a complex problem in itself.<br />

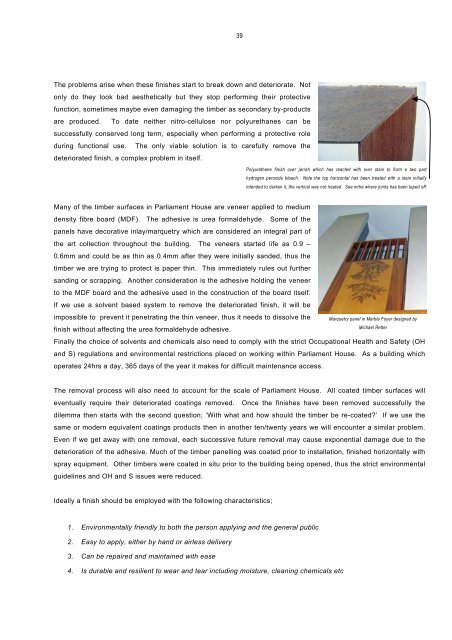

Polyurethane finish over jarrah which has reacted with over stain to form a two part<br />

hydrogen peroxide bleach. Note the top horiz<strong>on</strong>tal has been treated with a stain initially<br />

intended to darken it, the vertical was not treated. See mitre where joints has been taped <str<strong>on</strong>g>of</str<strong>on</strong>g>f<br />

Many <str<strong>on</strong>g>of</str<strong>on</strong>g> the timber surfaces in Parliament House are veneer applied to medium<br />

density fibre board (MDF). The adhesive is urea formaldehyde. Some <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

panels have decorative inlay/marquetry which are c<strong>on</strong>sidered an integral part <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

the art collecti<strong>on</strong> throughout the building. The veneers started life as 0.9 –<br />

0.6mm <str<strong>on</strong>g>and</str<strong>on</strong>g> could be as thin as 0.4mm after they were initially s<str<strong>on</strong>g>and</str<strong>on</strong>g>ed, thus the<br />

timber we are trying to protect is paper thin. This immediately rules out further<br />

s<str<strong>on</strong>g>and</str<strong>on</strong>g>ing or scrapping. Another c<strong>on</strong>siderati<strong>on</strong> is the adhesive holding the veneer<br />

to the MDF board <str<strong>on</strong>g>and</str<strong>on</strong>g> the adhesive used in the c<strong>on</strong>structi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the board itself.<br />

If we use a solvent based system to remove the deteriorated finish, it will be<br />

impossible to prevent it penetrating the thin veneer, thus it needs to dissolve the<br />

finish without affecting the urea formaldehyde adhesive.<br />

Marquetry panel in Marble Foyer designed by<br />

Michael Retter<br />

Finally the choice <str<strong>on</strong>g>of</str<strong>on</strong>g> solvents <str<strong>on</strong>g>and</str<strong>on</strong>g> chemicals also need to comply with the strict Occupati<strong>on</strong>al Health <str<strong>on</strong>g>and</str<strong>on</strong>g> Safety (OH<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> S) regulati<strong>on</strong>s <str<strong>on</strong>g>and</str<strong>on</strong>g> envir<strong>on</strong>mental restricti<strong>on</strong>s placed <strong>on</strong> working within Parliament House. As a building which<br />

operates 24hrs a day, 365 days <str<strong>on</strong>g>of</str<strong>on</strong>g> the year it makes for difficult maintenance access.<br />

The removal process will also need to account for the scale <str<strong>on</strong>g>of</str<strong>on</strong>g> Parliament House. All coated timber surfaces will<br />

eventually require their deteriorated coatings removed. Once the finishes have been removed successfully the<br />

dilemma then starts with the sec<strong>on</strong>d questi<strong>on</strong>; ‘With what <str<strong>on</strong>g>and</str<strong>on</strong>g> how should the timber be re-coated?’ If we use the<br />

same or modern equivalent coatings products then in another ten/twenty years we will encounter a similar problem.<br />

Even if we get away with <strong>on</strong>e removal, each successive future removal may cause exp<strong>on</strong>ential damage due to the<br />

deteriorati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the adhesive. Much <str<strong>on</strong>g>of</str<strong>on</strong>g> the timber panelling was coated prior to installati<strong>on</strong>, finished horiz<strong>on</strong>tally with<br />

spray equipment. Other timbers were coated in situ prior to the building being opened, thus the strict envir<strong>on</strong>mental<br />

guidelines <str<strong>on</strong>g>and</str<strong>on</strong>g> OH <str<strong>on</strong>g>and</str<strong>on</strong>g> S issues were reduced.<br />

Ideally a finish should be employed with the following characteristics;<br />

1. Envir<strong>on</strong>mentally friendly to both the pers<strong>on</strong> applying <str<strong>on</strong>g>and</str<strong>on</strong>g> the general public<br />

2. Easy to apply, either by h<str<strong>on</strong>g>and</str<strong>on</strong>g> or airless delivery<br />

3. Can be repaired <str<strong>on</strong>g>and</str<strong>on</strong>g> maintained with ease<br />

4. Is durable <str<strong>on</strong>g>and</str<strong>on</strong>g> resilient to wear <str<strong>on</strong>g>and</str<strong>on</strong>g> tear including moisture, cleaning chemicals etc