office of the chief engineer, project swastik, c/o 99 apo ... - Bro.nic.in

office of the chief engineer, project swastik, c/o 99 apo ... - Bro.nic.in

office of the chief engineer, project swastik, c/o 99 apo ... - Bro.nic.in

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

56<br />

B) For Granular Sub Base (G.S.B), Wet Mix Macadam (W.M.M), Dense Bitum<strong>in</strong>ous Macadam<br />

(DBM) & Bitum<strong>in</strong>ous Concrete (BC) Work :-<br />

i) Automatic Core cutt<strong>in</strong>g Mach<strong>in</strong>e ii) Thermometers :-<br />

a) Metallic type (Mercury <strong>in</strong> steel) with 30cm stem and 3m stem for near and distant read<strong>in</strong>gs.<br />

b) Glass type (Mercury <strong>in</strong> glass) <strong>of</strong> ranges 110 0 C, 250 0 C<br />

c) Infrared Temperature meter<br />

d) Digital <strong>the</strong>rmometer (-50 0 C to 300 0 C)<br />

iii) Electro<strong>nic</strong> balance <strong>of</strong> 10kg capacity <strong>of</strong> accuracy 0.5gm. iv) Electro<strong>nic</strong> balance <strong>of</strong> 5kg<br />

vi)<br />

vii)<br />

viii)<br />

ix)<br />

capacity <strong>of</strong> accuracy 0.01gm. v) Standard set <strong>of</strong> 16 sieves, lid and Pan :-<br />

a) 450mm dia for coarse aggregate:- 63mm, 53mm, 37.5mm, 26.50mm, 13.20mm,<br />

9.50mm, 6.7mm and 4.75mm.<br />

b) 200mm dia for file aggregates :- 2.36mm, 2.0mm, 1.18mm, 600 micron, 425 micron,<br />

300 micron, 150 micron, 75 micron.<br />

Flak<strong>in</strong>ess and Elongation test gauge as per IS:2386 Part-1<br />

Water Adsorption Test apparatus as per IS:2386 Part-5<br />

Aggregate Impact value test apparatus as per IS:2386 Part-4<br />

Penetration test apparatus<br />

x) S<strong>of</strong>ten<strong>in</strong>g po<strong>in</strong>t test apparatus<br />

xi)<br />

xii)<br />

Apparatus for determ<strong>in</strong><strong>in</strong>g solubility <strong>in</strong> trichloroethylene test<br />

Sayboly Furol Viscometer as per IS:3117 for emulsion<br />

xiii) Electrically operated centrifuge type bitumen extractor and Tolune (C 6 H 5 CH 3 )<br />

xiv)<br />

xv)<br />

xvi)<br />

xvii)<br />

Glassware, graduated cyl<strong>in</strong>der, spatula, scoops, steel scales, measur<strong>in</strong>g tapes, enamelled trays,<br />

filter paper, 4mm thick glass, glass mark<strong>in</strong>g pencils, heat resistant hard gloves.<br />

Mecha<strong>nic</strong>al sieve shaker – 450mm dia, 200mm dia.<br />

Riffle boxes for sampl<strong>in</strong>g <strong>of</strong> coarse and f<strong>in</strong>e ggregator.<br />

Marshall Stability Test Apparatus required for determ<strong>in</strong><strong>in</strong>g stability <strong>of</strong> mix for DBM & BC<br />

works.<br />

10. The follow<strong>in</strong>g tests must be carried out for Polymer Modified B<strong>in</strong>ders-70<br />

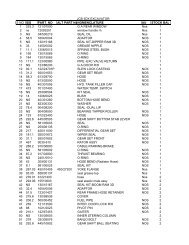

Sl.<br />

No<br />

Test<br />

Method <strong>of</strong> test<br />

Grade and<br />

requirement<br />

for CRMB-<br />

55<br />

1 Penetration at 25 deg C, 0.1mm, 100gm, 5 Sec.