high pressure plastic pipe systems offshore - Soluforce

high pressure plastic pipe systems offshore - Soluforce

high pressure plastic pipe systems offshore - Soluforce

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

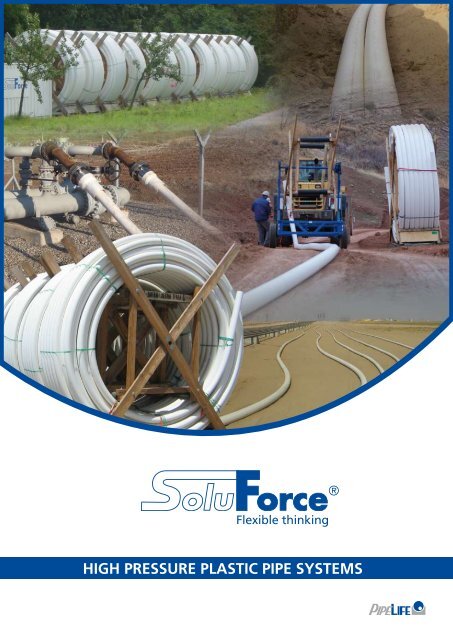

Flexible thinking<br />

HIGH PRESSURE PLASTIC PIPE SYSTEMS

Transportable<br />

SOLUFORCE ® BENEFITS<br />

<strong>Soluforce</strong> ® RTP (Reinforced Plastic Pipe) has been<br />

manufactured and used extensively since the year 2000.<br />

It is estimated that over a thousand kilometers worldwide<br />

is currently in operation.<br />

The concept of a completely non corrosive <strong>pipe</strong> system<br />

for <strong>high</strong> <strong>pressure</strong> hydrocarbon applications came about<br />

through the demand from oil companies who proactively<br />

participated in the development and qualification of RTP.<br />

In 1998 a JIP (Joint Industrial Project) which brought<br />

together manufacturers, users (such as Saudi Aramco,<br />

Petrobras, Shell, BP) and testing institutes was created.<br />

Out of the JIP was developed an API standard (API RP 15S)<br />

for RTP in 2006.<br />

<strong>Soluforce</strong> ® RTP is a complete non metallic piping system.<br />

It is qualified for Water, Hydrocarbons and Gas applications.<br />

Manufactured by Pipelife in Enkhuizen, The Netherlands,<br />

<strong>Soluforce</strong> ® RTP is supplied on disposable wooden reels<br />

which may be easily transported by either road or ship.<br />

SILOAM<br />

SPRINGS<br />

<strong>Soluforce</strong> ® RTP comes with a complete fitting system<br />

for its <strong>pipe</strong>s. It provides welding equipment and certified<br />

welders for installation wherever the customer requires.<br />

<strong>Soluforce</strong> ® is a business unit within the Pipelife<br />

International group of companies and benefits from<br />

belonging to one of the world’s largest <strong>plastic</strong> <strong>pipe</strong><br />

manufacturers.<br />

Robust<br />

2

Pipelife International G.m.b.H.<br />

is a global player in the manufacture<br />

of <strong>plastic</strong> <strong>pipe</strong> <strong>systems</strong> with offices<br />

and production facilities in over<br />

25 countries.<br />

SUMMARY<br />

Benefits Pages 4 - 7<br />

Water Pages 8-11<br />

Hydrocarbons Pages 12-17<br />

Connection Systems Pages 18-25<br />

HAPARANDA<br />

II<br />

UTAJÄRVI<br />

KAAVI<br />

SURNADAL<br />

STATHELL<br />

LJUNG<br />

TALLINN<br />

ÖLSREMMA<br />

ENKHUIZEN<br />

GDANSK<br />

ZHUKOV<br />

CORK<br />

BAD ZWISHENAHN<br />

RADOM<br />

KALMTHOUT<br />

OTROKOVICE<br />

GAILLON<br />

VIENNA<br />

DEBRECEN<br />

CHÂTEAUROUX<br />

MIERCUREA CIUC<br />

KARLOVAC<br />

ZARAGOZA<br />

ISTAMBUL<br />

THIVA<br />

Deployment<br />

3

SOLUFORCE ® BENEFITS<br />

Solves corrosion problems<br />

Very fast Installation<br />

Maintenance Free<br />

Design life up to 50 years<br />

<strong>Soluforce</strong> ® RTP deployed (floating)<br />

during an <strong>offshore</strong> installation.<br />

4

SOLUFORCE ® BENEFITS<br />

No scaling - No erosion<br />

Re-Usable<br />

400 meters length per coil<br />

Very robust<br />

<strong>Soluforce</strong> ® RTP installed<br />

in the desert<br />

5

Standards<br />

SOLUFORCE ®<br />

standards, testing AND qualificationS<br />

<strong>Soluforce</strong> ® complies with the following standards:<br />

Oilfield service:<br />

API RP 15S<br />

API 17J<br />

“Qualification of Spoolable Reinforced Plastic Line<strong>pipe</strong>”<br />

<strong>Soluforce</strong> ® Light, and <strong>Soluforce</strong> ® Classic <strong>pipe</strong> system<br />

“ Specification for Unbonded Flexible Pipe”<br />

<strong>Soluforce</strong> ® Heavy, <strong>pipe</strong> body<br />

Gas distribution and transport:<br />

ISO TS 18226<br />

“Reinforced Thermo<strong>plastic</strong> Piping Systems for Gaseous Fuels”<br />

(<strong>Soluforce</strong> ® Light and <strong>Soluforce</strong> ® Classic, gas transport & distribution)<br />

DVGW VP 642 “Faserverstärkte PE-Rohre (RTP) und zugehörige Verbinder für<br />

Gasleitungen mit Betreibsdrücken über 16 Bar”<br />

(German Standard for gas distribution and transport,<br />

<strong>Soluforce</strong> ® Light and <strong>Soluforce</strong> ® Classic)<br />

<strong>Soluforce</strong> ® has a proven track record in the oil and gas industry, and has been used<br />

since 2000 for different applications, including oil and gas line<strong>pipe</strong>, water injection<br />

<strong>pipe</strong>, water transportation, and gas distribution and transport.<br />

<strong>Soluforce</strong> ® maintains the <strong>high</strong>est quality levels with regard to the design, manufacturing<br />

and testing of their products, according to, or exceeding the requirements in international<br />

standards.<br />

Qualification and Certification<br />

The design, testing and qualification of <strong>Soluforce</strong> ® is verified according to the applicable<br />

standards by ISO accredited independent institutes. For oilfield applications: “Det Norske<br />

Veritas” (DNV). For gas distribution and transport: RWTÜV. Certification by Bureau Veritas<br />

for oil applications at 150 bars working <strong>pressure</strong>. Bureau Veritas certify that <strong>Soluforce</strong><br />

complies with AP 17J (specification for unbonded flexible <strong>pipe</strong>) 3 rd edition for sour<br />

applications.<br />

QA/QC System<br />

<strong>Soluforce</strong> ® is developed, manufactured and marketed<br />

under ISO9001 QA/QC system, approved by KIWA.<br />

6

SOLUFORCE ®<br />

DESIGN AND Reliability<br />

The reliability of <strong>Soluforce</strong> ® is guaranteed by extensive laboratory testing and long term<br />

field experience.<br />

To assess the long-term strength, <strong>Soluforce</strong> ® is <strong>pressure</strong> tested for a period of 10,000 hours<br />

(more than one year), according to internationally accepted standards. One of the most<br />

important test criteria is that the fitting system should be stronger than the <strong>pipe</strong> itself.<br />

Next to corrosion, third party interference is the major cause of <strong>pipe</strong>line failure.<br />

<strong>Soluforce</strong> ® Light and Classic, being completely non-metallic, including the fitting<br />

system, offer the ultimate in absolute corrosion resistance. The resistance to third party<br />

interference, earth quakes and landslides has been verified in the laboratory by falling<br />

weight impact testing, axial load and bending testing under supervision of major oil<br />

companies. In-field impact testing with digging machines has shown equal or better<br />

performance than steel <strong>pipe</strong>.<br />

<strong>Soluforce</strong> ® is field-proven since 2000, when the first flowlines were installed in the Middle<br />

East desert. These <strong>pipe</strong>s have been in service since without any interruption. Meanwhile<br />

<strong>Soluforce</strong> ® has been installed worldwide onshore and <strong>offshore</strong> at major oil and gas<br />

companies. No failure in service has been reported.<br />

Axial force test<br />

Test preparation<br />

Elevated temperature testing<br />

in a hot water bath at 85 C°.<br />

Squeeze test<br />

Bending test<br />

7

SOLUFORCE ® WATER<br />

HIGH PRESSURE<br />

PLASTIC PIPE SYSTEMS<br />

FOR WATER<br />

8

SOLUFORCE ® WATER<br />

<strong>Soluforce</strong> ® LIGHT : L450 - L540<br />

A synthetic fibre tape reinforcement<br />

for lower <strong>pressure</strong> applications.<br />

- Effluent water<br />

- Water supply<br />

<strong>Soluforce</strong> ® CLASSIC : M480 - M570<br />

An synthetic fibre tape reinforcement<br />

for medium <strong>pressure</strong> applications.<br />

- Effluent water<br />

- Saline water<br />

- Water injection<br />

<strong>Soluforce</strong> ® Classic and Light are resistant to ALL chemicals involved<br />

in water injection, also in extremely sour environments, including:<br />

- H 2<br />

S in any concentration/<strong>pressure</strong><br />

- (strong) inorganic acids like HCl, H 2<br />

SO 4<br />

- (strong) alkaline materials, including NaOH, KOH, and NH 3 solutions<br />

- CO 2<br />

in any concentration/<strong>pressure</strong><br />

- Anti-corrosion additives<br />

- Mineral salts<br />

- Hydrocarbons of any composition<br />

<strong>Soluforce</strong> ® HEAVY : H415 - H515<br />

A <strong>high</strong> strength steel wire reinforcement<br />

for <strong>high</strong> <strong>pressure</strong> water applications.<br />

- High <strong>pressure</strong> water injection<br />

9

SOLUFORCE ® WATER DATA SHEET<br />

<strong>Soluforce</strong> ® WATER Data Sheet<br />

<strong>Soluforce</strong> ® type L450 L540 M480 M570 H415 H515<br />

Dimensions<br />

Nominal diameter 100 mm / 4" 150 mm / 6" 100 mm / 4" 150 mm / 6" 100 mm / 4" 150 mm / 6"<br />

Outside diameter 125 mm / 5" 150 mm / 6" 125 mm / 5" 150 mm / 6" 125 mm / 5" 150 mm / 6"<br />

Inside diameter 100 mm / 4" 125 mm / 5" 100 mm / 4" 125 mm / 5" 100 mm / 4" 125 mm / 5"<br />

Weight in air < 6 kg/m / 4.2 Lb/ft 144 Bar /<br />

2088psi<br />

36 Bar /<br />

522 psi<br />

36 Bar /<br />

522 psi<br />

> 115 Bar /<br />

1670 psi<br />

29 Bar /<br />

421 psi<br />

N/A<br />

111 Bar /<br />

1610 psi<br />

> 360 Bar /<br />

5220 psi<br />

90 Bar /<br />

1305 psi<br />

65 °C / 150 °F<br />

90 Bar /<br />

1305 psi<br />

> 270 Bar /<br />

3915 psi<br />

72 Bar /<br />

1044 psi<br />

Above freezing point of fluid<br />

Hazen Williams friction factor (C) 150<br />

Darcy Weisbach surface<br />

roughness (e)<br />

0.0015 mm<br />

Design lifetime<br />

Surface installed<br />

20 years<br />

Buried<br />

50 years<br />

Minimum bending radius<br />

In storage 1.25 m / 4´1.2’’<br />

In service 3.00 m / 9´10.1’’<br />

Test <strong>pressure</strong><br />

Maximum Hydrotest Pressure<br />

49 Bar /<br />

711 psi<br />

40 Bar /<br />

421 psi<br />

123 Bar /<br />

1784 psi<br />

100 Bar /<br />

1450 psi<br />

195 Bar /<br />

2828 psi<br />

> 450 Bar /<br />

6525 psi<br />

150 Bar /<br />

2200 psi<br />

195 Bar /<br />

2828 psi<br />

Packaging<br />

Length per coil 400 m / 1312 ´ 220 m / 721´<br />

Dimensions per coil (l x h x w)<br />

Weight per coil<br />

400 x 420<br />

x 115 cm<br />

2200 kg /<br />

4846 Lbs<br />

410 x 420<br />

x 146 cm<br />

2720 kg /<br />

5991 Lbs<br />

400 x 420<br />

x 115 cm<br />

2240 kg /<br />

4933 Lbs<br />

410 x 420<br />

x 146 cm<br />

2760 kg /<br />

6079 Lbs<br />

1940 kg /<br />

4273 Lbs<br />

N/A<br />

195 Bar /<br />

2828 psi<br />

> 360 Bar /<br />

5220 psi<br />

150 Bar /<br />

2200 psi<br />

195 Bar /<br />

2828 psi<br />

410 x 420<br />

x 146 cm<br />

2380 kg /<br />

5242 Lbs<br />

10

SOLUFORCE ® WATER<br />

<strong>Soluforce</strong> ® LIGHT : L450 - L540<br />

With a maximum operating <strong>pressure</strong> of 36 Bar<br />

and 29 Bar for the (4” and 6” <strong>pipe</strong> resp.),<br />

SOLUFORCE ® LIGHT provides an excellent, flexible<br />

solution for medium <strong>pressure</strong> water transport.<br />

As it is fully non-metallic it serves any sour application,<br />

without restrictions regarding H 2<br />

S and CO 2<br />

content.<br />

<strong>Soluforce</strong> ® CLASSIC : M480 - M570<br />

Available with a maximum operating <strong>pressure</strong><br />

of 90 Bar and 72 Bar (4” and 6” resp.),<br />

SOLUFORCE ® CLASSIC serves a very wide range<br />

of applications due to its unique combination<br />

of properties. Being fully non-metallic it is the<br />

ideal solution for even the toughest <strong>high</strong> <strong>pressure</strong><br />

application such as sour service, without restrictions<br />

regarding H 2<br />

S and CO 2<br />

content.<br />

Temperature uprating factors and maximum <strong>pressure</strong> rating<br />

Temp [°C] Uprating Factor M480 [bar]* M570 [bar]*<br />

*water service<br />

10 1,54 137 109<br />

20 1,45 129 103<br />

30 1,34 120 96<br />

40 1,24 111 89<br />

50 1,14 102 81<br />

55 1,1 98 78<br />

60 1,05 93 75<br />

65 1 90 72<br />

70 0,95 85 68<br />

80 0,86 76 61<br />

<strong>Soluforce</strong> ® HEAVY : H415 - H515<br />

For very <strong>high</strong> operating <strong>pressure</strong>s up to 223 Bar (4”)<br />

and 178 Bar (6”) a steel wire reinforced <strong>pipe</strong> is<br />

available. SOLUFORCE ® HEAVY is specially developed<br />

for very <strong>high</strong> <strong>pressure</strong> (saline) water injection.<br />

It is resistant to (strong) inorganic acids like HCl,<br />

H 2<br />

SO 4<br />

and (strong) alkaline materials, including<br />

NaOH, KOH, and NH 3 solutions. As the <strong>pipe</strong> is steel<br />

cord reinforced the <strong>pipe</strong> has some limitations for<br />

sour H 2<br />

S applications. The CO 2<br />

content in the fluid<br />

can be very <strong>high</strong>, up to 7 % in the gas phase.<br />

11

SOLUFORCE ® HYDROCARBONS<br />

HIGH PRESSURE<br />

PLASTIC PIPE SYSTEMS<br />

FOR HYDROCARBONS<br />

<strong>Soluforce</strong> ® RTP oil hook up line<br />

12

SOLUFORCE ® HYDROCARBONS<br />

<strong>Soluforce</strong> ® LIGHT : L450 - L540<br />

A synthetic fibre tape reinforcement<br />

for lower <strong>pressure</strong> applications.<br />

<strong>Soluforce</strong> ® CLASSIC : M480 - M570<br />

A synthetic fibre tape reinforcement<br />

for medium <strong>pressure</strong> applications such as oil<br />

flow lines and water disposal lines.<br />

<strong>Soluforce</strong> ® CLASSIC HPG : M480 HPG - M570 HPG<br />

A synthetic fibre tape reinforcement with<br />

a low gas permeation grade liner for medium<br />

<strong>pressure</strong> gas applications.<br />

<strong>Soluforce</strong> ® HEAVY : H415 - H515<br />

A <strong>high</strong> strength steel wire reinforcement<br />

for <strong>high</strong> <strong>pressure</strong> oil flowlines.<br />

<strong>Soluforce</strong> ® HEAVY PA : H415 PA - H515 PA<br />

A <strong>high</strong> strength steel wire reinforcement<br />

with polyamide inner lining for <strong>high</strong><br />

<strong>pressure</strong> gas applications.<br />

13

SOLUFORCE ® HYDROCARBONS data sheet<br />

SYNTHETIC FIBER REINFORCED RTP - API RP 15S<br />

<strong>Soluforce</strong> ® HYDROCARBONS Data Sheet<br />

<strong>Soluforce</strong> ® type L450 L540 M480 M570 M480 HPG M570 HPG<br />

Dimensions<br />

Nominal diameter 100 mm / 4" 150 mm / 6" 100 mm / 4" 150 mm / 6" 100 mm / 4" 150 mm / 6"<br />

Outside diameter 125 mm / 5" 150 mm / 6" 125 mm / 5" 150 mm / 6" 125 mm / 5" 150 mm / 6"<br />

Inside diameter 100 mm / 4" 125 mm / 5" 100 mm / 4" 125 mm / 5" 100 mm / 4" 125 mm / 5"<br />

Weight in air < 6 kg/m / 4.2 Lb/ft < 10 kg/m / 7 Lb/ft<br />

Technical Details<br />

Liner material HDPE, black, type PE100 HDPE, low permeation grade<br />

Cover material<br />

HDPE, white, UV stabilised, type PE100<br />

Reinforcement<br />

Aramid Fibre<br />

Ratings<br />

Pressure Ratings<br />

Hydrostatic Design Basis (HDB),<br />

LCL 20 years (API RP 15S)<br />

Short term bursting <strong>pressure</strong><br />

(STHB)<br />

Maximum continuous<br />

operating <strong>pressure</strong> (20 yrs)<br />

Operating temperatures<br />

Maximum ambient and/or<br />

fluid temperature<br />

Minimum ambient and/or fluid<br />

temperature<br />

Design and Construction Parameters<br />

Flow<br />

45 Bar /<br />

644 psi<br />

> 144 Bar /<br />

2088psi<br />

26 Bar /<br />

377 psi<br />

36 Bar /<br />

522 psi<br />

> 115 Bar /<br />

1670 psi<br />

21 Bar /<br />

305 psi<br />

111 Bar /<br />

1610 psi<br />

> 360 Bar /<br />

5220 psi<br />

65 Bar /<br />

943 psi<br />

65 °C / 150 °F<br />

- 40 ºC / - 40 ºF<br />

Hazen Williams friction factor (C) 150<br />

Darcy Weisbach surface<br />

roughness (e)<br />

0.0015 mm<br />

Bubble Point (according to ASTM F316)<br />

Maximum bubble point <strong>pressure</strong><br />

@ 65°C / 150°F<br />

Design lifetime<br />

Surface installed<br />

Buried<br />

Minimum bending radius<br />

26 Bar /<br />

377 psi<br />

21 Bar /<br />

305 psi<br />

21 Bar /<br />

305 psi<br />

20 years<br />

50 years<br />

In storage 1.25 m / 4´1.2’’<br />

In service 3.00 m / 9´10.1’’<br />

Test <strong>pressure</strong><br />

Maximum Hydrotest Pressure<br />

49 Bar /<br />

711 psi<br />

40 Bar /<br />

421 psi<br />

123 Bar /<br />

1784 psi<br />

Packaging<br />

Length per coil 400 m / 1312 ´<br />

Dimensions per coil (l x h x w)<br />

Weight per coil<br />

400 x 420<br />

x 115 cm<br />

2200 kg /<br />

4846 Lbs<br />

410 x 420<br />

x 146 cm<br />

2720 kg /<br />

5991 Lbs<br />

400 x 420<br />

x 115 cm<br />

2240 kg /<br />

4933 Lbs<br />

90 Bar /<br />

1305 psi<br />

> 270 Bar /<br />

3915 psi<br />

52 Bar /<br />

754 psi<br />

21 Bar /<br />

305 psi<br />

100 Bar /<br />

1450 psi<br />

410 x 420<br />

x 146 cm<br />

2760 kg /<br />

6079 Lbs<br />

111 Bar /<br />

1610 psi<br />

> 360 Bar /<br />

5220 psi<br />

65 Bar /<br />

943 psi<br />

65 Bar /<br />

943 psi<br />

123 Bar /<br />

1784 psi<br />

400 x 420<br />

x 115 cm<br />

2240 kg /<br />

4933 Lbs<br />

90 Bar/<br />

1305 psi<br />

> 270 Bar /<br />

3915 psi<br />

52 Bar /<br />

754 psi<br />

52 Bar /<br />

754 psi<br />

100 Bar /<br />

1450 psi<br />

410 x 420<br />

x 146 cm<br />

2760 kg /<br />

6079 Lbs<br />

14

SOLUFORCE ® HYDROCARBONS data sheet<br />

STEEL CORD REINFORCED RTP - API 17J<br />

<strong>Soluforce</strong> ® HYDROCARBONS Data Sheet<br />

<strong>Soluforce</strong> ® type H415 H515 H415PA H515PA<br />

Dimensions<br />

Nominal diameter 100 mm / 4’’ 150 mm / 6’’ 100 mm / 4’’ 150 mm / 6’’<br />

Outside diameter 125 mm / 5’’ 150 mm / 6’’ 125 mm / 5’’ 150 mm / 6’’<br />

Inside diameter 100 mm / 4’’ 125 mm / 5’’ 100 mm / 4’’ 125 mm / 5’’<br />

Weight in air<br />

450 Bar / 6526 psi > 360 Bar / 5220 psi > 450 Bar / 6526 psi > 360 Bar / 5220 psi<br />

Maximum continuous operating<br />

<strong>pressure</strong> (20 yrs)<br />

150 Bar / 2200 psi 150 Bar / 2200 psi 150 Bar / 2200 psi 150 Bar / 2200 psi<br />

Operating temperatures<br />

Maximum ambient and/or fluid temperature 65 °C / 150 °F<br />

Minimum ambient and/or fluid temperature - 40 ºC / - 40 ºF<br />

Design and Construction Parameters<br />

Flow<br />

Hazen Williams friction factor (C) 150<br />

Darcy Weisbach surface roughness (e)<br />

0.0015 mm<br />

Bubble Point (according to ASTM F316)<br />

Maximum bubble point <strong>pressure</strong> @ 65°C / 150 °F 21 Bar / 305 psi 21 Bar / 305 psi 150 Bar / 2200 psi 150 Bar / 2200 psi<br />

Design lifetime<br />

Surface installed<br />

20 years<br />

Buried<br />

50 years<br />

Minimum bending radius<br />

In storage 1.25 m / 4´1.2’’<br />

In service 3.00 m / 9´10.1’’<br />

Test <strong>pressure</strong><br />

Maximum Hydrotest Pressure 195 Bar / 2828 psi 195 Bar / 2828 psi 195 Bar / 2828 psi 195 Bar / 2828 psi<br />

Packaging<br />

Length per coil 220 m / 721´<br />

Dimensions per coil (l x h x w)<br />

400 x 420 x 146 cm<br />

Weight per coil 1940 kg / 4273 Lbs 2380 kg / 5242 Lbs 1940 kg / 4273 Lbs 2380 kg / 5242 Lbs<br />

15

SOLUFORCE ® HYDROCARBONS<br />

<strong>Soluforce</strong> ® LIGHT : L450 - L540<br />

With a maximum operating <strong>pressure</strong> of 26 Bar and<br />

21 Bar (4” and 6” ND <strong>pipe</strong> resp.), <strong>Soluforce</strong> ® LIGHT<br />

provides an excellent, flexible solution for medium<br />

<strong>pressure</strong> oil transport. For example beam pump<br />

flow lines are a typical application for this <strong>pipe</strong>.<br />

As this <strong>pipe</strong> concept is fully non-metallic it can serve<br />

any sour application, without restrictions regarding<br />

H 2<br />

S and CO 2<br />

content.<br />

<strong>Soluforce</strong> ® CLASSIC : M480 - M570<br />

<strong>Soluforce</strong> ® CLASSIC is available with a maximum<br />

operating <strong>pressure</strong> of 65 Bar and 52 Bar (4” and<br />

6” ND resp.). Being fully non-metallic, it is the ideal<br />

solution for even the toughest applications such as<br />

sour oil service without restrictions regarding H 2<br />

S<br />

and CO 2<br />

content. Applications such as beam pump<br />

flow lines or ESP (electrical submerged pumps) flow<br />

lines are areas where this <strong>pipe</strong> will prove its benefits.<br />

<strong>Soluforce</strong> ® CLASSIC HPG : M480 HPG - M570 HPG<br />

For <strong>high</strong> <strong>pressure</strong> applications with a <strong>high</strong> associated<br />

gas content <strong>Soluforce</strong> ® CLASSIC HPG was<br />

developed. This <strong>pipe</strong> has a special low gas permeation<br />

inner liner. Beam pump or ESP flow lines for<br />

oil transport with a <strong>high</strong> GOR (gas to oil ratio) will<br />

benefit from the ease of use, even with very <strong>high</strong><br />

H 2<br />

S and CO 2<br />

contents. It is available with a maximum<br />

operating <strong>pressure</strong> of 65 Bar and 52 Bar<br />

(4” and 6” ND resp.) for <strong>high</strong> GOR applications.<br />

Ductile iron nylon coated<br />

end flange connection<br />

16<br />

Lekhwair, Oman sour oil service<br />

7200 m - Pressure 735 psi - Temperature 120 F°<br />

Installed in August 2000

SOLUFORCE ® HYDROCARBONS<br />

<strong>Soluforce</strong> ® HEAVY : H415 - H515<br />

For very <strong>high</strong> operating <strong>pressure</strong>s up to 150 Bar<br />

a steel cord reinforced <strong>pipe</strong> is available. It is<br />

resistant to (strong) inorganic acids like HCl, H 2<br />

SO 4<br />

and (strong) alkaline materials, including NaOH,<br />

KOH, and NH 3 solutions. As this <strong>pipe</strong> is steel wire<br />

reinforced the <strong>pipe</strong> has some limitations for sour H 2<br />

S<br />

applications according to NACE MR0175 / ISO15156.<br />

The CO 2<br />

content in the fluid may be very <strong>high</strong>.<br />

<strong>Soluforce</strong> ® HEAVY PA : H415 PA - H515 PA<br />

<strong>Soluforce</strong> ® Heavy PA <strong>pipe</strong>, is qualified by bureau<br />

Veritas for hydrocarbon service according to API17J,<br />

irrespective of the composition of the hydrocarbon<br />

composition, with certain limitations to the<br />

concentration of H 2<br />

S and CO 2<br />

, The liner materials<br />

(HDPE or PA12) are fully compatible with<br />

hydrocarbons and gas up to the maximum<br />

rated temperatures.<br />

<strong>Soluforce</strong> ® Heavy PA has a polyamide 12 (PA12)<br />

liner with a reduced rate of permeation.<br />

As a result, <strong>Soluforce</strong> ® Heavy PA may be used<br />

up to its full hydrostatic <strong>pressure</strong> capacity for gas,<br />

or for hydrocarbons with <strong>high</strong> associated gas<br />

content.<br />

In case of dry gas service, the temperature rating<br />

of <strong>Soluforce</strong> ® Heavy PA may, under certain<br />

conditions, be increased to 85 °C (185 °F). When<br />

there is no humidity present, PA12 is not affected<br />

by hydrolysis.<br />

17

SOLUFORCE ® CONNECTION SYSTEMS<br />

HIGH PRESSURE<br />

PLASTIC PIPE<br />

ASSEMBLY SYSTEMS<br />

End fitting parts<br />

18

SOLUFORCE ® CONNECTION SYSTEMS<br />

Summary<br />

COUPLINGS<br />

In-line coupling<br />

<strong>pipe</strong> to <strong>pipe</strong> coupling (P2P)<br />

END FITTINGS<br />

Flange<br />

Weld Stub<br />

« SOLUFORCE ® Electro fusion connection system is applicable<br />

up to 120 bars - 1740 psi at max. 65°C - 150°F »<br />

19

ELECTROFUSION SYSTEM<br />

IN-LINE COUPLINGS<br />

• Combination of butt welding<br />

and electro fusion<br />

• HDPE UV resistant<br />

protection sleeve<br />

• <strong>Soluforce</strong> ® Pipe to Pipe<br />

connectorin stainless steel 316L<br />

• Electro fusion only<br />

20

ELECTROFUSION SYSTEM<br />

END FITTINGS<br />

OPTION 1 : SOLUFORCE ® end fitting with stainless steel 316L flange 600 #<br />

• <strong>Soluforce</strong> ® end fitting in stainless<br />

steel 316L with electro fusion<br />

connection to the <strong>pipe</strong>.<br />

• Other flange ratings available<br />

on demand<br />

OPTION 2 : SOLUFORCE ® end fitting WITH nylon coated ductile iron flange 600 #<br />

• SOLUFORCE ® end fitting with<br />

nylon coated ductile iron<br />

• Nylon insert ensures no fluid<br />

to metal contact<br />

OPTION 3 : SOLUFORCE ® END FITTING WITH WELD STUB<br />

• SOLUFORCE ® end fitting with Stainless<br />

steel 316L weld stub (other materials<br />

can be supplied on demand)<br />

21

ELECTROFUSION MACHINE<br />

• Leak tight connection by butt fusion welding of liner <strong>pipe</strong>.<br />

• Electrofusion welding of the coupling gives strength<br />

• Completely non-metallic <strong>pipe</strong>line<br />

• Totally corrosion free<br />

• Eletrofusion welding of the end fitting<br />

• Base for<br />

- End flange<br />

- Weld stub<br />

- P2P system<br />

Coupling<br />

End fitting<br />

Full installation team in a working site<br />

22

ELECTROFUSION MACHINE COMPONENTS<br />

AND TOOLS<br />

Electrofusion control box<br />

Heater plate<br />

CNC control unit<br />

Trimmer<br />

« A completely<br />

computer controlled process<br />

Power required to run<br />

the machine 20 KVA »<br />

SOLUFORCE ® tools<br />

23

SWAGED FITTING SYSTEM<br />

SOLUFORCE® swaged fitting in stainless steel.<br />

SOLUFORCE ® swaging machine.<br />

SOLUFORCE® swaging machine on site.<br />

SOLUFORCE® can rent out swaging machines and<br />

provide swaging services upon request.<br />

Stainless<br />

steel insert<br />

• Metal and <strong>pipe</strong> sandwich after<br />

the swaging process.<br />

RTP <strong>pipe</strong> Sandwiched<br />

between the swaged<br />

fiting walls<br />

Stainless<br />

steel exterior<br />

fiting<br />

• The assembly consists in compressing<br />

the external ring against the expansion<br />

of the internal insert.<br />

End Fitting<br />

• ASTM Flange<br />

• Stub end<br />

Mid-Line connection<br />

• Grayloc<br />

• Slim line<br />

• Stub end<br />

« SOLUFORCE® swaging system<br />

for SOLUFORCE® Heavy RTP <strong>pipe</strong> system »<br />

24

SWAGED FITTING SYSTEM<br />

OPTION 1 : SOLUFORCE ® SWAGE fitting with GRAYLOC CONNECTOR 316L<br />

• Easy connection system.<br />

• Light weight.<br />

• Hooks up with<br />

Grayloc hub flange.<br />

OPTION 2 : SOLUFORCE ® SWAGE FITTING WITH SLIMLINE CONNECTOR IN 316l<br />

• Easy axial load<br />

• Heavy duty<br />

• Hooks up with Slimline<br />

hub flange.<br />

OPTION 3 : SOLUFORCE ® SWAGE FITTING WITH WELD STUB END IN 316l<br />

• Connection by steel welding.<br />

• Hooks up with any type<br />

of weld stub flange.<br />

Other alloys can be supplied on demand.<br />

25

APPLICATIONS<br />

SOLUFORCE ® lines hooked up to existing infra structure.<br />

Dual lines connect by Pipe to Pipe fittings.<br />

Installation in tropical rain forest.<br />

Flange to flange connection.<br />

Uncoiling of SOLUFORCE® <strong>pipe</strong> along mountain road.<br />

26<br />

Handling of SOLUFORCE ® installation equipment in the field.

PIPE TRANSPORT AND LOGISTICS<br />

Easy storage and manipulation<br />

Transport by sea<br />

Driving out to work site on the deployment trailer.<br />

Road transport<br />

Uncoiling<br />

27

SOLUFORCE ® OFFSHORE<br />

HIGH PRESSURE<br />

PLASTIC PIPE SYSTEMS<br />

OFFSHORE<br />

28<br />

Special over-size drums for <strong>offshore</strong><br />

can be supplied on demand

SOLUFORCE ® OFFSHORE<br />

When installed empty, the maximum external <strong>pressure</strong> on <strong>Soluforce</strong> ® , depending<br />

on diameter, is about 0.3 MPa, which limits the water depth to approximately 30 meters.<br />

However, when the <strong>Soluforce</strong> ® RTP system is kept pressurized or water filled during<br />

installation and operation there is no theoretical limit to the water depth.<br />

For oil and water <strong>pipe</strong>s, the maximum water depth is therefore much more than 30 meters,<br />

and limited in practice by the maximum allowable tensile load during installation.<br />

For gas <strong>pipe</strong>, the maximum water depth is determined by the hydrostatic collapse<br />

resistance.<br />

<strong>Soluforce</strong> ® type<br />

Dimensions<br />

<strong>Soluforce</strong> ® CLASSIC<br />

<strong>Soluforce</strong> ® HEAVY<br />

M480 M570 Standard H415 H415 Standard<br />

Nominal diameter (mm) 100 (4“) 150 (6“) 100 (4“) 125 (5“)<br />

Weight, empty in air (kg/m) 4,6 5,9 7,0 9,0<br />

Weight, empty submerged (kg/m) -8,1 -12,4 -5,6 -8,9<br />

Weight, waterfilled, submerged (kg/m) -0,3 -0,4 2,2 3,1<br />

Maximum <strong>pressure</strong>, water service (barg) 90 72 DNV 150 150 DNV<br />

Maximum <strong>pressure</strong>, hydrocarbon service (barg) 64 51 API RP 15S 150 150 API 17J<br />

Maximum <strong>pressure</strong>, gas service 1 (barg) 64 51 API RP 15S 150 150 API 17J<br />

Maximum hydrotest <strong>pressure</strong> 2 (barg) 123 100 DNV 195 195 DNV<br />

Maximum service température (C°) 65 65 65 65<br />

Internal surface roughness (Darcy Weisbach) (mm) 0,0015 0,0015 0,0015 0,0015<br />

Hazen Williams friction factor 150 150 150 150<br />

1<br />

Special grade HDPE liner<strong>pipe</strong><br />

2<br />

Max 24 hours, test medium: water. For <strong>Soluforce</strong> ® Heavy see API 17J, Chapter 9.<br />

For more information contact us directly at info@soluforce.com or visit our website<br />

www.soluforce.com to download our brochure and submit your questions.<br />

Project references can be supplied upon demand. A design guideline for <strong>offshore</strong><br />

installation can be obtained from <strong>Soluforce</strong>.<br />

Conforms to API RP 15S or API 17J for spoolable composite <strong>pipe</strong> <strong>systems</strong>.<br />

<strong>Soluforce</strong> ® RTP is DNV certified.<br />

29

SOLUFORCE ® OFFSHORE<br />

<strong>Soluforce</strong> ® is suitable and economical for multiple <strong>offshore</strong> applications such as water injection<br />

lines, oil flowlines, and static risers up to 6 inch diameter. <strong>Soluforce</strong> ® may also be recoiled and<br />

re-used for well intervention risers and test lines.<br />

The advantage of <strong>Soluforce</strong> ® Classic over (stainless) steel <strong>pipe</strong> and other flexible <strong>pipe</strong> <strong>systems</strong><br />

is its complete corrosion resistance even in heavily sour service. <strong>Soluforce</strong> ® Heavy can be used<br />

for sour service up to 0.3 Bars (4.5 psi) partial H2S <strong>pressure</strong>. <strong>Soluforce</strong> ® has a completely smooth<br />

bore, as opposed to most other <strong>offshore</strong> flexible <strong>pipe</strong> solutions. This ensures a much lower flow<br />

resistance and improved flow capacity.<br />

Designed originally for onshore operations <strong>Soluforce</strong> ® has limited external <strong>pressure</strong> resistance.<br />

However installed water filled and operated water or oil filled <strong>Soluforce</strong> ® may be used even<br />

in deep water. As a temporary test line, <strong>Soluforce</strong> ® has been used at 900 meters (3000 ft)<br />

water depth.<br />

Empty, or oil- or gas filled, the differential external <strong>pressure</strong> should be no more than 0.3 MPa<br />

(equivalent to 30 meters / 100 ft water depth). If the water depth is more than 30 meters (100 ft),<br />

used for gas service, or oil service with <strong>high</strong> GOR (Gas to Oil Ratio), a subsea <strong>Soluforce</strong> ® <strong>pipe</strong>line<br />

must be protected by some means to ensure that a positive differential <strong>pressure</strong> is maintained<br />

at all times. This could be, for instance, a safety shut off system. In such case, as long as the <strong>pipe</strong><br />

is installed water filled, there is no theoretical limit to the water depth.<br />

Being lightweight, <strong>Soluforce</strong> ® must be fitted with external weight to ensure sufficient onbottom<br />

stability. This may either be strap-on concrete blocks at regular intervals or a piggybacked<br />

heavy steel wire cable. Sometimes, concrete weight mattresses are used. In deeper water,<br />

a parallel steel wire cable is required to ensure sufficient axial strength during installation.<br />

<strong>Soluforce</strong> ® Heavy PA, with a PA12 liner has been specifically designed for subsea gas <strong>pipe</strong>lines,<br />

and is approved by Bureau Veritas for such service according to API 17J.<br />

As installation and operating conditions of flexible <strong>offshore</strong> <strong>pipe</strong>lines vary widely, the over-all<br />

suitability, installation method, and economy of <strong>Soluforce</strong> ® must be evaluated in detail for each<br />

individual project. <strong>Soluforce</strong> is happy to advise the <strong>offshore</strong> engineering office of your choice on<br />

this subject.<br />

<strong>Soluforce</strong> ® Classic RTP during installation<br />

with concrete block attachment for<br />

sinking to bottom of sea.<br />

30

SOLUFORCE ® OFFSHORE<br />

Disclaimer:<br />

All products purchased from or supplied by Pipelife are subjected to terms and conditions set out in the contract, order acknowledgement<br />

and/or bill of lading. Pipelife warrants only that its product will meet those specifi cations designated in such contracts, order acknowledgements,<br />

and/or bills of loading. All other information including that herein, supplied by Pipelife, is considered accurate but is furnished upon the<br />

express conditions that the customer shall make his own assessment to determine the product’s suitability for a particular purpose. Pipelife<br />

makes no other warranty either express or implied, regarding such other information, the data upon which the same is based, or the results<br />

to be obtained from the use thereof; that any products shall be merchantable or fit for any particular purpose; or that the use of such other information<br />

or product will not infringe any patent.<br />

31

SOLUFORCE ®<br />

FLEXIBLE THINKING<br />

www.soluforce.com<br />

Pipelife Nederland B.V.<br />

Flevolaan 7<br />

1601 MA ENKHUIZEN<br />

Netherlands<br />

Tel.: +31(0) 228 355 555<br />

Fax: +31(0) 228 355 520<br />

info@soluforce.com<br />

November, 2011 / Copyright: Pipelife Nederland bv