You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

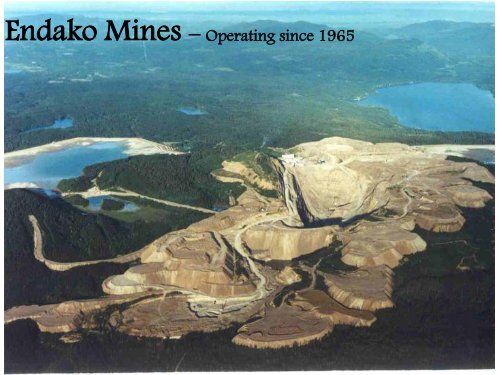

<strong>Endako</strong> <strong>Mine</strong>s – Operating since 1965

<strong>Endako</strong>’s History<br />

• 1927 – Deposit was discovered by two local hunters<br />

• 1962 – August, Placer Development started diamond drill program<br />

• 1964 – March, Clearing and construction of the site began<br />

• 1965 – May, Construction Completed – Capital Cost $22 million<br />

• 1965 – June 8 th , <strong>Endako</strong>’s Grand Opening<br />

• 1965 -1981, Various expansion stages from 16 ktpd to 28 ktpd<br />

• 1982 – 1986, milling portion was shut down, only Toll Roasting done<br />

• 1997 – <strong>Endako</strong> was sold to Thompson Creek Mining Joint Venture<br />

• 2006 – Blue Pearl Mining purchased 75% of <strong>Endako</strong> + 2 other TCM<br />

facilities, decides to keep Thompson Creek Name<br />

• 2008 – Thompson Creek announces $373 million, 52ktpd <strong>Endako</strong><br />

expansion<br />

• 2009 – March, expansion placed on hold<br />

• 2009 – Fall, <strong>Endako</strong> expansion Re-Start

Cumulative Mining History<br />

• <strong>Mine</strong>d 360 tonnes of ore, 290 tonnes of waste<br />

• Produced 500+ million pounds of Oxide<br />

• Provided 34.5 million man hours of employment<br />

• Paid in Excess of $430 million in wages<br />

Historical Wage Rates<br />

• 1966 Labourer<br />

• 1966 Trades Person<br />

$2.32/hr<br />

$3.29/hr<br />

• 2010 Labourer<br />

• 2010 Trades Person<br />

$21.00/hr<br />

$33.00/hr

52,000 tonne/day Expansion

Expansion Highlights<br />

• $498 Million dollar budget<br />

• 52,000 tonne per day mill<br />

– 36’ SAG and 2 x 22’Ball Mills<br />

– 14 x OK160 Rougher/Scavenger flotation cells<br />

– 3 x M1000 Isamills for regrinding<br />

– 5 stages of column cleaner flotation<br />

• 15 million lbs per year of Mo Production<br />

– Target 92% Mill operating time<br />

– Lower maintenance costs and downtime<br />

– Higher 79%recovery via better control and finer grinds<br />

– 18 year mine life at $12/lb Mo

52,000 TPD Flow sheet

SAG Mill – 36’ x 17.75’ - 17,000 hp

Pebble Crusher/SAG Feed Stockpile<br />

• 100,000 tpd live load<br />

• 360,000 tpd total load<br />

• Raptor 1100 pebble<br />

crusher

2x Ball Mills – 22’ x 34’, 11,000 hp each

Rougher/Scavenger Flotation<br />

• 2 Banks<br />

• 14 x OK 160’s<br />

• 24 min flotation time<br />

• 200 micron grind<br />

• 79% recovery

Regrind Circuit<br />

• 2 Stage Regrind<br />

• 3 x M1000<br />

Isamills<br />

• Final Product<br />

p80 = 15 microns

Cleaning Circuit<br />

• 5 Stages of Column<br />

Flotation, with<br />

Mechanical scavengers<br />

• Upgrading to 92% MoS2<br />

• Not purchased yet

Some Project Construction Stats

Current Contractors On site<br />

• Sharp Construction – Earthworks<br />

• Formula Contractors – Pre Eng Mill Building Erection<br />

• CIF – Mill Building Foundation Concrete<br />

• K2 Electric – Temporary Power Work<br />

• WD McIntosh – Site Surveying<br />

• PNG – Natural Gas line work<br />

• Hatch Engineering – EPCM contractor<br />

• Other local labour, catering, general support

Project Status<br />

• Construction and Engineering is ramping up<br />

• Price of Molybdenum is doing well at +$17/lb<br />

• Large experienced owners team<br />

• Project completion expected mid 2011

• <strong>Endako</strong>’s has been<br />

spending close to<br />

$500,000 / yr on<br />

Environmental<br />

Work.<br />

<strong>Endako</strong>’s Reclamation and<br />

• Regular monitoring<br />

• Re-vegetation<br />

• Education<br />

Environmental Highlights

Tailings Pond Planting

Waste Rock Piles

Questions?