XL-PH10397SG - saf-holland

XL-PH10397SG - saf-holland

XL-PH10397SG - saf-holland

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Pintle Hooks – Rigid Mount – Air Cushioned<br />

PH-400 and PH-400-H<br />

Application<br />

A rigid mount pintle hook designed for trailers and semitrailers in doubles<br />

and triples operations. Used for off- and over-the-road applications. Air<br />

cushioned snubber is designed to minimize the gap between the pintle<br />

hook and the drawbar eye on vehicles with air systems.<br />

Automatic secondary lock<br />

for improved <strong>saf</strong>ety.<br />

Plunger/snubber<br />

force is developed<br />

by the vehicle’s<br />

air system to<br />

reduce wear and<br />

to provide shock<br />

absorption.<br />

Air chambers<br />

are available<br />

for different<br />

mounting widths;<br />

see page 26.<br />

Weight: 48 lbs. (21.8 kg)<br />

The complete assembly includes a pintle hook, plunger, air chamber, and mounting<br />

bracket. For pintle hooks without an air chamber, bracket, or plunger, order PH-400-1<br />

or PH-400-1-H.<br />

The PH-400 and PH-400-H can be operated with or without the air chamber. For<br />

easier coupling, drawbar guides are available, see page 56.<br />

Capacities<br />

20,000 lbs. (9,070 kg) Maximum Vertical Load<br />

100,000 lbs. (45,360 kg) Maximum Gross Trailer Weight<br />

Drawbar Eye Dimensions<br />

2.38˝ to 3˝ I.D. with 1.25˝ to 1.63˝ diameter section.<br />

Additional Information<br />

Adjustable plunger<br />

Unique one-hand<br />

latch operation.<br />

• For severe off-road applications, reduce the above maximum<br />

capacities by 25% and use with a swivel-mount drawbar.<br />

• Tested in accordance with SAE J847.<br />

• For additional specification detail, refer to document<br />

number <strong>XL</strong>-PH244 or PH-247.<br />

Cast alloy<br />

steel body is<br />

heat treated<br />

for increased<br />

strength,<br />

durability,<br />

and wear<br />

resistance.<br />

The Holland PH-400 and PH-400-H complies with NOM-0350-SCT-2-2010<br />

Safety Specifications and Test Methods.<br />

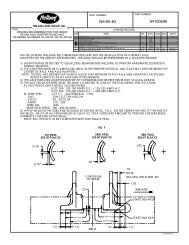

Mounting Dimensions<br />

PH-400 and PH-400-H<br />

6.62˝<br />

2.38˝<br />

2.12˝<br />

10.43˝<br />

11.75˝<br />

5.00˝<br />

PH-400<br />

7.6˝<br />

3.8˝<br />

3.25˝ DIA. MIN<br />

2.50˝5.00˝<br />

2.00˝<br />

1.06˝<br />

5.00˝<br />

10.43˝<br />

.81˝ DIA. TYP.<br />

(8 REQ.)<br />

Replacement Parts<br />

RK-02536<br />

*<br />

XB-03103<br />

XB-03104<br />

XE-01544-1<br />

5.76˝<br />

.75˝ MIN .<br />

2.25˝ MAX.<br />

3.8˝ to 1/4”<br />

NPT Reducer<br />

3.8˝NPT Plug<br />

* Center hole not required if<br />

used without air chamber.<br />

XB-165945<br />

3.25˝<br />

DIA. MIN.<br />

6.38˝<br />

*<br />

2.19˝<br />

2.38˝<br />

3.00˝<br />

XB-T-199<br />

XB-T-199<br />

.63˝<br />

7.00˝<br />

PH-400-H<br />

2.50˝<br />

7.6˝<br />

5.00˝<br />

6.00˝<br />

3.8˝<br />

Included with<br />

XB-165945<br />

XA-04156<br />

.94˝<br />

10.43˝<br />

1.81˝<br />

5.00˝<br />

.81˝ DIA. TYP.<br />

(8 REQ.)<br />

Included with<br />

XB-165945<br />

XA-02608 Cylinder and Bracket Sub-Assembly<br />

<strong>XL</strong>-<strong>PH10397SG</strong>-en-US Rev C 02-2013<br />

Amendments and errors reserved. © SAF-HOLLAND, Inc.<br />

21