Batteriestecker - Atech Antriebstechnik

Batteriestecker - Atech Antriebstechnik

Batteriestecker - Atech Antriebstechnik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

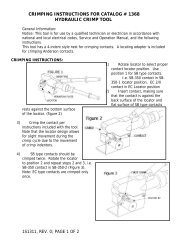

Q: Will the crimp tool I have for standard color-coded lugs, Mil Spec contacts, or another connector<br />

manufacturer, work for crimping APP ® contacts?<br />

A: No. APP ® contacts generally do not conform to standard crimp barrel dimensions used for lugs, Mil Spec contacts,<br />

or other connector manufacturers. The tooling recommended by APP ® must be used to ensure the performance<br />

designed by APP ® is achieved. Alternate tooling will void APP ® warranties and can affect safety agency approvals. In<br />

some instances Mil Spec tools are approved for crimping contacts with the dies and locators recommended by APP ® .<br />

See tooling charts for specific instances, or contact customer service for more information.<br />

SECTION 1<br />

Technical Reference<br />

Q: Can metric sized wires be used with APP ® contacts?<br />

A: Yes. The majority of our crimp tooling recommendations are based on testing and verification we have performed<br />

with AWG sized cables. Metric cables of the same or slightly smaller circular mils equivalent to the AWG wire recommended<br />

can typically be successfully terminated in APP ® contacts. There is a wire conversion chart at the end of this catalog<br />

section that can be used as a reference when converting AWG to mm² sizes. The 1368 series crimp tooling has a<br />

range taking capability that produces a reliable crimp with metric equivalents of AWG cables. Please contact customer<br />

service for metric tooling recommendations for other APP ® crimp tools.<br />

Q: Are APP ® connectors suitable for use in applications where the voltage exceeds 600V AC/DC?<br />

A: Possibly. See “Use of APP ® Connectors in Applications Exceeding 600V”, contact customer service with further<br />

questions.<br />

Q: How do Powerpole ® and Multipole connectors stay securely mated without latches?<br />

A: The proven flat wiping technology used in these connectors features a detent or bump in the contact surface along<br />

with powerful stainless steel springs that hold the connectors in the mated position. High mating force contacts have<br />

a detent that is raised higher than low mating force contacts. The higher the detent, the more force is required to mate<br />

and unmate the contacts. In many applications the detent and spring force is enough to securely hold the connectors<br />

in the mated position without the need for latches. Latching shells, clips, or other external devices can be used to<br />

secure flat wiping connectors in applications where shock, vibration, or cable strain may overcome the inherent force<br />

holding the connectors together.<br />

Q: How does APP ® ’s genderless connector design work to make a mated pair.<br />

A: Genderless Powerpole ® and Multipole housings do not have a male(pin) and female(socket) side. For wire-to-wire<br />

applications the exact same housings and contacts are used on both sides of the mated pair. If your application calls<br />

for wire-to-PCB or wire-to-busbar connections then different contacts and possibly housings will be required on each<br />

half (similar to male and female connectors).<br />

To make a mated pair of Powerpole ® or Multipole connectors simply assemble the connectors closely following the<br />

assembly instructions. After each connector half is fully assembled take one half and flip it over. The two halves will<br />

mate together. Multi-row Powerpole ® assemblies will need to be stacked in mirror images of each other to properly<br />

mate the correct circuits. This information is detailed at the beginning of the Powerpole ® section.<br />

All Data Subject To Change Without Notice<br />

www.andersonpower.com - 7 -