SoECS Laboratory Safety Manual - Swinburne University of ...

SoECS Laboratory Safety Manual - Swinburne University of ...

SoECS Laboratory Safety Manual - Swinburne University of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong><br />

1<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

Prepared by:<br />

(Health and <strong>Safety</strong><br />

Executive)<br />

Names Signature Date<br />

Nastassia Denis<br />

Reviewed by:<br />

(Senior Lecturer –<br />

Engineering / <strong>Laboratory</strong><br />

Coordinator - <strong>SoECS</strong>)<br />

Approved by:<br />

(Head <strong>of</strong> School - <strong>SoECS</strong>)<br />

Wallace Wong<br />

Anatoli Vakhguelt<br />

Associated to Documents<br />

<br />

<br />

<br />

<br />

<br />

Emergency Management Policy and Procedure<br />

Personal Protective Equipment (PPE)<br />

Incident / Hazard reporting and Investigation Procedure<br />

First Aid Procedure<br />

Hazard Identification Risk Assessment & Control Evaluation (HIRACE) Procedure<br />

Adapted from SUT FEIS <strong>Safety</strong> <strong>Manual</strong> prepared by: P. Watson, Faculty Technical Operations Manager<br />

This safety manual should be reviewed and revised when deemed necessary.<br />

2<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

CONTENTS<br />

1. Responsibilities 5<br />

Pages<br />

2. General <strong>Laboratory</strong> / Workshop Practices 7<br />

3. Waste Handling 13<br />

3.1 Decontamination<br />

3.2 Biohazard Waste Disposal<br />

3.3 Chemicals Waste Disposal<br />

3.4 Sharps<br />

3.5 Contaminated (potentially infectious) materials for autoclaving and reuse<br />

3.6 Contaminated (potentially infectious) materials for disposal<br />

4. Personal Protective Equipment (PPE) 15<br />

4.1 Lab coats, Gowns, Coveralls, Aprons<br />

4.2 Goggles, <strong>Safety</strong> Spectacles, Face Shields<br />

4.3 Respirators<br />

4.4 Gloves<br />

4.5 Foot Protection<br />

4.6 Ear Protection<br />

4.7 Head Protection<br />

5. Hazardous Chemicals 18<br />

5.1 Store <strong>of</strong> Chemicals<br />

5.2 General Rules Regarding Chemical Incompatibilities<br />

5.3 Toxic Effects <strong>of</strong> Chemicals<br />

5.4 Explosive Chemicals<br />

5.5 Chemical Spills<br />

5.6 Compressed and Liquefied Gases<br />

5.7 Handling <strong>of</strong> Cylinders<br />

5.8 Cryogenic Liquids<br />

5.9 Handling Cryogenic Liquids<br />

5.10 Moving Cylinders<br />

5.11 Material <strong>Safety</strong> Data Sheet (MSDS)<br />

5.12 Labelling<br />

6. Fire Hazards 24<br />

6.1 How To Use an Extinguisher<br />

6.2 Sand / Absorbent Material<br />

6.3 Sprinklers<br />

7. Storage Handling 28<br />

7.1 Type <strong>of</strong> Cabinets<br />

7.2 Refrigerators<br />

7.3 Eye Wash Station<br />

7.4 First Aid Kit<br />

7.5 Emergency<br />

7.6 Fire Drill<br />

3<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

8. Incident, Hazard Reporting and Identification 30<br />

9. Electrical Hazards 30<br />

10. Noise 30<br />

11. Ionising Radiation 30<br />

11.1 Principles <strong>of</strong> Ionizing Radiation Protect<br />

12. Housekeeping 31<br />

13. Worksite Inspection 32<br />

14. Training 32<br />

Appendix 1 33<br />

Appendix 2 34<br />

Appendix 3 35<br />

Appendix 4 36<br />

Appendix 5 37<br />

Appendix 6 38<br />

Appendix 7 40<br />

Appendix 8 41<br />

Appendix 9 42<br />

4<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

<strong>Swinburne</strong> <strong>University</strong> <strong>of</strong> Technology (Sarawak Campus) strives to ensure safety and health <strong>of</strong><br />

persons at the <strong>University</strong> and protecting others from safety and health risks in connection to<br />

the activities at the <strong>University</strong>.<br />

The School <strong>of</strong> Engineering & Science (SoES) at the <strong>University</strong> fully embraces the<br />

<strong>University</strong>’s commitment to ensure safe and healthy teaching, learning and research<br />

environment at the School.<br />

This document provides the guidelines for good Occupational <strong>Safety</strong> and Health practices to be<br />

followed by staff, student and visitor at the SoES.<br />

REFERENCES<br />

Name<br />

Occupational <strong>Safety</strong><br />

and Health, 1994<br />

Location<br />

http://www.dosh.gov.my/doshV2/index.php?option=com_phocadownload&view=c<br />

ategory&id=6%3Aregulations-under-occupational-safety-and-health-act-1994-act-<br />

514&Itemid=99&lang=en<br />

WHO <strong>Laboratory</strong><br />

Biosafety <strong>Manual</strong> (3 rd<br />

Edition)<br />

Princeton <strong>University</strong><br />

http://www.who.int/csr/resources/publications/biosafety/Biosafety7.pdf<br />

http://web.princeton.edu/sites/ehs/labsafetymanual/sec7f.htm<br />

<strong>University</strong> <strong>of</strong><br />

Wollongong<br />

http://www.uow.edu.au/content/groups/public/@web/@eng/documents/<br />

doc/uow062918.pdf<br />

John Hopkins<br />

<strong>University</strong><br />

1. Responsibilities<br />

Heads <strong>of</strong> Management units shall:<br />

<br />

<br />

<br />

<br />

http://www.civil.jhu.edu/current-undergraduatefacilities/JHU%20CE%20<strong>Laboratory</strong>%20<strong>Manual</strong>.pdf<br />

To ensure suitable OS&H policies and practices for civil, mechanical, electrical and chemical<br />

laboratories are developed, implemented and continuously improved.<br />

Ensure, as far as is reasonably practicable, that adequate financial provision is made available to<br />

implement the policies and practices<br />

Ensure that staff and students receive the appropriate information, instruction and training<br />

necessary for them to perform work safely;<br />

<strong>Laboratory</strong> Coordinator shall:<br />

Ensure that all staff and students receive an induction that includes information pertaining to<br />

emergency response procedures and personnel;<br />

5<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

Ensure that local occupational health and safety procedures are developed, documented and<br />

issued to staff and students as appropriate;<br />

<br />

Ensure that the facilities and equipment provided for staff and students are safe and suitable<br />

for the types <strong>of</strong> work to be carried out;<br />

<br />

Ensure that adequate financial provisions are made for occupational health and safety<br />

equipment and materials and the maintaining <strong>of</strong> occupational health and safety standards;<br />

<br />

Ensure that hazard identification and risk assessment procedures are developed,<br />

documented and maintained for the use, handling, storage, transport and disposal <strong>of</strong><br />

equipment, materials and substances and that appropriate risk controls are implemented and<br />

maintained<br />

<br />

To work with the different university departments (facilities, ITS, admin) to ensure OS&H quality.<br />

Staff & Students shall:<br />

<br />

<br />

<br />

<br />

Take reasonable care for their own health & safety, and for the health & safety <strong>of</strong> anyone else who<br />

may be affected by their acts or omissions in the work / study environment.<br />

Follow local arrangements / guidelines developed under this manual and any other additional<br />

requirements or procedures set out by the school.<br />

Report any hazards, incidents / near misses or injury / illness to the laboratory support staff<br />

Attend / participate in any safety training provided.<br />

Staff shall :<br />

Be alert to unsafe conditions and actions, and call attention to them so that<br />

corrections can be made as soon as possible.<br />

<br />

<br />

<br />

<br />

<br />

<br />

Label all storage areas, refrigerators, cabinets, etc. appropriately and keep all<br />

chemicals in properly labelled containers.<br />

Develop and implement a specific OS&H strategy within individual laboratories.<br />

Inform all staff & student <strong>of</strong> the specific hazards (chemicals, equipment) present in<br />

the laboratory and carry out the necessary steps to keep these hazards at bay.<br />

Analyse OS&H risk for all processes in the laboratory.<br />

Prepare Material <strong>Safety</strong> Data Sheets for chemicals available in laboratories.<br />

Obtain advice from Health and <strong>Safety</strong> Executive for the use <strong>of</strong> high-risk chemicals<br />

or equipment and the relevant procedures as required.<br />

The Health and <strong>Safety</strong> Executive shall:<br />

<br />

<br />

<br />

6<br />

Assist Head <strong>of</strong> School and <strong>Laboratory</strong> Coordinator to ensure OHS training has been delivered to<br />

the appropriate personnel to enable them to fulfil their obligations under this manual.<br />

Disseminate information arising from lab hazard to staff and students<br />

Provide training and guidance to Heads <strong>of</strong> School, laboratory coordinator, staff and students<br />

pertaining to safety in the laboratory / workshop<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

2. General <strong>Laboratory</strong> / Workshop Practices<br />

1. No food and drinks are allowed in the laboratory at all time.<br />

2. No smoking in the laboratory.<br />

3. No horseplay in the laboratory.<br />

4. Only covered shoes are to be worn in the laboratory. Open sandals are not permitted.<br />

5. Shirt or blouse must be at least short sleeves and legs must be covered with long pants<br />

when working in laboratory. Students are not allowed to wear jewelry during laboratory classes /<br />

workshop practical.<br />

6. Long hair must be tied back to reduce fire or chemical hazards.<br />

7. Keep hands and other objects away from your face, nose, eyes, ears and especially mouth. Do<br />

not chew pens, etc.<br />

8. Place bags, books and other personal items in specified location. Never put them on the<br />

working area.<br />

9. Wear the appropriate PPE (e.g. safety glass or goggles) during the experiment / practical<br />

workshops. Everyone is responsible on their own PPE. Do not leave the PPE unused on the table<br />

or on the floor. Return the PPE in its designated location.<br />

10. Report all injuries, accidents and broken equipment immediately to your demonstrators.<br />

Never engaged in horseplay, pranks or other act <strong>of</strong> mischief in the laboratory.<br />

11. Students are NOT permitted to work in the laboratory / workshop unless the demonstrator or<br />

laboratory instructor is present.<br />

12. Familiarize yourself with the safety equipment (safety shower, emergency eyewash, fire<br />

blanket, and fire extinguisher) in the laboratory and emergency escape routes.<br />

13. The use <strong>of</strong> contact lenses is not advisable. Even when worn under safety goggles, various fumes<br />

may accumulate under the lens and cause serious injuries or blindness.<br />

Microbiology / Biology / Biochemistry <strong>Laboratory</strong> Practices and <strong>Safety</strong> Rules<br />

14. Wash your hands with disinfectants soap when you enter the laboratory and again before you<br />

leave the laboratory.<br />

15. <strong>Laboratory</strong> coats must be worn and buttoned in the laboratory.<br />

16. Disposable gloves and other protective equipment (safety glass or goggles) have to be worn<br />

during the experiment.<br />

17. Thick insulated gloves must be worn to remove items from hot water baths. The lids <strong>of</strong> water<br />

baths must be opened such that the opening is away from the user. Never put a hand into the<br />

water baths to check for temperature. Use a thermometer.<br />

18. Working area must be disinfected with 70% ethanol at the beginning <strong>of</strong> the practical session<br />

and again when you have finished the exercises.<br />

19. Do not work with an uncovered cut. Bandages and gloves are available if needed.<br />

7<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

20. Be careful around Bunsen burner. Turn the burner on only when you are ready to use it and turn<br />

it <strong>of</strong>f immediately after use even if you have to use it for several short intervals. Blue flame <strong>of</strong><br />

Bunsen burner is <strong>of</strong>ten difficult to see.<br />

21. All cultures should be handled as being potentially pathogenic and the following precautions<br />

should be observed at all times:<br />

a) Label all materials and cultures with your name, date and any other applicable<br />

information (e.g., media, organism and etc)<br />

b) Cultures must always be carried in a test tube rack when moving around the<br />

laboratory.<br />

c) Cultures must be kept in a test tube rack on the bench tops when not in use.<br />

d) Inoculating loops and needles should be flame sterilized in a Bunsen burner before<br />

you lay them on the bench top.<br />

e) Do not walk around the laboratory with loops or pipettes containing infectious<br />

materials.<br />

f) Never pipette anything by mouth including broth cultures and water. Always use the<br />

pipetting devices.<br />

g) Report any chemical or biological fluid spillages to your demonstrators. Do not attempt<br />

to clean the spillages yourself.<br />

h) Never take cultures out <strong>of</strong> the laboratory unless absolute necessary.<br />

22. Note the hazard code on the bottle when handling chemicals and take the appropriate precautions<br />

indicated. Read all labels on chemicals twice before using them in the laboratory.<br />

23. Never leave sharp items (knives, forceps, surgical blades and needles) on the workbench<br />

which can hurt yourself or someone. All sharp instruments must remain in their wrappings until you<br />

are ready to use it.<br />

24. Removal <strong>of</strong> equipment and media from laboratory is prohibited without written permission <strong>of</strong><br />

the demonstrators or laboratory instructors.<br />

25. Dispose waste into their proper containers. (see Biohazard Waste Disposal below).<br />

26. Do not pour anything down the sink. Autoclave liquids and broth cultures to sterilize them<br />

before discarding them.<br />

27. Dispose all solid waste materials in a biohazard bag and autoclave them before discarding in<br />

the regular trash.<br />

28. Glassware should be washed with soap and water, and then rinsed with distilled water.<br />

29. Return all chemicals, reagents, culture and glassware to their appropriate places.<br />

Handling Life Culture<br />

30. Treat all microorganisms as if they were harmful. Use antiseptic procedures, as directed by your<br />

lecturer when working with microbes. Dispose <strong>of</strong> microbes as your lecturer directs.<br />

31. Treat living organisms carefully. Do not cause pain, discomfort, or injury to an organism. Follow<br />

your lecturer's directions when handling animals. Wash your hands thoroughly after handling<br />

animals or their cages.<br />

8<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

Preparation for Lab Work<br />

32. Prepare for the experiment by reading all <strong>of</strong> the directions before you start the lab. Be sure you<br />

understand all directions. Discuss the procedures with your lab partner or team. Assign specific<br />

tasks to individuals, especially if time is a factor in the procedure.<br />

33. Before you begin work, make sure that you know how to operate the equipment that will be used in<br />

the experiment.<br />

34. After you have completed your work, turn <strong>of</strong>f all equipment and clean your work area. Return all<br />

equipment and materials to the place that you got them. Report any broken or missing equipment.<br />

35. Keep hands away from your face, eyes, mouth and body while using chemicals or preserved<br />

specimens. Wash your hands before and after each experiment.<br />

36. Perform only those experiments authorized by your teacher. Never do an experiment that is not<br />

called for in the laboratory procedures or your instructor.<br />

37. Do not work alone in the lab. When entering the room, do not touch any equipment, chemicals or<br />

other materials in the laboratory area until you are instructed to do so.<br />

38. Experiments must be personally monitored at all times. You will be assigned a laboratory station<br />

at which to work. Do not wander around the room, distract other students, or interfere with the<br />

laboratory experiments <strong>of</strong> others.<br />

Handling Chemicals, Equipment & Glassware<br />

39. Read the labels on chemical containers twice. Label all containers into which you put materials.<br />

40. Do not touch, taste, or smell chemicals unless directed to by your lecturer. Waft fumes toward<br />

your nose by waving your hand over the mouth <strong>of</strong> the container if directed to smell a chemical.<br />

41. Take only what you need to avoid the contamination <strong>of</strong> chemicals. Do not return unused chemicals<br />

to the bottle. Dispose <strong>of</strong> chemicals only as directed by your lecturer.<br />

42. Always pour acid into water; never pour water into acid.<br />

43. Do not use your mouth to draw liquids into a pipette; use a pipette bulb.<br />

44. Never point the open end <strong>of</strong> a heated test tube toward yourself or anyone else.<br />

45. Do not use cracked, chipped, scored, or badly scratched glassware.<br />

46. Never handle broken glass with your bare hands.<br />

47. Allow plenty <strong>of</strong> time for hot glass to cool before touching it. It shows no visible signs <strong>of</strong> its<br />

temperature, and can cause painful burns.<br />

48. Learn the names <strong>of</strong> the equipment and glassware you use so there is no misunderstanding.<br />

49. Handle all equipment as directed. Note safety precautions in the instructions for your experiments.<br />

50. Handle all sharp instruments with extreme care. Never try to catch falling sharp instruments<br />

51. Do not stir solutions with a thermometer; use a glass stirring rod. If a thermometer breaks, inform<br />

your teacher at once. Do not touch the mercury from broken mercury thermometers.<br />

52. Take extreme care not to spill materials in the lab. Report all spills immediately, and follow your<br />

9<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

lecturer’s directions for cleaning them up. Keep your lab area neat and clean.<br />

53. Never use an open flame in Biology lab. Use tongs or a clamp to pick up hot containers. Test the<br />

temperatures <strong>of</strong> equipment and containers that have been heated by placing the back <strong>of</strong> your hand<br />

near any object before picking it up. If you can feel heat, the object might be too hot to handle.<br />

54. Dispose <strong>of</strong> materials only as directed. Do not pour chemicals or other solids into a sink or put<br />

specimens or their parts into the trash or sink.<br />

Access to <strong>Laboratory</strong> / Workshop<br />

55. Permitted lab users got no authorisation to allow other people (i.e. friends, family, group members)<br />

to enter the laboratory to joint in/help out the experiment, or for leisure purposes. Official written<br />

permission is required if more members are needed to conduct the experiment. Existing user may<br />

only grant enter permission to others for purpose <strong>of</strong> collecting and sending in samples to the<br />

laboratory, but general safety codes must be strictly followed.<br />

Working Alone<br />

56. Working alone refers to situations where people may be exposed to risks because:<br />

• the area they are working in is remote from others or isolated from the assistance <strong>of</strong> others<br />

because the nature, time or location <strong>of</strong> their work; or<br />

• it involves the operation or maintenance <strong>of</strong> equipment, or the handling <strong>of</strong> a hazardous<br />

substance; or<br />

• the work is dangerous for a person to perform alone<br />

Where any <strong>of</strong> the above is applicable, working alone must be avoided.<br />

For working alone, the following apply:<br />

• Staff and students may work alone in <strong>of</strong>fice environments, however, they must have<br />

completed the after hours access permission from laboratory support staff.<br />

• Staff and students must not work alone in workshops/laboratories where medium to high<br />

risk equipment is to be used.<br />

• Emergency assistance – refer to the Emergency poster for important contacts.<br />

Chemistry / Biochemistry <strong>Laboratory</strong> Practices and <strong>Safety</strong> Rules<br />

57. Wear disposable gloves or safety glasses when appropriate.<br />

58. Use UV goggles and protective clothing when work with UV light box. This is to minimize the<br />

risk or exposure to the UV light.<br />

59. Thick insulated gloves must be worn to remove items from hot water baths. The lids <strong>of</strong> water<br />

baths must be opened such that the opening is away from the user. Never put a hand into the<br />

water baths to check for temperature. Use a thermometer.<br />

60. Appropriate protective gloves must be worn for removing or placing items into freezers and<br />

while using liquid nitrogen.<br />

10<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

61. Do not touch the hot plate directly to find out whether it is hot.<br />

62. Do not work with an uncovered cut. Bandages and gloves are available if needed.<br />

63. Be careful around Bunsen burner. Turn the burner on only when you are ready to use it and turn<br />

it <strong>of</strong>f immediately after use even if you have to use it for several short intervals. Blue flame <strong>of</strong><br />

Bunsen burner is <strong>of</strong>ten difficult to see.<br />

64. Mouth pipetting is prohibited under all circumstances.<br />

65. Note the hazard code on the bottle when handling chemicals and take the appropriate<br />

precautions indicated. Read all labels on chemicals twice before using them in the laboratory.<br />

66. Keep all noxious and volatile chemicals in the fume hood.<br />

67. Do not dispose hazardous or noxious chemicals into the sink. All chemicals are to be<br />

disposed in waste containers. Pay attention to the waste container labels before adding the<br />

chemical to be discarded<br />

68. Always add acids to water and never water to acids.<br />

69. When using reagent, replace the lid immediately after used. Never return unused reagents to<br />

the stock bottles. Take only the amount needed for the experiment.<br />

70. Use caution when testing for odors. Never inhale the fumes directly. Waft them towards your<br />

nose carefully.<br />

71. Never leave sharp items (knives, forceps, surgical blades and needles) on the workbench<br />

which can hurt yourself or someone. All sharp instruments must remain in their wrappings until you<br />

are ready to use it.<br />

72. Do not use force for inserting glass pipettes or Pasteur pipettes into the rubber bulbs or<br />

dispensers. These can break and cause severe cuts. Use the bulbs or dispensers <strong>of</strong> a size which<br />

is appropriate for the size <strong>of</strong> the pipettes.<br />

73. Do not use any electrical equipment with frayed wirer or connections. This is most dangerous<br />

and will cause electrical shocks.<br />

74. Dispose <strong>of</strong> all biological waste in appropriate receptacles. Living cultures have to be treated<br />

with Clorox bleach or autoclaved. Never toss them into regular trash or down the drains without<br />

autoclaving.<br />

75. Dispose waste into their proper containers. (see Biohazard Waste Disposal below)<br />

76. Removal <strong>of</strong> equipment and media from laboratory is prohibited without proper authorization.<br />

77. Glassware should be washed with soap and water, and then rinsed with distilled water.<br />

78. Return all chemicals, reagents, and glassware to their appropriate place.<br />

11<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

Engineering Workshop Practices and <strong>Safety</strong> Rules<br />

79. Attire: In the labs, students must wear appropriate cloths for the work being performed. Loose<br />

cloths and shorts are not allowed. Jewelry is prohibited during workshops.<br />

80. Toe Protection: Students must always wear closed-toe shoes in the labs. Sandals and heels are<br />

not allowed.<br />

81. Eye Protection: Flying objects, tools, and particles cause eye injuries. In addition to the proper use<br />

<strong>of</strong> machine guards and screens, eye protection such as safety glasses and goggles must be used<br />

during the work that may have potential hazard to eyes including sawing, cutting, drilling, grinding,<br />

etc. Pairs <strong>of</strong> safety glasses can be found with the laboratory support staff.<br />

82. Hand Protection: Students must wear safety gloves during the work that may have any hazard to<br />

hands (e.g., lifting heavy metal pieces). Pairs <strong>of</strong> gloves can be found with the laboratory support<br />

staff.<br />

83. Head Protection: While working on assembly <strong>of</strong> test setups and perform dynamic or destructive<br />

tests, students have to wear hard hat to protect their head. Hard hats can be found with the<br />

laboratory support staff.<br />

84. Mouth Protection: During the work that have potential risks for air quality such as soldering and<br />

painting, wear protection masks. Masks can be found with the laboratory support staff.<br />

85. Ear Protection: While using noisy power tools such as band saws, use ear plugs or protection to<br />

prevent ear injuries. Ear plugs can be found with the laboratory support staff.<br />

86. Common Sense: Use common sense to ensure safety <strong>of</strong> the work in the labs. If you are not sure<br />

about the safety <strong>of</strong> your work, never attempt. Ask the laboratory support staff.<br />

87. Awareness: If you observe a potentially dangerous act in the labs, report it to the laboratory<br />

coordinator or the laboratory support staff. It is your responsibility to reduce risks <strong>of</strong> injuries and<br />

accidents in the workshop.<br />

88. Electric Power: Read specifications <strong>of</strong> the devices prior to connecting power supplies. Use only the<br />

specified power supply. Securely cover extension cords to prevent accidental power loss.<br />

89. Hydraulic Power: Hydraulic systems used for actuators and loading frames are under high<br />

pressure. Before starting hydraulic pumps, always check that valves are closed and connections<br />

are clean. If leakage is found, stop the pump immediately and notify the laboratory support staff.<br />

90. Ventilation: Do not turn <strong>of</strong>f ventilation fans to keep the air in the labs clean. If extra ventilation is<br />

needed (e.g., in case <strong>of</strong> indoor painting), consult the laboratory support staff and arrange the<br />

schedule to perform the required work.<br />

91. Lifting and Moving Heavy Items: When lifting and moving <strong>of</strong> heavy items are required, students<br />

must consult the laboratory support staff. Do not attempt without presence <strong>of</strong> at least one <strong>of</strong> them.<br />

Use protection items and appropriate items such as overhead crane with an assistance <strong>of</strong><br />

laboratory support staff.<br />

12<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

3. Waste Handling<br />

3.1 Decontamination<br />

Steam autoclaving is the preferred method for all decontamination processes. Materials for<br />

decontamination and disposal should be placed in containers, e.g. autoclavable plastic bags, that are<br />

colour-coded to whether the contents are to be autoclaved and/or incinerated. Alternative methods<br />

may be envisaged only if they remove and/or kill microorganisms.<br />

Handling and disposal procedures for contaminated materials and wastes<br />

1. Non-contaminated (non-infectious) waste that can be used or recycled or disposed <strong>of</strong> a<br />

general “household waste”<br />

2. Contaminated (infectious) “sharps” – hypodermic needles, scalpels, knives and broken glass;<br />

these should always be collected in puncture-pro<strong>of</strong> containers fitted with covers and treated as<br />

infectious<br />

3. Contaminated material for decontamination by autoclaving and thereafter washing and reuse<br />

or recycling<br />

4. Contaminated material for autoclaving and disposal<br />

5. Contaminated material for direct incineration<br />

3.2 Biohazard Waste Disposal<br />

Dispose <strong>of</strong> items are indicated as below. Any question regarding the proper disposal, please ask your<br />

demonstrators or laboratory instructors.<br />

Table 1 : Biohazard Waste Disposal<br />

Material<br />

Agar slants with biological material<br />

Biological liquids<br />

Petri dishes and contaminated solids<br />

Broken glass (contaminated)<br />

Broken glass (not contaminated)<br />

Cotton swabs, Pasteur pipette, disposable<br />

tips, glass slides (contaminated)<br />

Method <strong>of</strong> disposal<br />

Place in autoclave bag and autoclave them<br />

before discard in trash can.<br />

Place in autoclave bag and autoclave them<br />

before discard in trash can.<br />

Place in autoclave bag and autoclave them<br />

before discard in trash can.<br />

Disinfected with disinfectant and then place<br />

in sharps container<br />

Sharps container<br />

Disinfectant container (beakers or cylinder)<br />

13<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

Needles, syringes, pipette, other types <strong>of</strong><br />

sharps<br />

Non-contaminated paper<br />

Sharps container<br />

Regular trash<br />

3.3 Chemicals Waste Disposal<br />

Dispose <strong>of</strong> items are indicated as below. Any question regarding the proper disposal, please consult<br />

the laboratory support staff for advice. In general, waste products may be disposed <strong>of</strong> in three ways:<br />

1. Chemicals that are toxic, or harmful to the environment, should be placed in the bins provided<br />

for their waste.<br />

2. Chemicals, which are mildly toxic, but not harmful to the environment, may be washed down<br />

the sinks located in the fume cupboards.<br />

3. Chemicals that are neither toxic nor harmful to the environment may be flushed down the<br />

sinks. In general you will be informed when this is safe to do so.<br />

4. Do not put acidic or basic waste (pH 9) in metal cans. Metal cans corrode in a very<br />

short time. Keep acids and bases separate from hydrocarbons and ethers.<br />

5. When possible, keep all carcinogens/mutagens/teratogens separate from other waste. Keep<br />

aqueous wastes separate from organic solvents. Keep halogenated solvents and wastes<br />

separate from non-halogenated solvents. DO NOT FILL CONTAINERS TO THE TOP. Fill<br />

plastic carboys ONLY to the fill line. Leave about 50 mm at the top <strong>of</strong> all other containers. All<br />

waste must reside in closed, non-leaking containers. Do not use flasks or test tubes with<br />

stoppers, beakers with parafilm, or bottles with ground glass stoppers. The outside <strong>of</strong> the<br />

waste container must be reasonably clean.<br />

6. Do not put liquids (especially phenol) in bottles designed for solids. They leak!<br />

7. All chemical waste containers must remain CLOSED (capped).<br />

For proper chemical disposal, please refer to Material <strong>Safety</strong> Data Sheet (MSDS) prepared in the lab.<br />

3.4 Sharps<br />

After use, hypodermic needles should not be recapped, clipped or removed from disposable syringes.<br />

The complete assembly should be placed in a sharps disposal container. Disposable syringes, used<br />

alone or with needles, should be placed in sharps disposal containers and incinerated, with prior<br />

autoclaving if required.<br />

Sharps disposal containers must be puncture-pro<strong>of</strong>/-resistant and must not be filled to capacity. When<br />

they are three quarters full they should be placed in “infectious waste” containers and incinerated, with<br />

prior autoclaving if laboratory practice requires it. Sharps disposal containers must not be discarded in<br />

landfills.<br />

3.5 Contaminated (Potentially Infectious) Materials for Autoclaving and Reuse<br />

No pre-cleaning should be attempted <strong>of</strong> any contaminated (potentially infectious) materials to be<br />

autoclaved and reused. Any necessary cleaning or repair must be done only after autoclaving or<br />

disinfection.<br />

3.6 Contaminated (Potentially Infectious) Materials for Disposal<br />

Apart from sharps, which are dealt with above, all contaminated (potentially infectious) materials<br />

14<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

should be autoclave in leakpro<strong>of</strong> containers, e.g. autoclavable, colour-coded plastic bags, before<br />

disposal.<br />

4. Personal Protective Equipment (PPE)<br />

4.1 <strong>Laboratory</strong> Coats, Gowns, Coveralls, Aprons<br />

<strong>Laboratory</strong> coats should preferably be fully buttoned. Aprons may be worn over laboratory coats<br />

or gowns where necessary to give further protection against spillage <strong>of</strong> chemicals or biological<br />

materials such as blood or culture fluids.<br />

Different clothing materials protect against different elements:<br />

Type <strong>of</strong> Material<br />

Function<br />

Cotton - protects against flying objects, sharp or rough edges,<br />

and is a good fire retardant.<br />

Synthetic Fibres - protect against sparks, infrared and ultraviolet radiation.<br />

However, synthetic fibre lab coats can adversely magnify<br />

the effects <strong>of</strong> some laboratory hazards. For instance, some<br />

solvents may dissolve particular classes <strong>of</strong> synthetic fibres,<br />

thereby diminishing the protective ability <strong>of</strong> the coat.<br />

In addition, on contact with flames, some synthetic fibres<br />

will melt. This molten material can cause painful skin burns<br />

and release irritating fumes.<br />

Wool - protects against splashes <strong>of</strong> molten materials,<br />

small quantities <strong>of</strong> acid, and small flames.<br />

Aluminised and<br />

Reflective Clothing<br />

- protect against radiant heat<br />

Table 2 : Clothing Materials<br />

4.2 Goggles, <strong>Safety</strong> Spectacles, Face Shields<br />

The choice <strong>of</strong> equipment to protect eyes and face from splashes and impacting objects will<br />

depend on the activity performed. Prescription or plain eye glasses can be manufactured with<br />

special frames that allow lenses to be placed in frame from the front, using shatterpro<strong>of</strong> material<br />

either curved or fitted with side shields (safety glasses).<br />

<strong>Safety</strong> spectacles do not provide for adequate splash protection even when side shields are<br />

worn with them. Goggles for splash and impact protection should be worn over normal<br />

prescription against biological or chemical hazards). Face shields (visors) are made <strong>of</strong><br />

shatterpro<strong>of</strong> plastic, fit over the face and are held in place by head straps or caps.<br />

Goggles, safety spectacles, or face shields should not be worn outside the laboratory areas.<br />

4.3 Respirators<br />

Respiratory protection may be used when carrying out high-hazard procedures (e.g. cleaning up<br />

a spill <strong>of</strong> infectious material). The choice <strong>of</strong> respirator will depend on the type <strong>of</strong> hazard (s).<br />

Respirators are available with interchangeable filters for protection against gases, vapours,<br />

particulates and microorganisms. It is imperative that the filter is fitted in the correct type <strong>of</strong><br />

respirator. To achieve optimal protection, respirators should be individually fitted to the<br />

operator’s face and tested. Fully self-contained respirators with an integral air supply provide full<br />

protection. Advice should be sought from a suitably qualified person e.g. an occupational<br />

hygienist, for selection <strong>of</strong> the correct respirator. Surgical type masks are designed solely for<br />

patient protection and do not provide respiratory protection to workers.<br />

15<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

Respirators should not be worn outside the laboratory areas.<br />

4.4 Gloves<br />

Aside from acting as a shield between hands and hazardous materials, some<br />

gloves can also absorb perspiration and protect the hands from heat. Certain<br />

glove types can dissolve when in contact with solvents, it is important to take<br />

extra care in matching the protective glove with the nature <strong>of</strong> the job. Before<br />

use, check to make sure the gloves (especially latex gloves) are in good<br />

condition and free from holes, punctures and tears.<br />

Aside from acting as a shield between hands and hazardous materials, some<br />

gloves can also absorb perspiration and protect the hands from heat. Certain<br />

glove types can dissolve when in contact with solvents, it is important to take<br />

extra care in matching the protective glove with the nature <strong>of</strong> the job. Before<br />

use, check to make sure the gloves (especially latex gloves) are in good<br />

condition and free from holes, punctures and tears.<br />

When working with extremely corrosive material, wear thick gloves. Take extra<br />

precaution in checking for holes, punctures, and tears.<br />

Care should be taken when removing gloves. Peel the glove <strong>of</strong>f the hand,<br />

starting at the wrist and working toward the fingers. Keep the working surface<br />

<strong>of</strong> the glove from contacting skin during removal. Disposable gloves should be<br />

discarded in designated containers (e.g. regulated medical waste containers).<br />

Type <strong>of</strong> Gloves<br />

Function<br />

Plastic - protects against light corrosives and irritants<br />

Latex - provides light protection against irritants<br />

(some people can<br />

have an allergic reaction to latex which can lead to a<br />

serious medical<br />

condition).<br />

Natural Rubber - protects against light corrosive material and electric<br />

shock.<br />

Neoprene - for working with solvents, oils, or light corrosive<br />

material.<br />

Cotton - absorbs perspiration, keeps objects clean,<br />

provides some fire<br />

retarding properties.<br />

Zetex - when handling small burning objects. These<br />

are a good<br />

replacement for asbestos gloves.<br />

Asbestos - BANNED<br />

Table 3 : Type <strong>of</strong> Gloves<br />

16<br />

Disposable microbiologically approved latex, vinyl or nitrile surgical-type gloves are used widely<br />

for general laboratory work, and for handling infectious agents and blood and body fluids.<br />

Reusable gloves may also be used but attention be given to their correct washing, removal,<br />

cleaning and disinfection.<br />

Gloves should be removed and hands thoroughly washed after handling infectious materials,<br />

working in a biological safety cabinet and before leaving the laboratory. Used disposable gloves<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

should be discarded with infected laboratory wastes.<br />

4.5 Foot Protection<br />

a. Foot protection is designed to prevent injury from corrosive chemicals, heavy objects,<br />

electrical shock, as well as giving traction on wet floors. If a corrosive chemical or heavy<br />

object were to fall on the floor the most vulnerable portion <strong>of</strong> the body would be the feet. For<br />

this reason shoes that COMPLETELY COVER AND PROTECT the foot are recommended.<br />

b. Fabric shoes, such as tennis shoes absorb liquids readily. If chemicals happen to spill onto<br />

fabric shoes, remove the footwear immediately.<br />

c. When selecting footwear for the laboratory or workshop, choose sturdy leather shoes that<br />

cover the foot, these will provide the best protection.<br />

d. The following shoe types should not be worn in the laboratory/workshop:<br />

i. Sandals<br />

ii. Thongs<br />

iii. Clogs<br />

High heels shoes that expose the foot IN ANY WAY<br />

e. The following are recommended types <strong>of</strong> footwear:<br />

i. <strong>Safety</strong> Toe Shoes (steel-toed) --protect against crushing injuries caused by impact from<br />

any object during work activities (e.g., lifting heavy objects, using power tools, etc.).<br />

ii.<br />

Treated shoes, Rubber Boots or Plastic Shoe Covers --protect against corrosive<br />

chemicals.<br />

iii.<br />

Insulated Shoes – when welding they will protect against electric shock.<br />

4.6 Ear Protection<br />

Ear protection should be worn where the noise level is above 85 decibels<br />

(dB). Areas where excessive noise is present should be posted with signs<br />

indicating ear protection is required.<br />

Ear protectors should be readily available and composed <strong>of</strong> rubber or plastic.<br />

Types <strong>of</strong> ear protection include:<br />

i. Earplugs --provide basic protection to seal the ear against noise and<br />

are to be disposed <strong>of</strong> after use.<br />

ii. Ear muffs --provide extra protection against noise and are more<br />

comfortable than earplugs and are recommended for prolong use.<br />

iii. Cotton inserts --are poor suppressers <strong>of</strong> noise and should be avoided.<br />

17<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

4.7 Head Protection<br />

a. Some environments within the <strong>University</strong> and <strong>of</strong>f site have the potential for falling or flying<br />

objects. In these situations, appropriate head protection will protect workers from impacts,<br />

penetration by falling and flying objects, electric shock and burns.<br />

b. Unrestrained long hair can be hazardous the use <strong>of</strong> caps, elastic bands or hair nets will<br />

prevent the hair from coming into contact with instruments/machinery parts or flame-producing<br />

sources.<br />

5. Hazardous Chemicals<br />

Routes <strong>of</strong> exposure<br />

Exposure to hazardous chemicals may occur by:<br />

1. Inhalation<br />

2. Contact<br />

3. Ingestion<br />

4. Needle-sticks<br />

5. Through broken skin<br />

5.1 Store <strong>of</strong> Chemicals<br />

Only amounts <strong>of</strong> chemicals necessary for daily use should be stored in the laboratory.<br />

Bulk stocks should be kept in specially designated rooms or buildings.<br />

Chemicals should not be stored in alphabetical order.<br />

5.2 General rules regarding chemical incompatibilities<br />

To avoid fire and/or explosions, substances below should be stored and handled so that<br />

they cannot come into contact with the corresponding substances in the right-hand<br />

column <strong>of</strong> the table.<br />

Substance Category<br />

Alkali metals, e.g.<br />

sodium, potassium,<br />

caesium and lithium<br />

Incompatible Substances<br />

Carbon dioxide, chlorinated<br />

hydrocarbons, water<br />

Halogens<br />

Acetic acid, hydrogen<br />

sulphide, aniline,<br />

hydrocarbons,<br />

sulphuric acid<br />

Ammonia, acetylene, hydrocarbons<br />

Oxidizing agents, e.g. chromic acid,<br />

nitric acid, peroxides,<br />

permanganates<br />

Table 4 : Chemical Incompatibilities<br />

18<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

5.3 Toxic effects <strong>of</strong> Chemicals<br />

Some chemicals adversely affect the health <strong>of</strong> those who handle them or inhale their<br />

vapours. Apart from overt poisons, a number <strong>of</strong> chemicals are known to have various<br />

toxic effects. The respiratory system, blood, lungs, liver, kidneys and the gastrointestinal<br />

system, as well as other organs and tissues may be adversely affected or seriously<br />

damaged. Some chemicals are known to be carcinogenic or teratogenic.<br />

Some solvent vapours are toxic when inhaled. Apart from the more serious effects noted<br />

above, exposure may result in impairments that show no immediate discernible effects<br />

on health, but can include lack <strong>of</strong> coordination, drowsiness and similar symptoms,<br />

leading to an increased proneness to accident.<br />

Prolonged or repeated exposure to the liquid phase <strong>of</strong> many organic solvents can result<br />

in skin damage. This may be due to a defatting effect, but allergic and corrosive<br />

symptoms may also arise.<br />

5.4 Explosive Chemicals<br />

Azides, <strong>of</strong>ten used in antibacterial solutions, should not be allowed to come into contact<br />

with copper or lead (e.g. in waste pipes and plumbing), as they may explode violently<br />

when subjected even to a mild impact.<br />

Ethers that have aged and dried to crystals are extremely unstable, and potentially<br />

explosive.<br />

Perchloric acid, if allowed to dry on woodwork, brickwork or fabric, will explode and<br />

cause a fire on impact.<br />

Picric acid and picrates are denoted by heat and impact.<br />

5.5 Chemical Spills<br />

Most manufacturers <strong>of</strong> laboratory chemicals issue charts describing methods for dealing<br />

with spills. Spillage charts and spillage kits are also available commercially. Appropriate<br />

charts should be displayed in a prominent position in the laboratory. The following<br />

equipment should also be provided:<br />

1. Chemical spill kits<br />

2. Protective clothing<br />

3. Scoops and dustpans<br />

4. Forceps for picking up broken glass<br />

5. Mops, clothes and paper towels<br />

6. Buckets<br />

7. Soda ash (sodium carbonat) or sodium bicarbonate for neutralizing acids and<br />

corrosive chemcials<br />

8. Sand<br />

9. Non-flammable detergent<br />

19<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

The following actions should be taken in the event <strong>of</strong> a significant chemical spill.<br />

1. Notify the appropriate safety <strong>of</strong>ficer<br />

2. Evacuate non-essential personnel from the area<br />

3. Attend to persons who may have been contaminated<br />

4. If the spilled material is flammable, extinguish all open flames, turn <strong>of</strong>f gas in the<br />

room and adjacent areas, open windows (if possible) and switch <strong>of</strong>f electrical<br />

equipment that may spark<br />

5. Avoid breathing vapour from spilled material<br />

6. Establish exhaust ventilation if it is safe to do so<br />

7. Secure necessary items to clean up the spill<br />

5.6 Compressed and Liquefied Gases<br />

Container<br />

Compressed<br />

gas cylinders<br />

and liquefied<br />

gas containers<br />

Small, singleuse<br />

gas<br />

cylinders<br />

Storage Information<br />

Should be securely fixed (e.g.<br />

chained) to the wall or a solid bench<br />

so that they are not inadvertently<br />

dislodged<br />

Must be transported with their caps in<br />

place and supported on trolleys<br />

Should be stored in bulk in an<br />

appropriate facility at some distance<br />

from the laboratory. This area should<br />

be locked and appropriately<br />

identified.<br />

Should not be placed near radiators,<br />

open flames other heat sources,<br />

sparking electrical equipment, or in<br />

direct sunlight.<br />

Must not be incinerated<br />

The main high-pressure valve should be turned <strong>of</strong>f when the equipment is not in use and<br />

when the room is unoccupied.<br />

Rooms where flammables gas cylinders are used and/or stored should be identified by<br />

warning notices on the doors.<br />

20<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

Compressed gas containers may be labelled in five ways:<br />

Type <strong>of</strong> Gas<br />

Type <strong>of</strong> Label<br />

Flammable Gas labels show a flame on red label.<br />

Non-flammable<br />

Gas<br />

labels depict a gas canister on a<br />

green<br />

background.<br />

Poisonous Gas labels show skull and crossbones.<br />

Oxygencontaining<br />

Gas<br />

labels are designated by a flaming<br />

letter "O".<br />

Chlorine Gas labels are distinctly marked.<br />

Table 6 : Labelling <strong>of</strong> gas containers<br />

5.7 Handling <strong>of</strong> Cylinders<br />

1. The contents <strong>of</strong> the cylinder or compressed gas should be clearly marked and<br />

identified with proper labels or tags on the shoulder <strong>of</strong> the cylinder. Those<br />

cylinders or compressed gases that do not comply with identification<br />

requirements should be returned.<br />

2. If two labels are associated with one cylinder, affix the labels 180°apart on<br />

the shoulder <strong>of</strong> each cylinder. Label all empty cylinders EMPTY or MT and<br />

date the tag.<br />

3. All regulators, gauges, valves, manifolds, must be designed for the particular<br />

pressures and gases involved and should be checked regularly.<br />

4. All cylinders should be stored in cool, dry, well-ventilated surroundings and<br />

away from all flammable substances including oil, greases, and gasoline.<br />

5. Cylinders should not be located where objects may strike or fall on them.<br />

6. DO NOT use cylinders for rolling, supports, or any purpose other than the<br />

transportation and supply <strong>of</strong> gas.<br />

7. Cylinders should not be stored in damp areas, or near salt, corrosive<br />

chemicals, fumes, heat, or direct sunlight. Store cylinders by gas type,<br />

separating oxidizing gases from flammable gases.<br />

8. All cylinders and compressed gases (full or empty) should be properly<br />

fastened and supported by straps, belts, buckles, or chains to prevent them<br />

from falling and causing bodily harm.<br />

9. A cylinder should only be moved while strapped to a wheel cart to ensure<br />

stability. When storing or moving cylinders, always attach safety caps.<br />

10. All cylinders should be checked for damage prior to use. DO NOT attempt to<br />

repair damaged cylinders. Damaged or defective cylinders, valves, etc., must<br />

be taken out <strong>of</strong> use immediately and returned to the manufacturer for repair.<br />

21<br />

11. Each regulator valve should be inspected annually. Never force valve or<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

egulator connections. Threads and the configuration <strong>of</strong> valve outlets are<br />

different for each family <strong>of</strong> gases to prevent mixing <strong>of</strong> incompatible gases.<br />

12. Open cylinder valves SLOWLY. Do not use a wrench to open or close a hand<br />

wheel type cylinder valve. If it cannot be operated by hand, the valve should<br />

be repaired.<br />

13. DO NOT subject any part <strong>of</strong> a cylinder to a temperature higher than 50 °C. DO<br />

NOT drop cylinders or permit them to strike anything violently. DO NOT<br />

SMOKE in areas where there are flammable gases. DO NOT extinguish a<br />

flame caused by a gas until the gas source has been shut <strong>of</strong>f. DO NOT place<br />

a cylinder where it may become part <strong>of</strong> an electrical circuit. DO NOT use<br />

lubrication on valve regulators.<br />

5.8 Cryogenic Liquids<br />

1. Cryogenic liquids have boiling points less than -73ºC (-100ºF). Liquid<br />

nitrogen, liquid oxygen and carbon dioxide are the most common<br />

cryogenic materials used in the laboratory. Hazards may include fire,<br />

explosion, embrittlement, pressure build up, frostbite and asphyxiation.<br />

2. Many <strong>of</strong> the safety precautions observed for compressed gases also apply<br />

to cryogenic liquids. Two additional hazards are created from the unique<br />

properties <strong>of</strong> cryogenic liquids:<br />

a. Extremely Low Temperatures –The cold boil-<strong>of</strong>f vapor <strong>of</strong><br />

cryogenic liquids rapidly freezes human tissue. Most metals<br />

become stronger upon exposure to cold temperatures, but<br />

materials such as carbon steel, plastics and rubber become brittle<br />

or even fracture under stress at these temperatures. Proper<br />

material selection is important. Cold burns and frostbite caused by<br />

cryogenic liquids can result in extensive tissue damage.<br />

b. Vaporization - All cryogenic liquids produce large volumes <strong>of</strong> gas<br />

when they vaporize. Liquid nitrogen will expand 696 times as it<br />

vaporizes. The expansion ratio <strong>of</strong> argon is 847:1, hydrogen is<br />

851:1 and oxygen is 862:1. If these liquids vaporize in a sealed<br />

container, they can produce enormous pressures that could<br />

rupture the vessel. (See Anecdotes for an account <strong>of</strong> such an<br />

incident.) For this reason, pressurized cryogenic containers are<br />

usually protected with multiple pressure relief devices.<br />

c. Vaporization <strong>of</strong> cryogenic liquids (except oxygen) in an enclosed<br />

area can cause asphyxiation. Vaporization <strong>of</strong> liquid oxygen can<br />

produce an oxygen-rich atmosphere, which will support and<br />

accelerate the combustion <strong>of</strong> other materials. Vaporization <strong>of</strong><br />

liquid hydrogen can form an extremely flammable mixture with air.<br />

5.9 Handling Cryogenic Liquids<br />

a. Most cryogenic liquids are odorless, colorless, and tasteless when<br />

vaporized. When cryogenic liquids are exposed to the atmosphere,<br />

the cold boil-<strong>of</strong>f gases condense the moisture in the air, creating a<br />

highly visible fog.<br />

b. Always handle these liquids carefully to avoid skin burns and frostbite.<br />

Exposure that may be too brief to affect the skin <strong>of</strong> the face or hands<br />

22<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

may damage delicate tissues, such as the eyes.<br />

c. Boiling and splashing always occur when charging or filling a warm<br />

container with cryogenic liquid or when inserting objects into these<br />

liquids. Perform these tasks slowly to minimize boiling and splashing.<br />

Use tongs to withdraw objects immersed in a cryogenic liquid.<br />

d. Never touch uninsulated pipes or vessels containing cryogenic liquids.<br />

Flesh will stick to extremely cold materials. Even nonmetallic materials<br />

are dangerous to touch at low temperatures.<br />

e. Use wooden or rubber tongs to remove small items from cryogenic<br />

liquid baths. Cryogenic gloves are for indirect or splash protection<br />

only, they are not designed to protect against immersion into<br />

cryogenic liquids.<br />

f. Cylinders and dewars should not be filled to more than 80% <strong>of</strong><br />

capacity, since expansion <strong>of</strong> gases during warming may cause<br />

excessive pressure build up.<br />

g. Check cold baths frequently to ensure they are not plugged with<br />

frozen material.<br />

5.10 Moving Cylinders<br />

1. The majority <strong>of</strong> accidents involving gas cylinders occur while moving them<br />

from one location to another. The following control measures should be used<br />

to reduce the potential for an accident:<br />

2. The use <strong>of</strong> purpose-built trolleys or other suitable devices for gas cylinder<br />

transportation.<br />

3. Securing the gas cylinder’s valve, disconnecting and removing associated<br />

distribution equipment<br />

4. Shutting the cylinder’s valve, disconnecting and removing associated<br />

distribution equipment.<br />

5. A requirement that only properly trained personnel are permitted to move<br />

cylinders.<br />

6. Use properly designed lifting equipment for the movement <strong>of</strong> larger gas<br />

cylinders.<br />

5.11 Material <strong>Safety</strong> Data Sheet (MSDS)<br />

a. Make sure every newly received chemical is accompanied with MSDS<br />

and the MSDS should be kept in a designated file dedicated for MSDS<br />

only.<br />

b. Staff and students should familiarise themselves with MSDS and the<br />

location <strong>of</strong> MSDS.<br />

c. For any incident involving chemicals that requires medical assistance,<br />

make sure to present the MSDS to the medical personnel and return the<br />

23<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

MSDS in the MSDS file.<br />

5.12 Labelling<br />

The following guidelines for all containers <strong>of</strong> hazardous materials / chemicals<br />

i. There should be an appropriate hazard warning for identification <strong>of</strong> materials /<br />

chemicals in the container<br />

ii.<br />

iii.<br />

iv.<br />

Name, address, and telephone number <strong>of</strong> the chemical manufacturer, importer, or<br />

responsible party<br />

Date <strong>of</strong> receipt or generation <strong>of</strong> the chemical<br />

<strong>Laboratory</strong> workers would not remove or deface labels on containers or<br />

hazardous chemicals<br />

v. When chemicals are transferred from the manufacturer’s original container to a<br />

secondary container, that new container should be appropriately labelled as to<br />

chemical identity and hazard warning (s)<br />

vi.<br />

The colour coding and distinctive graphics <strong>of</strong> a label based on the hazard<br />

classification<br />

a. Container labelling problems with both chemical materials and wastes are<br />

common<br />

b. Container labels get damaged and deteriorated<br />

The absence <strong>of</strong> labels or misleading labels can pose safety and health hazard and<br />

can be expensive. Expenses can result from:-<br />

a. Good chemical going unused<br />

b. Good chemical being thrown away<br />

c. Bad chemical being substituted from good chemical<br />

d. Lab analysis to establish identification and quality <strong>of</strong> chemical in<br />

unmarked container<br />

e. Lab analysis to determine hazardous waste characteristics<br />

> Write or print neatly. The label should be clear and easy to read.<br />

> Old labels should not be written over with new or different information. This makes<br />

the label confusing.<br />

> Replacement labels should completely cover the original label, or better, the<br />

original label should be removed.<br />

> Replacement labels should include all the information that was on the original<br />

label.<br />

> Labels for stock solutions should include at least the chemical name and<br />

concentration, as well as any serious hazards that may exist.<br />

> The dimension <strong>of</strong> label shall be as per Table 7.<br />

> Each danger symbol shall cover at least one tenth <strong>of</strong> the surface area <strong>of</strong> the label<br />

24<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

ut shall not be less than one square centimetre.<br />

Capacity <strong>of</strong> the<br />

package<br />

Dimension in millimetres<br />

Not exceeding three litres At least 52 x 74<br />

Greater than three litres but not<br />

exceeding 50 litres<br />

At least 74 x 105<br />

Greater than 50 litres but not<br />

exceeding 500 litres.<br />

At least 105 x 148<br />

Greater than 500 litres At least 148 x 210<br />

Table 7 : Dimension <strong>of</strong> Label<br />

6. Fire Hazards<br />

Fire warning, instructions and escape routes should be displayed prominently in each<br />

room and in corridors and hallways.<br />

Common causes <strong>of</strong> fires in laboratories are:<br />

1. Electrical circuit overloading<br />

2. Poor electrical maintenance<br />

3. Excessively long gas tubing or long electrical leads<br />

4. Equipment unnecessarily left switched on<br />

5. Equipment that was not designed for a laboratory environment<br />

6. Open flames<br />

7. Deteriorated gas tubing<br />

8. Improper handling and storage <strong>of</strong> flammable or explosive materials<br />

9. Improper segregation <strong>of</strong> incompatible chemicals<br />

10. Sparking equipment near flammable substances and vapours<br />

11. Improper or inadequate ventilation<br />

Fire fighting equipment should be placed near room doors and a strategic points in<br />

corridors and hallways. This equipment may include hoses, buckets and a fire<br />

extinguisher. Fire extinguishers should be regularly inspected and maintained, and their<br />

shelf-life kept up to date. Specific types and uses <strong>of</strong> fire extinguishers are as per below:<br />

Extinguishers are classified according to a particular fire type :<br />

25<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

Classification<br />

Fire Type<br />

TYPE A Combustibles wood, cloth, paper,<br />

rubber and plastics<br />

TYPE B Flammable Liquids oil, grease and<br />

paint thinners.<br />

TYPE C Energized Electrical Equipment<br />

electrophoresis.<br />

TYPE D Combustible Metals (magnesium,<br />

titanium, sodium, lithium, potassium)<br />

Table 8 : Classification <strong>of</strong> Fire Extinguisher<br />

FIRE EXTINGUISHER TYPE USE FOR DO NOT USE FOR<br />

Water<br />

Paper, wood,<br />

fabric<br />

Electrical fires,<br />

flammable<br />

liquids, burning<br />

Carbon dioxide<br />

Dry powder<br />

Foam<br />

Flammable<br />

liquids and<br />

gases, electrical<br />

fires<br />

Flammable<br />

liquid and<br />

gases, alkali<br />

metals,<br />

electrical fires<br />

Flammable<br />

materials<br />

Table 9 : Type <strong>of</strong> Extinguisher<br />

metals<br />

Alkali metals<br />

Extinguishers are identified by appropriate signage and securely located on the wall near<br />

an exit.<br />

All extinguishers should be inspected at least every 12 months for broken seals, damage,<br />

low gauge pressure or improper mounting. Units should be replaced or recharged if they<br />

have been used, damaged or discharged.<br />

Personal fire safety precautions: Never reach over the fire. Never allow the fire to get<br />

between you and the exit. Never enter an unknown area to fight a fire.<br />

<br />

<br />

<br />

Reusable<br />

equipment and<br />

instruments, as<br />

residues are<br />

very difficult to<br />

remove<br />

Electrical fires<br />

26<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

6.1 HOW TO USE AN EXTINGUISHER: Remember the "PASS" word.<br />

Steps<br />

PULL THE PIN:<br />

AIM:<br />

SQUEEZE:<br />

SWEEP:<br />

Fire Type<br />

Place your hand on the top <strong>of</strong> the cylinder and pull the<br />

pin. This will unlock the handle and allow you to activate<br />

the unit.<br />

Point the nozzle <strong>of</strong> the hose at the base <strong>of</strong> the fire.<br />

the handle (lever) releasing the fire fighting agent.<br />

the nozzle from side to side over the fire. Keep the<br />

nozzle/hose directed at the base <strong>of</strong> the flame. Empty the<br />

fire extinguisher onto the fire.<br />

Blankets <strong>Laboratory</strong> personnel are DISCOURAGED from using fire safety blankets as a<br />

means to extinguish a fire. Fire safety blankets should be used as a means to keep shock<br />

victims warm.<br />

6.2 Sand / Absorbent Material<br />

They are designed for fast and easy extinguishing <strong>of</strong> small fires in the<br />

laboratory. These materials should be stored in a handy dispenser<br />

appropriately labelled and used according to the type <strong>of</strong> fire.<br />

Do not use sand buckets as ashtrays.<br />

6.3 Sprinklers<br />

Sprinklers are automatically activated. Items in the lab should be stored at<br />

least 18 inches away from the sprinkler heads and should not hang from the<br />

sprinkler heads. Intense heat should not be used near the sprinkler heads.<br />

7. Storage Handling<br />

Both the chemical containers and cabinets should be properly labelled.<br />

Chemicals should NEVER be stored in alphabetical order (unless already<br />

separated out into compatible groups). This system may contribute to the high<br />

probability <strong>of</strong> incompatible materials being stored next to one another.<br />

Incompatible reagents should not be stored next to each other.<br />

The vent cap on chemical storage cabinets should not be removed from its<br />

location unless the cabinet is attached to an existing ventilation system.<br />

Material <strong>Safety</strong> Data Sheets for all hazardous chemicals must be made<br />

available and known to all.<br />

Glass containers should be stored on the bottom shelf <strong>of</strong> storage cabinets.<br />

27<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

7.1 Types <strong>of</strong> Cabinets<br />

Type <strong>of</strong> Cabinet<br />

Flammable<br />

liquid cabinets<br />

<br />

<br />

Function<br />

are designed for storage <strong>of</strong><br />

flammable or<br />

combustible liquids.<br />

<br />

Acid/corrosive<br />

cabinets<br />

are designed for corrosion<br />

resistance.<br />

Stage cabinets can be used for storage <strong>of</strong><br />

flammable and corrosive<br />

liquids outside the laboratory setting.<br />

<br />

Table 10 : Type <strong>of</strong> Cabinets<br />

A “<strong>Safety</strong> Can” is an approved container <strong>of</strong> no more than 20 litres capacity. It<br />

has a spring closing lid and spout cover and is designed to safely relieve<br />

pressure build-up within the container. Vent caps may be purchased for<br />

original manufacturer's glass containers to help minimize explosion hazards.<br />

7.2 Refrigerators<br />

a. While domestic refrigeration units are appropriate for keeping foods cold,<br />

they are not designed to meet the special hazards presented by<br />

flammable materials. Therefore, laboratory refrigerators should be<br />

carefully selected for specific chemical storage needs.<br />

b. To prevent potential safety hazards, the length <strong>of</strong> storage <strong>of</strong> any material<br />

should be kept to a minimum In addition, refrigerators should be<br />

periodically inspected.<br />

c. Each refrigerator, freezer or cooler is to be prominently labelled with<br />

appropriate hazard signs, e.g. “For Chemical Storage Only. No Food or<br />

Drink Allowed."<br />

d. If radioactive materials are to be stored, a refrigerator must be clearly<br />

labelled<br />

e. The containers placed in the refrigerator should be completely sealed or<br />

capped, securely placed, and permanently labelled. Avoid capping<br />

materials with aluminium foil, corks, and glass stoppers.<br />

f. Because ignitable vapours can build up in normal refrigerators, it is<br />

important to store materials in refrigerators that have self-contained<br />

electrical elements to avoid spark-induced explosions.<br />

g. Explosion-pro<strong>of</strong> refrigerators are specifically designed for hazardous<br />

environments, featuring enclosed motors to eliminate sparking.<br />

h. Refrigerators should be frost free to prevent water drainage .<br />

28<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

7.3 Eye Wash Station<br />

1. Eye wash stations provide an effective means <strong>of</strong> treatment when chemicals<br />

come in contact with the eyes<br />

2. Water/eye solutions should not be directly aimed onto the eyeball, but rather,<br />

aimed at the base <strong>of</strong> the nose. This increases the chance <strong>of</strong> effectively rinsing<br />

the eyes free <strong>of</strong> chemicals (harsh streams <strong>of</strong> water may drive particles further<br />

into the eyes).<br />

3. Eyelids may have to be forcibly opened to ensure effective washing behind<br />

the eyelid.<br />

4. Be sure to wash from the nose out to the ear this will avoid washing chemicals<br />

back into the eye or into an unaffected eye.<br />

5. Flood eyes and eyelids with water/eye solution for a minimum <strong>of</strong> 15 minutes.<br />

6. Remove contact lenses as soon as possible to rinse eyes <strong>of</strong> any harmful<br />

chemicals.<br />

7. Cover both <strong>of</strong> the victim's eyes with a clean or sterile gauze.<br />

8. Eye wash stations should be inspected every six months.<br />

9. Plumbed eye wash stations should have protective covers to protect nozzles<br />

from airborne contaminants.<br />

7.4 First Aid Kit<br />

For minor and major injury, notify the laboratory staff in the area and contact the First Aid<br />

Responders as per Appendix 3. First Aid Responders and Wardens are responsible to<br />

ensure the first aid contents in the first aid kit are being replenished frequently.<br />

7.5 Emergency<br />

Refer to Appendix 4 for the Emergency Procedure and Appendix 2 for the Emergency<br />

Numbers. Wardens’ contacts are posted in the Warden posters. Warden posters are<br />

located on each floor <strong>of</strong> the building in the campus.<br />

7.6 Fire Drill<br />

Participate in the <strong>University</strong>’s fire drill and cooperate with the Wardens for instructions.<br />

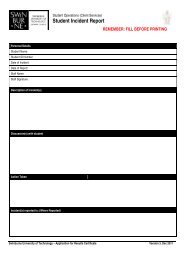

8.Incident, Hazard Reporting and Identification<br />

All incidents, near misses, hazards and injuries must be reported as soon as possible or<br />

within 24 hours to the laboratory support staff by the person who observed the hazard or<br />

who was involved in the incident. If circumstances prevent a person from making a report,<br />

a colleague, witness or the laboratory support staff has this responsibility.<br />

Where the incident involves a visitor, contractor, agency personnel or member <strong>of</strong> public,<br />

the relevant point <strong>of</strong> contact for the person within the university shall assist the person to<br />

make a report to the relevant laboratory support staff <strong>of</strong> the area.<br />

All incident, hazard or injury reports are to be recorded using <strong>Swinburne</strong>’s incident /<br />

29<br />

<strong>SoECS</strong> <strong>Laboratory</strong> <strong>Safety</strong> <strong>Manual</strong>

hazard report form.<br />

Section A for all incidents, hazards or near misses.<br />

Section B where an injury / illness has been sustained.<br />

9. Electrical Hazards<br />

It is essential that all electrical installations and equipment are inspected and tested<br />

regularly, including earthing / grounding systems.<br />

Circuit-breakers and earth-fault-interrupters should be installed in appropriate laboratory<br />

electrical circuits. Circuit-breakers do not protect people; they are intended to protect<br />

wiring from being overloaded with electrical current and hence to prevent fires. Earth-faultinterrupters<br />

are intended to protect people from electric shock.<br />

All laboratory electrical equipment should be earthed/grounded, preferably through threeprong<br />

plugs.<br />

All laboratory electrical equipment and wiring should conform to national electrical safety<br />

standards and codes.<br />

10. Noise<br />

The effect <strong>of</strong> excessive noise is insidious over time. Some types <strong>of</strong> laboratory equipment,<br />