Renold Clutches & Couplings - casa sueca s.a.

Renold Clutches & Couplings - casa sueca s.a.

Renold Clutches & Couplings - casa sueca s.a.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

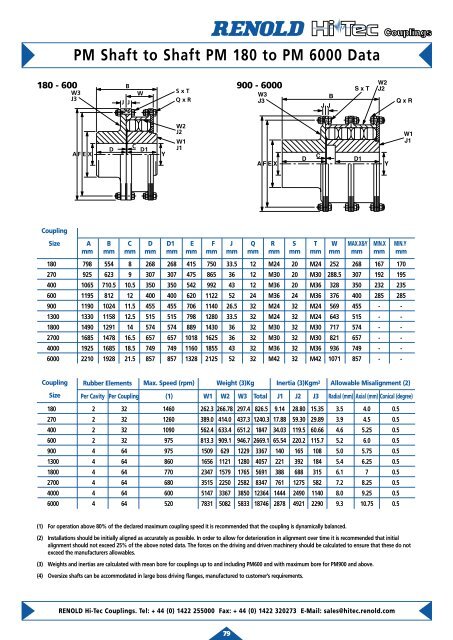

PM Shaft to Shaft PM 180 to PM 6000 Data<br />

180 - 600<br />

W3<br />

J3<br />

B<br />

J J<br />

W<br />

S x T<br />

Q x R<br />

900 - 6000<br />

W3<br />

J3<br />

JJ<br />

B<br />

S x T<br />

W2<br />

J2<br />

Q x R<br />

A F E X<br />

D<br />

C D1<br />

Y<br />

W2<br />

J2<br />

W1<br />

J1<br />

A F E X<br />

D<br />

C<br />

D1<br />

Y<br />

W1<br />

J1<br />

Coupling<br />

Size A B C D D1 E F J Q R S T W MAX.X&Y MIN.X MIN.Y<br />

mm mm mm mm mm mm mm mm mm mm mm mm mm mm mm mm<br />

180 798 554 8 268 268 415 750 33.5 12 M24 20 M24 252 268 167 170<br />

270 925 623 9 307 307 475 865 36 12 M30 20 M30 288.5 307 192 195<br />

400 1065 710.5 10.5 350 350 542 992 43 12 M36 20 M36 328 350 232 235<br />

600 1195 812 12 400 400 620 1122 52 24 M36 24 M36 376 400 285 285<br />

900 1190 1024 11.5 455 455 706 1140 26.5 32 M24 32 M24 569 455 - -<br />

1300 1330 1158 12.5 515 515 798 1280 33.5 32 M24 32 M24 643 515 - -<br />

1800 1490 1291 14 574 574 889 1430 36 32 M30 32 M30 717 574 - -<br />

2700 1685 1478 16.5 657 657 1018 1625 36 32 M30 32 M30 821 657 - -<br />

4000 1925 1685 18.5 749 749 1160 1855 43 32 M36 32 M36 936 749 - -<br />

6000 2210 1928 21.5 857 857 1328 2125 52 32 M42 32 M42 1071 857 - -<br />

Coupling Rubber Elements Max. Speed (rpm) Weight (3)Kg Inertia (3)Kgm 2 Allowable Misalignment (2)<br />

Size Per Cavity Per Coupling (1) W1 W2 W3 Total J1 J2 J3 Radial (mm) Axial (mm) Conical (degree)<br />

180 2 32 1460 262.3 266.78 297.4 826.5 9.14 28.80 15.35 3.5 4.0 0.5<br />

270 2 32 1260 389.0 414.0 437.3 1240.3 17.88 59.30 29.89 3.9 4.5 0.5<br />

400 2 32 1090 562.4 633.4 651.2 1847 34.03 119.5 60.66 4.6 5.25 0.5<br />

600 2 32 975 813.3 909.1 946.7 2669.1 65.54 220.2 115.7 5.2 6.0 0.5<br />

900 4 64 975 1509 629 1229 3367 140 165 108 5.0 5.75 0.5<br />

1300 4 64 860 1656 1121 1280 4057 221 392 184 5.4 6.25 0.5<br />

1800 4 64 770 2347 1579 1765 5691 388 688 315 6.1 7 0.5<br />

2700 4 64 680 3515 2250 2582 8347 761 1275 582 7.2 8.25 0.5<br />

4000 4 64 600 5147 3367 3850 12364 1444 2490 1140 8.0 9.25 0.5<br />

6000 4 64 520 7831 5082 5833 18746 2878 4921 2290 9.3 10.75 0.5<br />

(1) For operation above 80% of the declared maximum coupling speed it is recommended that the coupling is dynamically balanced.<br />

(2) Installations should be initially aligned as accurately as possible. In order to allow for deterioration in alignment over time it is recommended that initial<br />

alignment should not exceed 25% of the above noted data. The forces on the driving and driven machinery should be calculated to ensure that these do not<br />

exceed the manufacturers allowables.<br />

(3) Weights and inertias are calculated with mean bore for couplings up to and including PM600 and with maximum bore for PM900 and above.<br />

(4) Oversize shafts can be accommodated in large boss driving flanges, manufactured to customer’s requirements.<br />

RENOLD Hi-Tec <strong>Couplings</strong>. Tel: + 44 (0) 1422 255000 Fax: + 44 (0) 1422 320273 E-Mail: sales@hitec.renold.com<br />

79