AuSn Solder Sputtering Targets - Materion

AuSn Solder Sputtering Targets - Materion

AuSn Solder Sputtering Targets - Materion

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>AuSn</strong> <strong>Solder</strong><br />

<strong>Sputtering</strong> <strong>Targets</strong><br />

Microelectronics<br />

& services

Optimal <strong>AuSn</strong> Target Composition<br />

The Challenge<br />

New applications for LEDS and other products have<br />

increased the demand for solders deposited by PVD<br />

technology. The exact composition of <strong>AuSn</strong> solder<br />

is critical for flow, strength and device properties.<br />

The challenge is:<br />

■ You want the best possible ratio of Au to Sn in<br />

your deposited film to ensure optimal soldering.<br />

■ There are concerns about the loss of tin that occurs<br />

during the sputtering process.<br />

■ It is accepted practice to increase the amount<br />

of Sn in the sputtering target in order to<br />

off-set the loss of Sn during sputtering.<br />

■ Often 4 to 8 wt% of supplementary tin must be<br />

added to the sputtering target to achieve the<br />

desired ratio of Au to Sn in the deposited film.<br />

You want excellent thin film uniformity.<br />

The Solution<br />

<strong>Materion</strong>’s analytical support team can address your<br />

challenge! We will:<br />

■ Analyze your individual sputtering process,<br />

set-up and procedures.<br />

■ Optimize your manufacturing methods to control<br />

deposition power and chamber pressure.<br />

■ Partner with you to adjust and create an optimal<br />

composition of <strong>AuSn</strong> solder.<br />

■ Resolve the loss of Sn and achieve the highest quality<br />

final product.<br />

■ Improve thin film uniformity with our unique<br />

Patented VCT TM (Vibration Cast Technology) that<br />

produces consistent small grain sizes that ensure a<br />

uniform coating..<br />

The Benefits<br />

<strong>Materion</strong>’s innovative solution to your <strong>AuSn</strong> target challenge will:<br />

■ Determine the best target composition<br />

■ Effectively compensate for Sn loss<br />

■ Improve thin film uniformity<br />

■ Improve end product quality<br />

■ Reduce costs<br />

■ Customize manufacturing<br />

<strong>Materion</strong> provides <strong>AuSn</strong> sputtering targets manufactured with<br />

our VCT TM technology in a range of sizes, shapes and configurations<br />

to meet customer needs.

<strong>Materion</strong> Microelectronics & Services supplies thin film deposition materials, electronic<br />

packaging products, high purity and specialty materials, precision parts<br />

cleaning, and precious metals refining to the semiconductor, LED, photonics, data storage,<br />

wireless, military, medical and other demanding markets.<br />

Specifications<br />

■ Purity - We can achieve up to 4N’s 5 purity on various<br />

compositions of <strong>AuSn</strong><br />

■ Size - Rounds up to 13 inch diameter and rectangular up to 31”<br />

long. Also, various other shapes and configurations according<br />

to customer needs.<br />

■ Composition tolerance: Au-Sn composition held to ± 0.25.<br />

■ <strong>Targets</strong> can be metallically bonded and bond integrity verified<br />

by means of C-Scan<br />

Capabilities<br />

<strong>Materion</strong> provides enabling and advanced materials technologies<br />

and services that fully support the manufacturing of LEDs.<br />

■ Full array of materials, including Au, TiW, Cr, Pt, Pd, Cr and Ni.<br />

■ Newly developed <strong>AuSn</strong> and AuGe sputtering targets featuring<br />

our VCT TM technology.<br />

■ Other Au alloys<br />

Environmental Leadership and Compliance<br />

<strong>Materion</strong> complies with all state and federal regulations<br />

for disposal. Customers are invited to review or audit our<br />

manufacturing, environmental or financial policies and practices<br />

with respect to their refines. We are accredited:<br />

■ ISO 9001:2008 Quality System;<br />

■ ISO 14001:2004 Environmental & Safety<br />

Management System,<br />

■ ISO 17025:2005 Analytical Laboratory<br />

■ LeanSigma<br />

Other Related Services<br />

<strong>Materion</strong>’s full Metal Management service provides value-added cost<br />

solutions for by-products of thin film deposition processes including:<br />

■ Precision parts cleaning<br />

■ Chamber scrapings<br />

■ Scrap Wafers and materials<br />

■ Precious metal reclaim & refining<br />

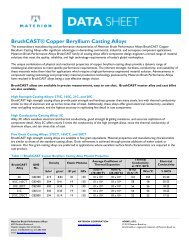

<strong>AuSn</strong> Phase Diagram<br />

Near the Eutectic Composition<br />

Calculated <strong>AuSn</strong> phase diagram (liquidus)<br />

Au % wt.<br />

81.50 81.00 80.50 80.00 79.50 79.00 87.50<br />

330<br />

320<br />

310<br />

300<br />

290<br />

280<br />

Composition<br />

after <strong>Solder</strong>ing<br />

Composition<br />

after Deposition<br />

270<br />

18.50 19.00 19.50 20.00 20.50 21.00 21.50<br />

Sn % wt.<br />

The liquidus slope of the hypo-eutectic (gold rich) solder is double<br />

that of the hyper-eutectic (tin rich) so gold rich solders will develop<br />

a wider melting range and a higher liquidus temperature rapidly and<br />

therefore will not solder properly. It is preferable for the deposited<br />

solder layer to begin as hyper-eutectic before soldering and end as<br />

hypo-eutectic after soldering.<br />

<strong>Materion</strong>...<br />

Smarter Solutions, Simplified Support and Stronger Relationships

<strong>Materion</strong> is a global advanced materials company, dedicated to providing solutions that enable our customers’ technologies and drive their growth. Our products include<br />

precious and non-precious specialty metals, precision optical filters, inorganic chemicals and powders, specialty coatings, specialty-engineered beryllium alloys, beryllium<br />

and beryllium composites, and engineered clad and plated metal systems. The <strong>Materion</strong> business is structured to enhance our ability to provide customers with innovative,<br />

best total-cost solutions.<br />

microelectronics & services<br />

2978 Main Street<br />

Buffalo, NY 14214<br />

Phone: +1 716.837.1000<br />

www.materion.com/microelectronics<br />

Europe: +44 1 488.686056<br />

Asia: +65 6559.4450<br />

materion corporation<br />

www.materion.com<br />

ME <strong>AuSn</strong> <strong>Solder</strong> Rev 04 02’12