Gelovit 200 - Bego USA

Gelovit 200 - Bego USA

Gelovit 200 - Bego USA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Gelovit</strong> <strong>200</strong><br />

Duplicating Unit<br />

BA 85 849/ 02<br />

313.00003 . . .<br />

(0421) 2028 - 272<br />

+49 421 2028 - 272

Table of Contents<br />

<strong>Gelovit</strong> <strong>200</strong><br />

Page<br />

Operating Instructions<br />

Safety instructions ------------------------------------------------------------------ 13<br />

The unit Description of the unit--------------------------------------- 14<br />

Scope of delivery and accessories ------------------------- 15<br />

Technical data------------------------------------------------- 15<br />

Operation Installation----------------------------------------------------- 15<br />

Check set temperatures ------------------------------------- 16<br />

Filling ----------------------------------------------------------- 16<br />

Switching on and duplicating------------------------------- 17<br />

Timer ----------------------------------------------------------- 18<br />

Care and maintenance --------------------------------------- 19<br />

Elimination of faults------------------------------------------ 19<br />

Spare parts list, circuit diagram ------------------------------------------Annex<br />

- 12 -

<strong>Gelovit</strong> <strong>200</strong><br />

Safety Instructions<br />

<strong>Gelovit</strong> is designed exclusively for heating up<br />

gel duplicating material. Any other use is not<br />

regarded as proper. We shall not be liable for<br />

damage resulting from improper use.<br />

Improper use includes, for example, heating water<br />

or other liquids or food!<br />

The safety instructions must be followed in order to<br />

prevent injury to persons or damage to equipment.<br />

We shall not be liable for injury or damage due to<br />

the failure to comply with the safety instructions.<br />

General safety instructions<br />

• The unit may only be operated by staff that is<br />

familiar with the contents of these operating<br />

instructions and follows them. • The operating<br />

instructions must be easily accessible during<br />

operation of the equipment. • The national<br />

accident prevention regulations must be<br />

complied with in addition to these operating<br />

instructions.<br />

• The unit may only be installed on an adequately<br />

stable surface. • The unit must only be used in<br />

closed rooms. • Prior to power connection<br />

check whether the data on the rating plate<br />

correspond to the power supply network. In<br />

the case of lack of clarity, consult a qualified<br />

electrician. • The unit is subject to safety class<br />

I and may only be connected to properly<br />

grounded power sources. • Modifications may<br />

not be carried out on the unit. • Always keep<br />

signs and stickers in easily legible condition.<br />

They must not be removed. • Check the unit<br />

and supply leads for damage regularly. The<br />

unit must not be operated if it has defects that<br />

may endanger employees or third parties. •<br />

Protect the supply leads against heat, oil and<br />

sharp edges. The leads may not be used to<br />

carry the unit or to pull out the plug.<br />

• Switch off the unit and pull out the mains plug<br />

prior to any care, cleaning or maintenance. •<br />

Use only dry or slightly moist cloths for<br />

cleaning purposes. Do not spray the unit with<br />

water or immerse it in water. • Have repairs,<br />

particularly of electrical parts, carried out only<br />

by qualified specialists or the after-sales service<br />

staff.<br />

Special safety instructions<br />

concerning this unit<br />

Risk of injury!<br />

• During the melting process the housing and<br />

cover become hot! Let the unit cool down or<br />

use safety gloves before touching the cover.<br />

• Be careful when reaching into the container.<br />

Pull out the mains plug before reaching in!<br />

- The agitator has sharp edges!<br />

- The container may be very hot!<br />

Symbols<br />

This symbol designates very important<br />

data. If it is not complied with, personal<br />

injury or damage to the unit is possible<br />

or the work result may be a failure.<br />

This symbol warns you of hot parts.<br />

- 13 -

Description of the unit<br />

<strong>Gelovit</strong> <strong>200</strong><br />

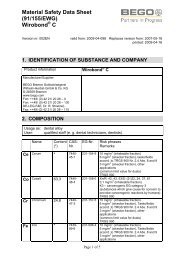

Fig. 1 1 main power switch, mains supply 4 cover<br />

2 outlet 5 fuse<br />

3 operating panel 6 documentation<br />

<strong>Gelovit</strong> <strong>200</strong> is used to melt and store gel duplicating<br />

material. The temperature of the duplicating material<br />

can be constantly read off an electronic display.<br />

• Lowerable operating temperature<br />

<strong>Gelovit</strong> <strong>200</strong> is equipped with an electronic temperature<br />

control. The automatic melting system starts after the<br />

duplicating material is inserted at the push of button<br />

: the material is melted and subsequently cooled<br />

down to the operating temperature “T2”. By pressing<br />

button , the temperature can be brought closer to<br />

the reduced operating temperature “T3” within<br />

approx. 40 minutes and contraction due to hardening<br />

can thus be prevented. Because duplicating material<br />

can be kept above the gelling temperature without<br />

clumps occurring only for a short time, it is automatically<br />

heated up to the operating temperature “T2”<br />

again after 20 minutes.<br />

• Provision time<br />

The melting and cooling down of 6 kg of duplicating<br />

material to the operating temperature takes approx. 4<br />

hours. The strong mixer motor crushes even solid<br />

cooled-down duplicating material, such as Castogel ®<br />

and Wirodouble ® .<br />

• Built-in timer<br />

By means of a timer, the unit can be set for the night<br />

so that duplicating material is available at operating<br />

temperature at the beginning of the next working day.<br />

• Quality assurance<br />

<strong>Gelovit</strong> <strong>200</strong> makes an important contribution to quality<br />

assurance because the number of quality-reducing<br />

melting operations can be monitored (see instructions<br />

in section on “Operation”).<br />

• Safety in the event of power failure<br />

In the event of a temporary power failure, the<br />

microprocessor registers the last operating mode and<br />

continues the setting last selected. It is melted again<br />

only when the duplication material has cooled down<br />

below the „reduced operating temperature“.<br />

• The temperatures are factory-set to 93°C for<br />

melting, 42°C for processing and 39°C for working at<br />

reduced operating temperature. The temperatures can<br />

be varied and thus adapted to the duplicating material<br />

used. For BEGO’s duplicating materials Castogel ® and<br />

Wirodouble ® we recommend the factory-set<br />

temperatures. The settings have to be changed for the<br />

BEGO duplicating material Wirogel M (see „Check set<br />

temperatures“ in section on Operation).<br />

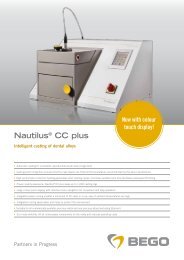

Fig. 2<br />

Function buttons<br />

Button Press, briefly (= ) Press, long (= )<br />

T 1 Melting, then automatic cooling to T2 Set T1<br />

T 2 Cooling / heating to T2 Set T2<br />

T 3 Cooling to T3 Set T3<br />

+ + 1 (for settings) Set number of melting operations<br />

until warning<br />

- - 1 (for settings) Restart counting of melting operations<br />

Set timer<br />

Start timer<br />

Display number of melting operations<br />

thus far<br />

- 14 -

<strong>Gelovit</strong> <strong>200</strong><br />

Scope of delivery and accessories<br />

Scope of delivery<br />

• <strong>Gelovit</strong> <strong>200</strong><br />

• Documentation<br />

• Spare fuse<br />

Accessories<br />

Castogel ® 6 kg tub Ref. No. 52 052<br />

Wirodouble ® 1 kg tub Ref. No. 52 040<br />

6 kg tub Ref. No. 52 050<br />

Wirogel M 6 kg tub Ref. No. 54 351<br />

Technical data<br />

Height / Width / Depth<br />

Weight<br />

Noise emission<br />

565 / 310 / 355 mm<br />

20 kg<br />

< 70 dB (A)<br />

Rated voltage<br />

Special voltages (on request)<br />

Max. power consumption<br />

230 V, 50/60 Hz<br />

100 .... 240 V, 50/60 Hz<br />

900 W<br />

Installation<br />

The unit may only be installed on an<br />

adequately stable surface. • The unit<br />

must only be used in closed rooms. •<br />

Prior to power connection check whether the data<br />

on the rating plate correspond to the power supply<br />

network. In the case of lack of clarity, consult a<br />

qualified electrician. • The unit is subject to safety<br />

class I and may only be connected to properly<br />

grounded power sources.<br />

- 15 -

Operation<br />

1<br />

Check set temperatures<br />

<strong>Gelovit</strong> <strong>200</strong><br />

2 2<br />

°C<br />

°F<br />

2 3<br />

1 Switch on main power switch on right side of unit:<br />

the display indicates the actual temperature in the<br />

duplicating material container.<br />

2 Keep button depressed until the acoustic signal<br />

sounds twice: the display indicates the set<br />

temperature desired for approx. 10 seconds.<br />

3 If necessary, change the temperature with the<br />

buttons "+" and "-".<br />

Note: The new temperatures are stored approx. 10<br />

seconds after the last input or by keeping button 2<br />

depressed again.<br />

• Check/change T2 and T3 in the same way.<br />

Notes:<br />

The factory-set temperatures are recommended for BEGO duplicating materials Castogel ® and Wirodouble ® :<br />

T1 melting temperature = 93 °C,<br />

T2 operating temperature = 42 °C,<br />

(T2 cannot be set lower than T3.)<br />

T3 reduced operating temperature = 39 °C.<br />

(T3 cannot be set higher than T2.)<br />

The temperatures for Wirogel M have to be changed to: T1 = 96 °C,<br />

T2 and T3 = 54 °C (Wirogel M cannot be processed at reduced temperature)!<br />

Filling<br />

Notes:<br />

• Used duplicating material can be re-utilised. Clean<br />

used duplicating material carefully with water. Do not<br />

put used duplicating material in the container until<br />

immediately before the next melting operation.<br />

• Do not forget: After filling with fresh duplicating<br />

material, reset the counter for the melting operations<br />

to 0 by keeping the "-" button depressed until the<br />

acoustic signal sounds twice!<br />

During the melting process the housing and<br />

cover become hot! Let the unit cool down or<br />

use safety gloves before touching the cover.<br />

Be careful when reaching into the container.<br />

Pull out mains plug before reaching in!<br />

• The mixer has sharp edges!<br />

• The container may be very hot!<br />

1 Open the cover.<br />

2 Fill with fist-size pieces of duplicating material:<br />

minimum of 2.5 kg, maximum of 6 kg.<br />

3 Close the cover and turn so that it is locked. The<br />

heating system and mixer only work when the<br />

cover is locked.<br />

- 16 -

<strong>Gelovit</strong> <strong>200</strong><br />

1<br />

2<br />

Switching on and duplicating<br />

Operation<br />

2 2<br />

3<br />

°C<br />

°F<br />

1 Switch on main power switch on right side of unit.<br />

2 Display shows actual temperature of the<br />

duplicating material.<br />

3 Press T1 (see notes).<br />

After the desired temperature is reached:<br />

4 Place flask under the outlet.<br />

5 Open cock to the left. Close cock. Remove and<br />

collect duplicating material after hardening.<br />

Notes:<br />

• Press T1: duplicating material is melted and<br />

subsequently cooled down to operating temperature.<br />

Duration with 6 kg of duplication material: approx.<br />

4 hours.<br />

Lamp T1 is constantly lit: melting.<br />

Lamp T2 flashes (or is constantly lit): operating<br />

temperature not yet reached (or has been reached).<br />

• Press T3 after operating temperature has been<br />

reached: duplicating material is cooled down to the<br />

reduced operating temperature - and is heated up to<br />

operating temperature again 20 minutes later.<br />

Lamp T3 flashes (or is constantly lit):<br />

reduced operating temperature not yet reached<br />

(or has been reached).<br />

• The number of previous melting operations is<br />

displayed for approx. 5 seconds when the " " button<br />

is kept depressed (until acoustic signal sounds twice).<br />

Attention: The last recommended melting operation<br />

is indicated by the flashing °F lamp (or °C lamp when<br />

°F is set). In addition, an acoustic signal sounds for<br />

approx. 30 seconds. - Duplicate as usual. Discharge<br />

the duplicating material before switching off the<br />

unit.<br />

Do not forget: After filling with fresh duplicating<br />

material, reset the counting mechanism for melting<br />

operations to 0 by holding down the "-" button (until<br />

the acoustic signal sounds twice)!<br />

• The number of recommended melting operations<br />

can be adjusted according to the duplicating material<br />

used:<br />

- Hold down the "+" button until the acoustic signal<br />

sounds twice: the display shows the number of<br />

recommended melting operations (basic setting: 8).<br />

- Change the value by means of "+" and "-" buttons.<br />

- The value is stored after 10 seconds or by holding<br />

down the "+" again (until the acoustic signal<br />

sounds twice).<br />

- 17 -

Operation<br />

Timer<br />

<strong>Gelovit</strong> <strong>200</strong><br />

6 2 0 0<br />

°C<br />

°F<br />

1<br />

3<br />

With the timer the unit can be switched on such that<br />

finished duplicating material is available at the<br />

operating temperature at a preselected time.<br />

Example: At 4 p.m. on Friday the timer is to be set so<br />

that the unit switches on at 6 a.m. on Monday:<br />

8 (Friday) + 24 (Saturday) + 24 (Sunday) +<br />

6 (Monday) = 62 hours.<br />

2<br />

1 Press button briefly: the last set time (hours) is<br />

displayed.<br />

2 If necessary, change the time by pressing the "+"<br />

and "-" buttons.<br />

(Holding the button down accelerates the<br />

adjustment procedure.)<br />

Press button 1 again briefly to switch off the time<br />

display and store the altered time.<br />

Note:<br />

If button 1 is not pressed again, the time display<br />

switches off automatically after approx. 10<br />

seconds. The altered time is stored.<br />

3 Start timer: press button 3.<br />

• The display shows the remaining time until the<br />

unit is switched on (hours:minutes).<br />

• Lamps T1 to T3 flash in succession (running<br />

light).<br />

Leave main power switch switched on!<br />

• Stop timer: press button 3 again.<br />

The display indicates the actual temperature of the<br />

duplicating material.<br />

Then press T1 - T3 as required.<br />

- 18 -

<strong>Gelovit</strong> <strong>200</strong><br />

Care and maintenance<br />

• Let duplicating material that has overflowed<br />

harden and then collect it. Fill in with new<br />

duplicating material at next melting operation.<br />

• Clean housing with water and mild cleaning agent.<br />

- Do not use cleaning agents in the duplicating<br />

material container.<br />

Elimination of faults<br />

Fault Cause Remedy<br />

No display The fuse of the unit Replace fuses on right side of unit.<br />

after the unit is switched on. is defective. If fault occurs again, contact<br />

Customer Service Department.<br />

The mains socket is defective. Check socket.<br />

No display, Display defective. Call Customer Service Department.<br />

but double acoustic signal.<br />

°F (or °C) flashes; The last set melting Duplicate as usual.<br />

acoustic signal approx. operation takes place. Before switching off the unit,<br />

30 seconds long. remove old duplicating material.<br />

E 1 Temperature sensors Call Customer Service Department.<br />

E 2<br />

do not work.<br />

E 3<br />

E 4 Motor or rotary sensor Call Customer Service Department.<br />

E 9<br />

defective.<br />

E 5 Clock defective. Call Customer Service Department.<br />

E 6<br />

E 8 after the unit is switched on Cover is not closed Close cover and turn<br />

or interrupted acoustic signal. correctly. so that it is locked.<br />

- 19 -