selfLAN® - Langguth

selfLAN® - Langguth

selfLAN® - Langguth

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Round-thecorner<br />

label<br />

Lid label<br />

Lug-enclosing<br />

(wraparound) label<br />

Multi-layer label<br />

Guarantee label<br />

Patch/shaped label<br />

Neck ring, shoulder,<br />

body label<br />

(various combinations)<br />

LoL label<br />

labelling machine 510<br />

selfLAN ®<br />

self-adhesive labellers<br />

Front and back label Characteristic<br />

Features<br />

selfLAN ® 510 labels different containers<br />

applying self-adhesive technology.<br />

• linear labeller<br />

• depending on the machine version<br />

application of front, back, wraparound<br />

or additional labels<br />

• high efficiency due to quick changeover<br />

and easy operation<br />

• stable frame, machine adjustable to<br />

different container sizes via spindles<br />

• possibility of upgrading the machine<br />

by automatic changeover to different<br />

container sizes<br />

• container orientation in the machine<br />

• possibility of installing coding systems<br />

• meeting all regulated safety<br />

requirements

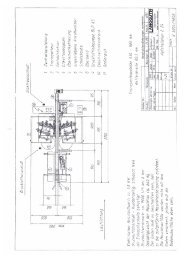

Technical Data<br />

2200<br />

Capacity 100 labellings /min<br />

Container passage from 25 mm<br />

Height of carrier paper 100 mm /150 mm /200 mm /220 mm<br />

Label length min. 12 mm<br />

Label distance on the carrier paper min. 3 mm<br />

Diameter of label rolls max. 350 mm<br />

Core diameter of label roll 41 mm<br />

Connected load 1,5 KW<br />

1450<br />

Additional equipment<br />

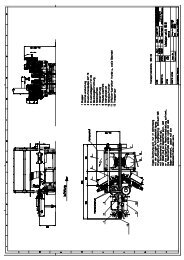

Mode of Operation<br />

The containers are fed into the<br />

machine via the conveyor in a<br />

linear run passing the labelling<br />

components positioned laterally.<br />

First the containers are spaced<br />

with the necessary distance to<br />

each other by the feed station so<br />

that in the further run one label<br />

after the other is released.<br />

At the dispensing edge the<br />

label is peeled off the carrier<br />

paper and then transferred<br />

to the container so that it can<br />

be firmly pressed onto the<br />

container by the subsequent<br />

label fixing elements.<br />

• extended corrosion-proof design<br />

• minimum recognition of end of label roll<br />

• integrated hot-stamping device<br />

• integrated ink-jet device for marking labels and folded boxes<br />

Any machine is as much customized as the requirements of our customers are. The LANGGUTH engineers also find<br />

a solution for your specific container shapes and process requirements. Just challenge our innovation!<br />

LANGGUTH GmbH<br />

Im Südfeld 17 · 48308 Senden-Bösensell · Germany<br />

Tel.: +49 (0) 2536 806-0 · Fax: +49 (0) 2536 806-66<br />

info@langguth.com · www.langguth.com