180 - Langguth

180 - Langguth

180 - Langguth

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

lid label<br />

round-the corner<br />

label<br />

labelling machine<br />

wet glue labeller<br />

<strong>180</strong><br />

Characteristic<br />

Features<br />

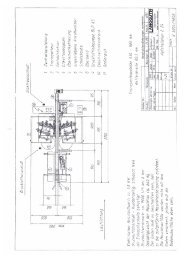

With this dispensing device rectangular<br />

labels and especially shaped labels can<br />

be processed and placed as “lid labels“<br />

onto flat containers such as cartons or<br />

pail lids “from above“.<br />

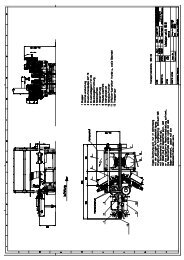

• linear machine for labelling flat containers<br />

with paper labels (wet glue)<br />

• integration into an existing conveyor possible;<br />

also available as separate labelling unit with<br />

transport distance<br />

• cost benefit since low-priced paper labels<br />

compared with self-adhesive labels can be<br />

applied<br />

• magazine capacities of approx. 5.000 labels<br />

• vertical storage of labels with the well-proven<br />

FVT magazine system<br />

• easy and quick changeover to other container<br />

and label sizes possible<br />

• easy cleaning since the glueing device can<br />

be removed as a complete unit<br />

• compact, sturdy design<br />

• precise adjustment – precise positioning of<br />

the labels onto the containers<br />

• meeting all regulated safety requirements

Technical Data<br />

Capacity<br />

Label dimensions<br />

Label material<br />

Label shapes<br />

Container material<br />

Container types<br />

upto 14.000 /h (depending on label length)<br />

length: 110 – 280 mm<br />

width: 50 – 210 mm<br />

paper, plastic<br />

rectangular, round, oval, shaped<br />

plastic, paper, cardboard, metal ...<br />

cartons, boxes, lids ...<br />

Any machine is as much customized as the requirements of our customers are.<br />

LANGGUTH GmbH<br />

Im Südfeld 17 · D-48308 Senden-Bösensell<br />

Phone: +49 (0) 2536 806-0 · Fax: +49 (0) 2536 806-66<br />

info@langguth.com · www.langguth.com<br />

Mode of Operations<br />

The containers to be labelled are fed<br />

beneath the label dispensor in a<br />

linear run on the machine conveyor<br />

existing at site. Accordingly all<br />

relevant machine components are<br />

positioned above the machine con-<br />

veyor. The containers release a label<br />

each which is placed onto the con-<br />

tainer from above and is firmly fixed<br />

by means of brushes and cellular<br />

rubber rolls.<br />

Additional Equipment<br />

• integration into existing lines possible<br />

• combination with <strong>Langguth</strong> labellers of the series<br />

“wetLAN 130“ or „selfLAN 510“ possible<br />

The LANGGUTH engineers also find a solution for your specific container shapes and process requirements.<br />

Just challenge our innovation!