labelling machine Characteristic Features - Langguth

labelling machine Characteristic Features - Langguth

labelling machine Characteristic Features - Langguth

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

front/back label<br />

wraparound label<br />

lug enclosing label<br />

<strong>labelling</strong> <strong>machine</strong><br />

wet glue labellers<br />

190<br />

<strong>Characteristic</strong><br />

<strong>Features</strong><br />

The semi-automatic <strong>machine</strong>s labels<br />

cylindrical containers out of plastic,<br />

glass, cardboard or metal with wet<br />

glue.<br />

• depending on the <strong>machine</strong> version a patch<br />

label or a wraparound label or alternatively –<br />

when using the <strong>machine</strong> version with two<br />

label magazines - a front and a back label<br />

can be applied onto the container in one<br />

single process.<br />

• label magazines with labels stored<br />

horizontally<br />

• high efficiency due to quick changeover<br />

• easy handling<br />

• changeover to different size parts without<br />

tools<br />

• low costs for size parts<br />

• cost-favourable procurement and economic in<br />

use<br />

• compact design with low weight<br />

(easy to be transported)<br />

• designed for semi-automatic <strong>labelling</strong> of<br />

small batches<br />

• meeting all regulated safety requirements<br />

• easy to re-fill and clean the glueing device

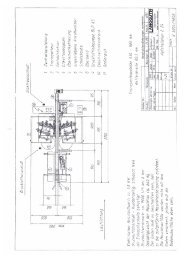

Technical Data<br />

Capacity<br />

Container material<br />

Label length magazine I<br />

magazine II<br />

Label height magazines I + II<br />

Additional Equipment<br />

• application of shaped labels<br />

• expandable for double-sided <strong>labelling</strong><br />

• expandable for lug enclosing <strong>labelling</strong><br />

• expandable for containers with Ø 28–160 mm<br />

• expandable for label heights from 30 mm<br />

Any <strong>machine</strong> is as much customized as the requirements of our customers are.<br />

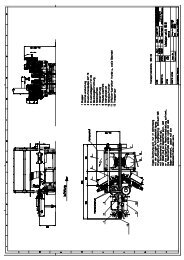

Mode of Operation<br />

The containers to be labelled are<br />

laid into the <strong>machine</strong> and the<br />

<strong>labelling</strong> process is then triggered<br />

automatically by a switch.<br />

Depending on the requirement the<br />

<strong>labelling</strong> process can also be<br />

released via foot or hand control<br />

switch.<br />

During this process the labels are<br />

extracted from the label magazine<br />

and are fed to the rotating glue roller<br />

which covers them with thin glue<br />

stripes. Then they are transferred<br />

onto the rotating container.<br />

Glueing<br />

The actual <strong>labelling</strong> process is<br />

achieved by means of a simple, but<br />

effective glue roller system.<br />

A pan supplies the glue to the roller;<br />

the labels are then thinly covered<br />

with glue. The glue thickness can be<br />

adjusted as required (e.g. depending<br />

on the paper quality).<br />

For re-filling and cleaning the glue<br />

pan it is simply removed from the<br />

<strong>labelling</strong> <strong>machine</strong> and re-inserted<br />

again.<br />

The LANGGUTH engineers also find a solution for your specific container shapes and process requirements.<br />

Just challenge our innovation!<br />

LANGGUTH GmbH<br />

Im Südfeld 17 · D-48308 Senden-Bösensell<br />

Phone: +49 (0) 2536 806-0 · Fax: +49 (0) 2536 806-66<br />

info@langguth.com · www.langguth.com<br />

max. 1.500 <strong>labelling</strong>s/h*<br />

(depending on operator)<br />

glass, plastic, metal, cardboard<br />

60–355 mm*<br />

45–250 mm*<br />

50–190 mm*<br />

* Modifcations possible depending on <strong>machine</strong> version.