PREMIER PARALLEL SLIDE GATE VALVES ... - Premier Valves

PREMIER PARALLEL SLIDE GATE VALVES ... - Premier Valves

PREMIER PARALLEL SLIDE GATE VALVES ... - Premier Valves

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

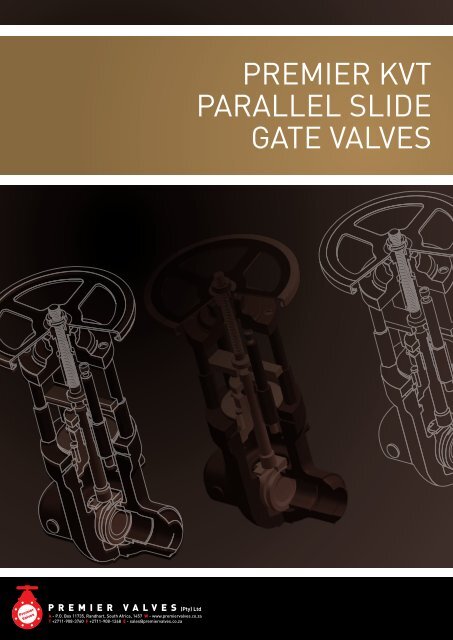

premier KVT<br />

parallel slide<br />

gate valves

2 parallel side gate valve<br />

KVT Range<br />

KVT is an innovative company with a niche in the High<br />

Energy Industries. Innovative and excellent designs<br />

are achieved with quality products as end result.<br />

The complete product range of KVT includes:<br />

• Descaling <strong>Valves</strong><br />

• Parallel Slide gate valves<br />

• Severe Duty Control valves<br />

• Steam Conditioning valves (general and custom designed)<br />

• Blowdown <strong>Valves</strong><br />

• Micro-flow Globe control valves<br />

• Fluid Flow Control devices (specially designed Orifice<br />

Plate systems)<br />

• Pump Minimum Bypass Flow Control valves<br />

Available Engineering Software<br />

• Computational Fluid Dynamics/CFD Tools<br />

• FEA Tools / Linear, Thermal, Dynamics<br />

• Fluid Flow & Network<br />

• Flow Instrumentation Sizing Program<br />

The Descaling valves use only metal seats and provide perfect<br />

tight shut-off. The sealing mechanism is pressure compensated<br />

and utilises balanced twin discs for efficient energy management<br />

and long life under frequent operation.<br />

Products and Services<br />

• Valve Manufacturing & Engineering Service<br />

• Parallel Slide Gate <strong>Valves</strong><br />

• Control <strong>Valves</strong>/Fluid Flow Control Devices<br />

• Blow Down <strong>Valves</strong><br />

• Y-Stop Check <strong>Valves</strong><br />

• Nozzle Check <strong>Valves</strong><br />

• Special <strong>Valves</strong><br />

• Actuators<br />

• Hydraulic Actuating Systems (HiFSEHS)<br />

• Pump minimum Flow Bypass devices<br />

Certificates<br />

• ISO 9001-2000<br />

• CE-PED<br />

• CRN<br />

• New Excellent Products (NeP)<br />

Facilities<br />

• Valve Comprehensive Testing and Inspection Equipments<br />

• Valve Assembler & Welding Machines<br />

• Valve Flow Capacity and Pressure Drop Inherent<br />

Measuring Equipment<br />

• Hydrostatic Shell & Seat Leakage Tester<br />

• Universal Milling Machine & Lathes, and Others

parallel side gate valve 3<br />

Contents<br />

Key Valve Technologies Research and Developments<br />

Model for CFD<br />

Analysis<br />

Flow Paths in the<br />

Valve(CFD)<br />

Fluid Flow Simulation<br />

of Dual Disc<br />

Products 4<br />

Parallel Slide Gate <strong>Valves</strong><br />

Structure and Parts 7<br />

Materials 8<br />

Pressure Temperature Ratings 12<br />

Design Data 16<br />

Cast Parallel Slide Gate <strong>Valves</strong> Dimension 17<br />

Forged Parallel Slide Gate <strong>Valves</strong> Dimension 22<br />

Exceptional Design Features of Spring Pack Loaded 24<br />

Operational Tips & Cautions 25<br />

Equaling & By-Passing Devices 26<br />

Parallel Gate Control valves 29<br />

Flange Dimensions 30<br />

Butt Weld Dimensions 33<br />

Socket Weld Dimensions 36<br />

Thrust & Torque Data 37<br />

Actuators 39<br />

Vapour Formation in<br />

the Valve Trim<br />

3-Dimensional CAD<br />

Design

4 parallel side gate valve<br />

Products<br />

Parallel Slide Gate Valve<br />

Cast Steel / Forged Steel<br />

Parallel Slide Control Gate Valve<br />

Advanced<br />

Pneumatic, Electrical, Hydraulic Power Operated Parallel<br />

Slide Control Gate <strong>Valves</strong><br />

Globe Control <strong>Valves</strong><br />

General Service Type<br />

Severe Duty Type<br />

Quick Change Trim<br />

Cage Trim<br />

Single Stage<br />

Multi Stage<br />

Steam Conditioning <strong>Valves</strong><br />

Steam Pressure (Reducing) and Temperature (Desuperheating) Conditioning

parallel side gate valve 5<br />

Products<br />

Special Check <strong>Valves</strong><br />

Y-Stop Check <strong>Valves</strong><br />

Nozzle Plug Check <strong>Valves</strong><br />

Custom Designed Check <strong>Valves</strong><br />

Check <strong>Valves</strong> for High Temp. Service<br />

Blowdown Control <strong>Valves</strong><br />

Angle Blowdown<br />

Straight Through Flow Control <strong>Valves</strong><br />

Tandem Blowdown <strong>Valves</strong><br />

Gate Style Control <strong>Valves</strong><br />

Twin Disc Parallel Slide Gate Valve<br />

Pressure Compensated & Balanced for<br />

Very High Pressure System

6 parallel side gate valve<br />

Products<br />

Valve Engineering Service<br />

• Flow Test Loop<br />

• Refurbishment Re-engineering<br />

• Reliable Maintenance Engineering<br />

• Engineering Service - CFD / CAE<br />

CFD Model of PSGV Control<br />

Actuator System<br />

• Electrical Actuator Application<br />

• Piston Actuator<br />

• Diaphragm Actuator<br />

• Special Large Capacity Pneumatic Actuator<br />

ROTORK<br />

AUMA<br />

HiFSEHS<br />

Hi-Fluidic ® Safety Electro-Hydraulic Actuator System<br />

Ex d IIB T5 (AC220V, 60Hz, 250W, 10.5A)<br />

Temperature Range: -25~ +80℃ others on request<br />

Request Required Power: 0.25 - 0.50 Kw dependent on torque<br />

output Power Supply: 24 V DC, 115 V AC, 230 V AC (50/60 Hz),<br />

others on request<br />

Solenoid Valve Power Demand: 12 Watt (operating voltage as<br />

needed) Operating Voltage Internal: 24 V DC<br />

Failsafe Operation: Bladder Accumulator<br />

Emergency Operation: Hand Pump<br />

Control System Pressure(Min/Max) : 60/100 bar(101.971577<br />

kgf/cm²)

parallel side gate valve 7<br />

Parallel Slide Gate <strong>Valves</strong> Structure and Parts<br />

Handwheel<br />

Yoke Flange<br />

Yoke Bar<br />

Stopper<br />

Packing Gland<br />

Packing<br />

Stem<br />

Bonnet<br />

Gasket<br />

Disc Guide<br />

Disc Holder<br />

Disc<br />

Seat Ring<br />

Body<br />

Fig.1 Structure and Parts<br />

Design Features<br />

• Pressure sealed bonnet using high density<br />

pure graphite gasket (Delta formed)<br />

• To protect bonnet over pressure introducing<br />

pressure relieving device<br />

• Bypass piping<br />

• SPL Parallel sliding discs<br />

• Wide flat seats<br />

• Travel stop on Yoke<br />

• Non-rotating stem by stopper<br />

• Different hardfacing on seatings<br />

Different hardness ( ~ 5 HRc) on seating<br />

Surface : Discs – Stl #12, Seat – Stl #6<br />

• Integral back seat in bonnet – conical type<br />

• Flow is directional<br />

• Two thrust bearings and Al-Bronze bushing<br />

Spring Pack Loaded<br />

Graphite Seal Gasket<br />

• The higher the internal pressure, the greater<br />

the sealing force.<br />

• We recommend the use of graphite pressure<br />

seal gaskets, in lieu of standard soft iron<br />

gaskets, in high temperature and frequently<br />

temperature-cycled applications.

8 parallel side gate valve<br />

Product Specification - Parallel Slide Gate <strong>Valves</strong> (Cast Steel & Forged Steel Hi-Fluidic PSGV Series)<br />

Table 1: Materials of Construction<br />

Cage Carbon Steel Alloy Steel Stainless<br />

BODY<br />

A216-WCB<br />

(A105N)<br />

A217-WC6<br />

(A182 - F11)<br />

A217-WC9<br />

(A182 - F22)<br />

A217-C12A<br />

(A182 - F91)<br />

A315-CF8M<br />

(A182 - F316)<br />

A182-F51<br />

A240 Gr. S31803<br />

BONNET A216-WCB A217-WC6 A217-WC9 A217-C12 A315-CF8M A240 Gr. S31803<br />

DISK SS410/A105+STL WC6/F11+STL WC9/F22+STL C12A/F91+STL SS316/CF8M+STL F51/A240+STL<br />

STEM A276-410 A276-410 A276-410/431 A276-410/431 A276-316/17-4Ph A276-316<br />

SEAT RING C/S 1020+STL A182-F11+STL A182-F22+STL A182-F91+STL SS316+STL SS316+STL<br />

GASKET Mould Graphite Mould Graphite Mould Graphite Mould Graphite Mould Graphite Mould Graphite<br />

PACKING Graphite Graphite Graphite Graphite Graphite Graphite<br />

PACKING GLAND C/S 1020 A276-410 A276-410 A276-410 A276-316 A276-316<br />

BONNET BOLT A193-B7 A193-B16 A193-B16 A193-B16 A193-B8 A193-B8<br />

BONNET CLAMP C/S 1045 C/S 1045 C/S 1045 C/S 1045 SS304 SS316<br />

RETAINER SS410 SS410 SS410 SS410 SS316 SS316<br />

ADAPTOR RING SS410 SS410 SS410 SS410 SS316 SS316<br />

Table 2-1. Material Properties<br />

Carbon Steel<br />

Alloy Steel<br />

1.25Cr-0.5Mo 5Cr 2.25Cr-1Mo 9Cr 9Cr-V<br />

Composition %<br />

ASTM<br />

Designation<br />

A216<br />

WCB<br />

A352<br />

LCB<br />

A217<br />

WC6<br />

Carbon C 0.30 0.30 0.20 0.20 0.18 0.15max 0.08~0.12<br />

Manganese Mn 1.00 1.00 0.50~0.80 0.40~0.70 0.40~0.70 0.40~0.70 0.3~0.4<br />

Phosphorus P 0.04 0.04 0.04 0.04 0.04 0.04max 0.03<br />

Surphur S 0.045 0.045 0.045 0.045 0.045 0.045max 0.01<br />

Silicon Si 0.60 0.60 0.60 0.75 0.60 0.50~1.00 0.2~0.5<br />

Nickel Ni 0.50 - 0.50 0.50 0.50 0.40<br />

Chromium Cr 0.40 - 1.00~1.50 4.00~6.50 2.00~2.75 8.00~10.0 8.0~9.5<br />

Molybdenum Mo 0.25 - 0.45~0.65 0.45~0.65 0.90~1.20 0.90~1.20 0.85~1.05<br />

Titanium Ti - - - - - -<br />

Copper Cu - 0.50 0.50 0.50 - -<br />

Vandium V - - - - - 0.8~0.25<br />

Nitrogen N - - - - - 0.03~0.07<br />

Niobium Nb (Cb) - - - - - 0.06~0.1<br />

Iron Fe bal bal bal bal bal bal bal<br />

Tungsten W - - - - - - -<br />

Cobalt Co - - - - - - -<br />

A217<br />

C5<br />

A217<br />

WC9<br />

Heat Treatment Anneal Quench Annealed<br />

Tensile(Min.), barg 4830 4480-6200 4830~6200 6200~7930 4830~6200 5860 5860<br />

Yielding(Min.), ba 2480 2410 2760 4140 2760 3790 4140<br />

Elongation(Min.), % 22 24 20 18 20 20 18<br />

Red. Area(Min.), % 35 35 35 18 35 40 45<br />

Hardness, HB 187 Max 197 Max 207 Max 217 Max 207 Max 207 Max 217 Max<br />

Parts<br />

Valve Body, Bonnet, Disc<br />

A217<br />

C12<br />

A217<br />

C12A

parallel side gate valve 9<br />

Parallel Slide Gate <strong>Valves</strong> (Cast Steel Hi-Fluidic PSGV Series)<br />

DATA FOR CALCULATION OF FLOW<br />

The coefficient of flow C V<br />

expresses the rate of flow in gallons per minute at 60ºF water with a pressure drop of 1 psi across<br />

the valve. The C V<br />

coefficients for the various types and sizes, shown in the tables, have been determined from actual flow tests.<br />

Note: K V<br />

is the metric equivalent of C V<br />

. (K V<br />

= C V<br />

x 0.856<br />

For Liquids:<br />

(1) Q L<br />

= C V<br />

For Steam:<br />

P<br />

2.1<br />

(1) W =<br />

G L<br />

1 + 0.0007T S<br />

C V<br />

P(P 1<br />

+ P 2<br />

)<br />

(2) P = G L<br />

( ) 2<br />

C V<br />

Q L<br />

= Flow in U.S. gallons per minute<br />

P = (P 1<br />

- P 2<br />

) Pressure drop in psi<br />

G L<br />

= Specific gravity of liquid (water = 1 at 60ºF)<br />

For Gases:<br />

P<br />

(3) Q g<br />

= 1360 C V<br />

•<br />

G g<br />

T<br />

(4) P = P1 –<br />

G L<br />

P 2 1 + 2G g<br />

P 1<br />

+ P 2<br />

2<br />

Q<br />

T( g<br />

)2<br />

1360C V<br />

Q g<br />

= Volumetric flow of gas (SCFH)<br />

g q<br />

= Specific gravity of gases at standard conditions<br />

(air at atmosphere and 60ºF = 1)<br />

T = Absolute temperature of gas (ºF + 460)<br />

(2) P = P1 –<br />

P 2 1 – K2<br />

1+ 0.00007T<br />

K = (<br />

S<br />

) • W<br />

2.1C V<br />

w = Pounds per hour of steam<br />

P = (P 1<br />

–P 2<br />

) Pressure drop in psi<br />

T S<br />

= Degree of superheat (ºF)<br />

P 1<br />

= inlet pressure<br />

P 2<br />

= outlet pressure<br />

NOTE: For saturated steam T S<br />

= 0<br />

NOTE: For gas and steam, max, P = ½P1, and min.<br />

P2 = ½P1, and P1, P2 are absolute pressures (psia)<br />

Table 2-2. Material Properties<br />

Composition, %<br />

ASTM - Designation<br />

Stainless Steel<br />

13Cr SS316 SS316L SS317<br />

A217<br />

CA15<br />

A351<br />

CF8M<br />

A351<br />

CF3M<br />

A317<br />

CG8M<br />

Monel<br />

Cast<br />

S-Monel<br />

Stellite<br />

#6 #12<br />

Carbon C 0.15 0.08 0.03 0.08 - 0.90~1.4 1.4~1.85<br />

Manganese Mn 1.00 1.50 1.50 1.50 - 1.00 1.0<br />

Phosphorous P 0.04 0.04 0.04 0.04 - - -<br />

Sulphur S 0.04 0.04 0.04 0.04 - - -<br />

Silicon Si 1.50 1.50 1.50 1.50 4.00 1.1 1.5<br />

Nickel Ni 1.00 9.0~12.0 9.0~13.0 11.5~13.5 63.0 3.0 Max 3.0 Max<br />

Chromium Cr 11.5~14.0 18.0~21.0 17.0~21.0 20.5~23.5 - 27.0~31.0 29.5<br />

Molybdenum Mo 0.50 2.0~3.0 2.0~3.0 3.4 - - -<br />

Titanium Ti - - - - - - -<br />

Copper Cu - - - - 30.0 - -<br />

Vandium V - - - - - - -<br />

Nitrogen N - - - 0.08~0.2 - - -<br />

Niobium Nb(Cb) - - - - - - -<br />

Iron Fe bal bal bal bal bal 3.0 Max 2.5 Max<br />

Tungsten W - - - - - 4.5 8.5<br />

Cobalt Co - - - - - bal bal<br />

Heat Treatment HT Solution Anneal Age Hard - -<br />

Tensile (Min.), barg 6200~7930 4830 4830 5170 7590 8970 8970<br />

Yeilding(Min.), barg 4480 2070 2070 2410 5520 - -<br />

Elongation(Min.), % 18 30 30 25 - 1 1<br />

Red. Area(Min.), % 30 - - 36 - - -<br />

Hardness, HB 327~381 187 Max 187 Max 185 Max 387 Max 390~451 390~451<br />

Parts Disc Body, Bonnet, Trim Trim Trim, HF Trim, HF

10 parallel side gate valve<br />

Parallel Slide Gate <strong>Valves</strong> (Cast Steel Hi-Fluidic PSGV Series)<br />

Table 3. ASTM Material Specifications, Per ASME B16.34 .<br />

MATERIAL SPECIFICATION LIST Applicable ASTM Specification<br />

Material Forgings Castings Plates Bars Tubular<br />

Group No<br />

Nominal Designation<br />

Pressure<br />

Temp Rating<br />

Spec No. Grade Spec No. Grade<br />

Spec<br />

No.<br />

Grade<br />

Spec<br />

No.<br />

Grade<br />

Spec<br />

No.<br />

Grade<br />

1.1 C<br />

C-Si<br />

C-Mn-Si<br />

2-1.1<br />

A105<br />

A350<br />

LF2<br />

A216 WCB A515<br />

A516<br />

A537<br />

70<br />

70<br />

CI.1<br />

A675<br />

A105<br />

A350<br />

A696<br />

70<br />

LF2<br />

C<br />

A672<br />

A672<br />

B70<br />

C70<br />

1.2 C-Si<br />

21/2Ni<br />

31/2Ni<br />

C-Mn-Si<br />

2-1.2<br />

A350<br />

LF3<br />

A352<br />

A352<br />

A216<br />

A352<br />

LC2<br />

LC3<br />

WCC<br />

LCC<br />

A203<br />

A203<br />

B<br />

E<br />

A350<br />

LF3 A105 C<br />

1.3 C<br />

C-Si<br />

21/2Ni<br />

31/2Ni<br />

C-Mn-Si<br />

2-1.3<br />

A352 LCB A515<br />

A203<br />

A203<br />

A516<br />

65<br />

A<br />

D<br />

65<br />

A675 65<br />

A672<br />

A672<br />

B 65<br />

C 65<br />

1.4 C<br />

C-Si<br />

C-Mn-Si<br />

2-1.4<br />

A350<br />

LF1<br />

A515<br />

A516<br />

60<br />

60<br />

A675<br />

A350<br />

A69<br />

60<br />

LF1<br />

B<br />

A106<br />

A672<br />

A672<br />

B<br />

B60<br />

C60<br />

1.5 C-1/2Mo 2-1.5 A182 F1 A217<br />

A352<br />

WC1<br />

LC1<br />

A204<br />

A204<br />

A<br />

B<br />

A182 F1 A691 CM-70<br />

1.6 C-1/2Mo<br />

1/2Cr-1/2Mo<br />

2-1.6 A387<br />

A387<br />

A387<br />

2 Ci.1<br />

2 Ci.2<br />

12 Ci.1<br />

A335<br />

A369<br />

A691<br />

P1<br />

FP1<br />

1/2Cr<br />

1Cr-1/2Mo<br />

1.7 C-1/2Mo<br />

1/2Cr-1/2Mo<br />

Ni-1/2Cr-1/2Mo<br />

3/4Ni-Mo-3/4Cr<br />

2-1.7 A182 F2 A217<br />

A217<br />

WC4<br />

WC5<br />

A204 C A182 F2 A691 CM-75<br />

1.9 1Cr-1/2Mo<br />

1-1/4Cr-1/2Mo-Si<br />

1-1/4Cr-1/2Mo<br />

2-1.9 A182<br />

A182<br />

F12 Cl.2<br />

F11 Cl.2<br />

A217 WC6 A387 11CI.2 A182<br />

A182<br />

A739<br />

F12CI.2<br />

F11 CI.2<br />

B11<br />

1.10 2-1/4Cr-1Mo<br />

3Cr-1Mo<br />

2-1.10 A182<br />

A182<br />

F22 CI.3<br />

F21<br />

A217 WC9 A387<br />

A387<br />

22 CI.2<br />

22 CI.2<br />

A182<br />

A739<br />

A182<br />

F22 CI.3<br />

B22 10.2<br />

F21<br />

1.11 Mn-1/2Mo<br />

Mn-s1/2Mo-1/2Ni<br />

Mn-1/2Mo-3/4Ni<br />

C-Mn-Si<br />

2-1.11 A302<br />

A302<br />

A302<br />

A537<br />

A& B<br />

C<br />

D<br />

CL2<br />

1.12 5Cr-1/2Mo<br />

5Cr-1/2Mo-Si<br />

1.13 5Cr-1/2Mo 2-1.13 A182<br />

A182<br />

2-1.12 A387<br />

A387<br />

F5a<br />

F5<br />

5 CI.1<br />

5 CI.2<br />

A217 C5 A182 F5a<br />

A691<br />

A335<br />

A369<br />

A335<br />

1.14 9Cr-1Mo 2-1.14 A182 F9 A217 C12 A192 F9<br />

1.15 9Cr-1Mo-V 2-1.15 A182 F91 A217 C12A A387 91 CI.2

parallel side gate valve 11<br />

Parallel Slide Gate <strong>Valves</strong> (Cast Steel Hi-Fluidic PSGV Series)<br />

Group 2. Materials<br />

Group<br />

No.<br />

Material<br />

Nominal<br />

Designation<br />

Pressure<br />

Temp.<br />

Rating<br />

Spec.<br />

No.<br />

Product Form<br />

Forgings Castings Plates Bars Tubular<br />

Grade<br />

Spec.<br />

No.<br />

Grade<br />

2.1 18Cr -8Ni 2-2.1 A182 F304 A351 CF3 A240 304 A182 F304 A312 TP304<br />

A182 F304H A351 CF8 A240 304H A182 F304H A312 TP304H<br />

2.2 16Cr-2Ni-2Mo 2-2.2 A182 F316 A240 316 A182 F316 A312 TP316<br />

A182 F316H A240 316H A182 F316H A312 TP316H<br />

18Cr-13Ni-3Mo A240 317 A312<br />

19Cr-10Ni-3Mo A351 CG8M<br />

2.3 18Cr-8Ni 2-2.3 A182 F304L A240 304L A182 F304L A312 TP304L<br />

16Cr-12Ni-2Mo A182 F316L A240 316L A182 F316L A312 TP316L<br />

A479 316L<br />

2.4 18Cr-10Ni-Cb 2-2.4 A182 F321 A240 321 A182 F321 A312 TP321<br />

A182 F321H A240 321H A479 321 A312 TP321H<br />

2.5 18Cr-10Ni-Ti 2-2.5 A182 F347 A351 CF8C A240 347 A182 F347 A312 TP347<br />

A182 F347H A240 347H A182 F347H A312 TP347H<br />

A182 F348 A240 348 A182 F348 A358 TP347<br />

A182 F348H A240 348H A182 F348H A376 TP347<br />

2.6 18Cr-12Ni 2-2.6 A351 CH8<br />

A351 CH20<br />

23Cr-20Ni A240 309S A312 TP309H<br />

A240 309H A358 309H<br />

2.7 25Cr-20Ni 2-2.7 A182 F310H A351 CK20 A240 310S A182 F310H A312 TP310H<br />

A240 310H A479 310H<br />

A479 310S A358 310H<br />

2.8 20Cr-18Ni-6Mo 2-2.8 A182 F44 A351 CK3MCuN A240 S31254 A312 S31254<br />

A479 S31254 A358 S31254<br />

22Cr-5Ni-3Mo-N A182 F51 A240 S31803 A479 S31803 A789 S31803<br />

A790 S31803<br />

25Cr-7Ni-4Mo-N A182 F53 A240 S32750 A479 S32750 A789 S32750<br />

A790 S32750<br />

Spec.<br />

No.<br />

Grade<br />

Spec.<br />

No.<br />

Grade<br />

Spec.<br />

No.<br />

Grade<br />

Group 2. Materials<br />

Group<br />

No.<br />

Material<br />

Nominal<br />

Designation<br />

Pressure<br />

Temp.<br />

Rating<br />

Spec.<br />

No.<br />

Product Form<br />

Forgings Castings Plates Bars Tubular<br />

Grade<br />

Spec.<br />

No.<br />

3.1 35Ni-35Fe-20Cr-Cb 2-3.1 B4632 N08020 B463 N08020 B473 N08020 B464 N08020<br />

B468<br />

28Ni-19Cr-Cu-Mo A351 CN7M<br />

3.2 99Ni 2-3.2 B160 N02200 B162 N02200 B160 N02200 B161 N02200<br />

B163 N02200<br />

3.3 99Ni-Low C 2-3.3 B160 N02201 B162 N02201 B160 N02200<br />

3.4 67Ni-30Cu 2-3.4 B564 N04400 B564 N04405 B127 N04400 B164 N04400 B165 N04400<br />

B163 N04400<br />

67Ni-30Cu-S B164 N04405<br />

3.5 72Ni-15Cr-8Fe 2-3.5 B564 N06600 B168 N06600 B166 N06600 B167 N06600<br />

B163 N06600<br />

3.6 33Ni-42Fe-21Cr 2-3.6 B564 N08800 B409 N08800 B408 N08800 N163 N08800<br />

3.7 65Ni-28Mo-2Fe 2-3.7 B335 N10665 B333 N10665 B335 N10665 B622 N10665<br />

3.8 54Ni-16Mo-15Cr B574 N10276 B575 N10276 B574 N10276 B622 N10276<br />

Grade<br />

Spec.<br />

No.<br />

Grade<br />

Spec.<br />

No.<br />

Grade<br />

60Ni-22Cr-9Mo-3.5Cb B564 N06625 B443 N06625 B446 N06625<br />

62Ni-28Mo-5Fe B335 N10001 B333 N10001 B335 N10001 B622 N10001<br />

70Ni-16Mo-7Cr-5Fe B573 N10003 B434 N10003 B573 N10003<br />

61Ni-16Mo-16Cr B574 N06455 B575 N06455 B574 N06455 B622 N06455<br />

42Ni-21.5Cr-3Mo-2.3Cu B425 N08825 B424 N08825 B425 N08825 B423 N08825<br />

3.9 47Ni-22Cr-9Mo-18Fe 2-3.8 B572 N06002 B435 N06002 B572 N06002 B622 N06002<br />

3.10 25Ni-47Fe-21Cr-5Mo 2-3.10 B672 N08700 B599 N08700 B672 N08700<br />

3.11 44Fe-25Ni-21Cr-Mo 2-3.11 B649 N08904 B625 N08904 B649 N08904 B677 N08904<br />

3.12 26Ni-43Fe-22Cr-5Mo 2-3.12 B621 N08320 B620 N08320 B621 N08320 B622 N08320<br />

47Ni-22Cr-20Fe-7Mo B581 N06985 B582 N06985 B581 N06985 B622 N06985<br />

Spec.<br />

No.<br />

Grade

12 parallel side gate valve<br />

Pressure-Temperature Ratings Acc. ANSI B16.34 - 1996 (Standard Class) Pressure in barg<br />

Table 4-1 Pressure and Temperature Ratings<br />

Class<br />

Temperature (degrees Celsius)<br />

Material 38 50 100 150 200 250 300 350 375 400 425 450 475 500 525 550 575 600<br />

150 A105/WCB 19 19 17 15 13 12 10 8 7 6 5<br />

F11/WC6 19 19 17 15 13 12 10 8 7 6 5 4 3 2 1 1 1<br />

F22/WC9 19 19 17 15 13 12 10 8 7 6 5 4 3 2 1 1 1<br />

F91/C12A 19 19 17 15 13 12 10 8 7 6 5 4 3 2 1 1 1 1<br />

F316/ 18 18 16 14 13 12 10 8 7 6 5 4 3 2 1<br />

F51/A240 19 19 17 15 13 12 10<br />

300 A105/WCB 51 50 46 45 43 41 38 36 36 34 28<br />

F11/WC6 51 51 51 49 48 46 42 40 38 36 35 33 31 25 18 12 8<br />

F22/WC9 51 51 51 50 48 46 42 40 38 36 35 33 31 27 21 15 10<br />

F91/C12A 51 51 51 50 48 46 42 40 38 36 35 33 31 28 25 25 23 19<br />

F316/ 49 48 42 38 35 33 31 30 29 29 28 28 28 27 25<br />

F51/A240 51 51 49 45 42 40 38<br />

600 A105/WCB 102 100 92 90 87 83 77 73 72 69 57<br />

F11/WC6 103 103 102 99 95 92 85 80 77 73 70 67 63 50 36 25 17<br />

F22/WC9 103 103 103 100 97 92 85 80 77 73 70 67 63 55 43 30 21<br />

F91/C12A 103 103 103 100 97 92 85 80 77 73 70 67 63 56 51 49 46 39<br />

F316/ 99 96 84 77 71 68 63 61 59 58 58 57 57 54 50<br />

F51/A240 103 102 98 91 85 80 77<br />

800 A105/WCB 136 133 123 120 116 111 103 98 97 91 76<br />

F11/WC6 137 137 137 132 127 123 114 107 103 97 93 90 84 67 48 33 23<br />

F22/WC9 137 137 137 133 129 123 114 107 103 97 93 90 84 74 57 40 28<br />

F91/C12A 137 137 137 133 129 123 114 107 103 97 93 90 84 75 68 66 62 52<br />

F316/ 132 128 112 102 95 89 84 81 79 78 77 76 76 72 67<br />

F51/A240 137 136 131 122 113 107 103<br />

900 A105/WCB 153 150 139 135 131 125 116 110 109 103 86<br />

F11/WC6 155 155 154 149 143 138 128 120 116 109 105 101 95 75 54 38 26<br />

F22/WC9 155 155 154 150 146 139 128 120 116 109 105 101 95 83 64 46 31<br />

F91/C12A 155 155 154 150 146 139 128 120 116 109 105 101 95 84 77 74 70 58<br />

F316/ 148 144 126 115 106 100 94 91 89 88 87 86 85 82 75<br />

F51/A240 155 153 147 137 128 120 116<br />

1500 A105/WCB 255 250 231 225 219 208 193 184 182 172 143<br />

F11/WC6 258 258 257 248 239 230 214 201 194 183 175 169 158 126 90 63 44<br />

F22/WC9 258 258 257 250 243 231 214 201 194 183 175 169 158 138 108 76 52<br />

F91/C12A 258 258 257 250 243 231 214 201 194 183 175 169 158 140 128 124 117 97<br />

F316/ 248 240 210 192 178 166 158 152 149 147 145 144 143 136 126<br />

F51/A 240 258 256 245 228 213 200 193<br />

1700 A105/WCB 289 283 262 256 248 236 219 209 206 195 163<br />

F11/WC6 292 292 291 281 271 261 242 227 219 207 198 191 179 142 102 71 49<br />

F22/WC9 292 292 291 284 276 262 242 227 219 207 198 191 179 157 122 87 59<br />

F91/C12A 292 292 291 284 276 262 242 227 219 207 198 191 179 159 146 141 132 110<br />

F316/ 281 272 239 218 202 189 179 172 169 166 165 163 162 154 143<br />

F51/A 240 292 290 278 259 241 227 219<br />

2500 A105/WCB 425 417 386 376 365 347 322 307 303 287 239<br />

F11/WC6 430 430 428 414 399 384 357 335 323 304 292 281 263 210 151 105 73<br />

F22/WC9 430 430 429 418 406 386 357 335 323 304 292 281 263 231 180 127 87<br />

F91/C12A 430 430 429 418 406 386 357 335 323 304 292 281 263 234 214 207 195 162<br />

F316/ 413 400 351 320 297 278 263 253 248 245 242 240 238 227 210<br />

F51/A240 430 427 409 381 355 334 322<br />

2700 A105/WCB 459 450 417 406 394 375 348 332 328 310 258<br />

F11/WC6 465 465 463 447 431 415 385 362 349 329 315 304 284 226 163 114 79<br />

F22/WC9 465 465 463 451 438 416 385 362 349 329 315 304 284 250 194 138 94<br />

F91/C12A 465 465 463 451 438 416 385 362 349 329 315 304 284 253 232 224 211 175<br />

F316/ 446 432 379 346 320 300 284 274 268 264 262 259 257 246 227<br />

F51/A240 465 461 442 411 383 361 348<br />

4500 A105/WCB 765 750 695 678 657 625 580 554 546 517 431<br />

F11/WC6 775 775 772 745 719 692 642 603 581 548 526 506 474 378 272 190 132<br />

F22/WC9 775 775 772 752 731 694 642 603 581 548 526 506 474 417 325 230 157<br />

F91/C12A 775 775 772 752 731 694 642 603 581 548 526 506 474 422 386 374 351 292<br />

F316/ 744 721 632 577 534 500 474 456 448 441 436 432 430 410 378<br />

F51/A240 775 768 737 686 639 602 581

parallel side gate valve 13<br />

ANSI Pressure Temperature Ratings<br />

Table 4-2 Pressure and Temperature Ratings<br />

°F<br />

STANDARD CLASS B16.34 - 1996 SPECIAL CLASS B16.34 - 1996<br />

MAXIMUNM NON-SHOCK WORKING PRESSURE. PSIG<br />

NOTE : Upon prolonged exposure to temperatures above 800ºF, the carbide phase of steel may be converted to graphite.<br />

Permissible, but not recommended for prolonged use above 800ºF.<br />

ASTM A216 GR.WCB<br />

MAXIMUNM NON-SHOCK WORKING PRESSURE. PSIG<br />

150 300 600 900 1500 2500 150 300 600 900 1500 2500<br />

HYDROSTATIC SHELL TEST 450 1125 2225 3375 5625 9375 450 1125 2250 3375 5625 9375<br />

HYDROSTATIC SEAT TEST 325 825 1650 2450 4100 6800 325 825 1650 2475 4125 6875<br />

-20 to 100 285 740 1480 2220 3705 6170 290 750 1500 2250 3750 6250<br />

200 260 675 1350 2025 3375 5625 290 750 1500 2250 3750 6250<br />

300 230 655 1315 1970 3280 5470 290 750 1500 2250 3750 6250<br />

400 200 635 1270 1900 3170 5280 290 750 1500 2250 3750 6250<br />

500 170 600 1200 1795 2995 4990 290 750 1500 2250 1750 6250<br />

600 140 550 1095 1640 2735 4560 275 715 1425 2140 3565 5940<br />

650 125 535 1075 1610 2585 4475 270 700 1400 2100 3495 5825<br />

700 110 535 1065 1600 2665 4440 265 695 1390 2080 3470 5780<br />

750 95 505 1010 1510 2520 4200 240 630 1260 1890 3150 5250<br />

800 80 410 825 1235 2060 3430 200 515 1030 1545 2570 4285<br />

°F<br />

ASTM A217 GR.WC6<br />

STANDARD CLASS B16.34 - 1996 SPECIAL CLASS B16.34 - 1996<br />

MAXIMUNM NON-SHOCK WORKING PRESSURE. PSIG<br />

MAXIMUNM NON-SHOCK WORKING PRESSURE. PSIG<br />

150 300 600 900 1500 2500 150 300 600 900 1500 2500<br />

HYDROSTATIC SHELL TEST 450 1125 2225 3375 5625 9375 450 1125 2250 3375 5625 9375<br />

HYDROSTATIC SEAT TEST 325 825 1650 2475 4125 6875 325 825 1650 2475 4125 6875<br />

-20 to 100 290 750 1500 2250 3750 6250 290 750 1500 2250 3750 6250<br />

200 260 750 1500 2250 3750 6250 290 750 1500 2250 3750 6250<br />

300 230 720 1445 2165 3610 6015 290 750 1500 2250 3750 8250<br />

400 200 695 1385 2080 3485 5775 290 750 1500 2250 3750 6250<br />

500 170 665 1330 1995 3325 5540 290 750 1500 2250 3750 6250<br />

600 140 605 1210 1815 3025 5040 290 750 1500 2260 3750 6250<br />

650 125 590 1175 1765 2940 4905 290 750 1500 2250 3750 8250<br />

700 110 570 1135 1706 2840 4730 280 735 1485 2200 3665 6110<br />

750 95 530 1065 1595 2660 4430 280 730 1460 2185 3645 6070<br />

800 80 510 1015 1525 2540 4230 275 720 1440 2180 3600 6000<br />

850 65 485 975 1460 2435 4060 260 680 1355 2030 3385 5645<br />

900 50 450 900 1360 2245 3745 225 585 1175 1760 2935 4895<br />

950 35 320 840 955 1595 2655 155 400 795 1195 1995 3320<br />

1000 20 215 430 650 1080 1800 105 270 540 810 1350 2250<br />

1050 20(1) 145 290 430 720 1200 70 180 360 540 900 1500<br />

1100 20(1) 95 190 290 480 800 45 120 240 360 600 1000<br />

NOTE: (1) For welding end valves only. Flanged end ratings terminate at 1000°F.

14 parallel side gate valve<br />

Parallel Slide Gate <strong>Valves</strong> (Cast Steel Hi-Fluidic PSGV Series)<br />

°F<br />

ASTM A217 GR.WC9<br />

STANDARD CLASS B16.34 - 1996 SPECIAL CLASS B16.34 - 1996<br />

MAXIMUM NON-SHOCK WORKING PRESSURE. PSIG<br />

MAXIMUM NON-SHOCK WORKING PRESSURE. PSIG<br />

150 300 600 900 1500 2500 150 300 600 900 1500 2500<br />

HYDROSTATIC SHELL TEST 450 1125 2225 3375 5625 9375 450 1125 2250 3375 5625 9375<br />

HYDROSTATIC SEAT TEST 325 825 1650 2475 4125 6875 325 825 1650 2475 4125 6875<br />

-20 to 100 290 750 1500 2250 3750 6250 290 750 1500 2250 3750 6250<br />

200 260 750 1500 2250 3750 6250 290 750 1500 2250 3750 6250<br />

300 230 730 1455 2185 3640 6070 285 740 1486 2225 3705 8180<br />

400 200 705 1410 2115 3530 5880 280 725 1450 2175 3620 6035<br />

500 170 665 1330 1995 3325 5540 275 720 1440 2600 3600 6000<br />

600 140 605 1210 1815 3025 5040 275 729 1440 2160 3600 6000<br />

650 125 590 1175 1765 2940 4905 275 715 1430 2146 3580 5965<br />

700 110 570 1135 1705 2840 4730 275 710 1425 2135 3555 5930<br />

750 95 530 1065 1595 2660 4430 265 690 1380 2070 3450 5750<br />

800 80 510 1015 1525 2540 4230 260 676 1345 2020 3365 5605<br />

850 65 485 975 1460 2435 4060 245 645 1285 1930 3215 5355<br />

900 60 450 900 1350 2245 3745 230 600 1200 1800 3000 5000<br />

950 35 375 755 1130 1885 3145 180 470 945 1415 2355 3930<br />

1000 20 260 520 780 1305 2170 125 325 650 975 1630 2715<br />

1050 20(1) 175 350 525 875 1455 85 220 435 655 1096 1820<br />

1100 20(1) 110 220 330 550 915 55 135 275 410 685 1145<br />

NOTE: (1) For welding end valves only. Flanged end ratings terminate at 1000ºF. Must not used over 1100°F.<br />

°F<br />

ASTM A217 GR.C12A<br />

STANDARD CLASS B16.34 - 1996 SPECIAL CLASS B16.34 - 1996<br />

MAXIMUM NON-SHOCK WORKING PRESSURE. PSIG<br />

MAXIMUM NON-SHOCK WORKING PRESSURE. PSIG<br />

150 300 600 900 1500 2500 150 300 600 900 1500 2500<br />

HYDROSTATIC SEAT TEST 325 825 1650 2475 4125 6875 325 825 1650 2475 4125 6875<br />

-20 to 100 290 750 1500 2250 3750 6250 290 750 1500 2250 3750 6250<br />

200 260 750 1500 2250 3750 6250 290 750 1500 2250 3750 6250<br />

300 230 730 1455 2185 3640 6070 290 750 1500 2250 3750 6250<br />

400 200 705 1410 2115 3530 5880 290 750 1500 2250 3750 6250<br />

500 170 665 1330 1995 3325 5540 290 750 1500 2250 3750 6250<br />

600 140 605 1210 1815 3025 5040 290 750 1500 2250 3750 6250<br />

650 125 590 1175 1765 2940 4905 290 750 1500 2250 3750 6250<br />

700 110 570 1135 1705 2840 4730 280 735 1465 2200 3665 6110<br />

750 95 530 1065 1595 2660 4430 280 730 1460 2185 3645 6070<br />

800 80 510 1015 1525 2540 4230 275 720 1440 2160 3600 6000<br />

850 65 485 975 1450 2435 4060 260 680 1355 2030 3385 5645<br />

900 50 450 900 1350 2245 3745 230 600 1200 1800 3000 5000<br />

950 35 385 775 1160 1930 3220 180 470 945 1415 2360 3930<br />

1000 20 365 725 1090 1820 3030 160 420 840 1260 2105 3505<br />

1050 20(1) 360 720 1080 1800 3000 160 420 840 1260 2105 3505<br />

1100 20(1) 300 605 905 1510 2515 145 375 755 1885 1885 3145<br />

1150 20(1) 225 445 670 1115 1855 105 230 355 835 1395 2320<br />

1200 20(1) 145 290 430 720 1200 70 180 360 540 900 1500<br />

NOTE: (1) For welding end valves only. Flanged end ratings terminate at 1000°F.

parallel side gate valve 15<br />

Parallel Slide Gate <strong>Valves</strong> (Cast Steel Hi-Fluidic PSGV Series)<br />

°F<br />

ASTM A351 GR.CF8M<br />

STANDARD CLASS B16.34 - 1996 SPECIAL CLASS B16.34 - 1996<br />

MAXIMUM NON-SHOCK WORKING PRESSURE. PSIG<br />

MAXIMUM NON-SHOCK WORKING PRESSURE. PSIG<br />

150 300 600 900 1500 2500 150 300 600 900 1500 2500<br />

HYDROSTATIC SHELL TEST 425 110 2175 3250 5400 9000 450 1125 2250 3375 5625 9375<br />

HYDROSTATIC SEAT TEST 325 800 1600 2400 3975 6600 325 825 1650 2475 4125 6875<br />

-20 to 100 275 720 1440 2160 3600 6000 290 750 1500 2250 3750 6250<br />

200 235 620 1240 1860 3095 5160 265 690 1380 2070 3450 5750<br />

300 215 560 1120 1680 2795 4660 240 625 1250 1870 3120 5200<br />

400 195 515 1025 1540 2570 4280 220 570 1140 1710 2850 4750<br />

500 170 480 955 1435 2390 3980 205 530 1065 1595 2655 4430<br />

600 140 450 900 1355 2255 3760 195 505 1005 1510 2520 4195<br />

650 125 445 890 1330 2220 3700 190 495 985 1480 2465 4105<br />

700 110 430 870 1305 2170 3620 185 485 970 1455 2420 4035<br />

750 95 425 855 1280 2135 3560 180 475 950 1425 2380 3965<br />

800 80 420 845 1265 2110 3520 180 470 945 1415 2355 3930<br />

850 65 420 835 1255 2090 3480 100 465 930 1400 2330 3885<br />

900 50 415 830 1245 2075 3400 175 405 925 1390 2315 3855<br />

950 35 385 775 1160 1930 3220 175 460 915 1375 2290 3815<br />

1000 20 350 700 1050 1750 2915 160 420 840 1260 2105 3505<br />

1050 20(1) 345 685 1030 1720 2865 160 420 840 1260 2105 3505<br />

1100 20(1) 305 610 915 1525 2545 145 380 765 1145 1905 3180<br />

1150 20(1) 235 475 710 1185 1970 115 295 590 885 1480 2465<br />

1200 20(1) 185 370 555 925 1545 90 230 465 695 1155 1930<br />

1250 20(1) 145 295 440 735 1230 70 185 370 555 920 1535<br />

1300 20(1) 115 235 350 585 970 55 145 290 435 730 1215<br />

1350 20(1) 95 190 290 480 800 45 120 240 360 600 1000<br />

1400 20(1) 75 150 225 380 630 35 95 190 285 470 785<br />

1450 20(1) 60 115 175 290 485 30 75 145 220 365 610<br />

1500 20(1) 40 85 125 205 345 20 50 105 155 260 430<br />

NOTE: (1) For welding end valves only. Flanged end ratings terminate at 1000ºF.<br />

°F<br />

ASTM A182 GR.F51<br />

STANDARD CLASS B16.34 - 1996 SPECIAL CLASS B16.34 - 1996<br />

MAXIMUM NON-SHOCK WORKING PRESSURE. PSIG<br />

MAXIMUM NON-SHOCK WORKING PRESSURE. PSIG<br />

150 300 600 900 1500 2500 150 300 600 900 1500 2500<br />

HYDROSTATIC SHELL TEST 425 110 2175 3250 5400 9000 450 1125 2250 3375 5625 9375<br />

HYDROSTATIC SEAT TEST 325 825 1650 2475 4125 6875 325 825 1650 2475 4125 6875<br />

-20 to 100 290 750 1500 2250 3750 6250 290 750 1500 2250 3750 6250<br />

200 260 720 1440 2160 3600 6000 290 750 1500 2250 3750 6250<br />

300 230 665 1330 1995 3325 5540 285 740 1485 2225 3710 6185<br />

400 200 615 1230 1845 3070 5120 265 685 1370 2055 3430 5715<br />

500 170 575 1150 1730 2880 4600 245 645 1285 1930 3215 5355<br />

600 140 555 1115 1670 2785 4640 240 620 1245 1865 3105 5180<br />

650 125 550 1100 1650 2750 4580 235 615 1225 1840 3065 5110<br />

700 110 540 1085 1625 2710 4520 230 605 1210 1815 3025 5045<br />

750 95 530 1065 1595 2660 4430 230 595 1195 1790 3985 4980<br />

NOTE: This steel may become brittle after service at moderately elevated temperatures. Not to be used over 600ºF.

16 parallel side gate valve<br />

KVT Standard Parallel Slide Gate Valve Design Data<br />

Table 5. PSGV Standard Design Data<br />

Class Valve Size(inch) 2.5” 3” 4” 6” 8” 10” 12” 14” 16” 18” 20” 24”<br />

DN(mm) 65 80 100 150 200 250 300 350 400 450 500 600<br />

Seat Diameter(mm) 62 76 102 152 200 238 285 322 374 394 435 525<br />

Stem Diameter(mm) 19 22 28 36 40 42 44 50 52 62 70 80<br />

600<br />

Thread(TR) 16×4 20×4 26×5 32×6 36×6 38×6 40×7 46×8 48×8 55×9 65×10 75×10<br />

RUN(Turns) 17.8 21.3 22.6 27.7 35.5 41.7 43.2 42.7 49.0 46.2 46.2 55.6<br />

Cv (Flow Capacity) 340 510 960 2,260 3,990 6,200 9,090 11,400 16,070 18,190 23,790 42,700<br />

DN(mm) 65 80 100 150 200 250 300 350 400 450 500 600<br />

Seat Diameter(mm) 53 70 92 127 178 238 282 295 338 376 418 500<br />

Stem Diameter(mm) 22 28 32 40 42 42 50 52 62 70 70 80<br />

900<br />

Thread(TR) 20×4 26×5 28×5 36×6 38×6 38×6 46×8 48×8 55×9 65×10 65×10 75×10<br />

RUN(Turns) 15.2 16.3 21.0 25.0 31.5 41.7 36.6 39.1 39.5 40.0 44.6 53.2<br />

Cv (Flow Capacity) 260 420 770 1,790 6,120 5,710 8,120 9,910 13,010 16,540 20,490 38,630<br />

DN(mm) 65 80 100 150 200 250 300 350 400 450 500 600<br />

Seat Diameter(mm) 53 70 92 137 178 222 247.5 271.4 328 349 390.8 468<br />

600 22 28 32 40 42 50 50 62 70 80 90 95<br />

1500<br />

Thread(TR) 20×4 26×5 28×5 36×6 38×6 46×8 46×8 55×9 65×10 75×10 85×12 90×12<br />

RUN(Turns) 15.2 16.3 21.0 25.0 31.5 28.8 33.4 32.5 34.7 37.4 34.8 41.9<br />

Cv (Flow Capacity) 260 420 770 1,790 3,120 4,960 7,040 8,500 11,180 14,210 17,890 29,100<br />

DN(mm) 65 80 100 150 200 250 300 350 400 450 500 600<br />

Seat Diameter(mm) 44.6 57 73 104.3 146 175 219 241 259.5 292.5 325 375<br />

Stem Diameter(mm) 22 32 36 42 50 52 62 70 80 90 90 95<br />

2500<br />

Thread(TR) 20×4 28×5 34×6 38×6 46×8 48×8 58×7 65×10 75×10 85×12 85×12 90×12<br />

RUN(Turns) 13.7 14.0 14.5 17.1 20.1 23.7 34.2 26.0 28.0 26.2 29.6 33.5<br />

Cv (Flow Capacity) 170 260 460 1,150 2,070 3,360 4,810 5,880 7,750 9,910 11,400 16,300<br />

# Consult Factory for Class 300 Lbs and Lower.

parallel side gate valve 17<br />

Parallel Slide Gate <strong>Valves</strong> - Cast Steel Hi-Fluidic Psgv Series<br />

<strong>PARALLEL</strong> <strong>SLIDE</strong> <strong>GATE</strong> VALVE<br />

Bolted Bonnet<br />

Carbon Or Stainless Steel<br />

Asme Class 300 , 2 1/2”-24”(65 - 600mm)<br />

<br />

<br />

<br />

<br />

<br />

<br />

Product Number: KKM00ABB, KKM00ABR<br />

Valve Size : 50A(2”) - 300A(12”)<br />

<br />

<br />

Product Number: KKG00ABB, KKG00ABR<br />

Valve Size : 350A(14”) - 600A(24”)<br />

Table 6. Cast Steel Parallel Slide Gate Valve Dimension (Class 300/Pn40)<br />

Nominal Size A B¹ C D Weight (B.W/R.F)<br />

mm in mm in mm in mm in mm in Kg lb<br />

50 2 420 16.54 216 8.50 175 6.89 45 1.77 22/27 49/60<br />

65 2½ 480 18.89 241 9.50 175 6.89 61 2.40 26/34 57/75<br />

80 3 525 20.67 282 11.10 250 9.84 72 2.83 40/51 88/112<br />

100 4 630 24.80 305 12.00 250 9.84 96 3.78 69/91 152/200<br />

150 6 895 35.24 403 15.87 350 13.78 146 5.75 135/166 298/366<br />

200 8 1150 45.28 419 16.50 400 15.75 200 7.87 256/292 564/644<br />

250 10 1375 54.13 457 18.00 450 17.72 247 9.72 304/369 670/814<br />

300 12 1740 68.50 502 19.76 500 19.69 303 11.93 410/520 904/1146<br />

350 14 1345 52.95 762 30.00 400 15.75 335 13.19 555/718 1224/1583<br />

400 16 1513 59.57 838 33.00 400 15.75 385 15.16 742/972 1636/2143<br />

450 18 1647 64.84 914 36.00 500 19.69 426 16.77 994/1272 2191/2804<br />

500 20 1902 74.88 919 39.00 500 19.69 480 18.90 1174/1492 2588/3289<br />

600 24 2313 91.06 1143 45.00 630 24.80 585 23.03 1535/2055 3384/4531<br />

vv<br />

(1) Per ASME B16.10<br />

• Flange dimensions on page 30<br />

• Butt welding end dimensions on page 33

D<br />

A<br />

C<br />

18 parallel side gate valve<br />

Parallel Slide Gate <strong>Valves</strong> - Cast Steel Hi-Fluidic PSGV Series (ASME Class 600)<br />

<strong>PARALLEL</strong> <strong>SLIDE</strong> <strong>GATE</strong> VALVE<br />

Pressure Sealed Bonnet<br />

Carbon Or Stainless Steel<br />

Asme Class 600 , 2 1/2”-24”(65 - 600mm)<br />

C<br />

D<br />

A(OPEN)<br />

B<br />

B1<br />

B<br />

B1<br />

Product Number: KKM00ADB, KKM00ADR<br />

Valve Size : 65A(2½”) - 20A(8”)<br />

Product Number: KKG00ADB, KKG00ADR<br />

Valve Size : 250A(10”) - 600A(24”)<br />

Table 7. Cast Steel Parallel Slide Gate Valve Dimension (Class 600/Pn100)<br />

Nominal Size A B¹ B1² C D Weight (B.W/R.F)<br />

mm in mm in mm in mm in mm in mm in Kg lb<br />

65 2½ 505 19.88 216 8.50 330 13.00 250 9.84 62 2.44 42/47 93/104<br />

80 3 565 22.24 254 10.00 356 14.00 250 9.84 76 2.99 53/57 114/130<br />

100 4 780 30.71 305 12.00 432 17.00 350 13.78 102 4.02 92/222 203/489<br />

150 6 1140 44.88 457 18.00 559 22.00 450 17.72 152 5.98 210/255 463/562<br />

200 8 1400 55.12 584 23.00 660 26.00 500 19.69 200 7.87 380/456 838/1005<br />

250 10 1182 46.54 711 28.00 787 31.00 400 15.75 238 9.37 648/793 1429/1748<br />

300 12 1264 49.76 813 32.00 838 33.00 500 19.69 284 11.18 710/865 1565/1907<br />

350 14 1542 60.71 889 35.00 889 35.00 500 19.69 322 12.68 938/1093 2068/2410<br />

400 16 1730 68.11 991 39.00 991 39.00 630 24.80 374 14.72 1487/1735 3278/3825<br />

450 18 1776 69.92 1092 43.00 1092 43.00 710 27.95 398 15.67 1980/2250 4365/4960<br />

500 20 1834 72.20 1194 47.00 1194 47.00 710 27.95 435 17.13 2635/3010 5809/6636<br />

600 24 2105 82.87 1397 55.00 1397 55.00 800 31.50 525 20.67 3730/4260 8223/9392<br />

(1) Per ASME B16.10 Short pattern<br />

(2) Per ASME B16.10 Long pattern<br />

• Flange dimensions on page 30<br />

• Butt welding end dimensions on page 33

D<br />

A<br />

C<br />

parallel side gate valve 19<br />

Parallel Slide Gate <strong>Valves</strong> - Cast Steel Hi-Fluidic PSGV Series (ASME Class 600)<br />

<strong>PARALLEL</strong> <strong>SLIDE</strong> <strong>GATE</strong> VALVE<br />

Pressure Sealed Bonnet<br />

Carbon Or Stainless Steel<br />

Asme Class 900 , 2 1/2”-24”(65 - 600mm)<br />

C<br />

D<br />

A(OPEN)<br />

B<br />

B1<br />

B<br />

B1<br />

Product Number: KKM00AFB, KKM00AFR<br />

Valve Size : 65A(2½”) - 200A(8”)<br />

Product Number: KKG00AFB, KKG00AFR<br />

Valve Size : 250A(10”) - 600A(24”)<br />

Table 8. Cast Steel Parallel Slide Gate Valve Dimension (Class 900/Pn150)<br />

Nominal Size A B¹ B1² C D Weight (B.W/R.F)<br />

mm in mm in mm in mm in mm in mm in Kg lb<br />

65 2½ 495 19.49 254 10.00 419 16.50 250 9.84 53 2.09 45/55 99/121<br />

80 3 650 25.59 305 12.00 381 15.00 350 13.78 70 2.76 80/92 176/203<br />

100 4 810 31.89 356 14.00 457 18.00 400 15.75 92 3.62 140/185 309/408<br />

150 6 1080 42.52 508 20.00 610 24.00 500 19.69 137 5.39 282/367 622/809<br />

200 8 1260 49.61 660 26.00 737 29.00 500 19.69 178 7.00 410/560 904/1235<br />

250 10 1205 47.44 787 31.00 838 33.00 500 19.69 238 9.37 694/860 1530/1896<br />

300 12 1330 52.36 914 36.00 965 38.00 630 24.80 268 10.55 1027/1252 2264/2760<br />

350 14 1500 59.06 991 39.00 1029 40.50 630 24.80 295 11.61 1213/1475 2674/3252<br />

400 16 1625 63.95 1092 43.00 1130 44.50 710 27.95 338 13.31 1510/1885 3329/4156<br />

450 18 1720 67.72 1219 48.00 1219 48.00 800 31.50 376 14.80 1750/2020 3858/4453<br />

500 20 1840 72.44 1321 52.00 1321 52.00 800 31.50 418 16.46 2380/2680 5247/5908<br />

600 24 2310 90.94 1549 61.00 1549 61.00 900 35.43 500 19.69 3650/4260 8047/9392<br />

(1) Per ASME B16.10 Short pattern<br />

(2) Per ASME B16.10 Long pattern<br />

• Flange dimensions on page 31<br />

• Butt welding end dimensions on page 33

D<br />

A<br />

20 parallel side gate valve<br />

Parallel Slide Gate <strong>Valves</strong> - Cast Steel Hi-Fluidic PSGV Series (ASME Class 1500)<br />

<br />

<br />

<br />

C<br />

<strong>PARALLEL</strong> <strong>SLIDE</strong> <strong>GATE</strong> VALVE<br />

Pressure Sealed Bonnet<br />

Carbon Or Stainless Steel<br />

Asme Class 1500 , 2 1/2”-24”(65 - 600mm)<br />

<br />

Product Number: KKM00AGB<br />

Valve Size : 65A(2½”) - 150A(6”)<br />

B<br />

Product Number: KKG00AGB<br />

Valve Size : 200A(8”) - 600A(24”)<br />

Table 9. Cast Steel Parallel Slide Gate Valve Dimension (Class 1500/Pn250)<br />

Nominal Size A B¹ C D Weight (B.W)<br />

mm in mm in mm in mm in mm in Kg lb<br />

65 2½ 495 19.49 254 10.00 250 9.84 53 2.10 55 121<br />

80 3 650 25.59 305 12.00 350 13.78 70 2.76 80 176<br />

100 4 810 31.89 406 16.00 400 15.75 92 3.62 142 313<br />

150 6 1095 43.11 559 22.00 500 19.69 137 5.40 350 772<br />

200 8 1052 41.42 711 28.00 500 19.69 178 7.00 540 1190<br />

250 10 1260 49.61 864 34.00 630 24.80 222 8.74 963 2123<br />

300 12 1320 51.97 991 39.00 630 24.80 248 9.76 1182 2606<br />

350 14 1395 54.92 1067 42.00 710 27.95 270 10.63 1410 3109<br />

400 16 1660 65.35 1194 47.00 800 31.50 328 12.91 2230 4916<br />

450 18 1705 67.13 1346 53.00 900 35.43 349 13.74 2915 6426<br />

500 20 1890 74.41 1473 58.00 900 35.43 391 15.39 4040 8907<br />

600 24 2020 79.53 1676² 66.00² 1000 39.37 468 18.43 6375 14054<br />

vv (1) Per ASME B16.10 Short pattern<br />

(2) Per ASME B16.10 Long pattern<br />

• Butt welding end dimensions on page 33<br />

• Alternatives are available on request.

D<br />

A<br />

C<br />

parallel side gate valve 21<br />

Parallel Slide Gate <strong>Valves</strong> - Cast Steel Hi-Fluidic PSGV Series (ASME Class 2500)<br />

<strong>PARALLEL</strong> <strong>SLIDE</strong> <strong>GATE</strong> VALVE<br />

Pressure Sealed Bonnet<br />

Carbon Or Stainless Steel<br />

Asme Class 2500 , 2 1/2”-24”(65 - 600mm)<br />

<br />

<br />

<br />

<br />

B<br />

Product Number: KKM00AHB<br />

Valve Size : 65A(2½”) - 2150A(6”)<br />

Product Number: KKG00AHB<br />

Valve Size : 200A(8”) - 500A(20”)<br />

Table 10. Cast Steel Parallel Slide Gate Valve Dimension (Class 2500/Pn420)<br />

Nominal Size A B¹ C D Weight (B.W)<br />

mm in mm in mm in mm in mm in Kg lb<br />

65 2½ 505 19.88 330 13.00 250 9.84 45 1.77 76 168<br />

80 3 620 24.41 368 14.50 400 15.75 57 2.24 110 243<br />

100 4 775 30.51 457 28.00 450 17.72 73 2.87 160 353<br />

150 6 1055 41.53 610 24.00 500 19.69 104 4.10 446 983<br />

200 8 975 38.38 762 30.00 630 24.80 146 5.75 615 1356<br />

250 10 1145 45.08 914 36.00 710 27.95 175 6.90 1050 2315<br />

300 12 1330 52.36 1041 41.00 800 31.50 219 8.60 1650 3638<br />

350 14 1395 54.92 1181 44.00 800 31.50 241 9.50 1910 4211<br />

400 16 1490 58.66 1245 49.00 900 35.43 260 10.23 2915 6426<br />

450 18 1660 65.35 1397 55.00 900 35.43 293 11.53 3880 8554<br />

500 20 1800 70.87 1473² 58.00² 1000 39.37 325 12.80 5250 11574<br />

(1) Per ASME B16.10 Short pattern<br />

(2) Dimension is manufacture standard.<br />

• Buttwelding end dimensions on page 33<br />

• Alternatives are available on request.

22 parallel side gate valve<br />

Parallel Slide Gate <strong>Valves</strong> -Forged Steel Hi-Fluidic PSGV Series (ASME Class 1500)<br />

<strong>PARALLEL</strong> <strong>SLIDE</strong> <strong>GATE</strong> VALVE<br />

Pressure Sealed Bonnet<br />

Die Forged Carbon, Alloy Or Stainless Steel<br />

Asme Class 900/1500/2500/3500/4500, 1/2”-2”(15 - 50mm)<br />

<br />

product number : KJpm, KJpp<br />

Table 11. Materials Of Construction<br />

BODY A105 F22 F316<br />

<br />

<br />

<br />

BONET A105 F22 F316<br />

DISK SS410 SS410/SS431 SS316<br />

STEM SS410/HF SS410/SS431/HF SS316/HF<br />

SEAT RING CS+HF F22+HF SS316HF<br />

GASKET Expanded Graphite Expanded Graphite Expanded Graphite<br />

GUIDE FLANGE SS410/GN-HT SS410/GN-HT SS304/GN-HT<br />

YOKE SS410 SS410 SS410<br />

DISK HOLDER CF8M CFM8 CF8M<br />

Table 12. Forged Steel Parallel Slide Gate Valve Dimension (Class 900/1500/2500/3500)<br />

Nominal Size<br />

A B¹ C D Weight<br />

CLASS<br />

mm in mm in mm in mm in mm i n Kg lb<br />

15 ½<br />

20 ¾<br />

25 1<br />

32 1¼<br />

40 1½<br />

50 2<br />

900/1500<br />

2500/3500<br />

900/1500<br />

2500/3500<br />

900/1500<br />

2500/3500<br />

900/1500<br />

2500/3500<br />

900/1500<br />

2500/3500<br />

900/1500<br />

2500/3500<br />

285<br />

298<br />

285<br />

298<br />

308<br />

335<br />

384<br />

435<br />

384<br />

435<br />

468<br />

485<br />

11.22<br />

11.73<br />

11.22<br />

11.73<br />

12.13<br />

13.19<br />

15.12<br />

17.13<br />

15.12<br />

17.13<br />

18.43<br />

19.09<br />

117<br />

130<br />

117<br />

130<br />

130<br />

165<br />

165<br />

203<br />

165<br />

203<br />

203<br />

218<br />

4.61<br />

5.12<br />

4.61<br />

5.12<br />

5.12<br />

6.50<br />

6.50<br />

7.99<br />

6.50<br />

7.99<br />

7.99<br />

8.58<br />

175<br />

175<br />

175<br />

175<br />

175<br />

200<br />

200<br />

250<br />

200<br />

250<br />

250<br />

250<br />

6.89<br />

6.89<br />

6.89<br />

6.89<br />

6.89<br />

7.87<br />

7.87<br />

9.84<br />

7.87<br />

9.84<br />

9.84<br />

9.84<br />

12<br />

12<br />

15<br />

15<br />

20<br />

20<br />

31<br />

31<br />

31<br />

31<br />

45<br />

45<br />

0.47<br />

0.47<br />

0.59<br />

0.59<br />

0.79<br />

0.79<br />

1.22<br />

1.22<br />

1.22<br />

1.22<br />

1.77<br />

1.77<br />

8<br />

10<br />

8<br />

10<br />

10<br />

16<br />

16<br />

30<br />

16<br />

30<br />

28<br />

40<br />

18<br />

22<br />

18<br />

22<br />

22<br />

35<br />

35<br />

66<br />

35<br />

66<br />

62<br />

88<br />

Table 13. Forged Steel Parallel Slide Gate Valve Dimension (Class 4500)<br />

Nominal Size A B¹ C D Weight<br />

mm in mm in mm in mm in mm i n Kg lb<br />

15 ½ 298 11.73 130 5.12 175 6.89 10 0.39 14 31<br />

22 ¾ 298 11.73 130 5.12 175 6.89 10 0.39 14 31<br />

25 1 335 13.19 165 6.50 200 7.87 15 0.59 22 49<br />

32 1¼ 435 17.13 203 7.99 250 9.84 19 0.75 35 77<br />

40 1½ 435 17.13 203 7.99 250 9.84 19 0.75 35 77<br />

50 2 485 19.09 218 8.58 250 9.84 25 0.98 46 101<br />

(1) Dimensions are manufacture standard<br />

• Butt welding end dimensions on page 33<br />

• Socket welding dimensions on page 36<br />

• Alternatives are available on request.

parallel side gate valve 23<br />

Parallel Slide Gate <strong>Valves</strong> - Design Features<br />

PSGV Standard Design Data<br />

Class Valve Size (inch) ½” ¾” 1” 1-1¼” 11½” 2”<br />

DN (mm) 15 20 25 32 40 50<br />

Seat Diameter (mm) 12 15 20 31 31 45<br />

600<br />

Stem Diameter (mm) 14 14 14 19 19 19<br />

900<br />

Thread (TR) 12x3 12x3 12x3 16x4 16x4 16x4<br />

1500<br />

RUN (Turns) 7 7 9 9.4 9.4 13.4<br />

Cv (Flow Capacity) 5 7 19 71 71 180<br />

DN (mm) 15 20 25 40 40 50<br />

Seat Diameter (mm) 12 15 20 31 31 45<br />

2500<br />

Stem Diameter (mm) 14 14 16 19 19 22<br />

Thread (TR) 12x3 12x3 14x3 16x4 16x4 20x4<br />

RUN (Turns) 7 7 9 9.4 9.4 13.4<br />

Cv (Flow Capacity) 5 7 19 71 71 180<br />

DN (mm) 15 20 25 40 40 50<br />

Seat Diameter (mm) 10 10 15 19 19 25<br />

4500<br />

Stem Diameter (mm) 14 14 16 19 19 22<br />

Thread (TR) 12x3 12x3 14x3 16x4 16x4 20x4<br />

RUN (Turns) 5.5 5.5 7.5 6.7 6.7 8.5<br />

Cv (Flow Capacity) 3 3 7 16 16 39<br />

<strong>PARALLEL</strong> <strong>SLIDE</strong> <strong>GATE</strong> VALVE<br />

Pressure Sealed Bonnet<br />

Free Forged Carbon, Alloy Or Stainless Steel<br />

Asme Class 900/1500/2500, 4”-24”(100 - 600mm)<br />

Consult Factory for Details.<br />

Closed and Opened PSGV<br />

Structure of the Spring Pack<br />

Structure of the Disc Assembly<br />

Structure of the PSGV

24 parallel side gate valve<br />

Design Features<br />

Exceptional Design Features of Spring Pack Loaded(SPL) Parallel Slide Gate <strong>Valves</strong><br />

• KVT Parallel Slide Gate <strong>Valves</strong>(PSGV) are designed for more reliable sealing tightness and valve operation in fluid flow control. As a<br />

final control component the reliable tight shutoff function in the valve is one of the most important control factors.<br />

KVT introduces a long lifetime of the valves with freedom from most problems. Each PSGV in this brochure is based on the<br />

principles of parallel slide gate design with independent discs; wide flat seats, variable numbers of spring pack to be allowed proper<br />

sealing forces and a sharp shaped edge on the discs. More than just assuring fluid seating tightness, KVT PSGV design provides<br />

freedom from sticking or binding results by thermal effects associated with wedge gate valves.<br />

• No tendency to mark, notch or indent the sealing surfaces, even in presence of girt and positive contacting loads, because parallel<br />

slide gate valves close with a sliding action, not by compression. This results in better tightness and a longer maintenance free<br />

lifetime of the discs/seats sealing surfaces.<br />

• Our, KVT, wide flat seating surface discs with a sharp shape edge have a cleaning action with intimate contact on the seats during<br />

the closing action. Any polluted impurities on the seats/discs are eliminated and the sealing contact is free from undesirable<br />

particles. It also reduces seat bearing stress and guarantees long life. The wide flat seating can minimize the effect of minor<br />

damage to the surface as sealing occurs over the entire surface.<br />

• Since sealing is obtained by sliding, not by compression, there is no need for final surge of torque to make the seating leak tight.<br />

No additional power is required for the first effort in unseating the discs. Therefore, actuator size of the parallel slide gate valve can<br />

be much smaller than the wedge type. Hammering or impacting handwheels are not usually necessary on the parallel slide gate<br />

valves.<br />

• Because of the low torque operation, the stress and fatigue on the trim is less on parallel slide gate valves which results in longer<br />

lifetime and greater leak tight reliability.<br />

• Since sealing is obtained by sliding, not by compression, the exact position of stem is not critical when the valve is closed. As a<br />

result, there is no problem with the differences of the thermal expansion coefficient of the materials. Also the actuators can be<br />

stopped with general position switches.<br />

• It is possible that wedge gate valves have a tendency to jam as a result of body contraction, if they are closed while hot, and cooled<br />

afterwards. Undesirable malfunction like this never occurs with parallel slide gate valves.<br />

• In wedge gate valves, the wedge must have positioning guides on its sides to keep it in line while closing under full flow condition.<br />

These guides are not usually made of any hard material, and tend to wear, and eventually may cause jamming. This never occurs in<br />

KVT designed parallel slide gate valves, as the disc is guided only by its Stellite Hardfaced sealing surface.<br />

Another Advantages of SPL Parallel Slide Gate Valve<br />

The unique SPL(Disc Spring Pack Loaded) gate trim unit comprises all of the operating<br />

parts of sliding discs. No wedging effects and much smaller contacting stresses on the<br />

seating mechanism. In high temperature service and high pressure service, the valve is<br />

never subjected to thermal binding since the SPL gate trim unit absorbs irregular thermal<br />

expansion due to the structural discontinuity of valve body.<br />

To avoid the seat wear problems, the disc and seat are hardfaced to keep a different<br />

hardness with Stellite #12 and Stellite #6 respectively. Remarkable different hardness is<br />

kept to minimize a galling & its built-up effects on sliding metal surfaces. It results in long<br />

life cycle of the valve.<br />

The SPL centralized INCONEL cone springs which distribute uniformly loading on both<br />

seats as well as compensating for irregular expansion of seats and seat wear. Also the<br />

precision guiding system in gate trim unit and stem connection eliminate vibration (due<br />

to flow turbulence) of gate trim unit even the disc position in partially open. KVTs’ SPL<br />

parallel slide gate valves can be flow throttling in any form of flowing condition.

parallel side gate valve 25<br />

Operating Tips & Caution<br />

Operating Tips and Cautions of SPL Parallel Slide Gate <strong>Valves</strong><br />

• Operating Tips for long life service the parallel slide gate valves<br />

- Operate the valves at least every three months.<br />

- Keep the stem clean and lubricated (to avoid the corrosion of valves).<br />

- Inspect the valves regularly per service importance level predefined.<br />

- Lap seats promptly if the valve leaks.<br />

- Do not use the hammer blow and/or impacting leverages.<br />

- Check the packing regularly.<br />

• General Cautions when operating the parallel slide gate valves<br />

Since open/close thrust of the parallel slide gate valves is remarkably lower than other types of gate valves, no need to use hammer<br />

blow hand wheel or big sized hand wheel or impact type leverage. Also do not over torque the stem and watch carefully the stopper not<br />

bent when the stopper reaches the yoke pillars.<br />

In case of electric motor actuated valves, a torque value calculated is only determined to select an appropriate size of motor actuator.<br />

The limits of stem travel are determined solely by limit switches. Only allows limit switch setting for closed position(sealing position) and<br />

for open position will be set with torque switch in electric motor actuator.<br />

At all the times it is never necessary to use extra force at the end of the stroke to make seal for parallel slide gate valves.<br />

For valves fitted with a bypass, which are electrical actuated, the motor actuated operators shall be sequenced as following cycles,<br />

- With main and bypass closed, it shall not be possible to open the main valve until the bypass valve has been opened.<br />

- When main valve has opened fully, the bypass valve shall be closed automatically.<br />

- With the main valve open, the signal for it to close shall be automatically cause the bypass valve to open.<br />

- When the main valve reaches the shut position fully, the bypass valve shall be automatically closed and then the cycles will be<br />

completed.<br />

For valves fitted with a pressure equalizing valve in addition to the normal bypass valve, the equalizing valve is manually operated and is<br />

locked in the open position during normal operation.<br />

• Bypass <strong>Valves</strong>, Equalizing <strong>Valves</strong>, and Equalizing Devices Bypass valves are used to reduce the traversing differential pressure across<br />

the valve seat. This reduces the size of the operating device force, resulting in considerable savings. Also bypass valve provides convenient<br />

means for the initial warming through pipe line. Equalizing devices are used to relieve the fluid trapped between the seat faces,<br />

and provide outlet for the fluid displaced by the valve stem traversing to the shut position in non compressible fluid such as boiler feed<br />

water system. Also the equalizing devices are useful for steam service due to steam condensation. When bypass valve be used, it provides<br />

a fitting for an equalizing connection from main valve, through the bypass and to the main line. For equalizing inside of the valve<br />

a hole(drilled hole in seat or disc) or connecting flow passage on the trim can be used as an equalizing device. Alternatively, relief valve<br />

mounted on bonnet is used to relieve the high pressurized trappings.

26 parallel side gate valve<br />

Equalizing & By-Passing Device<br />

WEDGE <strong>GATE</strong> AND <strong>PARALLEL</strong> <strong>SLIDE</strong> <strong>GATE</strong><br />

<strong>VALVES</strong> FAIL TO OPEN<br />

Under certain process conditions may be<br />

attributed to an increase in the required<br />

unwedging thrust to open the valve due to<br />

the following phenomena:<br />

OVER PRESSURIZATION<br />

May result when liquid, entrapped in<br />

the center cavity of valves, is heated.<br />

- The trapped fluid expands and<br />

the resultant increase in pressure<br />

may make the valve inoperable.<br />

In extreme cases, a breach of the<br />

pressure boundary may occur.<br />

- Each 1°F rise in temperature<br />

results in a pressure increase of<br />

150 psi.<br />

- Over pressurization may occur<br />

in both pressure seal and bolted<br />

bonnet type valves and is not<br />

restricted to valve size.<br />

- A length of pipe isolated at both<br />

ends by a valve may also suffer<br />

from over pressurization.<br />

PRESSURE LOCKING<br />

When P 1<br />

is significantly larger<br />

than P a<br />

or P b<br />

, pressure locking<br />

occurs.<br />

- The potential for pressure<br />

locking is greater in parallel<br />

slide valves (double disc<br />

gate) due to the effective<br />

area on which the entrapped<br />

pressure acts.<br />

THERMAL BINDING<br />

May occur in wedge type gate valves<br />

between the wedge and seats due<br />

to temperature differential between<br />

inlet and outlet of the valve, when the<br />

valve was closed hot and the system<br />

cools down.<br />

- It may make the valve<br />

inoperable.<br />

- The stem expansion and<br />

other stresses, mechanical or<br />

thermal, may also contribute as<br />

valve bodies are not rigid.<br />

- Thermal binding is more<br />

common in high temperature<br />

applications.<br />

- While wedge type gate valves are<br />

susceptible to thermal binding,<br />

parallel slide valves are not.<br />

Pressure increase of the trapped liquid<br />

P1<br />

P1<br />

HEAT<br />

HEAT<br />

Pa<br />

Pb<br />

p₁= pressure of trapped liquid between seats<br />

p₁= pressure of trapped liquid between seats<br />

pa or pb = line pressure<br />

Fig. 4 Over -Pressurization Fig. 5 Pressure Locking Fig. 6 Thermal Binding

parallel side gate valve 27<br />

Operating Tips & Caution<br />

RECOMMENDATIONS<br />

1. OVERPRESSURIZATION AND<br />

PRESSURE LOCKING<br />

After evaluating and determining that the<br />

potential for problems exist, the solution for<br />

over-pressurization and pressure locking<br />

is to provide pressure relief from the body<br />

cavity. This can be done in several ways:<br />

- An internal hole in the disc face (Fig. 7), or in<br />

the seat (Fig. 8), connecting the body cavity<br />

to the high pressure side of the valve. The<br />

valve however will seal only in one direction.<br />

- An equalizing-pipe and equalizing-valve<br />

(Fig. 9), connecting the body cavity to<br />

the high pressure side of the valves, the<br />

valve must be open to provide relief.<br />

- Relief valve (Fig. 10 & 11), connecting the<br />

body cavity to the atmosphere, is another<br />

way to provide pressure relief, however the<br />

exhaust from the self-activating type reliefvalve<br />

must be piped to a safe location.<br />

Caution must be used when opening<br />

the drain type relief-valve.<br />

High pressure side<br />

hen valve closed<br />

Internal hole<br />

High<br />

pressure<br />

side<br />

High pressure side<br />

hen valve closed<br />

Equalizing pipe<br />

Equalizing valve<br />

Internal Hole<br />

High pressure side<br />

hen valve closed<br />

Fig. 7 Fig. 8<br />

Relief Valve<br />

Fig. 9 Fig. 10<br />

2. THERMAL-BINDING (Fig. 12)<br />

- Bypass-pipes and a valve will allow warm up<br />

of both sides of the wedge. (Warm-up lines<br />

located far away from the valve do not have a<br />

significant impact on thermal equalization.)<br />

By-pass valve<br />

Drain valve<br />

By-pass pipe<br />

3. COMBINED EFFECTS OF<br />

OVERPRESSURIZATION PRESSURE LOCKING<br />

AND THERMAL BINDING (Fig. 13-16)<br />

When evaluation determines that thermal<br />

binding may exist in combination with overpressurization<br />

and/or pressure locking, the<br />

solution will require combination of both<br />

equalizing and bypass pipes and valves.<br />

Fig. 11 Fig. 12<br />

Equalizing pipe<br />

Equalizing pipe<br />

By-pass valve<br />

By-pass pipe<br />

By-pass pipe<br />

By-pass pipe<br />

By-pass equalising valve<br />

Fig. 13 Fig. 14<br />

Equalizing pipe<br />

Equalizing valve<br />

Equalizing valve<br />

By-pass valve<br />

By-pass pipe<br />

By-pass equalizing valve<br />

Fig. 15 Fig. 16

28 parallel side gate valve<br />

Equalizing & By-Passing Device<br />

4. OTHER RECOMMENDATIONS<br />

- Verify the process to see if ∆T between closing and opening<br />

can be reduced.<br />

- After closing a wedge type gate valve, back up the stem (1/8”<br />

to 1/4” turn) to allow room for stem expansion. This is only<br />

practical in manual valves or electronically controlled motor<br />

operated valves.<br />

- Adequate pipe supports can reduce piping stresses.<br />

- Stroke the valves a few times, immediately after closure,<br />

if practical, to allow for wedge to warm up, or close valve<br />

slowly.<br />

- Under exceptional circumstances for electrically actuated<br />

valves opt for position seating instead of torque seating on<br />

closure. This must be discussed with the KVT for warranty<br />

considerations.<br />

- Consider the use of parallel slide gate valves, which are not<br />

subject to thermal binding. It is, however important to realize<br />

that they are more susceptible to pressure locking, higher<br />

seat wear, as well as difficulties in positive sealing at low<br />

pressures. - Contact the KVT for specific design solutions.<br />

Over Pressure<br />

Protection<br />

Relief Valve<br />

(Option)<br />

Bypass<br />

3 Way Combination<br />

SPL PSGV Bypass Valve<br />

Equalizing 3 Way Combination line<br />

SPL PSGV Bypass Valve<br />

Bypass Outlet<br />

Over Pressure<br />

Bypass Inlet<br />

Protection<br />

Relief Valve<br />

(Option)<br />

Bypass<br />

Fig. 12: 3-Way Center Equalizing Cavity lineBalancer Valve.<br />

Bypass Inlet<br />

Bypass Outlet<br />

Fig. 12: 3-Way Center Cavity Balancer Valve.<br />

3-WAY CENTER-CAVITY AUTOMATIC BALANCER<br />

We offer a self-actuating pressure-relief device, connected<br />

to the body cavity and the inlet/outlet of the valve.<br />

Fig. 13: 3-Way Center Cavity Automatic Balancer Valve.<br />

Description of Operation<br />

Port A is connected to one valve pipe side.<br />

Port B is connected to the body centre cavity.<br />

Port C is connected to the other valve pipe side.<br />

A<br />

B<br />

C<br />

High Pressure on the “A” Port Side: (Figure 14)<br />

- The shuttle is pushed to seat on the LP side.<br />

- The pressure is then equalized between the HP side “A”<br />

and the body cavity “B”.<br />

High Pressure on “B” Port (Body Cavity):<br />

- The pressure will escape to “A” port, preventing<br />

overpressure build-up in the body cavity.<br />

Reverse Pressure: (Figure 15)<br />

- The shuttle is pushed to seat on the Low Pressure side.<br />

- The pressure is then equalized between the High Pressure<br />

side “C” and the body cavity “B”.<br />

High Pressure on “B” port (Body Cavity):<br />

- The pressure will escape to the “C” port, preventing<br />

overpressure build-up in the body cavity.<br />

Fig. 13: 3-Way Center Cavity Automatic Balancer Valve.<br />

B<br />

A<br />

C<br />

Fig. 14: Cut shoing the check valve operation.<br />

B<br />

A<br />

C<br />

Fig. 14: Cut shoing the check valve operation.<br />

B<br />

A<br />

C<br />

Fig. 15: Cut shoing the check valve operation.<br />

Fig. 15: Cut shoing the check valve operation.

parallel side gate valve 29<br />

Advances Parallel Slide Gate <strong>Valves</strong> – Parallel Slide Gate Control <strong>Valves</strong><br />

Bypasses-MSS SP 45 Series A<br />

Bypasses are used in steam service for warming up before the main line is opened and for balancing pressure where the lines are<br />

of limited volume. Bypasses are attached at the side of the main valve with the steam of both valves parallel, pointing vertically<br />

upward as shown below.<br />

When other Bypass configuration are required, a sketch or drawing must accompany the order.<br />

X<br />

Y<br />

Bypass sizes conform to<br />

MSS SP-45, Series A<br />

Bypass Sizes And Dimensions<br />

Class<br />

300<br />

600<br />

900<br />

Main X Y Bypass<br />

Main X Y By-<br />

Valve<br />

pass<br />

Valve<br />

Class<br />

size mm in mm in Size<br />

size mm in mm in Size<br />

(NPS)<br />

(NPS) (NPS)<br />

(NPS)<br />

16 395 15.55 580 22.83 1<br />

8 305 12.01 400 15.75 ¾<br />

18 445 17.52 700 27.56 1 10 335 13.19 420 16.54 1<br />

20 475 18.70 700 27.56 1 12 370 14.57 520 20.47 1<br />

24 505 19.88 750 29.53 1 1500 14 390 15.35 570 22.44 1<br />

30 535 21.06 800 31.50 1 16 445 17.52 650 25.59 1<br />

36 565 22.24 850 33.46 1 18 500 19.69 670 26.38 1<br />

10 300 11.81 530 20.87 1 20 560 22.05 700 27.56 1<br />

12 360 14.17 580 22.83 1<br />

6 290 11.42 420 16.54 ¾<br />

14 380 14.96 580 22.83 1 8 350 13.78 430 16.93 ¾<br />

16 420 16.54 660 25.98 1 10 390 15.35 510 20.08 1<br />

18 465 18.31 730 28.74 1 2500 12 450 17.72 600 23.62 1<br />

20 495 19.49 970 38.19 1 14 450 17.72 700 27.56 1<br />

24 525 20.67 1200 47.24 1 16 500 19.69 750 29.53 1<br />

8 315 12.40 500 19.69 ¾ 18 550 21.65 800 31.50 1<br />

10 340 13.39 530 20.87 1<br />

6 370 14.57 340 13.39 ¾<br />

12 375 14.76 580 22.83 1 3500 8 420 16.54 1500 19.69 ¾<br />

14 395 15.55 660 25.98 1 10 450 17.72 2550 21.65 1<br />

16 420 16.54 730 28.74 1<br />

18 480 18.90 750 29.53 1<br />

20 540 21.26 850 33.46 1<br />

Parallel Slide Gate Control <strong>Valves</strong> - Linear Characteristic<br />

Parallel Slide Gate Control <strong>Valves</strong> - EQ% Characteristic<br />

PSGV on Seismic Simulator<br />

Parallel Slide Gate Control <strong>Valves</strong> - Pressure Let-Down

30 parallel side gate valve<br />

Flange Dimensions (Ansi Class 150lb-2500lb)<br />

n-øh<br />

T<br />

F<br />

øG<br />

øC<br />

øD<br />

23°<br />

øP<br />

øk<br />

f<br />

F<br />

Table 14. Flange Dimensions(Class 150lb)<br />

Normal size C D E F f G K P T n-øh<br />

mm in mm in mm in mm in mm in mm in mm in mm in mm in mm in mm in<br />

15 ½ 60.3 2.38 90 3.5 - - 2.00 0.06 - - 34.9 1.38 - - - - 9.6 0.38 4-16 4-⅝<br />

20 ¾ 69.9 2.75 100 3.88 - - 2.00 0.06 - - 42.9 1.69 - - - - 11.2 0.44 4-16 4-⅝<br />

25 1 79.4 3.12 110 4.25 6.35 0.25 2.00 0.06 8.74 0.34 50.8 2.00 63.5 2.50 47.6 1.88 12.7 0.50 4-16 4-⅝<br />

40 1½ 98.4 3.88 125 5.00 6.35 0.25 2.00 0.06 8.74 0.34 73.0 2.88 82.5 3.25 65.1 2.56 15.9 0.62 4-16 4-⅝<br />

50 2 120.7 4.75 150 6.00 6.35 0.25 2.00 0.06 8.74 0.34 92.1 3.62 102.0 4.00 82.6 3.25 17.5 0.69 4-19 4-¾<br />

65 2½ 139.7 5.50 180 7.00 6.35 0.25 2.00 0.06 8.74 0.34 104.8 4.12 121.0 4.75 101.6 4.00 20.7 0.81 4-19 4-¾<br />

80 3 152.4 6.00 190 7.50 6.35 0.25 2.00 0.06 8.74 0.34 127.0 5.00 133.0 5.25 114.3 4.50 22.3 0.88 4-19 4-¾<br />

100 4 190.5 7.50 230 9.00 6.35 0.25 2.00 0.06 8.74 0.34 157.2 6.19 171.0 6.75 149.2 5.88 22.3 0.88 8-19 8-¾<br />

150 6 241.3 9.50 280 11.00 6.35 0.25 2.00 0.06 8.74 0.34 215.9 8.50 219.0 8.62 193.7 7.63 23.9 0.94 8-22 8-⅞<br />

200 8 298.3 11.75 343 13.50 6.35 0.25 2.00 0.06 8.74 0.34 269.9 10.62 273.0 10.75 247.7 9.75 27.0 1.06 8-22 8-⅞<br />

250 10 362.0 14.25 405 16.00 6.35 0.25 2.00 0.06 8.74 0.34 323.8 12.75 330.0 13.00 304.8 12.00 28.6 1.12 12-25 12-1<br />

300 12 431.8 17.00 485 19.00 6.35 0.25 2.00 0.06 8.74 0.34 381.0 15.00 406.0 16.00 381.0 15.00 30.2 1.19 12-25 12-1<br />

350 14 476.3 18.75 535 21.00 6.35 0.25 2.00 0.06 8.74 0.34 412.8 16.25 425.0 16.75 396.9 15.63 33.4 1.31 12-29 12-1⅛<br />

400 16 539.8 21.25 595 23.50 6.35 0.25 2.00 0.06 8.74 0.34 469.9 18.50 483.0 19.00 454.0 17.88 35.0 1.38 16-29 16-1⅛<br />

450 18 577.9 22.75 635 25.00 6.35 0.25 2.00 0.06 8.74 0.34 533.4 21.00 546.0 21.50 517.5 20.38 38.1 1.50 16-32 16-1¼<br />

500 20 635.0 25.00 700 27.50 6.35 0.25 2.00 0.06 8.74 0.34 584.2 23.00 597.0 23.50 558.8 22.00 41.3 1.62 20-32 20-1¼<br />

600 24 749.3 29.50 815 32.00 6.35 0.25 2.00 0.06 8.74 0.34 692.2 27.25 711.0 28.00 673.1 26.50 46.1 1.81 20-35 20-1¼<br />

Table 15. Flange Dimensions (Class 300lb)<br />

Normal size C D E F f G K P T n-øh<br />

mm in mm in mm in mm in mm in mm in mm in mm in mm in mm in mm in<br />

20 ¾ 82.6 3.25 115 4.62 6.35 0.25 2.00 0.06 8.74 0.34 42.9 1.69 63.5 2.50 42.9 1.69 14.3 0.56 4-19 4-¾<br />