sivacon

sivacon

sivacon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The Variable Low-Voltage Switchboard 8PV<br />

Economical, Requirement-Oriented, Type-Tested<br />

<strong>sivacon</strong>

Economical, Requirement-Oriented and Type-Tested:<br />

the SIVACON Variable Low-Voltage Switchboard<br />

Economical, requirement-oriented and<br />

type-tested (TTA) – these are the identifying<br />

features of the new low-voltage switchboard<br />

from Siemens. SIVACON®is suitable for<br />

all power levels: from the power centre<br />

with a rating of 6300 A through main and<br />

subdistribution boards to the motor control<br />

centre, installed either in fixed-mounted,<br />

plug-in or withdrawable unit design.<br />

Modular technology<br />

Every SIVACON assembly<br />

is manufactured exclusively<br />

from standardized and<br />

series-produced modules<br />

oriented to requirements.<br />

All modules are type-tested<br />

and incorporate high quality.<br />

By virtue of a wide range of<br />

possible module combinations,<br />

justice is done to all<br />

stipulations. Adaptations to<br />

new performance demands<br />

can be realized easily and<br />

swiftly by simply replacing<br />

or adding modules. The<br />

advantages of the modular<br />

concept are obvious:<br />

• Type-testing provides proof<br />

of safety and quality for each<br />

installation<br />

• All requirement profiles are<br />

fulfilled with the high quality<br />

of standard production<br />

• Ordering of spares and<br />

additions is easy and<br />

delivery times are short<br />

SIVACON offers<br />

advantages that set<br />

new standards<br />

• Type-tested standard<br />

modules (TTA)<br />

• Space-saving base areas<br />

from only 400 x 400 mm<br />

• High packing density with<br />

up to 40 feeders per cubicle<br />

• Test and disconnected<br />

position with door closed<br />

• Visible isolating gaps and<br />

points of contact<br />

• Standard operator interface<br />

for all withdrawable units<br />

• Solid wall design for safe<br />

cubicle-to-cubicle separation<br />

• Alternative busbar<br />

positioning at top or rear<br />

• Cable or bar connection<br />

from above or below<br />

The SIVACON variable low-voltage switchboard<br />

2

Fig. 1 Power Center,<br />

Main distribution<br />

board<br />

Fig. 2 Subdistribution<br />

board<br />

Fig. 3 Motor Control<br />

Center<br />

Fig. 4 Communication<br />

SIVACON adapts to your<br />

requirements<br />

(Pages 4 and 5)<br />

Circuit-breaker design<br />

(Pages 6 and 7)<br />

Withdrawable unit design<br />

(Pages 8 – 13)<br />

1<br />

2<br />

3 4<br />

5<br />

Fixed-mounted design<br />

(Pages 14 – 17)<br />

3<br />

In-line plug-in design<br />

(Pages 18 and 19)<br />

In-line-type plug-in<br />

design 3NJ6<br />

(Page 20)<br />

SIVACON is capable of<br />

communication<br />

(Page 21)<br />

Solid wall frame for<br />

enhanced safety<br />

(Pages 22 and 23)<br />

Variable busbar systems<br />

(Page 24)<br />

SIVACON is resistant to<br />

internal arcing faults<br />

(Page 25)<br />

Type-tested switchgear<br />

and controlgear<br />

assembly (TTA);<br />

technical data<br />

(Pages 26 and 27)<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11

SIVACON Adapts to Your<br />

Requirements<br />

Modular technology in every single cubicle and<br />

in the design of the overall system allows the<br />

SIVACON switchboard system to adapt to all<br />

requirements.<br />

• Busbars can optionally be<br />

located at the top or rear<br />

• Any components can be<br />

installed in the device<br />

compartments regardless<br />

of the busbar position and<br />

cubicle depth<br />

• Requirement-oriented<br />

subdivision of function<br />

compartments from<br />

Form 1 to Form 4<br />

(VDE 0660 Part 500)<br />

• Withdrawable and fixedmounted<br />

units can be<br />

combined in one cubicle<br />

Optimum adaptation to<br />

space conditions<br />

• When installed, all<br />

switchboard cubicles are<br />

flush at the front and rear<br />

• Cables and bars can<br />

optionally be connected<br />

from above or below<br />

• Busbars can be installed<br />

easily in constricted space<br />

on site<br />

Swift adaptation<br />

to new performance<br />

demands<br />

• Easy replacement or addition<br />

of function units<br />

• Good busbar accessibility<br />

allows simple replacement<br />

• Modular technology enables<br />

simple subsequent ordering<br />

and short delivery times<br />

400 400 400<br />

600 400<br />

400 600<br />

4<br />

Device compartment<br />

Cross-wiring compartment<br />

Busbar compartment<br />

Cable connection compartment<br />

optionally at the side, top or bottom

SIVACON for All Applications<br />

in the Low-Voltage Network<br />

Power Center<br />

I n up to 6300 A<br />

I cw up to 100 kA<br />

I pk up to 220 kA<br />

Main distribution board<br />

I n up to 4000 A<br />

I cw up to 100 kA<br />

I pk up to 250 kA<br />

Motor Control Center<br />

I n up to 2500 A<br />

I cw up to 50 kA<br />

I pk up to 110 kA<br />

Subdistribution board<br />

I n up to 2500 A<br />

Icw up to 50 kA<br />

I pk up to 110 kA<br />

Loads<br />

M M M M M M M<br />

5

Circuit-Breaker Design –<br />

Compact, Reliable and User-Friendly<br />

Distribution boards for substantial energy requirements are<br />

generally followed by a number of subdistribution boards<br />

and loads. Particular demands are therefore made in terms<br />

of long-term reliability and safety. That is to say, "supply",<br />

"coupling" and "feeder" functions must be reliably available<br />

over long periods of time. Maintenance and testing must not<br />

involve long standstill times.<br />

SIVACON meets these requirements with circuit-breaker design<br />

components.<br />

Compact and reliable<br />

• High degree of safety by<br />

virtue of type-tested<br />

standard modules (TTA)<br />

• Test and disconnected<br />

position with door closed<br />

• Cubicle dimensions tailored<br />

to circuit-breaker sizes (e.g.<br />

1600 A with 400 mm width<br />

and 3200 A with 600 mm<br />

width)<br />

• For every rated current<br />

range, optimum connection<br />

conditions for cables and<br />

busbars<br />

• Separate function<br />

compartments consisting<br />

of a switching device<br />

compartment, an auxiliary<br />

equipment compartment<br />

and a cable or bar<br />

connection compartment<br />

• High degree of safety for<br />

assembly personnel by<br />

virtue of cubicle separation<br />

on both sides<br />

User-friendly<br />

with Sentron WL<br />

Siemens 3WL non-withdrawable<br />

and withdrawable<br />

circuit-breakers are used for<br />

the rated current range from<br />

630 to 6300 A. This means:<br />

• Free choice of the supply<br />

direction without any<br />

sacrifices in terms of<br />

technical data<br />

• High short-time currentcarrying<br />

capacity for timegraded<br />

short-circuit<br />

protection (up to 400 ms)<br />

assures reliable operation<br />

of sections of the switchboard<br />

not affected by a<br />

short circuit<br />

• Short-circuit protection with<br />

short-time grading control<br />

(zss) for very brief delay<br />

times (50 ms)<br />

• LCD operating current<br />

indication in the control<br />

console (without ammeters<br />

and current transformers)<br />

• Indication and operation<br />

when the door is closed<br />

Sentron WL circuit-breaker;<br />

1600 A rated current<br />

with a 400 mm cubicle<br />

width<br />

6

Every circuit-breaker is assigned<br />

an auxiliary equipment<br />

compartment and a cable or<br />

bar connection compartment.<br />

Auxiliary equipment compartment<br />

• Optimum space conditions<br />

for installing auxiliary<br />

devices, even for extensive<br />

control and interlocking<br />

systems<br />

• For adaptations, the auxiliary<br />

device module can be<br />

separated from the power<br />

section and taken out<br />

Cable or bar connection<br />

compartment<br />

• Cable or bar connection<br />

optionally from above or<br />

below<br />

• A rated current-dependent<br />

connection compartment<br />

offers optimum connection<br />

conditions for cables and<br />

bars<br />

• Assembly times are<br />

shortened by optimum<br />

connection compartments<br />

Switching device compartment<br />

• Reliable travel of the circuitbreaker<br />

while the door is<br />

closed<br />

• A maintenance position<br />

allows direct local<br />

inspection without removal<br />

of the circuit-breaker<br />

Safe movement of the<br />

circuit-breaker while<br />

the door is closed.<br />

Detachable auxiliary<br />

device module for swift<br />

adaptations<br />

High degree of safety for assembly<br />

personnel by virtue of cubicle<br />

separation on both sides<br />

7

Withdrawable Unit Design –<br />

Ergonomic, Reliable and Versatile<br />

Whether in power plants, industrial installations<br />

or office complexes, an adequate amount of<br />

energy must be available at the necessary<br />

location and at all times. However, requirements<br />

frequently change. For example, motor power<br />

ratings change or new loads have to be<br />

connected.<br />

SIVACON's withdrawable unit design offers the<br />

required degree of power supply flexibility.<br />

What's more, it was conceived on the basis of<br />

ergonomic criteria. Easy handling and short<br />

conversion times assure high availability of the<br />

system.<br />

Ergonomic, reliable and<br />

versatile<br />

• High degree of safety by<br />

virtue of type-tested<br />

standard modules (TTA)<br />

• Test and disconnected<br />

position with door closed<br />

• High packing density with<br />

a minimum base area (up<br />

to 40 feeders per cubicle)<br />

• Standard operator interface<br />

for all withdrawable units<br />

• Visible isolating gaps on the<br />

supply and feeder sides<br />

• Easy insertion without<br />

having to overcome plugin<br />

forces<br />

• Easy adaptation to<br />

changing operating<br />

conditions without<br />

disconnection of a cubicle<br />

Withdrawable unit design for maximum<br />

operating and safety convenience<br />

8

Plug-on bar system, protected<br />

against internal arcing, embedded<br />

in the left of the cubicle<br />

The plug-on bus system<br />

The plug-on bus system is<br />

located on the left of the<br />

cubicle. It offers safe-to-touch<br />

protection without additional<br />

shutters to live parts.<br />

• Embedded in a safe<br />

environment with regard<br />

to arcing faults<br />

• Phase separation<br />

• 3 and 4-pole versions<br />

possible<br />

• Safe-to-touch (IP 20B)<br />

• Tap openings in a modular<br />

grid of 175 mm for withdrawable<br />

unit sizes 1 to 4<br />

and for miniature withdrawable<br />

unit adapters<br />

Miniature withdrawable unit adapter<br />

The miniature withdrawable<br />

unit adapter has contact with<br />

the plug-on bus system and<br />

contains the supply/feeder<br />

and control wiring for size 1/4<br />

and 1/2 withdrawable units.<br />

• Embedded in a safe<br />

environment with regard<br />

to arcing faults<br />

• Phase separation<br />

• 3 and 4-pole versions<br />

possible<br />

• Safe-to-touch (IP 20B)<br />

• Tap openings for up to<br />

4 size 1/4 withdrawable<br />

units or<br />

2 size 1/2 withdrawable<br />

units<br />

Miniature withdrawable unit adapter,<br />

protected against internal arcing,<br />

embedded in the top compartment<br />

Miniature withdrawable unit adapter<br />

(inside view)<br />

9

Withdrawable Unit Design –<br />

Ergonomic, Reliable and Versatile<br />

SIVACON withdrawable<br />

units offer<br />

operating<br />

and handling safety<br />

• Standard operating method<br />

for all sizes of withdrawable<br />

units<br />

• Six withdrawable unit sizes<br />

(sizes 1/4, 1/2, 1, 2, 3 and 4)<br />

• All parts are inside the<br />

contours of the<br />

withdrawable units and are<br />

therefore protected against<br />

damage<br />

• Integrated maloperation<br />

protection in all<br />

withdrawable units<br />

• Positions of withdrawable<br />

units are indicated clearly<br />

• Master switch and<br />

withdrawable unit positions<br />

are actuated separately<br />

• Test and disconnected<br />

position with door closed,<br />

but without cancelling the<br />

degree of protection<br />

• Constant isolation gap<br />

conditions by virtue of a<br />

separate isolating contact<br />

system<br />

• Hinged instrument panel<br />

for adjustments during<br />

operation<br />

• Possibility of fitting<br />

components at the rear,<br />

with plenty of space for<br />

auxiliary equipment<br />

• Fused and non-fused<br />

withdrawable units for<br />

motor and cable feeders up<br />

to 630 A<br />

Maloperation protection<br />

prevents travel of the<br />

isolating contacts when<br />

the master switch is "ON"<br />

Easy insertion without<br />

having to overcome<br />

plug-in forces<br />

10

Size 1 withdrawable<br />

unit, 30 kW, with<br />

contactor-type<br />

star-delta starter<br />

Rear components,<br />

Size 2 withdrawable<br />

unit<br />

Hinged instrument<br />

panel<br />

Size 1/4 withdrawable<br />

unit, 11 kW, with<br />

direct contactor<br />

Size 1/2 withdrawable<br />

unit, 18.5 kW, with<br />

direct contactor and<br />

SIMOCODE-DP<br />

11

Withdrawable Unit Design –<br />

Ergonomic, Reliable and Versatile<br />

Withdrawable principle: Moving<br />

of isolating contact system with<br />

door closed<br />

Withdrawable principle<br />

Indication of the withdrawable<br />

unit position on the unit itself<br />

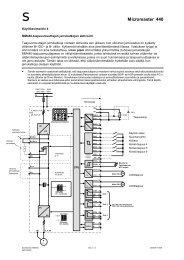

Description of functions<br />

L3<br />

L2<br />

L1<br />

N<br />

I<br />

(Connected position)<br />

Isolating contact system<br />

for main circuit<br />

for auxiliary circuit<br />

Master switch position<br />

Compartment door<br />

closed<br />

closed<br />

0/I<br />

closed<br />

Moving from the<br />

connected position to the<br />

disconnected position or<br />

vice versa<br />

L3<br />

L2<br />

L1<br />

N<br />

0<br />

(Disconnected position)<br />

Isolating contact system<br />

for main circuit<br />

for auxiliary circuit<br />

Master switch position<br />

Visible isolating gap<br />

Compartment door<br />

open<br />

open<br />

0/I<br />

closed<br />

Moving from the disconnected<br />

position to the<br />

test position or vice versa<br />

L3<br />

L2<br />

L1<br />

N<br />

TEST<br />

(Test position)<br />

Isolating contact system<br />

for main circuit<br />

for auxiliary circuit<br />

Master switch position<br />

Compartment door<br />

open<br />

closed<br />

0/I<br />

closed<br />

12

All power and control<br />

cables are connected<br />

in a separate<br />

cable connection<br />

compartment<br />

Versatility and reliability<br />

with adaptation to<br />

changing requirements<br />

• Simple conversion of<br />

withdrawable compartments<br />

without disconnection<br />

of the cubicle<br />

• No connection work<br />

necessary in the<br />

withdrawable compartment<br />

• Connections for power<br />

and control cables in the<br />

separate cable connection<br />

compartment<br />

• Cable connection<br />

compartment up to<br />

400 mm wide<br />

Rapid replacement of<br />

withdrawable compartments<br />

from sizes 1 to<br />

4 with sizes 1/4 and 1/2<br />

by inserting a miniature<br />

withdrawable unit adapter<br />

13

Fixed-Mounted Design –<br />

4Economical, Reliable and Variable<br />

In certain applications, either there is no need<br />

to replace components under operating<br />

conditions or short standstill times are<br />

acceptable. In this case, the SIVACON fixedmounted<br />

design offers excellent economy,<br />

reliability and variability.<br />

• High degree of safety by<br />

virtue of type-tested<br />

standard modules (TTA)<br />

• Any combination of<br />

modular function units<br />

• Swift conversion by virtue<br />

of the lateral universal<br />

cubicle busbar<br />

• Easy replacement of<br />

function units after<br />

deenergizing the<br />

switchboard<br />

• Add-on components for<br />

subdivision of function<br />

areas right up to<br />

compartmentalization in<br />

accordance with<br />

requirements<br />

Variable fixed-mounted design<br />

14

Diverse<br />

connection<br />

possibilities<br />

Fused modular function<br />

unit with direct contactor,<br />

45 kW<br />

Universal cubicle busbar<br />

The lateral universal cubicle<br />

busbar offers diverse<br />

possibilities for connecting<br />

cables, conductors and bars.<br />

• Devices are connected<br />

without the need for drilling<br />

or piercing, and precisely<br />

where they are needed<br />

• Easily accessible<br />

connections for swift<br />

conversion and expansion<br />

• Connections are visible and<br />

can be tested from the front<br />

Internal separation of<br />

function areas<br />

Modular function<br />

units<br />

The modular function units<br />

enable efficient installation,<br />

above all whenever<br />

operationally required<br />

changes or adaptations are<br />

necessary.<br />

• Devices and device<br />

combinations for motor<br />

and cable feeders up to<br />

800 A can be fitted as<br />

required<br />

• Modular function units<br />

can be combined as<br />

required within one<br />

cubicle<br />

• A securing system for<br />

"one-man assembly"<br />

enables swift and simple<br />

replacements<br />

Internal separation<br />

Add-on components to meet<br />

individual convenience and<br />

safety needs.<br />

• Internal separation between<br />

function units<br />

• Individual doors for each<br />

respective function area<br />

• Shock-hazard protection<br />

with respect to the cable<br />

connection compartment<br />

15

Fixed-Mounted Design –<br />

Economical, Reliable and Variable<br />

460 mm busbar system<br />

60 mm busbar system for<br />

space-saving installation with<br />

direct adaptation of:<br />

• Contactor combinations<br />

up to 15 kW<br />

• Circuit-breakers<br />

up to 160 A<br />

• Fuse switch-disconnectors<br />

up to 160 A<br />

• Clear arrangement of<br />

devices<br />

• Easy replacement<br />

• Installation of up to<br />

40 feeders per cubicle<br />

Fixed-mounted fuse<br />

switches in strip design<br />

With their compact and<br />

modular design, the strip<br />

design switching devices offer<br />

a high packing density.<br />

• Cable feeders up to 630 A<br />

• High packing density of up<br />

to 27 feeders per cubicle<br />

• Dead-state fuse replacement<br />

Fixed-mounted<br />

fuse switch in<br />

strip design<br />

60 mm busbar<br />

system<br />

16

Capacitor and controller<br />

modules for<br />

central reactive power<br />

compensation<br />

Controller module with<br />

electronic reactive power<br />

controller for door mounting<br />

• Self-adaption of the C/k value<br />

• Nominal cos phi adjustable<br />

from 0.8 ind to 0.98 cap<br />

• Manual switching<br />

Capacitor modules up to<br />

100 kvar<br />

• Fuse switch-disconnector<br />

• Capacitor switching<br />

contactors<br />

• MKK power capacitors<br />

• Discharging units<br />

• Filter circuit chokes<br />

(choked)<br />

Choked reactive power<br />

compensation 250 kvar<br />

17

In-Line Plug-In Design –<br />

5Economical, Reliable, Versatile<br />

The In-Line Plug-In design represents a low-priced<br />

alternative to both the classic fixed-mounted<br />

and the convenient withdrawable unit design.<br />

By virtue of the supply-side plug-in contact, the<br />

modules provide the facility for quick<br />

interchangeability without the switchboard having<br />

to be isolated. This design is therefore used<br />

wherever changing requirements are imposed<br />

on operation, if for example motor ratings have to<br />

be changed or new loads connected.<br />

The SIVACON In-Line Plug-In design offers<br />

excellent economy, reliability and versatility.<br />

• High degree of safety by<br />

virtue of type-tested<br />

standard modules (TTA)<br />

• Supply-side plug-in contact<br />

enables quick replacement<br />

• Load feeders<br />

up to 45 kW<br />

• 3RV circuit-breaker units up<br />

to 100 A<br />

• High packing density (up to<br />

35 feeders per cubicle)<br />

• Protection against electric<br />

shock from plug-on bus<br />

system<br />

• Auxiliary current plug<br />

connector<br />

• Lateral guide to ensure<br />

positive contact<br />

• With/without instrument<br />

panel<br />

• combinable with plug-in<br />

fuse strips 3NJ6<br />

• 400 mm wide cable<br />

connection compartment<br />

• Possible to replace a feeder<br />

without having to shut<br />

down the system<br />

In-Line Plug-In design<br />

combined with plug-in<br />

fuse strips 3NJ6<br />

18

Plug-on bus system<br />

Lateral guide rail<br />

on left of cubicle<br />

Plug-on bus system<br />

The plug-on bus system is<br />

located at the rear of the<br />

cubicle. It offers safe-to-touch<br />

protection without additional<br />

shutters to live parts.<br />

• Integrated protection<br />

against electric shock<br />

• 3 and 4-pole versions<br />

possible<br />

• Safe-to-touch (IP 20B)<br />

• Tap openings in a modular<br />

grid of 50 mm<br />

In-line module height 50 mm<br />

11 kW with direct starter<br />

In-line module height 100 mm<br />

45 kW with direct starter<br />

and SIMOCODE-DP<br />

19

6In-Line-Type Plug-In Design 3NJ6 –<br />

Economical, Reliable, Versatile<br />

In-Line-Type switching devices with supply-side plugin<br />

contact are an economical alternative to the<br />

withdrawable unit design. The switches can be replaced<br />

without the system having to be shut down. The<br />

SIVACON in-line-type plug-in design 3NJ6 offers<br />

excellent economy, reliability and versatility.<br />

• High degree of safety by<br />

virtue of type-tested<br />

standard modules (TTA)<br />

• Supply-side plug-in contact<br />

enables quick replacement<br />

• In-line-type switching<br />

devices for cable feeders<br />

up to 630 A available in the<br />

following designs:<br />

– Fuse module<br />

– Fuse switchdisconnectors<br />

(single-break)<br />

– Fuse switchdisconnectors<br />

(double-break)<br />

– Switch-disconnectors<br />

• High packing density (up to<br />

35 feeders per cubicle)<br />

• Dead-state fuse<br />

replacement<br />

• Protection against electric<br />

shock from plug-on bus<br />

system<br />

• 400 mm wide cable<br />

connection compartment<br />

• Degree of protection<br />

up to IP 41<br />

• Possible to replace a feeder<br />

without having to shut<br />

down the system<br />

Fuse switchdisconnector<br />

125 A with<br />

supply-side<br />

plug-in contact<br />

In-line-type plugin<br />

design 3NJ6<br />

20

SIVACON<br />

is capable of communication<br />

7<br />

With SIMOCODE®-DP for motor and cable feeders<br />

and the communication-capable circuit-breakers<br />

Sentron WL, SIVACON offers an economical possibility<br />

of exchanging data with automation systems.<br />

The widespread standardized, cross-manufacturer-<br />

PROFIBUS®-DP serves as the bus system, offering<br />

links to a very diverse range of programmable<br />

controllers.<br />

Communication-capable<br />

circuit-breaker 3WL<br />

• Remote-control for opening<br />

and closing<br />

• Remote diagnostics for<br />

preventive maintenance<br />

• Signalling of operating<br />

states<br />

• Transmission of current<br />

values e.g. for power<br />

management<br />

• Easy installation planning<br />

• Savings in wiring<br />

Communication-capable<br />

motor protection and control<br />

device SIMOCODE-DP<br />

• Integrated full motor<br />

protection<br />

• Extensive control functions<br />

• Convenient diagnostics<br />

possibilities<br />

• Autonomous operation of<br />

each feeder via an operator<br />

control block<br />

AS-interface<br />

• Status messages via AS-I<br />

modules (On/Off/Control)<br />

AS-interface<br />

module 4I<br />

Sentron WL<br />

circuit-breaker<br />

SIMOCODE-DP in size 1/4<br />

withdrawable unit<br />

21

8Solid Wall Frame for<br />

Enhanced Safety<br />

The frame side walls are made from one piece<br />

and are connected by means of crossbars to obtain<br />

the dimensionally accurate and sturdy SIVACON<br />

frame.<br />

• All necessary cutouts for<br />

the switchboard are<br />

integrated in the side walls,<br />

ensuring a high degree of<br />

safety by way of only a few<br />

parts<br />

• The use of galvanized<br />

sheets assures long-term<br />

corrosion protection and<br />

absolutely safe earthing<br />

• Powder-coating of the<br />

visible enclosure largely<br />

prevents damage during<br />

transport, assembly and<br />

operation<br />

• Detachable frame and<br />

enclosure parts enable<br />

subsequent assembly of<br />

the horizontal busbars<br />

• Without the need for<br />

additional partitions, the<br />

part-integrating solid wall<br />

design offers safety from<br />

one cubicle to another<br />

• Securing systems enable<br />

subsequent upgrading with<br />

expansion components<br />

• Spring-loaded locks reliably<br />

prevent doors from<br />

springing open<br />

unintentionally. They also<br />

ensure safe pressure<br />

equalization in the event of<br />

an arcing fault<br />

• The switchboard is capable<br />

of withstanding very high<br />

seismic stress<br />

Frame for<br />

top busbars<br />

22

Part-integrating<br />

solid wall design<br />

Partial view of cable<br />

connection compartment<br />

Ventilation grille to busbar<br />

compartment to degree<br />

of protection IP 40<br />

Spring-loaded lock<br />

The transport unit dividing<br />

points are easily accessible<br />

when the cover is removed<br />

Earthquake test<br />

SIVACON<br />

on the vibration table<br />

23

9Variable<br />

Busbar Systems<br />

Differing switching tasks require individual<br />

realization possibilities. Whether simple systems<br />

or extensive networks with transverse and<br />

longitudinal couplings are involved, SIVACON<br />

offers an economical design of high quality.<br />

Top busbar system<br />

• Top or rear busbar system<br />

• Busbar systems for rated<br />

currents up to 6300 A<br />

• Rated impulse withstand<br />

current (lpk) up to 250 kA<br />

• Local integration of busbars<br />

possible<br />

• Two busbar systems<br />

can be routed within the<br />

switchboard<br />

• Transport unit dividing<br />

points easily accessible<br />

from the front or top<br />

• Device compartment can<br />

be separated from<br />

interconnected busbar<br />

• Busbar connections require<br />

no maintenance<br />

• Busbar systems for corner<br />

installation<br />

• Additional arc barrier<br />

Rear busbar system<br />

24

SIVACON is resistant<br />

to internal arcing faults<br />

10<br />

Testing of low voltage switchboards under internal<br />

arcing fault conditions is classified as a special<br />

test in accordance with IEC 61641 or VDE 0660<br />

Part 500, supplement 2.<br />

This test serves to gauge the dangers to which<br />

persons might be exposed in the event of an internal<br />

arcing fault.<br />

By way of the test under internal arcing fault<br />

conditions, SIVACON provides evidence of personnel<br />

safety in terms of the following assessment criteria<br />

as standard:<br />

Arc barrier<br />

Assessment criteria<br />

1. Doors, covers etc. must not<br />

open<br />

2. No parts may fly off<br />

3. No holes may be burnt into<br />

the enclosure<br />

4. Indicators must not ignite<br />

5. The protective conductor<br />

circuit for touchable parts<br />

of the enclosure must still<br />

be in working order<br />

Additional modules for limiting<br />

the effects of the arcing fault<br />

inside the switchboard<br />

• Restriction to one cubicle<br />

(Arc barrier)<br />

• Restriction to the function<br />

compartment or place of<br />

origin<br />

• Insulated main busbars<br />

(design without base)<br />

Arcing fault<br />

test<br />

Insulated<br />

main busbar<br />

Device compartment can<br />

be separated from<br />

interconnected busbars<br />

25

1Type-Tested Switchgear and<br />

1Controlgear Assembly (TTA)<br />

SIVACON is a type-tested switchgear and<br />

controlgear assembly (TTA) whose physical<br />

characteristics were designed in the test<br />

laboratory both for normal operating conditions<br />

and for fault situations. Conclusive<br />

type tests assure a maximum of reliability<br />

and safety. SIVACON has passed the<br />

following verification tests as detailed in<br />

IEC 60439-1 and DIN EN 60439-1<br />

(VDE 0660 Part 500):<br />

• Verification of temperaturerise<br />

limits by test<br />

• Verification of dielectric<br />

properties by test<br />

• Verification of the shortcircuit<br />

withstand strength<br />

by test<br />

• Verification of the effective<br />

connection between the<br />

exposed conductive parts<br />

of the assembly and the<br />

protective circuit by<br />

inspection or by resistance<br />

measurement<br />

• Verification of the shortcircuit<br />

withstand strength of<br />

the protective circuit by test<br />

• Verification of clearances<br />

and creepage distances<br />

• Verification of mechanical<br />

operation<br />

• Verification of the degree of<br />

protection<br />

Every SIVACON switchboard<br />

assembly undergoes routine<br />

testing before delivery:<br />

• Inspection of the assembly<br />

including inspection of<br />

wiring and, if necessary,<br />

electrical operation test<br />

• Dielectric test<br />

• Checking of protective<br />

measures and of the<br />

electrical continuity of the<br />

protective circuits<br />

These safety requirements<br />

are met by a series of details<br />

in SIVACON, for example:<br />

• With the use of the<br />

withdrawable design,<br />

operating errors are ruled<br />

out by exactly shaped<br />

mechanical guides and<br />

interlocks<br />

• Use is made of only a few,<br />

exclusively high-grade<br />

insulating materials<br />

(e.g. for rail mounts and<br />

reinforcements, etc.)<br />

• Use of reliable Siemens<br />

switchgear reduces the risk<br />

of premature failures<br />

• Reliable disconnection after<br />

70 to 100 ms even in the<br />

event of long delay times by<br />

3WN circuit-breakers with<br />

short-time grading control<br />

• Computer-assisted project<br />

planning assures error-free<br />

selection and placement of<br />

items<br />

• Arcing fault-tested<br />

• Quality management<br />

system to DIN EN ISO 9001<br />

• Environmental management<br />

system to<br />

DIN EN ISO 14001<br />

26

Technical Data<br />

at a Glance<br />

Standards and specifications<br />

Type-tested low-voltage switchgear<br />

and controlgear assembly (TTA)<br />

Protection against electrical shock<br />

Testing of response to internal faults<br />

(arcing faults)<br />

Induced vibrations<br />

IEC 60439-1, DIN EN 60439-1<br />

(VDE 0660 Part 500)<br />

DIN VDE 0106 Part 100<br />

IEC 61641, VDE 0660 Part 500, Supplement 2<br />

IEC 68 Part 2, IEC 980<br />

Creepage distances<br />

and clearances<br />

Rated impulse withstand<br />

voltage (U imp )<br />

Overvoltage category<br />

Pollution degree<br />

8 kV<br />

III<br />

3<br />

Rated insulation<br />

voltage (U i )<br />

1000<br />

V<br />

Rated operational<br />

voltage (U e )<br />

up to<br />

690<br />

V<br />

Busbars<br />

(3 and 4-pole)<br />

Main horizontal<br />

busbars<br />

Rated current<br />

Rated peak withstand<br />

current (I pk )<br />

Rated short-time<br />

withstand current (I cw )<br />

up to 6300<br />

up to<br />

up to<br />

A<br />

250 kA<br />

100 kA<br />

Vertical busbars for<br />

circuit-breakers<br />

See main horizontal<br />

busbars<br />

for fixed-mounted design<br />

for in-line plug in design<br />

for In-line-type plug-in design 3NJ6<br />

Rated current<br />

Rated peak withstand<br />

current (I pk )<br />

Rated short-time<br />

withstand current (I cw )<br />

up to 2000<br />

up to<br />

up to<br />

A<br />

110 kA<br />

50 kA*<br />

for withdrawable unit design<br />

Rated current<br />

Rated peak withstand<br />

current (I pk )<br />

Rated short-time<br />

withstand current (I cw )<br />

up to 1000<br />

up to<br />

up to<br />

A<br />

143 kA<br />

65 kA*<br />

Device rated currents<br />

Circuit-breakers<br />

Cable feeders<br />

Motor feeders<br />

up to 6300<br />

up to 1600<br />

up to 630<br />

A<br />

A<br />

A<br />

Internal separation<br />

Form 1 to Form 4<br />

IEC 60439-1, Section 7.7<br />

DIN EN 60439-1<br />

Surface treatment<br />

Degree of protection<br />

(Paint finish to DIN 43656)<br />

Frame parts<br />

Enclosure<br />

Doors<br />

Colour of powder-coated parts<br />

(Coat thickness 80 µm)<br />

To IEC 60529, EN 60529<br />

Sendzimir galvanized<br />

Sendzimir galvanized/powder-coated<br />

Powder-coated<br />

RAL 7032, pebble grey<br />

IP 20 to IP 54<br />

Dimensions<br />

(Preferred dimensions to DIN 41488)<br />

Height:<br />

Width:<br />

Depth: Single front<br />

Double front<br />

Power centre<br />

2200<br />

400, 500, 600, 800, 1000<br />

400, 600<br />

1000<br />

1200<br />

mm<br />

mm<br />

mm<br />

mm<br />

mm<br />

* Rated conditional short-circuit current I CC up to 100 kA<br />

27

Subject to change without prior notice 03/03 | Order No. E20001-A180-P309-X-7600 | Dispo 27606 | 21C7892 DMSI.52.3.02 WS 03035.0 | Printed in Germany<br />

Siemens AG<br />

Automation and Drives<br />

Low Voltage Controls and Distribution<br />

P.O. Box 32 40, 91050 Erlangen<br />

Germany<br />

www.siemens.com/<strong>sivacon</strong>