You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NR.04/ 11<br />

7<br />

Picking the low hanging fruits:<br />

– New hull cleaning and propeller polishing schemes<br />

give important fuel and emission savings<br />

By Svend Foyn-Bruun and Erik Hjortland<br />

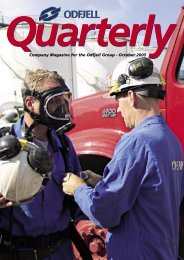

Equipment for hull cleaning<br />

The recent trial of a new hull cleaning and<br />

propeller polishing scheme on a ship has<br />

showed very promising results. The fuel efficiency<br />

increased significantly compared to<br />

previous measurements.<br />

Although hull cleaning and propeller<br />

polishing are normal part of ordinary drydocking<br />

work, the remarkable result may<br />

lead to a new practice by which all our ships,<br />

both time chartered and owned, will be more<br />

closely monitored and the cleaning intervals<br />

shortened.<br />

Fuel and emission savings<br />

We estimate that on this particular trial ship,<br />

the new and advanced hull cleaning and<br />

propeller polishing scheme will reduce the<br />

CO 2<br />

emissions by 5,000 mt in one year.<br />

It would be hard to make an individual underwater<br />

cleaning programme for each ship, but<br />

a scheme that introduces a shorter interval<br />

compared to todays practice combined with<br />

a closer performance evaluation seem to be<br />

optimal both from an environmental and a<br />

financial viewpoint.<br />

New techniques<br />

The underwater hull cleaning and propeller<br />

techniques have improved over the last<br />

couple of years. Today it is possible to carry<br />

out the cleaning during a normal port stay<br />

without arranging for the vessel to be off hire.<br />

The ‘robotized’ hull cleaning may take place<br />

at anchorage or at cargo berths without any<br />

significant release of antifouling residues.<br />

The whole operation can be completed within<br />

12 hours. The result is a significant reduction<br />

of consumption and emissions of CO 2<br />

, NOx<br />

and SOx.<br />

odfjell quarterly magazine