Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Bow Leopard -<br />

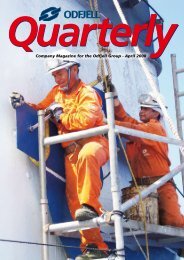

The superintendent’s view<br />

By Ashok Nair, Superintendent Bow Leopard<br />

Photos: Captain Luisito G. Cantona<br />

The first considerations<br />

on converting the KSEC<br />

ships to double-hull<br />

started within Fleet<br />

Asia team in Singapore<br />

already in June 2005.<br />

However, assistance<br />

was required by the<br />

Project/Newbuilding department in<br />

Bergen, and subsequently both the classification<br />

society, DnV, and the design<br />

department of Stocznia Szczecinska<br />

Nova yard in Poland got involved.<br />

When Cosco Shipyard in Nantong was<br />

awarded the task of undertaking the<br />

conversion works, the Superintendents<br />

in Fleet Asia added on specifications for<br />

general repair and maintenance.<br />

The initial yard estimate was that the<br />

entire stay at the yard for the conversion<br />

work would be about fifty days<br />

for each vessel. However, the rebuilding<br />

turned out to be more complicated,<br />

and we spent close to eighty days<br />

with the first vessel, which we realize is<br />

necessary. In September there will be<br />

three <strong>Odfjell</strong> vessels at the yard; Bow<br />

Puma, Bow Leopard and Bow Panther.<br />

All of us are looking forward to this<br />

moment.<br />

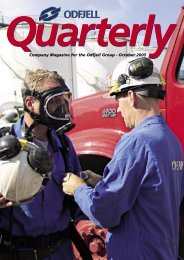

July and August were exceptionally<br />

hot in the Nantong area this year, with<br />

The old ship’s side being removed<br />

temperatures touching 36°C. Try to<br />

imagine what it was like inside the<br />

cargo tanks! The authorities prohibited<br />

work between 1100 and 1700 hrs, and<br />

obviously this slowed us down despite<br />

the fact that the yard increased the<br />

night shifts. Luckily, temperatures have<br />

since dropped, and schedules are back<br />

to normal.<br />

Such a long docking period is unusual<br />

and quite a challenge for the crew and<br />

the shore staff. The three Ds (difficult,<br />

dirty and dangerous) of shipyard work<br />

are obvious everyday. It is not possible<br />

to keep the decks and engine room<br />

clean due the large amount of steel<br />

work, coating/blasting and machinery<br />

work involved. There is also considerable<br />

steel work around the accommodation<br />

block, inside the accommodation,<br />

work on the air conditioning<br />

plant, sewage treatment plant and steel<br />

work in the fresh water tanks. Although<br />

we concentrate on keeping the accommodation<br />

space clean, the work has<br />

lead to lot of discomfort to the ship’s<br />

crew from time to time. To the credit of<br />

the ship staff and shipboard management<br />

team, all this has been borne with<br />

a smile.<br />

The double-side blocks ready for installation<br />

Besides the normal supervisory and<br />

coordinating role of a Superintendent,<br />

the challenge during such a long project<br />

is to motivate the crew and to<br />

sustain the focus on the yard to deliver<br />

in time and in quality. Maximizing the<br />

daily morning meetings with ship staff<br />

and yard key personnel is the key to the<br />

successful execution of this project. My<br />

6 ODFJELL Quarterly September 2006