You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

By Toralf Sørenes<br />

HSE Issues and Transparency<br />

In this world of collaboration and transparency,<br />

our customers expect that we,<br />

as one of their strategic service providers,<br />

communicate not only commercial<br />

but also HSE issues of significance. With<br />

today’s control systems, almost every<br />

negative outcome of what we do will<br />

come to light sooner or later. It is therefore<br />

very important to be proactive and<br />

notify relevant stakeholders of any problems<br />

as early as possible. A brief note is<br />

better than nothing. Early reporting has<br />

two advantages. Advice and guidance<br />

can be obtained at an early time when<br />

it can still be useful. Further, it will<br />

reduce and could<br />

even take away the<br />

negative perception<br />

of us trying to hide<br />

things. Although<br />

potential sanctions<br />

could act as a hindrance<br />

for openness,<br />

it is important to recognize<br />

that if sanctions<br />

are relevant,<br />

they will normally<br />

come. Port state and<br />

similar databases are<br />

monitored continuously,<br />

and if we wait<br />

with notifications<br />

and reports until it<br />

has become known<br />

through other sources,<br />

sanctions will<br />

come and be stronger.<br />

With a large fleet of nearly 100 ships<br />

such as <strong>Odfjell</strong>’s, the probability of having<br />

an incident that reaches the media<br />

is higher than if you own and manage<br />

a small fleet. The Law of Large Numbers<br />

implies that the bigger you get,<br />

the more important it will be to work<br />

proactively and systematically with risk<br />

reduction and loss preventive measures.<br />

Let us for instance consider port state<br />

detention. This is a very serious matter<br />

that must be sorted out before the ship<br />

is given clearance to sail from a port.<br />

But this is not the end of it; underlying<br />

issues and customer concerns may take<br />

a long time of hard and dedicated work<br />

to sort out.<br />

One issue that has been in focus for<br />

some time is inerting of all flammable<br />

cargoes. With the Bow Mariner and NCC<br />

Mekka still clear in mind, <strong>Odfjell</strong> has<br />

been active in this work and has strongly<br />

supported a change towards more robust,<br />

comprehensive and clearer regulations<br />

in this important area. While we<br />

are waiting for these new regulations to<br />

come, we must maintain a strong focus<br />

on inerting. It is a very high risk area involving<br />

two main elements: the equipment<br />

itself and the proper use of it.<br />

1 - The system with its various equipment<br />

and controls must be well maintained<br />

and operable at all times.<br />

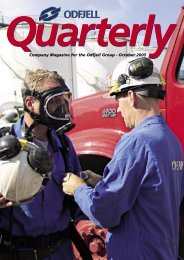

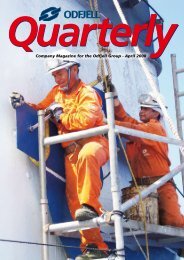

Personal Protective Equipment – USE IT!!<br />

2 - Those responsible must be fully familiar<br />

with the systems, equipment, its limitations,<br />

operation and the underlying<br />

requirements. Guidance and procedures<br />

must be clear and implementation done<br />

not only through written exchanges<br />

but also through training and on board<br />

attendance from the fleet units ashore.<br />

In addition to oily water systems and<br />

pollution, inerting has high focus within<br />

port state administrations in the trades<br />

<strong>Odfjell</strong> operates. In particular the US<br />

Coast Guard seems to have their focus<br />

on this. This is perhaps particularly relevant<br />

for our older<br />

ships. We may not<br />

be using these systems<br />

as frequently<br />

as product carriers<br />

do, and therefore<br />

testing and regular<br />

training is essential.<br />

It is also important<br />

to be well prepared<br />

for port state inspections,<br />

with the fleet<br />

units discussing all<br />

relevant issues in<br />

that respect. All our<br />

ships must report unsafe<br />

conditions and<br />

defective equipment,<br />

and appropriate risk<br />

assessments must be<br />

carried out on operations<br />

that deviate<br />

from normal routine.<br />

It is also essential that corrective and/or<br />

preventive actions that have been identified<br />

by the shipboard management<br />

teams during the risk assessment are<br />

timely and properly attended to, not<br />

only by themselves but also by the fleet<br />

units ashore.<br />

Safety Bulletin<br />

We always focus on the use of appropriate<br />

personal protective equipment<br />

(PPE), during internal audits and ship<br />

visits, and as part of reviewing near<br />

misses and high risk incidents. Regrettably<br />

we still come across events or situations<br />

where PPE should have been used<br />

but was not. We will again highlight the<br />

importance of strict adherence in this<br />

area whether it is working aloft, entry<br />

into enclosed spaces, cargo lines and<br />

systems on deck, etc. Both the general<br />

and individual PPE like non skid shoes,<br />

helmets and boiler suits, and more task<br />

specific PPE like harnesses and personal<br />

gas detectors are important. If we shall<br />

progress towards our zero accident<br />

goal, we must have high focus on critical<br />

success factors among which the use<br />

of PPE is essential. USE IT!!<br />

ODFJELL Quarterly September 2006 23