Split Type Room Air Conditioner Installation Manual - Friedrich Air ...

Split Type Room Air Conditioner Installation Manual - Friedrich Air ...

Split Type Room Air Conditioner Installation Manual - Friedrich Air ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

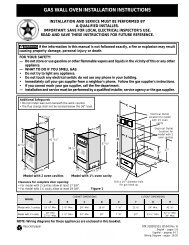

OUTDOOR UNIT<br />

OUTDOOR UNIT INSTALLATION<br />

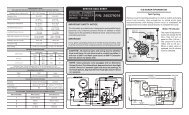

ELECTRICAL WIRING (OUTDOOR UNIT)<br />

●<br />

●<br />

Set the unit on a strong stand, such as one made of concrete blocks<br />

to minimize shock and vibration.<br />

Do not set the unit directly on the ground because it will cause trouble.<br />

Connector cover removal<br />

●<br />

Remove the two mounting screws.<br />

Fig. 9<br />

1. Remove the screws, then remove the control box cover.<br />

2. Fasten the Inter unit wire harness and power supply to the conduit holder using the lock nut.<br />

3. Connect inter-unit wire harness and power supply to the terminal.<br />

Refer to the wiring diagram<br />

4. Use the screws to install the control box cover.<br />

Installing the connector cover<br />

(1) After inserting the three front hooks, then insert the rear hook.<br />

(2) Tighten the two mounting screws.<br />

WARNING<br />

(1) Install the unit where it will not be tilted by more<br />

than 5°.<br />

(2) When installing the outdoor unit where it may exposed<br />

to strong wind, fasten it securely.<br />

Tapping screw<br />

Front hooks<br />

Rear hooks<br />

Connector cover<br />

WARNING<br />

Be sure to comply with local codes while running<br />

the wire from the indoor unit to the outdoor<br />

unit (size of wire and wiring method, etc. ).<br />

Every wire must be connected firmly.<br />

No wire should be allowed to touch refrigerant<br />

tubing, the compressor or any moving part.<br />

NOTE:<br />

• Connector trade size for this unit is 1/2” (12.7 mm). The connector<br />

can be bought at a hardware store. Refer to “How to connect<br />

wiring to the terminals” for instructions on connecting depending<br />

on the wire type you are using.<br />

• The fuse located in the outdoor unit provides power supply protection<br />

and may blow when power is applied if the system has<br />

been incorrectly wired.<br />

AIR PURGE<br />

Always use a vacuum pump to purge the air.<br />

Refrigerant for purging the air is not charged in the<br />

outdoor unit at the factory.<br />

Close the high pressure side valve of the gauge manifold fully and do<br />

not operate it during the following work.<br />

Loose wiring may cause the terminal to overheat<br />

or result in unit malfunction. A fire hazard<br />

may also exist. Therefore, be sure all wiring is<br />

tightly connected.<br />

Connect wires to the matching numbers of<br />

terminals.<br />

Lock nut<br />

1. Check if the piping connections are secure.<br />

2. Check that the stems of 2-way valve and 3-way valve are closed<br />

fully.<br />

3. Connect the gauge manifold charge hose to the charging port<br />

of the 3-way valve (side with the projection for pushing in the<br />

valve core).<br />

4. Open the low pressure side valve of the gauge manifold fully.<br />

5. Operate the vacuum pump and start pump down.<br />

6. Slowly loosen the flare nut of the 3-way valve and check if air<br />

enters, then retighten the flare nut.<br />

(When the flare nut is loosened the operating sound of the<br />

vacuum pump changes and the reading of the compound<br />

pressure gauge goes from minus to zero.)<br />

11. Firmly tighten the 2-way valve and 3-way valve blank cap and<br />

the charging port cap.<br />

Fig. 10<br />

3-way valve<br />

Charging port cap<br />

2-way valve<br />

Gauge manifold<br />

Compound pressure gauge<br />

Flare nut<br />

Valve stem<br />

Charging port<br />

-0.1 MPa<br />

(-76 cmHg<br />

-1 bar)<br />

Low pressure<br />

side valve<br />

Blank cap<br />

Charge hose<br />

LO HI<br />

Pressure gauge<br />

High<br />

pressure<br />

side valve<br />

(closed)<br />

Charge<br />

hose<br />

Vacuum pump<br />

Fig. 11<br />

Indoor unit<br />

Terminal<br />

G<br />

3<br />

2<br />

1<br />

DISCONNECT<br />

SWITCH<br />

(FIELD SUPPLY)<br />

Grounding line<br />

Control line<br />

(Inter Unit)<br />

Power line<br />

208/230V<br />

208/230V<br />

208/230V<br />

Outdoor unit<br />

(L) (N)<br />

Terminal<br />

G<br />

5<br />

4<br />

1 2 3<br />

POWER SUPPLY<br />

1 phase, 208/230V<br />

Cord Clamp<br />

Conduit<br />

connector<br />

Power supply<br />

Inter-unit<br />

wire harness<br />

7. Pump down the system for at least 15 minutes, then check if the<br />

compound pressure gauge reads -0.1 MPa (-76 cmHg, -1 bar).<br />

8. At the end of pump down, close the low pressure side gauge of<br />

the gauge manifold fully and stop the vacuum pump.<br />

9. Slowly loosen the valve stem of the 3-way valve. When the<br />

compound pressure gauge reading reaches 0.1-0.2 MPa,<br />

retighten the valve stem and disconnect the charge hose<br />

from the 3-way valve charging port.<br />

(If the stem of the 3-way valve is opened fully before the<br />

charge hose is disconnected, it may be difficult to disconnect<br />

the charge hose.)<br />

Table 6<br />

Blank cap (2-way valve)<br />

Blank cap (3-way valve)<br />

Charging port cap<br />

Tightening torque<br />

14.47 to 18.08 ft•lbs (200 to 250 kgf•cm)<br />

20.25 to 23.15 ft•lbs (280 to 320 kgf•cm)<br />

9.04 to 11.57 ft•lbs (125 to 160 kgf•cm)<br />

CAUTION<br />

(1) Refrigerant must not be discharged into atmosphere.<br />

Earth screw<br />

G<br />

Indoor unit<br />

terminal block<br />

1 2 3 4<br />

Disconnect switch<br />

Outdoor unit<br />

terminal block<br />

1 2 3 4 5<br />

Earth screw<br />

G<br />

10. Fully open the valve stems of the 2-way valve and 3-way valve<br />

using a hexagon wrench. (After the valve stem begins to turn,<br />

turn it with a torque of less than 2.17ft •lbs (30 kgf•cm) until it<br />

stops turning.)<br />

(2) After connecting the piping , check the joints for<br />

gas leakage with gas leak detector.<br />

Power supply line