SS SERVICE SPECIFICATIONS - TodoAutos

SS SERVICE SPECIFICATIONS - TodoAutos

SS SERVICE SPECIFICATIONS - TodoAutos

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

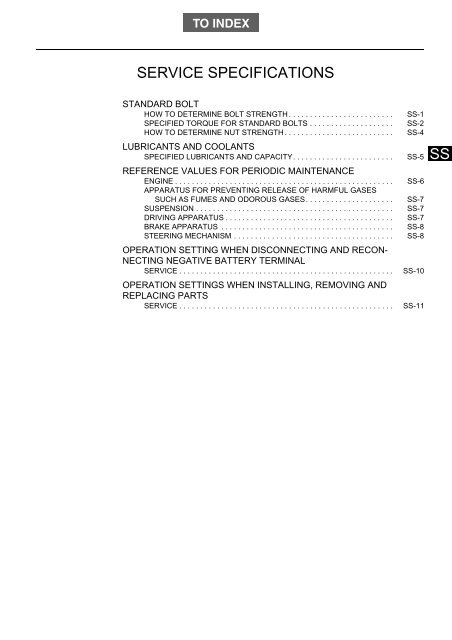

TO INDEX<br />

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong><br />

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong><br />

STANDARD BOLT<br />

HOW TO DETERMINE BOLT STRENGTH . . . . . . . . . . . . . . . . . . . . . . . . .<br />

SPECIFIED TORQUE FOR STANDARD BOLTS . . . . . . . . . . . . . . . . . . . .<br />

HOW TO DETERMINE NUT STRENGTH . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

LUBRICANTS AND COOLANTS<br />

SPECIFIED LUBRICANTS AND CAPACITY. . . . . . . . . . . . . . . . . . . . . . . .<br />

REFERENCE VALUES FOR PERIODIC MAINTENANCE<br />

ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

APPARATUS FOR PREVENTING RELEASE OF HARMFUL GASES<br />

SUCH AS FUMES AND ODOROUS GASES. . . . . . . . . . . . . . . . . . . . .<br />

SUSPENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

DRIVING APPARATUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

BRAKE APPARATUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

STEERING MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

OPERATION SETTING WHEN DISCONNECTING AND RECON-<br />

NECTING NEGATIVE BATTERY TERMINAL<br />

<strong>SERVICE</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

OPERATION SETTINGS WHEN INSTALLING, REMOVING AND<br />

REPLACING PARTS<br />

<strong>SERVICE</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

<strong>SS</strong>-1<br />

<strong>SS</strong>-2<br />

<strong>SS</strong>-4<br />

<strong>SS</strong>-5<br />

<strong>SS</strong>-6<br />

<strong>SS</strong>-7<br />

<strong>SS</strong>-7<br />

<strong>SS</strong>-7<br />

<strong>SS</strong>-8<br />

<strong>SS</strong>-8<br />

<strong>SS</strong>-10<br />

<strong>SS</strong>-11<br />

<strong>SS</strong>

<strong>SS</strong>–1<br />

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong> - STANDARD BOLT<br />

STANDARD BOLT<br />

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong><br />

HOW TO DETERMINE BOLT<br />

STRENGTH<br />

<strong>SS</strong><br />

Bolt Types<br />

Hexagonal Bolt<br />

Normal Recess Bolt Deep Recess Bolt<br />

Stud Bolt<br />

Welded Bolt<br />

Class<br />

No Mark<br />

No Mark<br />

No Mark<br />

w/ Washer<br />

w/ Washer<br />

D025089J01

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong> - STANDARD BOLT<br />

<strong>SS</strong>–2<br />

SPECIFIED TORQUE FOR STANDARD<br />

BOLTS<br />

1. SPECIFIED TORQUE<br />

HINT:<br />

The torque values listed below are the specifications for tightening<br />

unlubricated zinc-plated bolts.<br />

Class Diameter (mm) Pitch (mm)<br />

Specified Torque (Hexagon<br />

Head Bolt)<br />

(N*m [kgf*cm])<br />

Hexagon Flange Bolt<br />

(N*m [kgf*cm])<br />

4T 6 1.0 5{55} 6{60}<br />

<strong>SS</strong><br />

8 1.25 12.5{130} 14{145}<br />

10 1.25 26{260} 29{290}<br />

12 1.25 47{480} 53{540}<br />

14 1.5 74{760} 84{850}<br />

16 1.5 115{1150} 127{1300}<br />

5T 6 1.0 6.5{65} 7.5{75}<br />

8 1.25 15.5{160} 17.5{175}<br />

10 1.25 32{330} 36{360}<br />

12 1.25 59{600} 65{670}<br />

14 1.5 91{930} 100{1050}<br />

16 1.5 140{1400} 157{1600}<br />

6T 6 1.0 8{80} 9{90}<br />

8 1.25 19{195} 21{210}<br />

10 1.25 39{400} 44{440}<br />

12 1.25 71{730} 80{810}<br />

14 1.5 110{1100} 125{1250}<br />

16 1.5 170{1750} 191{1950}<br />

7T 6 1.0 10.5{110} 12{120}<br />

8 1.25 25{260} 28{290}<br />

10 1.25 52{530} 58{590}<br />

12 1.25 95{970} 105{1050}<br />

14 1.5 145{1500} 165{1700}<br />

16 1.5 230{2300} 255{2600}<br />

8T 6 1.0 12{125} 14{145}<br />

8 1.25 29{300} 33{330}<br />

10 1.25 61{620} 68{690}<br />

12 1.25 110{1100} 120{1250}<br />

14 1.5 170{1750} 195{2000}<br />

16 1.5 260{2700} 299{3050}<br />

9T 8 1.25 34{340} 37{380}<br />

10 1.25 70{710} 78{790}<br />

12 1.25 125{1300} 140{1450}<br />

10T 8 1.25 38{390} 42{430}<br />

10 1.25 78{800} 88{890}<br />

12 1.25 140{1450} 155{1600}<br />

11T 8 1.25 42{430} 47{480}<br />

10 1.25 87{890} 97{990}

<strong>SS</strong>–3<br />

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong> - STANDARD BOLT<br />

Class Diameter (mm) Pitch (mm)<br />

Specified Torque (Hexagon<br />

Head Bolt)<br />

(N*m [kgf*cm])<br />

Hexagon Flange Bolt<br />

(N*m [kgf*cm])<br />

12 1.25 155{1600} 175{1800}<br />

<strong>SS</strong>

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong> - STANDARD BOLT<br />

<strong>SS</strong>–4<br />

HOW TO DETERMINE NUT STRENGTH<br />

Standard Hexagonal Bolt<br />

Nut Types<br />

Old Standard Hexagon Nut<br />

Cold Forged Nut<br />

Cutting Processed Nut<br />

Class<br />

<strong>SS</strong><br />

No Mark<br />

No Mark (w/ Washer )<br />

No Mark (w/ Washer)<br />

No Mark<br />

No Mark<br />

More than one mark on the back of the nut<br />

D025090J01<br />

HINT:<br />

When replacing a nut, use a nut with a nut strength classification that is<br />

equal or higher than the strength classification number of the opposing bolt.<br />

(Example: Bolt = 4 T, Nut = 4 N or more)

<strong>SS</strong>–5<br />

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong> - LUBRICANTS AND COOLANTS<br />

LUBRICANTS AND COOLANTS<br />

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong><br />

SPECIFIED LUBRICANTS AND CAPAC-<br />

ITY<br />

1. ENGINE OIL<br />

<strong>SS</strong><br />

Engine oil viscosity chart<br />

C -29 -18 -7 4 16 27 38<br />

TEMP.<br />

F -20 0 20 40 60 80 100<br />

Engin oil<br />

(4 stroke)<br />

5W-20*<br />

0W-20*<br />

10W-30,10W-40,10W-50<br />

20W-40,20W-50<br />

5W-30<br />

* Standard recommended oil<br />

30<br />

D101273<br />

Engine Model<br />

Oil Only Replacement<br />

Filling Volume (L)<br />

Oil and Oil Filter<br />

Filling Volume When<br />

Replacing (L)<br />

3SZ-VE 2.9 3.2<br />

K3-VE 2.0 3.5<br />

HINT:<br />

The filling volume when replacing the oil or the oil filer is the amount<br />

of oil that is drained from the drain plug.<br />

NOTICE:<br />

• Based on the table, use an oil with a viscosity that is best<br />

suited to the air temperature.<br />

• Close the drain plug after confirming that the old oil has been<br />

sufficiently drained.<br />

• With an oil level gauge, always perform a final check of the<br />

amount of oil. (After warming up the engine, with the engine<br />

stopped and after it has been allowed to idle for 5 minutes,<br />

check that the amount of oil is at the F level of the gauge.)<br />

2. LUBRICANTS AND COOLANTS OTHER THAN ENGINE OIL<br />

Item (Type) Capacity (L) (Reference) Specified Lubricant<br />

Coolant (3SZ-VE) M/T: 4.6 Ethylene glycol based anti-freeze solution<br />

A/T: 4.4 <br />

Coolant (K3-VE) M/T: 4.3 <br />

A/T: 4.2 <br />

Automatic transmission fluid<br />

(Transmission)<br />

4.6 DEXRON-III<br />

Transfer oil<br />

(Four wheel drive vehicles with automatic transmission)<br />

1.6<br />

Manual Transmission Gear Oil<br />

(API GL-3 or GL-4, SAE 75W-90, 75W-85 or 75W-80)<br />

Manual transmission oil<br />

(FR vehicle)<br />

1.2 <br />

Manual transmission oil<br />

(4WD)<br />

2.2<br />

(Including transfer)<br />

Front differential oil 0.45<br />

Rear differential oil (excluding vehicles equipped<br />

with limited slip differential)<br />

Rear differential oil<br />

(Vehicles equipped with limited slip differential)<br />

<br />

Differential Gear Oil<br />

(API GL-5, SAE 80W-90)<br />

1.8 <br />

1.8<br />

Limited Slip Differential Gear Oil<br />

(API GL-5, SAE 80W-90)<br />

Power steering fluid 0.7 DEXRON-III<br />

Brake fluid - FMV<strong>SS</strong>116 DOT3 or DOT4<br />

Clutch fluid - <br />

A/C compressor oil - ND-OIL8

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong> - REFERENCE VALUES FOR PERIODIC MAINTENANCE<br />

REFERENCE VALUES FOR PERIODIC MAINTENANCE<br />

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong><br />

ENGINE<br />

<strong>SS</strong>–6<br />

1. ENGINE-RELATED<br />

Standard:<br />

Item 3SZ-VE K3-VE<br />

W/P pulley and P/S pump belt deflection (thrust force 100 N [10.2 kgf])<br />

(mm): when installing new parts (when cold)<br />

9-11 <br />

W/P pulley and P/S pump belt deflection (thrust force 100 N [10.2 kgf])<br />

(mm): for maintenance (when cold)<br />

13-15 <br />

W/P pulley and P/S pump belt tension (N [kgf]): when installing new parts<br />

(when cold)<br />

883 49{90 5} 637 49{65 5}<br />

W/P pulley and P/S pump belt tension (N [kgf]): for maintenance (when<br />

cold)<br />

441 98{45 10} <br />

Battery fluid specific gravity (fluid temperature 20C [68F]): specified<br />

values<br />

1.25-1.29 <br />

Battery fluid specific gravity (fluid temperature 20C [68F]): difference<br />

between cells<br />

Below 0.04<br />

<br />

Ignition timing (BTDC)/(r/min): EFI-T short circuit (*1) 4-8/600-750 <br />

Ignition timing (BTDC)/(r/min): EFI-T open circuit (*1) 0-15/600-750 <br />

Ignition timing (using the DS-II): TC terminal ON BTDC 4-8CA <br />

Ignition timing (using the DS-II): TC terminal OFF BTDC 0-15CA <br />

Idle speed (N and P range) (r/min) 600-750 <br />

IN valve clearance (when cold) (mm) 0.145-0.235 <br />

EX valve clearance (when cold) (mm) 0.275-0.365 <br />

Tightening torque [N*m{kgf*cm} ]<br />

Check is unnecessary due to tightening<br />

of plasticity area<br />

<br />

Intake manifold tightening torque (N*m [kgf*cm]) 19{194} <br />

Exhaust manifold tightening torque [N*m{kgf*cm}] 35{357} <br />

<strong>SS</strong><br />

Compression pressure (330 r/min) (MPa [kgf/cm 2 ]): standard value 1.47{15.0} <br />

Compression pressure (330 r/min) (MPa [kgf/cm 2 ]): limit 1.08{11.0} <br />

Compression pressure (330 r/min) (MPa [kgf/cm 2 ]): difference between<br />

cylinders<br />

0.15 (1.5) or below <br />

Spark plug gap (mm): specified values 0.8-0.9(*2) 1.0-1.1<br />

Spark plug gap (mm): maximum 1.1 <br />

Radiator cap valve opening pressure (kPa[kgf/cm 2 ]): specified values 93.3-122.7{0.95-1.25} <br />

Radiator cap valve opening pressure (kPa[kgf/cm 2 ]): maximum 78.5{0.8} <br />

(*1):<br />

Between terminals EFI-T and E of the DLC<br />

(*2):<br />

No adjustments required because the iridium plug is used.

<strong>SS</strong>–7<br />

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong> - REFERENCE VALUES FOR PERIODIC MAINTENANCE<br />

APPARATUS FOR PREVENTING<br />

RELEASE OF HARMFUL GASES SUCH<br />

AS FUMES AND ODOROUS GASES<br />

1. EXHAUST GAS PREVENTION-RELATED APPARATUSES<br />

Standard:<br />

<strong>SS</strong><br />

Item 3SZ-VE K3-VE<br />

Idle CO Concentration (%) Below 0.2 <br />

Idle HC Concentration (ppm) Below 200 <br />

SUSPENSION<br />

1. FRONT SUSPENSION-RELATED<br />

Standard:<br />

Item J200LG J210LG J211LG J200RG J210RG<br />

Front side slip (per 1 m) (mm) 0 5 <br />

Front toe-in (mm) 0 2 <br />

Front camber (degree) 030' 45' <br />

Front caster (degree) 447' 1 <br />

Front steering axis inclination<br />

(degree)<br />

1225' 1 <br />

Tire turning angle (vehicles<br />

with tire size of<br />

215/65 R16)<br />

Tire turning angle (vehicles<br />

with tire size of<br />

235/60 R16)<br />

Inside 4032' 2 <br />

Outside 3405' 2 <br />

Inside 3906' 2 - 3906' 2 <br />

Outside 3306' 2 - 3306' 2 <br />

DRIVING APPARATUS<br />

1. DRIVING APPARATUS<br />

Standard:<br />

Item J200LG J210LG J211LG J200RG J210RG<br />

Looseness of front axle hub (mm) Below 0.05 <br />

Looseness of rear axle hub (mm) Below 0.8 <br />

Wheel nut tightening torque<br />

(N*m[kgf*cm])<br />

103{1050} <br />

Remaining tire groves (mm) 1.6 or more <br />

2. AIR PRE<strong>SS</strong>URE<br />

(a) Same for both general and high speeds<br />

Standard:<br />

Tire Size<br />

Front wheels<br />

(kPa [kgf/cm 2 ])<br />

Rear wheels<br />

(kPa [kgf/cm 2 ])<br />

215 / 65R16 98S 200{2.0} <br />

235 / 60R16 100H 210{2.1}

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong> - REFERENCE VALUES FOR PERIODIC MAINTENANCE<br />

BRAKE APPARATUS<br />

<strong>SS</strong>–8<br />

1. BRAKE-RELATED<br />

Standard:<br />

Item J200LG J210LG J211LG J200RG J210RG<br />

Brake pedal free play<br />

(without vacuum) (mm)<br />

0.5-2 <br />

Brake pedal reserve<br />

distance (mm)<br />

Parking brake pedal<br />

release rate<br />

(Operating force of 196<br />

N [20 kgf] ) (number of<br />

notches)<br />

Parking brake engagement:<br />

braking force<br />

Thickness of rear drum<br />

brake shoe lining<br />

(mm): maximum<br />

Inner diameter of rear<br />

brake drum (mm): maximum<br />

Thickness of front disc<br />

brake pad (mm): maximum<br />

Thickness of front disc<br />

rotor (mm): maximum<br />

Brake engagement<br />

(braking force) (*): total<br />

of back wheels<br />

Brake engagement<br />

(braking force) (*):<br />

asymmetry in each<br />

wheel<br />

Brake engagement<br />

(braking force) (*): sum<br />

total<br />

122 or more<br />

(The engine is idling after<br />

warmed up, and pedaling force is<br />

294 N [30 kgf])<br />

(*):<br />

For vehicles where all front wheels are locked and therefore<br />

difficult to measure, presume in such a situation that this conforms<br />

with the sum total.<br />

STEERING MECHANISM<br />

1. CHA<strong>SS</strong>IS-RELATED<br />

Standard:<br />

<strong>SS</strong><br />

<br />

4-7 <br />

Above 20% of vehicle weight<br />

upon inspection<br />

1.0<br />

(Reference: 5.5 for a new product)<br />

229.6<br />

(Reference: 228.6 for a new product)<br />

1.0<br />

(Reference: 10.0 for a new product)<br />

15.0 (solid disc)<br />

(Reference: 16.0 for a new product)<br />

21.0 (ventilated disc)<br />

(Reference: 22.0 for a new product)<br />

<br />

<br />

<br />

<br />

<br />

Over 10% of the axle load <br />

Under 8% of the axle load <br />

Above 50% of vehicle weight<br />

upon inspection

<strong>SS</strong>–9<br />

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong> - REFERENCE VALUES FOR PERIODIC MAINTENANCE<br />

Item J200LG J210LG J211LG J200RG J210RG<br />

Steering wheel free play<br />

(Outer circumference of wheel)<br />

(mm)<br />

0-30 <br />

<strong>SS</strong>

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong> - OPERATION SETTING WHEN DISCONNECTING AND RECONNECTING NEGATIVE<br />

BATTERY TERMINAL<br />

<strong>SS</strong>–10<br />

OPERATION <strong>SERVICE</strong> <strong>SPECIFICATIONS</strong><br />

SETTING WHEN DISCONNECTING AND<br />

RECONNECTING NEGATIVE BATTERY TERMINAL<br />

<strong>SERVICE</strong><br />

Work item<br />

Initialization of power window<br />

system<br />

Work procedure<br />

1. Disconnect the negative (-)<br />

terminal of the battery or the<br />

connector to the power window<br />

master switch.<br />

2. After 5 seconds or more has<br />

elapsed, connect the negative<br />

(-) terminal of the battery<br />

or the connector to the power<br />

window master switch.<br />

3. Fully open the window of the<br />

driver seat door.<br />

4. Make the window of the driver<br />

seat door go up and continue<br />

to keep the switch in the UP<br />

direction for at least 2 seconds<br />

even after the window is<br />

fully closed.<br />

Non-compliant Behavior, Non-working<br />

Functions<br />

• Automatic opening and closing function<br />

of the door window<br />

• Jam protection function<br />

• Remote operation of each seat with<br />

the driver seat switch<br />

Remarks<br />

Settings are required for the<br />

driver seat master switch<br />

<strong>SS</strong>

<strong>SS</strong>–11<br />

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong> - OPERATION SETTINGS WHEN INSTALLING, REMOVING AND REPLACING PARTS<br />

OPERATION SETTINGS WHEN INSTALLING, REMOVING<br />

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong><br />

AND REPLACING PARTS<br />

<strong>SERVICE</strong><br />

1. Replacement Work<br />

<strong>SS</strong><br />

Replacement Part<br />

• Automatic transmission assembly<br />

• Valve body assembly<br />

• Engine assembly<br />

• Transmission wire<br />

Required Work<br />

1. Automatic transmission<br />

learned value initialization<br />

Non-compliant Behavior, Nonworking<br />

Functions<br />

• Transmission harsh engagement<br />

Remarks<br />

• Yaw rate sensor<br />

1. Acquire yaw rate sensor<br />

and G sensor and<br />

master cylinder pressure<br />

sensor zero point<br />

• Slip indicator light comes on<br />

• Buzzer sounds<br />

• VSC control prohibition or<br />

erroneous operation<br />

• Actuator assembly (equipped in skid<br />

control ECU)<br />

1. Acquire yaw rate sensor<br />

and G sensor and<br />

master cylinder pressure<br />

sensor zero point<br />

• Slip indicator light comes on<br />

• Buzzer sounds<br />

• VSC control prohibition or<br />

erroneous operation<br />

• Master cylinder pressure sensor<br />

1. Acquire yaw rate sensor<br />

and G sensor and<br />

master cylinder pressure<br />

sensor zero point<br />

• Slip indicator light comes on<br />

• Buzzer sounds<br />

• VSC control prohibition or<br />

erroneous operation<br />

• Immobiliser code computer (ID code<br />

box)<br />

1. Identification code<br />

registration (see the<br />

manual for registration<br />

method)<br />

• Wireless functions<br />

• Engine start<br />

• Power window master switch assembly<br />

• Power window regulator motor<br />

assembly (driver seat)<br />

• Front door window regulator (driver<br />

seat)<br />

1. Initialization of power<br />

window system<br />

• Automatic opening and closing<br />

function of the door window<br />

• Jam protection function<br />

• Remote operation of each<br />

seat with the driver seat<br />

switch<br />

• Settings are required for the<br />

driver seat master switch<br />

2. AUTOMATIC TRANSMI<strong>SS</strong>ION LEARNED VALUE INITIALIZATION<br />

NOTICE:<br />

Wait at least 1 minute after connecting the battery terminal<br />

before performing the initialization of the automatic transmission<br />

learned values.<br />

HINT:<br />

Learned values will not be initialized (erased) by simply disconnecting<br />

the negative (-) terminal of the battery.<br />

(a) After confirming that the shift position is in the P range, connect<br />

the DS-II to the DLC and turn the ignition switch ON and the<br />

DS-II power ON.<br />

NOTICE:<br />

Do not start the engine.<br />

(b) Conduct AT learned value initialization<br />

(1) To initialize learned values, follow the DS-II screen display,<br />

select MAIN MENU [OPERATION SUPPORT] OPERA-<br />

TION SUPPORT CLA<strong>SS</strong>IFICATION [A/T] [AT LEARNED

<strong>SERVICE</strong> <strong>SPECIFICATIONS</strong> - OPERATION SETTINGS WHEN INSTALLING, REMOVING AND REPLACING PARTS<br />

<strong>SS</strong>–12<br />

VALUE INITIALIZATION] and run [AT LEARNED VALUE<br />

INITIALIZATION].<br />

HINT:<br />

Initialization will complete in about 1 minute.<br />

3. ACQUIRE YAW RATE SENSOR AND G SENSOR AND MASTER<br />

CYLINDER PRE<strong>SS</strong>URE SENSOR ZERO POINT<br />

NOTICE:<br />

Always measure the zero point on a level surface (incline of less<br />

than 1%). Do not open or close the doors or shake the vehicle<br />

during the operation. Also, do not start the engine to avoid idling<br />

vibration.<br />

(a) ACTIVATE SENSOR ZERO POINT ACQUISITION MODE<br />

(1) Stop the vehicle on a level surface.<br />

(2) Turn the ignition switch to the ON position, and press the<br />

TRC OFF switch to activate the sensor zero point acquisition<br />

mode.<br />

HINT:<br />

The slip indicator turns on and a buzzer will sound at the<br />

same time.<br />

(b) Acquire zero point for yaw rate sensor and master cylinder<br />

pressure sensor.<br />

(1) Leave the vehicle stationary and release the brake pedal<br />

for 1 second or more.<br />

HINT:<br />

When the zero point of the master cylinder pressure sensor<br />

is successfully acquired, only the buzzer will turn off.<br />

(2) When the zero point of each sensor is acquired, the zero<br />

point acquisition mode ends and the slip indicator turns off.<br />

HINT:<br />

• If wheel speed is detected, the acquire zero point mode<br />

will be canceled and the slip indicator light will go out.<br />

• If the TRC OFF switch is handled during the acquire<br />

zero point mode the slip indicator light will go out and<br />

the acquire zero point mode will be cancelled. (Turning<br />

off the ignition switch will cancel the acquire zero point<br />

mode as well.)<br />

• Pressing the TRC OFF switch again will restart the<br />

acquire zero point mode. However, the zero point acquisition<br />

mode will not be performed for the items which<br />

have been completed.<br />

• If malfunction items are detected, the acquire zero point<br />

mode is terminated due to handling of the TRC OFF<br />

switch, and the applicable items cannot be reexamined<br />

without restarting the acquire zero point mode.<br />

<strong>SS</strong><br />

TO INDEX<br />

TO NEXT SECTION