SpeCial-high-performanCe hot-work tool Steel GSF - Kind & Co ...

SpeCial-high-performanCe hot-work tool Steel GSF - Kind & Co ...

SpeCial-high-performanCe hot-work tool Steel GSF - Kind & Co ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

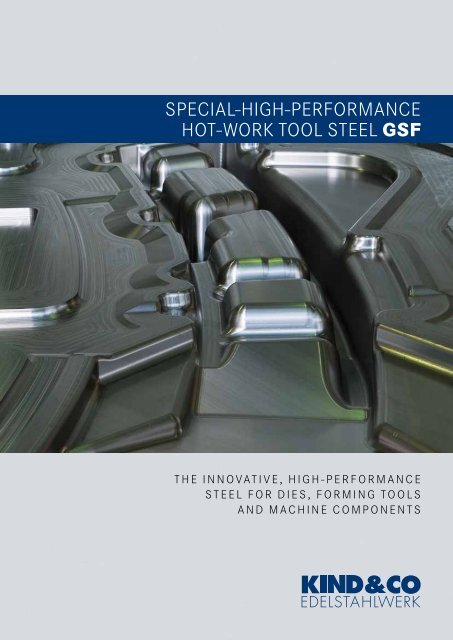

<strong>SpeCial</strong>-<strong>high</strong>-performance<br />

<strong>hot</strong>-<strong>work</strong> <strong>tool</strong> steel <strong>GSF</strong><br />

t h e i n n o vat i v e , h i g h - p e r f o r m a n c e<br />

s t e e l f o r d i e s , f o r m i n g to o l s<br />

a n d m a c h i n e c o m p o n e n t s

2<br />

From the casting of<br />

steel to finished die...<br />

LONG-STANDING KNOWLEDGE, INNOVATIVE MATERIALS TECHNOLOGY,<br />

AND ADVANCED EQUIPMENT ALL FORM THE BASIS FOR TOP QUALITY<br />

For over 125 years KIND & CO. Edelstahlwerk<br />

has been developing expertise in producing,<br />

finishing and developing <strong>high</strong>-alloy steels. Our<br />

experience has manged to extend our services<br />

to a truly global platform, while maintaining our<br />

traditional values.<br />

Customer orientation and quality: these are<br />

the benchmarks for our daily operations using<br />

advanced technology and flexible production as<br />

well as a proven quality management system.<br />

In addition to a broad range of <strong>tool</strong> steels and<br />

corrosion, acid and heat resistant steels, we offer<br />

a large selection of special steel grades as well<br />

as titanium- and nickel-based alloys. Furthermore,<br />

KIND & CO. has developed specific materials for<br />

various special applications.<br />

Our steels can be found in all major industries<br />

including die casting, plastics, extrusion, pipe engineering,<br />

die forging, power engineering, aviation,<br />

mechanical and apparatus engineering, amongst<br />

others.<br />

Our customers receive everything in one single<br />

package: <strong>high</strong> quality steel as well as die processing<br />

and finishing services to match their specific<br />

requirements.

3<br />

Our flexibility allows us to develop tailored techniques<br />

and processes aligned with your requirements<br />

to help you achieve top performance.<br />

Each one of our global customers is unique. Yet we<br />

are proud to state that they all have one thing in<br />

common: steel by KIND & CO.<br />

This is why we constantly <strong>work</strong> to further enhance<br />

our <strong>high</strong> quality and customer-focused service.<br />

We are large enough to serve every customer but<br />

still small enough to find individual solutions.<br />

Do not settle with less than the best.

4<br />

<strong>GSF</strong> – the innovative <strong>high</strong>-performance steel<br />

for dies, forming <strong>tool</strong>s and machine components<br />

• OUTSTANDING Toughness<br />

• EXCELLENT HEAT RESISTANCE<br />

• HIGH YIELD POINT RATIO<br />

• GOOD Machinabilty<br />

• VERY GOOD THROUGH-HARDENING<br />

CAPABILITY<br />

• READILY TEMPERED TO WORKING<br />

HARDNESS<br />

MATERIAL PROPERTIES<br />

<strong>GSF</strong> is an innovative <strong>high</strong>-performance NiCrMoV alloy<br />

steel that was designed for dies, which are used under<br />

forging hammers, or for large-scale dies. <strong>GSF</strong> represents<br />

an advancement of the 55NiCrMoV7 standard steel<br />

(1.2714) and is distinguished by improved toughness, heat<br />

resistance and weldability.<br />

Due to its outstanding mechanical properties in a<br />

tempered state, <strong>GSF</strong> is well suited for various dies and<br />

heavy-duty machine components. <strong>GSF</strong> is an exceptional<br />

alternative to common tempering steels, especially when<br />

it comes to large cross-sections or diameters of up to<br />

650mm and strengths of more than 1000 MPa.<br />

APPLICATION<br />

Typical applications include:<br />

M Hammer forging dies in steel forming, specifically<br />

for deep contours prone to cracking<br />

M Press dies where <strong>high</strong> toughness and good heat<br />

resistance is required (e.g dies for medium sized<br />

or larger hydraulic presses)<br />

M Calibration and deburring dies for forging presses<br />

M Hammers and press saddles, hammer heads, jaws<br />

in forging machines<br />

M Roughing rolls (forging rolls)<br />

M Dies for the extrusion industry including mandrel<br />

holders, die holders, press columns, piston rods,<br />

return plungers, nuts<br />

M Piercers and piercing sleeves for production of<br />

seamless steel bottles<br />

M Rolling mandrels and tapered rolls in the rolling<br />

technology sector<br />

M Die holders and armoring with strengths of<br />

up to 1450 MPa<br />

M Shafts and heavy-duty machine components with<br />

yield points of 750 > MPa<br />

AS-DELIVERed CONDITION<br />

<strong>GSF</strong> is usually supplied pre-tempered to 38 - 44 HRc<br />

thus eliminating any additional cost and risk involved with<br />

external heat treatment.<br />

<strong>GSF</strong> is easily weldable and excellently suited for filler/<br />

overlay welding. Due to the reduced C content, the risk<br />

of cracking in the welding transition zone is limited.<br />

<strong>GSF</strong> is nitridable.<br />

Material Short name C Si Mn Cr Mo Ni V<br />

PWM 55NiCrMoV7 0.55 0.30 0.80 1.10 0.45 1.70 0.10<br />

<strong>GSF</strong><br />

0.28 0.30 0.70 2.80 0.60 1.00 0.40<br />

Handling instructions<br />

Soft annealing 740 - 760 °C<br />

6 – 8 h furnace cooling<br />

Hardness annealed max. 230 HB<br />

Stress relief approx. 630 °C<br />

annealing<br />

slow cooling<br />

Hardening Hardening 920 - 940 °C<br />

in oil, polymer or vacuum hardening<br />

cooling must be interrupted at<br />

150 - 180 °C<br />

Quenched hardness approx. 51 HRC for 60 mm Ø<br />

and oil or polymer quenching<br />

Tempering<br />

400 - 650 °C as needed,<br />

see tempering illustration.<br />

Usually <strong>GSF</strong> comes tempered<br />

with a hardness of 38 - 44 HRC<br />

Nitriding or<br />

Tenifer treatment<br />

Preheating<br />

of dies<br />

Toughness (Joule)<br />

possible<br />

<strong>Co</strong>mparison of toughness<br />

40<br />

20<br />

<strong>GSF</strong><br />

1.2714<br />

0<br />

38<br />

Hardness HRC<br />

100 - 250 °C<br />

is recommended prior to use<br />

<strong>GSF</strong><br />

42<br />

1.2714<br />

<strong>GSF</strong><br />

44<br />

Fine tempered microstructure for best toughness<br />

1.2714<br />

<strong>GSF</strong><br />

46<br />

1.2714

5<br />

<strong>GSF</strong> hammer die with fine engraving,<br />

performance increased by currently 47% compared to 1.2714<br />

Typical application – hammer die<br />

with contour prone to overload

6 Technical data<br />

Tempering diagram 60 mm Ø, 930 °C oil<br />

52<br />

50<br />

48<br />

46<br />

44<br />

42<br />

40<br />

38<br />

High temperature strength diagram<br />

1600<br />

Rp 0.2 and Rm in MPa<br />

1400<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

0<br />

X X X X<br />

20 40 200 300 400 500 600<br />

Temperature °C<br />

X<br />

Rm<br />

Rp 0,2<br />

Z % x 0,1<br />

X<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Z in %<br />

Hardness HRC<br />

36<br />

34<br />

32<br />

30<br />

28<br />

400 500 600 700<br />

Tempering temperature °C<br />

TTT-Diagram Austenitizing temperature 930 °C<br />

1200<br />

Mechanical properties at different strength classes<br />

Ø / mm Yield point Tensile Elongation<br />

Applicable Rp 0.2 / MPa Strength A5 / %<br />

Rm / MPa<br />

250 - 500<br />

Physical-mechanical properties of <strong>GSF</strong><br />

Temperature °C 20 100 200 300 400 500 600<br />

Thermal conductivity W/(m x K) 31 34 34 34 33 33 31<br />

<strong>Co</strong>efficient of linear<br />

thermal expansion<br />

10 -6 / K 11.8 11.8 12.0 13.0 13.0 14.0 14.0<br />

Density<br />

7.76 g / cm³<br />

Austenitization: 930 °C 45 min<br />

Notch impact<br />

strength<br />

ISO-V / Joule<br />

min. 950 1300 - 1450 min. 12 min. 25<br />

min. 880 1150 - 1300 min. 14 min. 30<br />

min. 780 1000 - 1150 min. 16 min. 40<br />

1000<br />

A c1e<br />

800<br />

Temperature [°C]<br />

600<br />

A<br />

P 70<br />

λ = 0.06 λ = 0.45 λ = 0.9 λ = 1.8 50.0 25.0 12.5 5.0 2.5 1.25 0.50C/min<br />

A c1e<br />

400<br />

M S<br />

B<br />

200<br />

3<br />

10 15 25 40 100 100 100 100 30<br />

0<br />

584 597 551 564 557 559 557 478 441 429 414 303 Härte [HV]<br />

0,1 1 10 100 1000 10000<br />

Time[min]

filler welded <strong>high</strong><br />

performance dies with <strong>GSF</strong><br />

7<br />

Mass production molds of all types such as dies or<br />

tapered rolls in ring production – specifically for contours<br />

leading to increased wear – call for a combination of <strong>high</strong><br />

isotropic <strong>hot</strong> toughness and maximum <strong>hot</strong> wear resistance.<br />

Due to the specific material properties and the<br />

reduced C content, <strong>GSF</strong> makes for an ideal <strong>tool</strong> steel<br />

for filler welding.<br />

MACHINING<br />

<strong>GSF</strong> is well suited for machining even in its tempered<br />

state as delivered. Optimal machining parameters may<br />

vary due to material condition, machine, <strong>work</strong>piece<br />

clamping, die clamping and machining strategy.<br />

KIND & CO. provides application and project advice<br />

from selection of the right die to a suitable machining<br />

strategy to optimizing process parameters for machining<br />

operations.<br />

Our technical consultants will be happy to provide advice<br />

on the right dies for your machining applications.<br />

Increased performance using <strong>Co</strong>-based alloy<br />

(Stellite) welded on <strong>GSF</strong><br />

1.2714 42-44 HRC<br />

<strong>GSF</strong> 42-44 HRC,<br />

welded<br />

100%<br />

Good mechanical processing even in tempered condition

Tailored Quality dies for<br />

peak performance<br />

More service<br />

Tool steels and<br />

special materials<br />

Melting<br />

Forging<br />

Ring rolling<br />

Heat treatment<br />

Machining<br />

PRODUcts<br />

Hot <strong>work</strong> <strong>tool</strong> steels<br />

<strong>Co</strong>ld <strong>work</strong> <strong>tool</strong> steels<br />

Die steels<br />

Plastic mould steels<br />

Surface treatment<br />

Industries<br />

die casting<br />

Die forging<br />

Extrusion<br />

Pipe production<br />

Plastics technology<br />

KIND & CO., Edelstahlwerk, KG<br />

Bielsteiner Str. 124-130 . D-51674 Wiehl-Bielstein<br />

Tel. +49 (0) 22 62 / 84-0 . Fax +49 (0) 22 62 / 84-175<br />

info@kind-co.de . www.kind-co.de<br />

aw.05.13<br />

All information on properties and applications provided in this leaflet are for information only<br />

and cannot be considered to be guaranteed. Guaranteed properties must be specifically agreed.