PPC Package

PPC Package

PPC Package

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

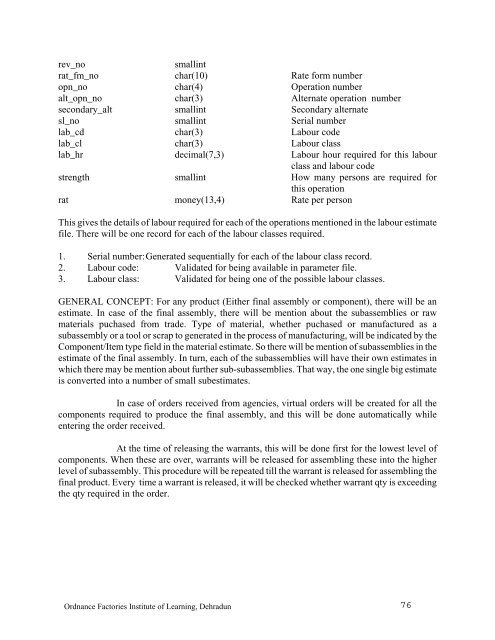

ev_no<br />

smallint<br />

rat_fm_no char(10) Rate form number<br />

opn_no char(4) Operation number<br />

alt_opn_no char(3) Alternate operation number<br />

secondary_alt smallint Secondary alternate<br />

sl_no smallint Serial number<br />

lab_cd char(3) Labour code<br />

lab_cl char(3) Labour class<br />

lab_hr decimal(7,3) Labour hour required for this labour<br />

class and labour code<br />

strength smallint How many persons are required for<br />

this operation<br />

rat money(13,4) Rate per person<br />

This gives the details of labour required for each of the operations mentioned in the labour estimate<br />

file. There will be one record for each of the labour classes required.<br />

1. Serial number: Generated sequentially for each of the labour class record.<br />

2. Labour code: Validated for being available in parameter file.<br />

3. Labour class: Validated for being one of the possible labour classes.<br />

GENERAL CONCEPT: For any product (Either final assembly or component), there will be an<br />

estimate. In case of the final assembly, there will be mention about the subassemblies or raw<br />

materials puchased from trade. Type of material, whether puchased or manufactured as a<br />

subassembly or a tool or scrap to generated in the process of manufacturing, will be indicated by the<br />

Component/Item type field in the material estimate. So there will be mention of subassemblies in the<br />

estimate of the final assembly. In turn, each of the subassemblies will have their own estimates in<br />

which there may be mention about further sub-subassemblies. That way, the one single big estimate<br />

is converted into a number of small subestimates.<br />

In case of orders received from agencies, virtual orders will be created for all the<br />

components required to produce the final assembly, and this will be done automatically while<br />

entering the order received.<br />

At the time of releasing the warrants, this will be done first for the lowest level of<br />

components. When these are over, warrants will be released for assembling these into the higher<br />

level of subassembly. This procedure will be repeated till the warrant is released for assembling the<br />

final product. Every time a warrant is released, it will be checked whether warrant qty is exceeding<br />

the qty required in the order.<br />

Ordnance Factories Institute of Learning, Dehradun 76