Keep cool!

Keep cool!

Keep cool!

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Keep</strong> <strong>cool</strong>!<br />

Products for solar heat management in plastics

Cooler colors for solar heat<br />

management in plastics<br />

NIR-reflecting pigments for solar heat management in plastics<br />

Ultraviolet (UV, 295 – 400 nm)<br />

Recently, with energy prices rising and no end in sight, intelligent<br />

solutions for temperature management have moved into the focus<br />

of designers, architects and consumers. With this brochure, we<br />

would like to give an overview of BASF’s portfolio of pigments for<br />

the heat management of surfaces exposed to infrared radiation.<br />

The solar spectrum<br />

Light energy emitted by the sun spans a wide range of wavelengths.<br />

Part of the total energy is absorbed by our atmosphere<br />

and never reaches the earth's surface. The light that does get<br />

through is commonly classified into three ranges according to its<br />

wavelength. Generally, light with a shorter wavelength (or higher<br />

energy) than the visible range is referred to as ultraviolet (= beyond<br />

violet), while light with a longer wavelength (lower energy) than the<br />

visible range is referred to as infrared (= before red).<br />

The UV region starts at 295 nm where the atmosphere cut-off<br />

occurs and ends at 400 nm where we start to perceive the light<br />

as violet. Even though less than 5 % of the total solar energy<br />

reaching the earth is UV light, it is this part of the sunlight that<br />

causes degradation of polymers by breaking chemical bonds.<br />

UV light leads to phenomena such as chalking and the loss of<br />

mechanical properties of polymers and is also known to destroy<br />

colorants with inferior fastness to light as well as certain fillers.<br />

BASF offers a broad range of UV stabilizers for polymers, tailormade<br />

for the special demand of various polymers and various<br />

applications.<br />

Irradiant energy from the sun<br />

ultraviolet energy<br />

visible energy<br />

infrared (IR) energy<br />

C-C<br />

C C<br />

1<br />

1<br />

1<br />

C<br />

C<br />

C<br />

295 nm – 400 nm / 2.7 % of energy<br />

interaction with chemical bonds<br />

400 nm – 700 nm / 51.2 % of energy<br />

interaction with electrons<br />

700 nm – 2,500 nm / 46.1 % of energy<br />

interaction: vibration and/or rotation

W<br />

m 2 μm<br />

Visible (VIS, 400 – 700 nm)<br />

Infrared (IR, 700 – 2,500 nm)<br />

Roughly 50 % of the solar energy reaching the earth’s surface is<br />

“visible light”. The human eye translates different wavelengths<br />

(energy levels) into various colors. The interaction of this radiation<br />

with electrons in different energy levels of colored compounds<br />

determines the absorption and sometimes re-emission of light of<br />

different wavelengths. Combined with the scattering of light at solid<br />

particles’ surfaces, these phenomena define what we refer to as<br />

the color of an object. If an object reflects light across the complete<br />

wavelength range, then it appears white, black surfaces absorb all<br />

the energy at these wavelengths. If some wavelengths of this light<br />

are absorbed and others reflected, then an object appears to be<br />

colored. BASF offers organic and inorganic pigments for every color<br />

meeting the most stringent requirements with regard to fastness<br />

to light and weathering as well as long-term stability. Besides pigments,<br />

BASF also offers standard and fluorescent dyes which are<br />

soluble in the polymer matrix.<br />

Nearly 45 % of the sun’s energy is in the infrared (IR) range, with<br />

the major part in the near-IR range (NIR, 700 – 1,200 nm). NIR<br />

radiation interacts with chemical bonds, leading to stretching,<br />

bonding and rotating of molecules, finally increasing the material’s<br />

temperature. The higher the absorption in the infrared range, the<br />

higher the material’s temperature when exposed to solar radiation.<br />

The fact that infrared energy is emitted by all objects according to<br />

their surface temperature is utilized in, e.g., IR cameras. However,<br />

as the temperature of most objects is exceedingly low compared to<br />

the sun’s surface, this IR light is found at much longer wavelengths<br />

and the energy transferred is almost negligibly small.<br />

BASF offers pigments with optimized NIR absorbance as well as<br />

NIR-reflecting pigments for indoor and outdoor applications and<br />

<strong>cool</strong>er colors.<br />

Radiation at sea level<br />

2,500<br />

VIS<br />

NIR radiation<br />

2,000<br />

D e<br />

1,500<br />

1,000<br />

1<br />

2<br />

3<br />

500<br />

2<br />

2<br />

0<br />

0 0.25 0.5 0.75 1.0 1.25 1.5 1.75 2.0 2.25 2.5<br />

μm<br />

4 4<br />

black body radiation 5900 K 1 O 2<br />

extraterrestric sunlight, AM 0<br />

2 H 2<br />

O<br />

terrestric sunlight, AM 1.5<br />

3 O 2<br />

, H 2<br />

O<br />

4 H 2<br />

O, CO 2<br />

02 03

eflectance [%]<br />

NIR-reflecting pigments<br />

NIR Reflectance properties of Sicotan ® pigments<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

Ni-Sb-Ti Cr-Sb-Ti Mn-Sb-Ti<br />

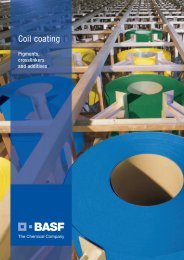

Windows, garage doors, fences, roofing and siding<br />

NIR-reflecting pigments<br />

Rigid PVC is a temperature-sensitive product that degrades as it<br />

gets hotter. Vinyl siding, windows and door profiles will thus warp<br />

and twist out of shape if not manufactured with greatest care.<br />

Other polymers and rubbers used for outdoor applications such as<br />

fences, roofing tiles and balcony elements act similarly, because<br />

regular pigments used for coloration often considerably increase<br />

the tendency to warp by raising the temperature of the surface<br />

upon exposure to sunlight.<br />

BASF’s NIR-reflecting pigments offer an easy way of making colors,<br />

other than white, while reducing, if not eliminating, warping and<br />

twisting of the finished article in use.<br />

Both UV and IR light are invisible to the human eye and have no<br />

direct influence on the color of an object. However, all light, whether<br />

visible or invisible, will increase the temperature of an object<br />

when absorbed by it. The more solar energy the object absorbs, the<br />

greater the heat build-up. Conversely, the greater the reflectivity of<br />

an object, the lower its temperature when exposed to direct sunlight.<br />

Two objects can be identical in visible color, but have very different<br />

characteristics in the IR spectrum. An object that reflects IR light<br />

will remain <strong>cool</strong>er than an object that absorbs it.

Because IR light comprises 45 % of the incident solar energy,<br />

the IR reflectivity of an object is even slightly more important than<br />

its color when it comes to heat build-up.<br />

In addition to their reflective properties, pigments can differ in their<br />

weatherability, chemical resistance and other durability criteria.<br />

BASF offers a broad range of inorganic pigments with special<br />

performance in IR radiation. BASF's Sicotan ® pigments are based<br />

on titanium dioxide where selected atoms are incorporated in the<br />

crystal lattice of TiO 2 . The colors available cover the range from yellow<br />

(nickel incorporated, Pigment Yellow 53), beige and light brown<br />

(chromium incorporated, Pigment Brown 24) to dark and intense<br />

brown (manganese incorporated, Pigment Brown 164). Their fastness<br />

to light and weathering have been proven in more than three<br />

decades of exposure to the South Florida sun. Thus they are the<br />

pigments of choice for products that offer warranties against fading<br />

for 25 years or more.<br />

BASF's Sicopal ® pigments are hematite-structured metal oxides<br />

with intense brown and deep black colors (chrome-iron oxides,<br />

Pigment Brown 29), spinel-structured metal oxides with light brown<br />

colors (zinc oxide, Pigment Yellow 119) and blue and green shades<br />

(cobalt oxide, Pigment Blue 28 and Pigment Green 50) as well as<br />

intensely yellow bismuth vanadate (Pigment Yellow 184).<br />

04 05

Coextrusion<br />

Multi-layer structures<br />

Intense colors on top of a reflecting base<br />

In order to combine the excellent quality of NIR-reflecting pigments<br />

with intense colors in full shade, multi-layer systems are used, e.g.,<br />

formed by coextrusion. Not only do these organic pigments have to<br />

be transparent (non-absorbant for NIR light which most organic pigments<br />

are), but they must also offer outstanding fastness to light<br />

and weathering. To achieve the effects along with NIR-reflecting<br />

properties to increase the service life of the finished part, TiO 2 or<br />

NIR-reflecting pigments are used for the mass coloration of, e.g.,<br />

PVC as core material and organic pigments are used for the top<br />

layer of, e.g., PMMA or PC.<br />

This NIR-transparent top layer can contain the additives for UV<br />

protection of the complete system and the selected organic pigments<br />

for strong, intense colors.<br />

NIR light unhinderedly passes through the transparent layer, is<br />

reflected by the core material pigmented with TiO 2 - or NIR-reflecting<br />

pigments and again passes the transparent layer unhinderedly<br />

without absorption and consequently without heating the material.<br />

The part stays <strong>cool</strong>.<br />

Multi-layer profiles<br />

NIR-transparent<br />

colored topcoat<br />

NIR-reflecting pigment<br />

opaque substrate, pigmented with NIR-reflecting pigments<br />

(e.g., PVC window profile with TiO 2 , Sicotan ® Yellow or Brown)

eflectance [%]<br />

Reflectance of typical organic pigments<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400 2,600<br />

wavelength [nm]<br />

yellow pigment red pigment purple pigment<br />

Measured in PVC in front of a reflecting white standard<br />

06 07

Lumogen ® Black –<br />

a black that stays <strong>cool</strong><br />

Transparent black – the missing link in coextrusion<br />

As many organic pigments are transparent for NIR light, a wide<br />

range of colors is possible using the coextrusion method. But if darker<br />

shades are looked for, until now, basically the only option for<br />

long-term stable shading has been carbon black. However, Carbon<br />

black as a highly efficient broadband absorber absorbs the complete<br />

range of wavelengths of incident sunlight at the earth’s surface,<br />

including UV and IR. This is why our experience tells us that in<br />

summer a black surface is also a hot surface. Even at very low<br />

concentrations, carbon black can thus decisively change the solar<br />

heat absorption behavior of a surface.<br />

NIR-reflecting black pigments have been available for some time<br />

now, but all of them are designed for the mass coloration of the<br />

opaque core, not for the transparent top coat. For these highperformance<br />

applications, BASF now offers two new black pigments,<br />

which offer superb temperature stability, excellent fastness<br />

to light and fastness to weathering and high color strength while<br />

exhibiting outstanding transparency in the NIR range.<br />

Lumogen ® Black FK 4280 and Lumogen ® Black FK 4281 make it<br />

possible not only to generate <strong>cool</strong> black, but also to create dark<br />

shades of other colors as well as all shades of <strong>cool</strong> grays for many<br />

different polymers including polyolefins, PMMA, SAN, PA and PVC,<br />

even PVC-p.<br />

Fastness to weathering and fastness to light in different polymers after 2000 h<br />

Fastness to weathering<br />

Fastness to light<br />

Lumogen ® Black Lumogen ® Black Lumogen ® Black Lumogen ® Black<br />

FK 4280 FK 4281 FK 4280 FK 4281<br />

PMMA Plexiglas ®1 7 N 5 5 8 8<br />

SAN Luran ® 378 P 5 5 8 8<br />

PA Ultramid ® B 3 S 5 5 8 8<br />

five-step-scale: 5 = best value<br />

eight-step-scale: 8 = best value

transmission [%]<br />

Transmission properties of Lumogen ® and carbon black<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

UV visible NIR<br />

300 500 700 900 1,100 1,300<br />

wavelength [nm]<br />

Lumogen ® Black FK 4280<br />

Lumogen ® Black FK 4281<br />

carbon black<br />

08 09

eflectance [%]<br />

reflectance [%]<br />

reflectance [%]<br />

transmission<br />

transmission<br />

transmission<br />

Sicotan ® Yellow and<br />

Sicotan ® Brown<br />

Sicotan ® Yellow K 1010 FG / 2.0 % in PVC-u<br />

Sicotan ® Yellow K 1010 FG / 2.0 % in PVC-u<br />

100<br />

100<br />

80<br />

80<br />

60<br />

PVC<br />

PVC<br />

60<br />

40<br />

40<br />

20<br />

PVC<br />

20<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

PVC<br />

100<br />

Sicotan ® Yellow K 2001 FG / 1.0 % in PVC-u<br />

100<br />

Sicotan ® Yellow K 2001 FG / 1.0 % in PVC-u<br />

80<br />

80<br />

60<br />

PVC<br />

PVC<br />

60<br />

40<br />

40<br />

20<br />

PVC<br />

20<br />

PVC<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

100<br />

Sicotan ® Brown K 2611 / 1.0 % in PVC-u<br />

100<br />

Sicotan ® Brown K 2611 / 1.0 % in PVC-u<br />

80<br />

80<br />

60<br />

PVC<br />

PVC<br />

60<br />

40<br />

40<br />

20<br />

PVC<br />

20<br />

PVC<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

all reflectance data determined on PVC in front of a white reflecting standard

Sicotan ® Yellow K 1010 FG<br />

1:4<br />

Sicotan ® Yellow K 1010 and Yellow K 1011 are rutile-structured<br />

pigments in yellow shades (Pigment Yellow 53), available in powder<br />

form and as fine granules (FG).<br />

Sicotan ® pigments have excellent fastness to light, fastness to<br />

weathering and stability against chemicals; their high heat stability<br />

makes them suitable in most resins even in extreme reductions.<br />

Sicotan ® Yellow K 1010 FG<br />

2.0 %<br />

Sicotan ® pigments are suitable for use in blends with organic<br />

pigments for brilliant shades with high opacity.<br />

The high reflectance ratio for NIR light makes the Sicotan ® pigments<br />

the ideal pigments for outdoor application which offer warranties<br />

against fading for lots of years.<br />

Sicotan ® Yellow K 2001 FG<br />

1:4<br />

Sicotan ® Yellow K 2001, Yellow K 2007 and Yellow K 2011 are<br />

pigments of light beige color, Sicotan ® Yellow K 2111 and Yellow<br />

K 2112 are light brown and more reddish (all are Pigment Brown 24).<br />

They are available both in powder form and as fine granules (FG).<br />

Sicotan ® pigments have excellent fastness to light, fastness to<br />

weathering and stability against chemicals; their high heat stability<br />

makes them suitable in most resins even in extreme reductions.<br />

Sicotan ® Yellow K 2001 FG<br />

1.0 %<br />

Sicotan ® pigments are suitable for use in blends with organic<br />

pigments for brilliant shades with high opacity.<br />

The high reflectance ratio for NIR light makes the Sicotan ® pigments<br />

the ideal pigments for outdoor application which offer warranties<br />

against fading for many years, especially for window profiles and<br />

sidings applications.<br />

Sicotan ® Brown K 2611<br />

1:4<br />

Sicotan ® Brown K 2611 and Brown K 2711 are pigments in brown<br />

shades (Pigment Brown 164), available in powder form.<br />

Sicotan ® pigments have excellent fastness to light, fastness to<br />

weathering and stability against chemicals; their high heat stability<br />

makes them suitable in most resins even in extreme reductions.<br />

Sicotan ® Brown K 2611<br />

1.0 %<br />

The high reflectance ratio for NIR light makes the Sicotan ® pigments<br />

the ideal pigments for outdoor application which offer warranties<br />

against fading for many years, especially in brown PVC profiles<br />

(free from Fe ions) and in reddish gray shades at high tinting rates<br />

in sidings and roofing.<br />

10 11

eflectance [%]<br />

reflectance [%]<br />

reflectance [%]<br />

transmission<br />

transmission<br />

transmission<br />

Sicopal ® Brown and<br />

Sicotrans ® Red<br />

Sicopal ® Brown K 2595 / 0.5 % in PVC-u<br />

Sicopal ® Brown K 2595 / 0.5 % in PVC-u<br />

100<br />

100<br />

80<br />

80<br />

60<br />

PVC<br />

PVC<br />

60<br />

PVC<br />

PVC<br />

40<br />

40<br />

PVC<br />

20<br />

PVC<br />

20<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

100<br />

Sicopal ® Brown K 2795 FG / 0.5 % in PVC-u<br />

100<br />

Sicopal ® Brown K 2795 FG / 0.5 % in PVC-u<br />

80<br />

80<br />

60<br />

PVC<br />

PVC<br />

60<br />

PVC<br />

PVC<br />

40<br />

40<br />

PVC<br />

20<br />

PVC<br />

20<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

100<br />

Sicotrans ® Red K 2915 / 0.5 % in PVC-u<br />

100<br />

Sicotrans ® Red K 2915 / 0.5 % in PVC-u<br />

80<br />

60<br />

PVC<br />

PVC<br />

80<br />

60<br />

PVC<br />

PVC<br />

PVC<br />

40<br />

40<br />

20<br />

PVC<br />

20<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

all reflectance data determined on PVC in front of a white reflecting standard

Sicopal ® Brown K 2595<br />

1:4<br />

Sicopal ® Brown K 2595<br />

0.5 %<br />

Sicopal ® Brown K 2595 is a spinel-structured metal oxide of<br />

medium brown color (Pigment Brown 119). The very good heat<br />

resistance makes it suitable for the coloration of nearly all plastics,<br />

Sicopal ® Brown K 2595 causes no warpage in injection-molded or<br />

extruded parts – not even large ones.<br />

Sicopal ® Brown K 2595 is outstandingly fast to weathering in<br />

outdoor applications. Due to the many established PVC stabilization<br />

systems based on calcium/zinc or certain tin compounds, we<br />

recommend suitability tests under customer-specific processing<br />

parameters for PVC-u and PVC-p.<br />

Sicopal ® Brown K 2795 FG<br />

1:4<br />

Sicopal ® Brown K 2795 FG<br />

0.5 %<br />

Sicopal ® Brown K 2795 is a hematite-structured metal oxide of<br />

intense dark brown color (Pigment Brown 29). The very good heat<br />

resistance makes it suitable for the coloration of nearly all plastics,<br />

Sicopal ® Brown K 2795 causes no warpage in injection-molded or<br />

extruded parts – not even large ones.<br />

Sicopal ® Brown K 2795 is outstandingly fast to weathering in<br />

outdoor applications. Due to the many established PVC stabilization<br />

systems based on calcium/zinc or certain tin compounds, we<br />

recommend suitability tests under customer-specific processing<br />

parameters for PVC.<br />

Sicotrans ® Red K 2915<br />

1:4<br />

Sicotrans ® Red K 2915 is a semi-transparent, Sicotrans ® Red K 2819<br />

a transparent iron oxide, both are iron oxide (Pigment Red 101) with<br />

an extremely small particle size.<br />

Sicotrans ® Red K 2819 yields highly transparent colorations with<br />

UV-absorbing properties. Sicotrans ® Red K 2915 allows semitransparent<br />

full-shade colorations with high chroma to be achieved.<br />

Sicotrans ® Red K 2915<br />

0.5 %<br />

Iron ions can cause degradation especially in some PVC<br />

applications, so we recommend suitability tests under customerspecific<br />

processing parameters.<br />

The outstanding transparency of these pigments is particularly<br />

advantageous in the coloration of polyolefin fibers or polymers<br />

for bottles.<br />

12 13

eflectance [%]<br />

reflectance [%]<br />

reflectance [%]<br />

transmission<br />

transmission<br />

transmission<br />

Sicopal ® Yellow, Sicopal ® Blue<br />

and Sicopal ® Green<br />

Sicopal ® Yellow K 1160 FG / 1.0 % in PVC-u<br />

Sicopal ® Yellow K 1160 FG / 1.0 % in PVC-u<br />

100<br />

100<br />

80<br />

80<br />

PVC<br />

PVC<br />

60<br />

60<br />

PVC<br />

PVC<br />

40<br />

40<br />

PVC<br />

20<br />

PVC<br />

20<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

100<br />

Sicopal ® Blue K 6310 / 1.0 % in PVC-u<br />

100<br />

Sicopal ® Blue K 6310 / 1.0 % in PVC-u<br />

80<br />

80<br />

60<br />

60<br />

PVC<br />

40<br />

40<br />

20<br />

PVC<br />

PVC<br />

PVC<br />

20<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

100<br />

Sicopal ® Green K 9710 / 1.0 % in PVC-u<br />

100<br />

Sicopal ® Green K 9710 / 1.0 % in PVC-u<br />

80<br />

80<br />

60<br />

60<br />

40<br />

40<br />

20<br />

PVC<br />

20<br />

PVC<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

0<br />

400 600 800 1,000 1,200 1,400 1,600 1,800 2,000 2,200 2,400<br />

wavelength [nm]<br />

all reflectance data determined on PVC in front of a white reflecting standard

Sicopal ® Yellow K 1160 FG<br />

1:4<br />

Sicopal ® Yellow K 1160 FG and Sicopal ® K 1120 FG are low-dusting<br />

fine-granule bismuth vanadate pigments (C.I. 184).<br />

The heat resistance of Sicopal ® Yellow K 1160 FG is excellent: 260 –<br />

280 °C (500 – 536 °F) in polyolefins and ABS as well as 280 – 300 °C<br />

(536 – 572 °F) in PA.<br />

Sicopal ® Yellow K 1120 FG is especially designed for polyolefins.<br />

Sicopal ® Yellow K 1160 FG<br />

1.0 %<br />

Their outstanding fastness to weathering makes them particularly suitable<br />

for outdoor applications (garden furniture, garbage cans)<br />

as a substitute to lead- or cadmium-based pigments.<br />

Both bismuth vanadate pigments can show low alkaline stability in<br />

some applications.<br />

Sicopal ® Blue K 6310<br />

1:4<br />

Sicopal ® Blue K 6310<br />

1.0 %<br />

Sicopal ® Blue K 6210, Blue K 6310, Blue K 7210 and Blue K 7310 are<br />

spinel-structured metal oxides with transparent intense blue shades<br />

(Pigment Blue 28).<br />

Their very good heat resistance makes them suitable for the<br />

coloration of nearly all plastics. Sicopal ® pigments do not cause<br />

warpage in injection-molded or extruded parts – not even large<br />

ones. This and their outstanding fastness to weathering make them<br />

perfectly suitable for special applications such as, e.g., bottle crates.<br />

Sicopal ® Green K 9710<br />

1:4<br />

Sicopal ® Green K 9710 is a spinel-structured metal oxide with a dark<br />

green color (Pigment Green 50).<br />

Their very good heat resistance makes them suitable for the<br />

coloration of nearly all plastics. Sicopal ® pigments do not cause<br />

warpage in injection-molded or extruded parts – not even large<br />

ones. This and their outstanding fastness to weathering make them<br />

perfectly suitable for special applications in technical polymers.<br />

Sicopal ® Green K 9710<br />

1.0 %<br />

14 15

Contact worldwide<br />

Asia<br />

BASF East Asia Regional Headquarters Ltd.<br />

45/F, Jardine House<br />

No. 1 Connaught Place<br />

Central<br />

Hong Kong<br />

Tel.: +852 2731 4312<br />

Fax: +852 2734 9670<br />

Europe<br />

BASF Aktiengesellschaft<br />

Performance Chemicals for<br />

Coatings, Plastics and Specialties<br />

E-EVP/EP – J 550<br />

67056 Ludwigshafen<br />

Germany<br />

Tel.: +49 621 60-72736<br />

Fax: +49 621 60-58320<br />

Eastern Europe, Africa, West Asia<br />

BASF Aktiengesellschaft<br />

Regional Business Management<br />

Performance Chemicals<br />

EUM/SE – Benckiserplatz 1<br />

67056 Ludwigshafen<br />

Germany<br />

Tel.: +49 621 60-76246<br />

Fax: +49 621 60-6676246<br />

South America<br />

BASF S.A.<br />

Estrada Samuel Aizemberg<br />

1707-Bloco C-3°<br />

09851-550 São Bernardo do Campo – SP<br />

Brazil<br />

Tel.: +55 11 4343-3637<br />

Fax: +55 11 4343-2040<br />

North America<br />

BASF Corporation<br />

100 Campus Drive<br />

Florham Park, NJ 07932<br />

USA<br />

Tel.: +1-973-245-6131<br />

Fax: +1-973-245-6733<br />

The data contained in this publication are based on our current knowledge and experience. In view of<br />

the many factors that may affect processing and application of our product, these data do not relieve<br />

processors from carrying out their own investigations and tests; neither do these data imply any guarantee<br />

of certain properties, nor the suitability of the product for a specific purpose. Any descriptions,<br />

drawings, photographs, data, proportions, weights etc. given herein may change without prior information<br />

and do not constitute the agreed contractual quality of the product. It is the responsibility of the<br />

recipient of our products to ensure that any proprietary rights and existing laws and legislation are<br />

observed. When handling these products, advice and information given in the safety data sheet must be<br />

complied with. Further, protective and workplace hygiene measures adequate for handling chemicals<br />

must be observed.<br />

® = registered trademark of BASF Aktiengesellschaft<br />

®1 = registered trademark of Röhm GmbH & Co. KG<br />

www.basf.com/pigment<br />

BASF Aktiengesellschaft<br />

Performance Chemicals for<br />

Coatings, Plastics and Specialties<br />

67056 Ludwigshafen<br />

Germany<br />

EVP 2506 e