Electronic Heat Cost Allocators - Brunata

Electronic Heat Cost Allocators - Brunata

Electronic Heat Cost Allocators - Brunata

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Electronic</strong> <strong>Heat</strong> <strong>Cost</strong> <strong>Allocators</strong><br />

- what to measure and where to be installed<br />

The Danish Agency for Development of Trade and Industry issue Danish type approval certificates for German heat cost<br />

allocators with German type approval certificates, despite the fact that the installation point on the radiator is both<br />

wrong and unsubstantiated. This leads to incorrect readings, in particular in Danish heating systems with dimensioned<br />

temperatures of 70/40/20-12 ºC. Nevertheless, the Agency has announced that the Danish type approval certificates will<br />

be based on ”German experience and practise”.<br />

By Managing Director, J.P.<br />

Fischer Hansen (MSc Engineering),<br />

<strong>Brunata</strong> a/s<br />

Ideally, electronic heat cost<br />

allocators are to meter the<br />

emission of heat from every radiator<br />

in the building. Thus, we<br />

can set up the following:<br />

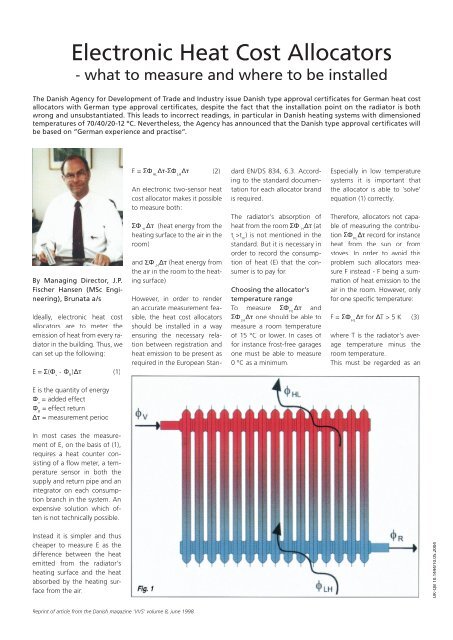

E = Σ(Φ v<br />

- Φ R<br />

)Δτ (1)<br />

E = ΣΦ HL<br />

Δτ-ΣΦ LH<br />

Δτ (2)<br />

An electronic two-sensor heat<br />

cost allocator makes it possible<br />

to measure both:<br />

ΣΦ HL<br />

Δτ (heat energy from the<br />

heating surface to the air in the<br />

room)<br />

and ΣΦ LH<br />

Δτ (heat energy from<br />

the air in the room to the heating<br />

surface)<br />

However, in order to render<br />

an accurate measurement feasible,<br />

the heat cost allocators<br />

should be installed in a way<br />

ensuring the necessary relation<br />

between registration and<br />

heat emission to be present as<br />

required in the European Standard<br />

EN/DS 834, 6.3. According<br />

to the standard documentation<br />

for each allocator brand<br />

is required.<br />

The radiator’s absorption of<br />

heat from the room ΣΦ LH<br />

Δτ (at<br />

t L<br />

>t m<br />

) is not mentioned in the<br />

standard. But it is necessary in<br />

order to record the consumption<br />

of heat (E) that the consumer<br />

is to pay for.<br />

Choosing the allocator’s<br />

temperature range<br />

To measure ΣΦ HL<br />

Δτ and<br />

ΣΦ LH<br />

Δτ one should be able to<br />

measure a room temperature<br />

of 15 ºC or lower. In cases of<br />

for instance frost-free garages<br />

one must be able to measure<br />

0 ºC as a minimum.<br />

Especially in low temperature<br />

systems it is important that<br />

the allocator is able to ‘solve’<br />

equation (1) correctly.<br />

Therefore, allocators not capable<br />

of measuring the contribution<br />

ΣΦ HL<br />

Δτ record for instance<br />

heat from the sun or from<br />

stoves. In order to avoid this<br />

problem such allocators measure<br />

F instead - F being a summation<br />

of heat emission to the<br />

air in the room. However, only<br />

for one specific temperature:<br />

F = ΣΦ HL<br />

Δτ for ΔT > 5 K (3)<br />

where T is the radiator’s average<br />

temperature minus the<br />

room temperature.<br />

This must be regarded as an<br />

E is the quantity of energy<br />

Φ v<br />

= added effect<br />

Φ R<br />

= effect return<br />

Δτ = measurement period<br />

In most cases the measurement<br />

of E, on the basis of (1),<br />

requires a heat counter consisting<br />

of a flow meter, a temperature<br />

sensor in both the<br />

supply and return pipe and an<br />

integrator on each consumption<br />

branch in the system. An<br />

expensive solution which often<br />

is not technically possible.<br />

Instead it is simpler and thus<br />

cheaper to measure E as the<br />

difference between the heat<br />

emitted from the radiator’s<br />

heating surface and the heat<br />

absorbed by the heating surface<br />

from the air:<br />

UK-QB 10.1444/10.05.2004<br />

Reprint of article from the Danish magazine ‘VVS’ volume 8, june 1998

E/R = emitted energy from the radiator per registered unit on the allocator<br />

M/Mn= Volume flow through the radiator in proportion to the norm volume flow<br />

(90/70/20). Radiator and allocator exponent = 1.3<br />

‘emergency solution’ which<br />

leads to significant registration<br />

errors – in particular when it<br />

comes to low temperature systems.<br />

Due to the radiators’ low<br />

average temperatures a considerable<br />

part of the heat emitted<br />

at low capacity (typically during<br />

autumn and spring) will not be<br />

recorded. Still, a considerable<br />

part of the heat absorbed during<br />

warm summer periods and<br />

later on emitted will be registered<br />

as consumption.<br />

The allocators are to be approved<br />

by accredited laboratories.<br />

These laboratories are<br />

designed and accredited for<br />

allocator testing (3). But they<br />

are not able to test allocators<br />

using (2).<br />

Documentation for the<br />

installation point<br />

In connection with new Danish<br />

requirements on type approvals,<br />

German laboratories have<br />

turned out to have tested and<br />

approved allocators without<br />

checking wheather the installation<br />

point, as stated by the<br />

manufacturer, is correct. Even if,<br />

according to the standard, this<br />

must be certified.<br />

All German allocators are installed<br />

in 75 % of the radiator<br />

height – regardless of make.<br />

Used as “documentation” for<br />

this installation point is an article<br />

in the German magazine<br />

“Heizung, Lüftung und Haustechnik”:<br />

Montageart für HKV<br />

nach dem Verdunstungsprinzip<br />

(HLH 1980/6). I.e. an article<br />

about evaporative heat cost allocators.<br />

All German electronic<br />

two-sensor allocators are also<br />

installed in this incorrect position<br />

of height, as the high point<br />

of installation for evaporative<br />

allocators must compensate for<br />

decreased registration at low<br />

capacity due to the relation to<br />

the air temperature – a problem<br />

which does not exist for electronic<br />

allocators.<br />

This has been clearly confirmed<br />

throughout the last 30<br />

years, during which <strong>Brunata</strong><br />

has carried out a number of<br />

tests on the correct installation<br />

point. It was, by the way,<br />

<strong>Brunata</strong>’s own tests on the installation<br />

point of evaporative<br />

heat cost allocators which lead<br />

to the tests referred to in HLH<br />

1980/6. <strong>Brunata</strong>’s tests on<br />

electronic heat cost allocators<br />

can be seen in figure 2, which<br />

shows three different installation<br />

heights.<br />

The Danish Agency for Development<br />

of Trade and Industry<br />

issue type approval certificates<br />

based on German type approvals,<br />

but they do not ask for<br />

proper documentation as to<br />

the point of installation. Thus,<br />

Danish customers will have to<br />

ask for special documentation.<br />

When the installation point is<br />

too high it implies that consum-<br />

ers do not receive the reduction<br />

in their heating bill to which<br />

they are entitled if lowering<br />

their consumption of heat. As<br />

a result a significant part of the<br />

incentive to lower ones heat<br />

consumption disappears. In<br />

consequence of this the cooling<br />

may become inadequate in the<br />

district heating system.<br />

Conclusion<br />

At the next revision the European<br />

Standard must be changed.<br />

It ought to focus more on allocators<br />

measuring the heat<br />

emission E. The present standard<br />

focuses on German conditions<br />

with relatively high dimensioned<br />

temperatures for<br />

heating systems (90/70/20).<br />

A revised standard should open<br />

the possibility for designing allocators<br />

whose specifications<br />

correspond to the conditions<br />

under which they are used, for<br />

instance dimensioned temperatures<br />

70/40/20, which is the<br />

case in Denmark. Furthermore,<br />

the administrative practice<br />

must be tightened so that allocators<br />

in non-compliance with<br />

the standard are not approved<br />

by national authorities.