(best examples and good practices) on household organic waste ...

(best examples and good practices) on household organic waste ...

(best examples and good practices) on household organic waste ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

54<br />

pulled through an induced draft blower, which maintains all equipment under<br />

a negative pressure. (Moustakas et. al.,2003)<br />

Once gasificati<strong>on</strong> is completed, the in<strong>organic</strong> porti<strong>on</strong> of <strong>waste</strong> melts by c<strong>on</strong>tact<br />

with a pool of molten slag. The layer of molten slag is maintained in the liquid<br />

state by a current flowing through two graphite electrodes. Electrodes are<br />

positi<strong>on</strong>ed slightly above the surface of the bath, creating two electric arcs. The<br />

current also flows through the molten bath. Thus, both resistive <str<strong>on</strong>g>and</str<strong>on</strong>g> arc mode<br />

heating are used. Below the surface of the slag, a layer of molten ir<strong>on</strong> (or ir<strong>on</strong><br />

heel) is maintained, improving the flow of the current through the slag. (Table<br />

4.) shows the typical applicati<strong>on</strong> range of the main different thermal<br />

technologies. (Moustakas et. al.,2003)<br />

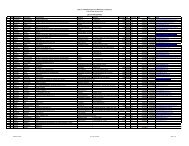

Technology<br />

Typical applicati<strong>on</strong> range<br />

(t<strong>on</strong>es/day)<br />

Moving grate 120-720<br />

Fluidised bed 36-200<br />

Rotary kiln 10-350<br />

Modular (starved air) 1-75<br />

Pyrolysis 10-100<br />

Gasificati<strong>on</strong> 250-500<br />

(Table 4.): Typical throughput ranges of thermal technologies<br />

3.3. L<str<strong>on</strong>g>and</str<strong>on</strong>g>filling<br />

3.3.1. Introducti<strong>on</strong><br />

Historically l<str<strong>on</strong>g>and</str<strong>on</strong>g>filling has been the major practice for municipal solid <strong>waste</strong><br />

disposal. Nowadays municipalities are forced to find new methods for <strong>waste</strong><br />

disposal due to critical envir<strong>on</strong>mental problems from old l<str<strong>on</strong>g>and</str<strong>on</strong>g>fills <str<strong>on</strong>g>and</str<strong>on</strong>g> a lack of<br />

l<str<strong>on</strong>g>and</str<strong>on</strong>g> availability caused by a fast growing populati<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> a higher rate of <strong>waste</strong><br />

producti<strong>on</strong>. L<str<strong>on</strong>g>and</str<strong>on</strong>g>filling solid <strong>waste</strong> is a permanent disposal process by which<br />

we spread, compact, <str<strong>on</strong>g>and</str<strong>on</strong>g> cover (seal) <strong>waste</strong> with either ash from the Waste-to<br />

Energy facility or soil. It is still the most comm<strong>on</strong> form of disposal in the vast