3M™ Die-Cuttable Tape Series DC2000 - Fabrico

3M™ Die-Cuttable Tape Series DC2000 - Fabrico

3M™ Die-Cuttable Tape Series DC2000 - Fabrico

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Die</strong>-<strong>Cuttable</strong> <strong>Tape</strong> <strong>Series</strong> DC 2000<br />

Technical Data Sheet May 2007<br />

General Description<br />

3M <strong>Die</strong>-<strong>Cuttable</strong> <strong>Tape</strong> <strong>Series</strong> <strong>DC2000</strong> is a black foam tape designed for the<br />

attachment of nameplates, badges and emblems to the exterior of vehicles. This tape is<br />

designed to process easily in all die-cutting operations, including high-speed rotary<br />

operations. 3M <strong>Series</strong> <strong>DC2000</strong> tape exhibits high resistance to pluck and torque<br />

(twisting) forces normally associated with the attachment of nameplates and emblems.<br />

3M <strong>Series</strong> <strong>DC2000</strong> tape offers the following key features:<br />

• Excellent adhesion to paint and chrome<br />

• Excellent torque (twist) resistance. 3M <strong>Series</strong> <strong>DC2000</strong> tape has a firm core that<br />

resists twisting forces that may result in the detachment of individual letters.<br />

• Excellent resistance to impact in cold weather.<br />

Some typical applications for 3M <strong>Series</strong> <strong>DC2000</strong> tape include:<br />

● Nameplates, badges and emblems<br />

• Low demand applications whose primary attachment methods are mechanical.<br />

Examples include: attachment of lightweight pillar covers, miscellaneous sealing<br />

applications and spoiler applications that require tape to perform as a gasket.<br />

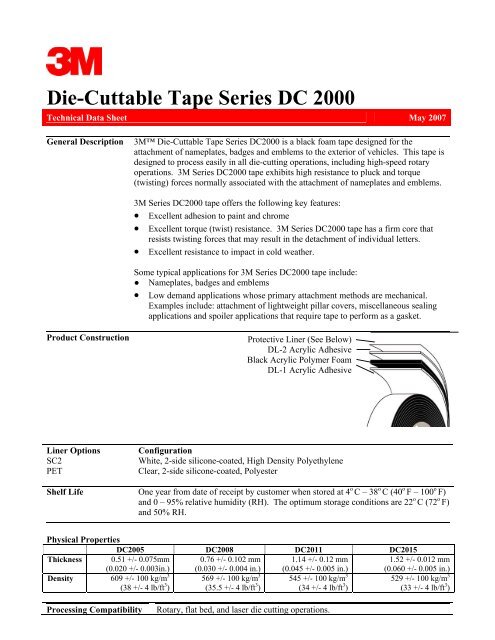

Product Construction<br />

Protective Liner (See Below)<br />

DL-2 Acrylic Adhesive<br />

Black Acrylic Polymer Foam<br />

DL-1 Acrylic Adhesive<br />

Liner Options<br />

SC2<br />

PET<br />

Shelf Life<br />

Configuration<br />

White, 2-side silicone-coated, High Density Polyethylene<br />

Clear, 2-side silicone-coated, Polyester<br />

One year from date of receipt by customer when stored at 4 o C – 38 o C (40 o F – 100 o F)<br />

and 0 – 95% relative humidity (RH). The optimum storage conditions are 22 o C (72 o F)<br />

and 50% RH.<br />

Physical Propertie s<br />

DC2005 DC2008 DC2011 DC2015<br />

Thickness 0.51 +/- 0.075mm<br />

( 0.020 +/- 0.003in.)<br />

0.76 +/- 0.102 mm<br />

(0.030 +/- 0.004 in.)<br />

1.14 +/- 0.12 mm<br />

(0.045 +/- 0.005 in.)<br />

1.52 +/- 0.012 mm<br />

(0.060 +/- 0.005 in.)<br />

D ensity 609 +/- 100 kg/m 3<br />

3<br />

(38 +/- 4 lb/ft )<br />

569 +/- 100 kg/m 3<br />

3<br />

(35.5 +/- 4 lb/ft )<br />

545 +/- 100 kg/m 3<br />

3<br />

(34 +/- 4 lb/ft )<br />

529 +/- 100 kg/m 3<br />

3<br />

(33 +/- 4 lb/ft )<br />

Processing Compatibility<br />

Rotary, flat bed, and laser die cutting operations.

Technical Data Sheet<br />

3M <strong>Die</strong>-<strong>Cuttable</strong> <strong>Tape</strong> <strong>Series</strong> <strong>DC2000</strong><br />

Page 2<br />

Pluck Testing (Typical Results)<br />

Maintains pluck adhesion on new low surface energy and scratch- and<br />

mar-resistant paint systems in addition to conventional paint systems.<br />

Torque Testing (Typical Results):<br />

3M <strong>Series</strong> <strong>DC2000</strong> tape demonstrates higher resistance to twisting<br />

forces (torque) compared to typical competitive tapes.<br />

Static Shear (Typical Results):<br />

Exceeds 100 hours at 70 o C (158 o F)<br />

Static shear tests are run with 25.4 mm (1.0 in.) wide by 25.4 mm (1 X 1 in.) long<br />

tape on chrome, 6.8 kg. (15 lb.) roll down against enamel paint. Weight is 500<br />

grams (1.1 lb.).

Technical Data Sheet<br />

3M <strong>Die</strong>-<strong>Cuttable</strong> <strong>Tape</strong> <strong>Series</strong> <strong>DC2000</strong><br />

Page 3<br />

Applications Diagraphic<br />

Contact Information The information provided in this technical document is intended as a guide for this<br />

product. For more information, and help selecting a 3M product for an application,<br />

please contact a 3M technical service representative.<br />

3M is a Trademark of 3M Company.<br />

Warranty and Limited Remedy: This product will be free from defects in material and workmanship at the time of<br />

shipment. 3M MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO,<br />

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. User is<br />

responsible for determining whether the 3M product is fit for a particular purpose and suitable for user's application. If this<br />

product is defective, your exclusive remedy and 3M's and seller's sole obligation shall be, at 3M's option, to replace the<br />

product or refund the purchase price.<br />

Limitation of Liability: Except as provided above, 3M and seller will not be liable for any loss or damage arising from or<br />

related to the use or inability to use this 3M product, whether direct, indirect, special, incidental or consequential, regardless<br />

of the legal theory asserted.<br />

3<br />

M<br />

Automotive Division<br />

3M Center, Building 223-1S-02<br />

St. Paul, MN 55144-1000<br />

www.3M.com/autosolutions<br />

© 3M 2007<br />

75-3470-8835-5<br />

ISO/TS 16949:2002<br />

File No. A2109