110 / 210 Fiber Optic Oxygen Monitor - Instech Laboratories, Inc.

110 / 210 Fiber Optic Oxygen Monitor - Instech Laboratories, Inc.

110 / 210 Fiber Optic Oxygen Monitor - Instech Laboratories, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Probe Calibration<br />

Physical Calibration Setup<br />

Assemble a system that will maintain constant<br />

temperature of the medium and probe and a means of<br />

presenting known oxygen concentration to the probe.<br />

The easiest concentrations will be atmospheric<br />

oxygen levels (20.9%) and zero. Zero oxygen is best<br />

attained by adding sodium dithionite to the solution.<br />

This will chemically remove the oxygen. Bubbling<br />

with nitrogen or an inert gas is more difficult and<br />

fraught with pitfalls. Decide on the units of oxygen<br />

concentration you will be using.<br />

<strong>Inc</strong>luded with the unit is equipment to facilitate the<br />

calibration procedure for dissolved oxygen levels if<br />

the OR125 series probes are being used. A black<br />

holder attached to a long ¼” handle has two holes for<br />

probes and one small hole for a thermocouple<br />

temperature monitoring device (user supplied).<br />

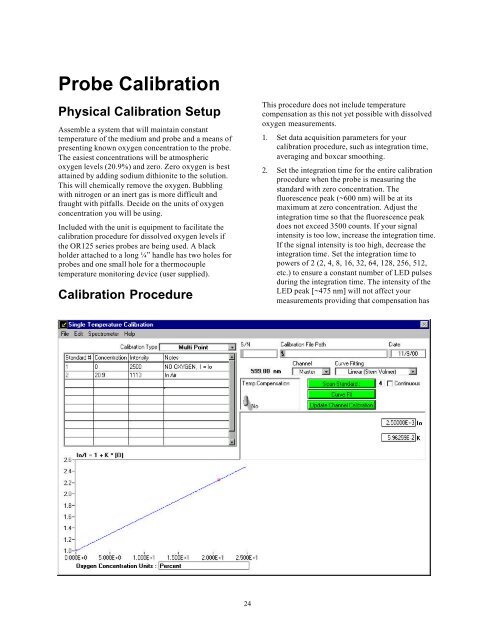

Calibration Procedure<br />

This procedure does not include temperature<br />

compensation as this not yet possible with dissolved<br />

oxygen measurements.<br />

1. Set data acquisition parameters for your<br />

calibration procedure, such as integration time,<br />

averaging and boxcar smoothing.<br />

2. Set the integration time for the entire calibration<br />

procedure when the probe is measuring the<br />

standard with zero concentration. The<br />

fluorescence peak (~600 nm) will be at its<br />

maximum at zero concentration. Adjust the<br />

integration time so that the fluorescence peak<br />

does not exceed 3500 counts. If your signal<br />

intensity is too low, increase the integration time.<br />

If the signal intensity is too high, decrease the<br />

integration time. Set the integration time to<br />

powers of 2 (2, 4, 8, 16, 32, 64, 128, 256, 512,<br />

etc.) to ensure a constant number of LED pulses<br />

during the integration time. The intensity of the<br />

LED peak [~475 nm] will not affect your<br />

measurements providing that compensation has<br />

24