TROUBLESHOOTING - ROTATIONAL MOULDING Problem ...

TROUBLESHOOTING - ROTATIONAL MOULDING Problem ...

TROUBLESHOOTING - ROTATIONAL MOULDING Problem ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

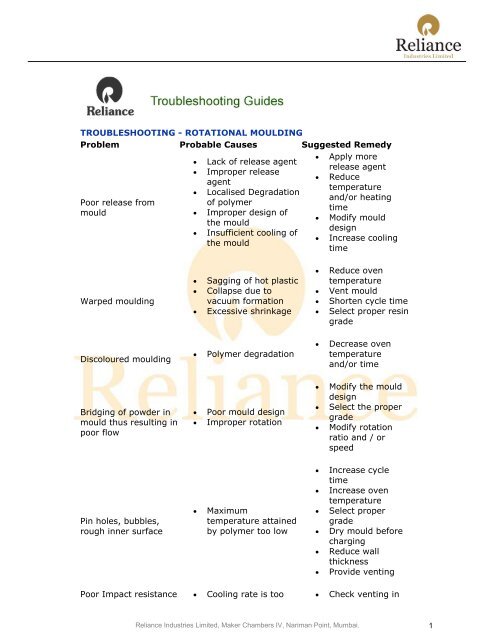

<strong>TROUBLESHOOTING</strong> - <strong>ROTATIONAL</strong> <strong>MOULDING</strong><br />

<strong>Problem</strong> Probable Causes Suggested Remedy<br />

Poor release from<br />

mould<br />

• Lack of release agent<br />

• Improper release<br />

agent<br />

• Localised Degradation<br />

of polymer<br />

• Improper design of<br />

the mould<br />

• Insufficient cooling of<br />

the mould<br />

• Apply more<br />

release agent<br />

• Reduce<br />

temperature<br />

and/or heating<br />

time<br />

• Modify mould<br />

design<br />

• Increase cooling<br />

time<br />

Warped moulding<br />

• Sagging of hot plastic<br />

• Collapse due to<br />

vacuum formation<br />

• Excessive shrinkage<br />

• Reduce oven<br />

temperature<br />

• Vent mould<br />

• Shorten cycle time<br />

• Select proper resin<br />

grade<br />

Discoloured moulding<br />

• Polymer degradation<br />

• Decrease oven<br />

temperature<br />

and/or time<br />

Bridging of powder in<br />

mould thus resulting in<br />

poor flow<br />

• Poor mould design<br />

• Improper rotation<br />

• Modify the mould<br />

design<br />

• Select the proper<br />

grade<br />

• Modify rotation<br />

ratio and / or<br />

speed<br />

Pin holes, bubbles,<br />

rough inner surface<br />

• Maximum<br />

temperature attained<br />

by polymer too low<br />

• Increase cycle<br />

time<br />

• Increase oven<br />

temperature<br />

• Select proper<br />

grade<br />

• Dry mould before<br />

charging<br />

• Reduce wall<br />

thickness<br />

• Provide venting<br />

Poor Impact resistance • Cooling rate is too • Check venting in<br />

Reliance Industries Limited, Maker Chambers IV, Nariman Point, Mumbai. 1

slow<br />

the mould<br />

• Increase cooling<br />

rate<br />

Excessive flash<br />

• Poor parting line<br />

• Remake parting<br />

line<br />

• Check venting<br />

Long oven cycles<br />

• Oven temperature<br />

too low<br />

• Oven capacity<br />

insufficient<br />

• Moulds shielded<br />

• Increase oven<br />

temperature<br />

• Increase air<br />

circulation<br />

• Avoid shielding of<br />

the mould<br />

• Select proper<br />

grade<br />

Reliance Industries Limited, Maker Chambers IV, Nariman Point, Mumbai. 2